Pressurization type generator of marsh gas

A generator and biogas technology, applied in the direction of gas production bioreactors, waste fuels, etc., can solve the problems of small gas production, slow gas production speed, low cost, etc., and achieve the effect of stable gas source pressure and convenient refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

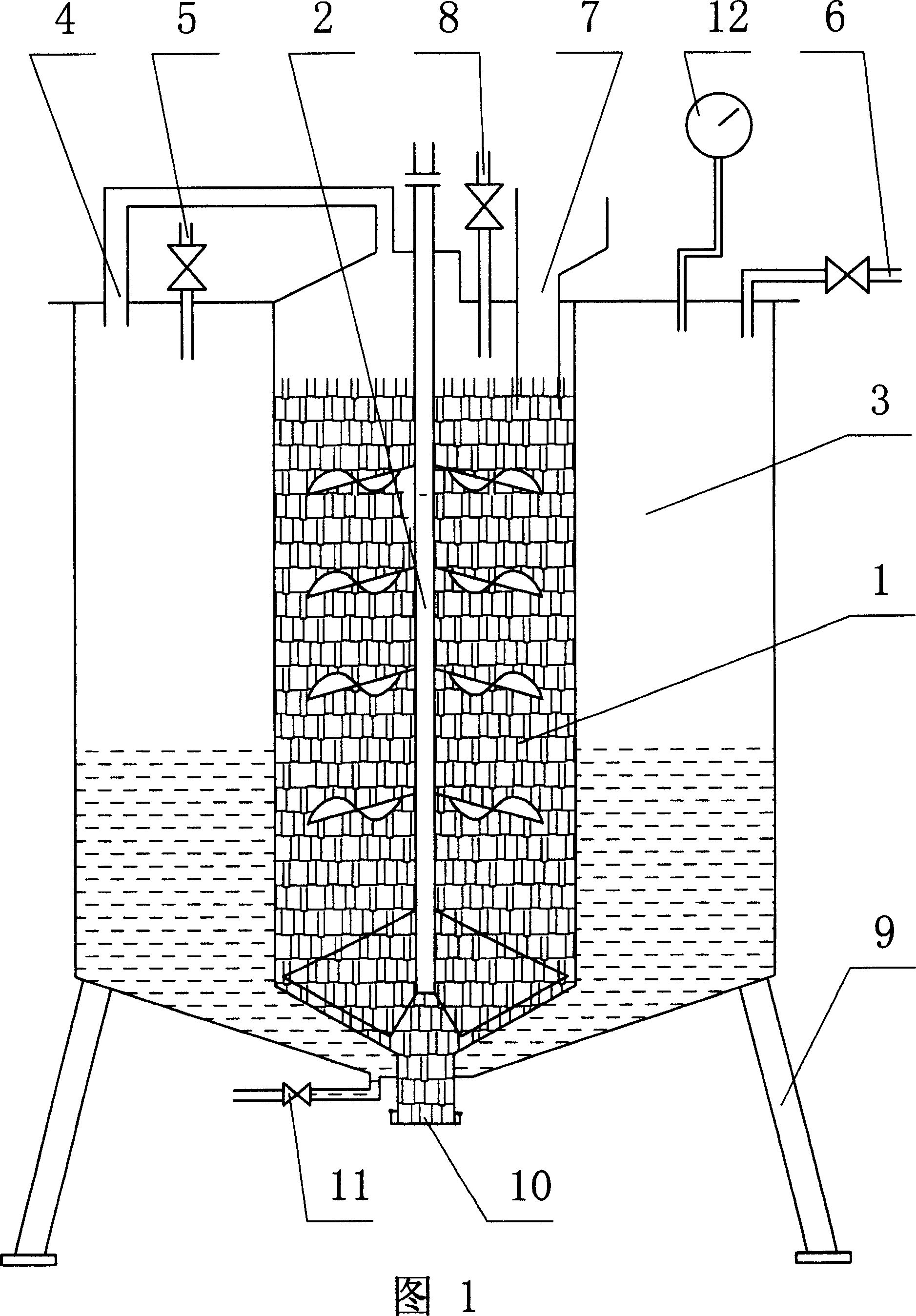

[0018] As shown in Figure 1, there is a biogas generating chamber 1 in the middle, a stirrer 2 is installed in the generating chamber 1, and a pressurized chamber 3 is formed on the periphery of the generating chamber 1, and the upper ends of the generating chamber 1 and the pressurized chamber 3 pass through the air duct 4 are connected, the water inlet pipe 5 is externally connected to the pressurization chamber 3, and the gas outlet pipe 6 is connected to the upper end of the pressurization chamber 3, which can be connected with the biogas appliance. 8. The bottom of the pressurization chamber 3 is shaped on a support foot 9, which is movable as a whole. An openable discharge port 10 is formed at the bottom of the generation chamber 1 . A drain valve 11 is installed at the bottom of the boost chamber 3 . The top of the pressurization chamber 3 is also provided with an air pressure indicating gauge 12 .

