Low-concentration coal-bed methane engine anti-explosion gas supply system and operation method

A gas supply system, coalbed methane technology, applied in gaseous engine fuels, engine components, combustion engines, etc., can solve problems such as easy explosion, safety accidents, ignition difficulties, etc., to prevent emissions into the atmosphere and save water resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the low-concentration coalbed methane engine explosion-proof gas supply system provided by the present invention and the method for operating the system will be described in detail through embodiments with reference to the accompanying drawings. It should be understood that the following embodiments are only illustrative, not restrictive.

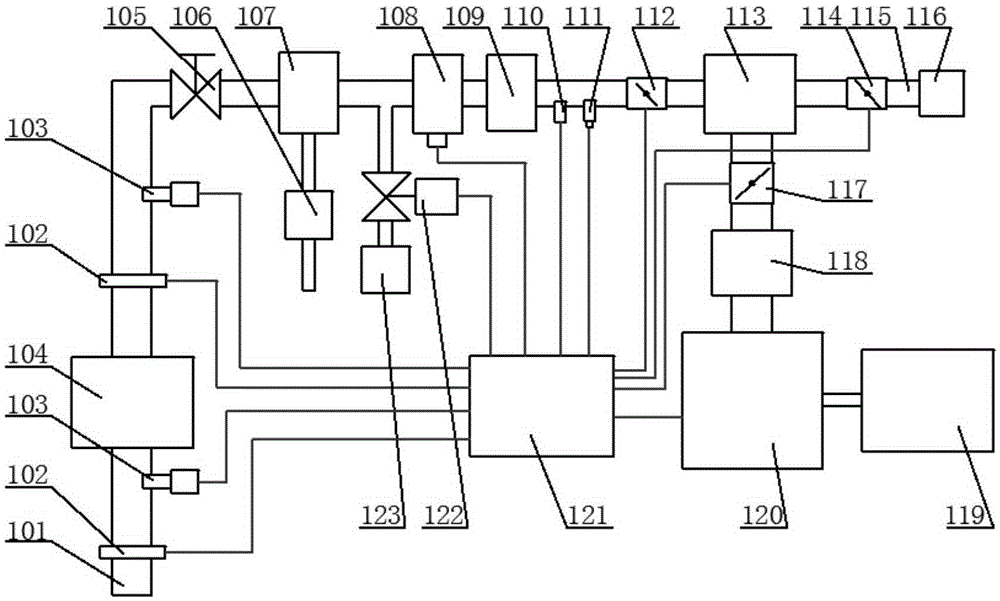

[0032] Such as figure 1 As shown, the low-concentration CBM engine explosion-proof gas supply system includes a gas pipeline 101, an electrostatic detection releaser 102, a water mist injector 103, a fan 104, a manual stop valve 105, a filter 106, and a cyclone water and dust collector 107, electromagnetic cut-off valve 108, pressure regulator valve 109, methane concentration sensor 110, pressure sensor 111, coalbed methane flow control valve 112, coalbed methane / air mixer 113, air flow control valve 114, air intake pipeline 115, air Filter 116, electronic throttle 117, flame arrester 118, generator 119, coalbed methane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com