Spliced thermal insulation methane tank

A biogas tank and splicing technology, which is applied in the fields of gas production bioreactors, biochemical instruments, biological sludge treatment, etc., can solve the problems of industrial production, installation and transportation of biogas tanks, difficulties in popularization and use of biogas, and inability of biogas tanks to produce gas. and other problems, to achieve the effect of simple structure and manufacturing process, low cost and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

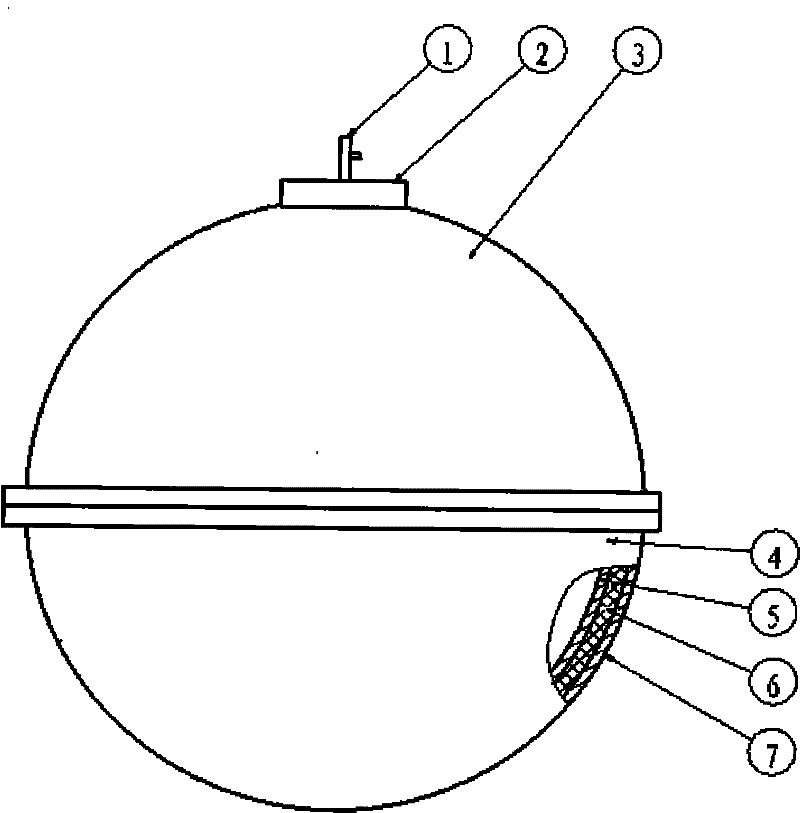

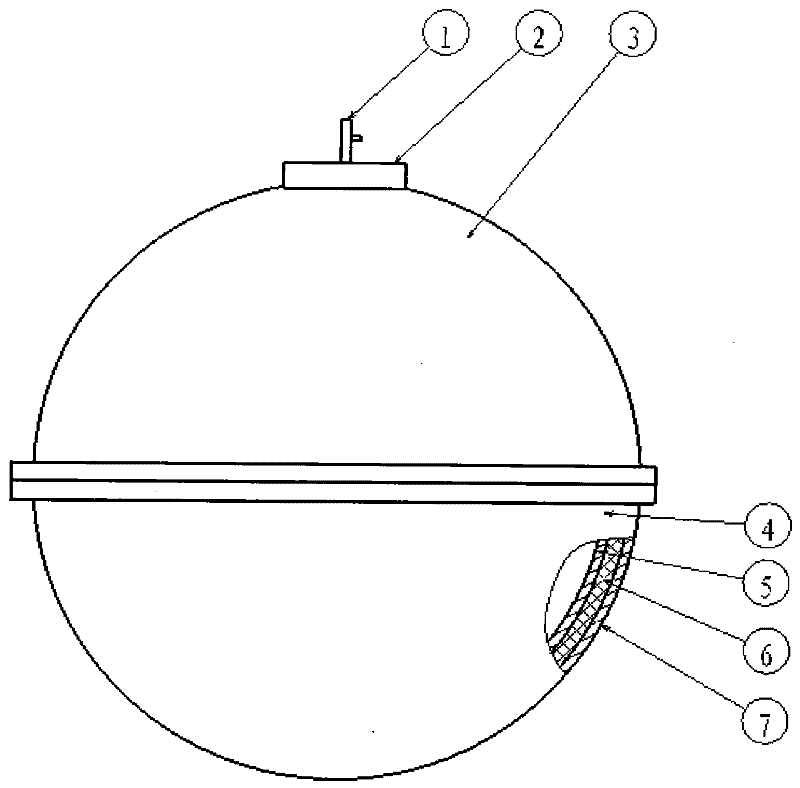

[0009] The embodiments will be described in detail below in conjunction with the accompanying drawings. The invention is a spherical or cylindrical tank body, which is spliced by an upper tank body (2) and a lower tank body (3). , to ensure the convenience of material in and out; the material inlet and outlet and the sealing cover are tightly connected by bolts to ensure the tightness of the tank body; the sealing cover is equipped with a gas nozzle and a pressure relief module (1) to ensure that the external gas supply and the biogas pressure in the tank do not exceed Safety range; the tank body is divided into an inner layer (5), an insulation layer (6) and an outer layer (7) to ensure the insulation, structural strength, and water and seepage resistance of the tank body; the inner and outer layers are fiber reinforced Composite material or inorganic material, the insulation layer is inorganic foam insulation material. The structure of the sealing cover is the same as tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com