[0019] The working principle is: add raw materials such as straw, h...

Embodiment 2

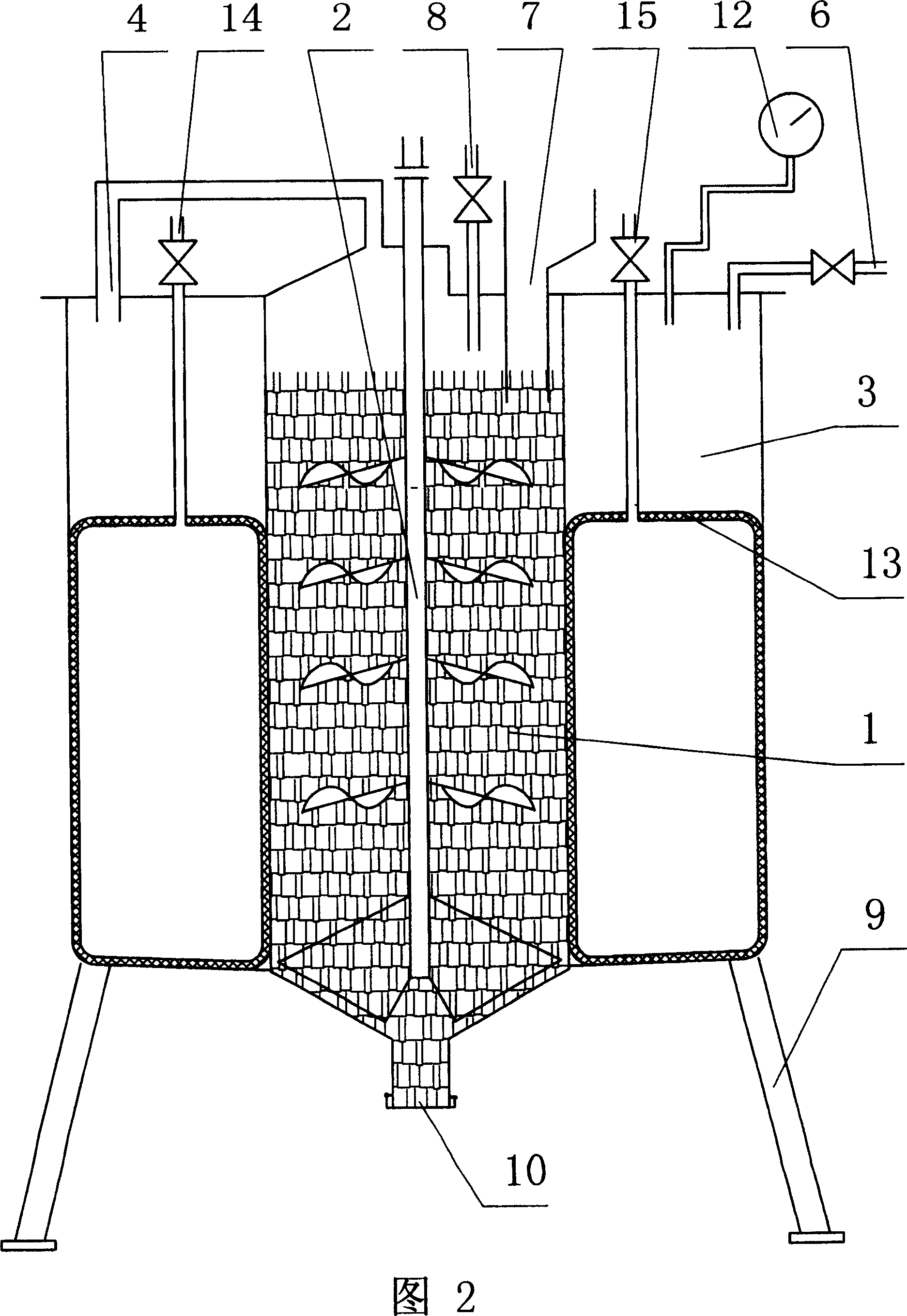

[0021] Fig. 2 is a structural principle diagram of a biogas booster generator with a booster chamber equipped with a booster air bag. Compared with embodiment 1, its pressurization mode is that a pressurized air bag 13 is provided in the pressurized chamber 3 , and the intake pipe 14 and the deflation valve 15 communicate with the pressurized air bag 13 . When the air pressure in the pressurized chamber 3 is too low, close the release valve 15 and communicate with the pressurized air bag 13 . When the air pressure in the pressurization chamber 3 was too low, the air release valve 15 was closed, and the pressurized air bag 13 in the pressurized chamber 3 was inflated by the intake pipe 14, so that the volume of the pressurized air bag 13 was increased, and the air pressure in the pressurized chamber 3 was increased. The biogas pressure increased rapidly. When the biogas is not in use, the air release valve 15 can be opened, and the air in the pressurized air bag 13 can be rele...

