Methane safety pressure-limiting valve

A pressure limiting valve and biogas technology, applied in the field of safety valves, can solve the problems of damaged biogas equipment and accessories, complicated manufacturing process, short life of safety valve, etc., and achieve the effect of preventing biogas pressure from being too high, simple production and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

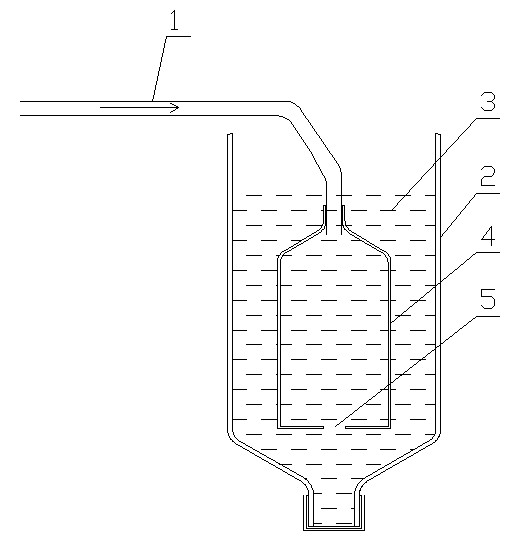

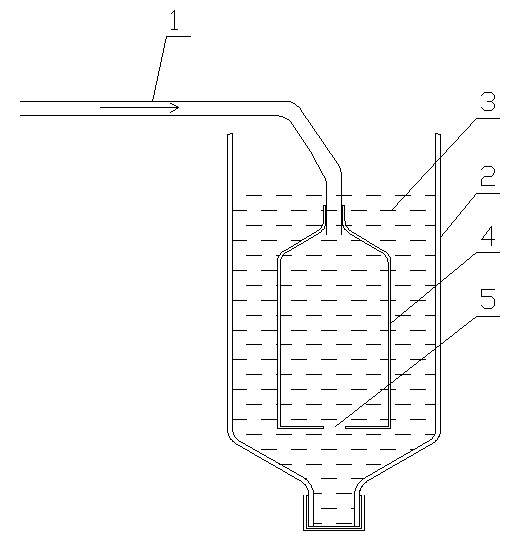

[0015] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the biogas safety pressure limiting valve of the present invention includes a pressure limiting exhaust pipe 1 and an open container 2 filled with water 3, and one end of the pressure limiting exhaust pipe 1 is connected to the biogas tank The gas storage chamber is connected, and the other end extends into the water surface in the open container 2; use the water sealing effect of the open container 2 to limit the biogas pressure in the biogas digester, when the biogas pressure is within the control range, rely on the effect of the water seal Seal the biogas, when the biogas pressure is too high, the water seal fails, and the biogas escapes from the open container 2, which reduces the biogas pressure in the pond, maintains the normal bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com