Embodiment 3

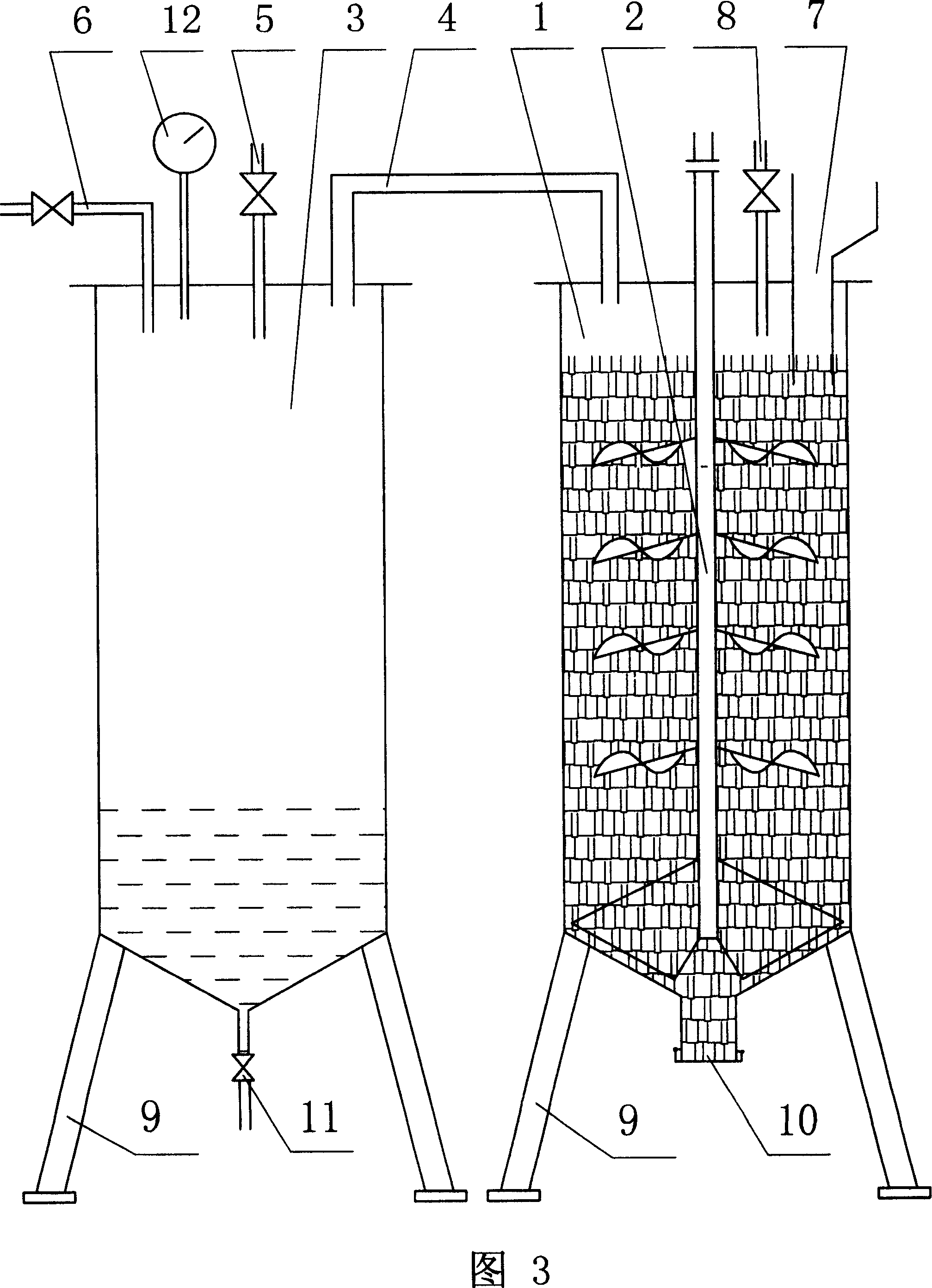

[0023] Figure 3 is a schematic structural diagram of a split-type biogas booster generator; compared with Embodiment 1, its feature is that the pressurization chamber 3 and the generation chamber 1 are separate forms, and the upper ends of the generation chamber 1 and the pressurization chamber 3 It is connected through air duct 4. The bottoms of the generating chamber 1 and the pressurizing chamber 3 are respectively shaped with supporting feet 9, which are movable as a whole. All the other make by embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com