Wet garbage disposal device

A technology of waste treatment device and anaerobic tank, which is applied in biomass post-treatment, biomass pre-treatment, biochemical cleaning device, etc. Property loss and other problems, to achieve the effect of improving the generation rate, improving the utilization rate, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

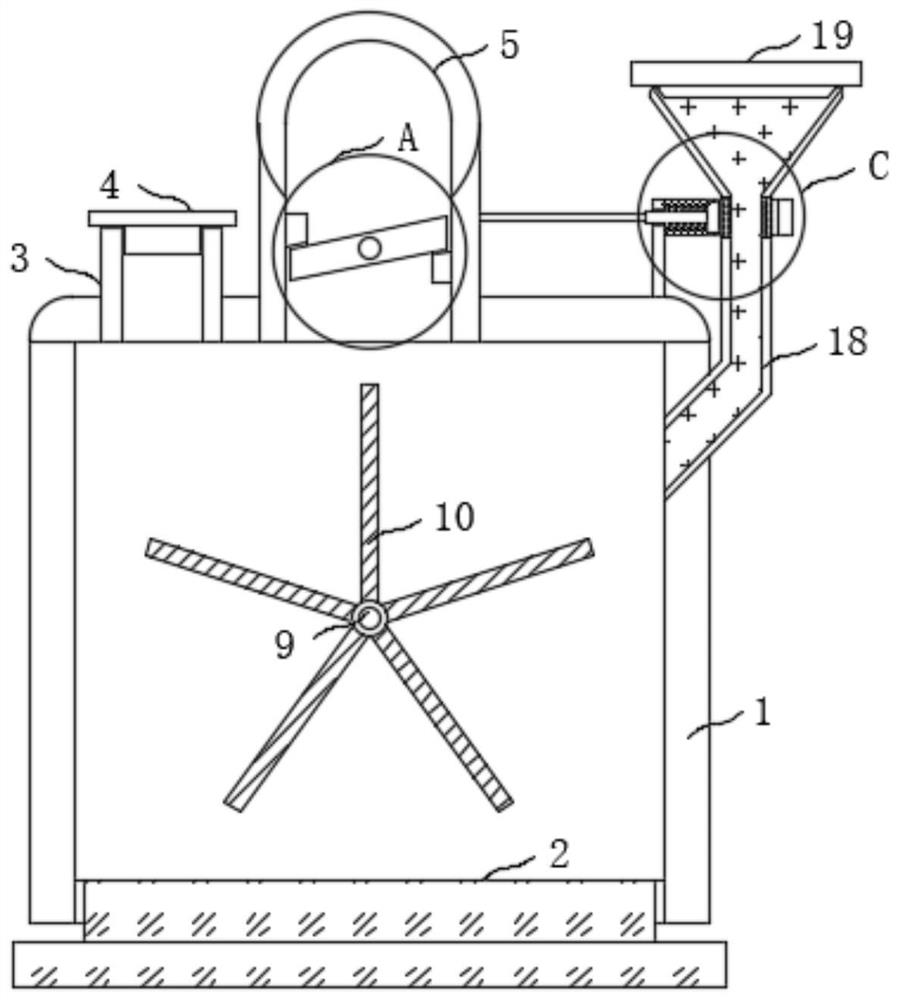

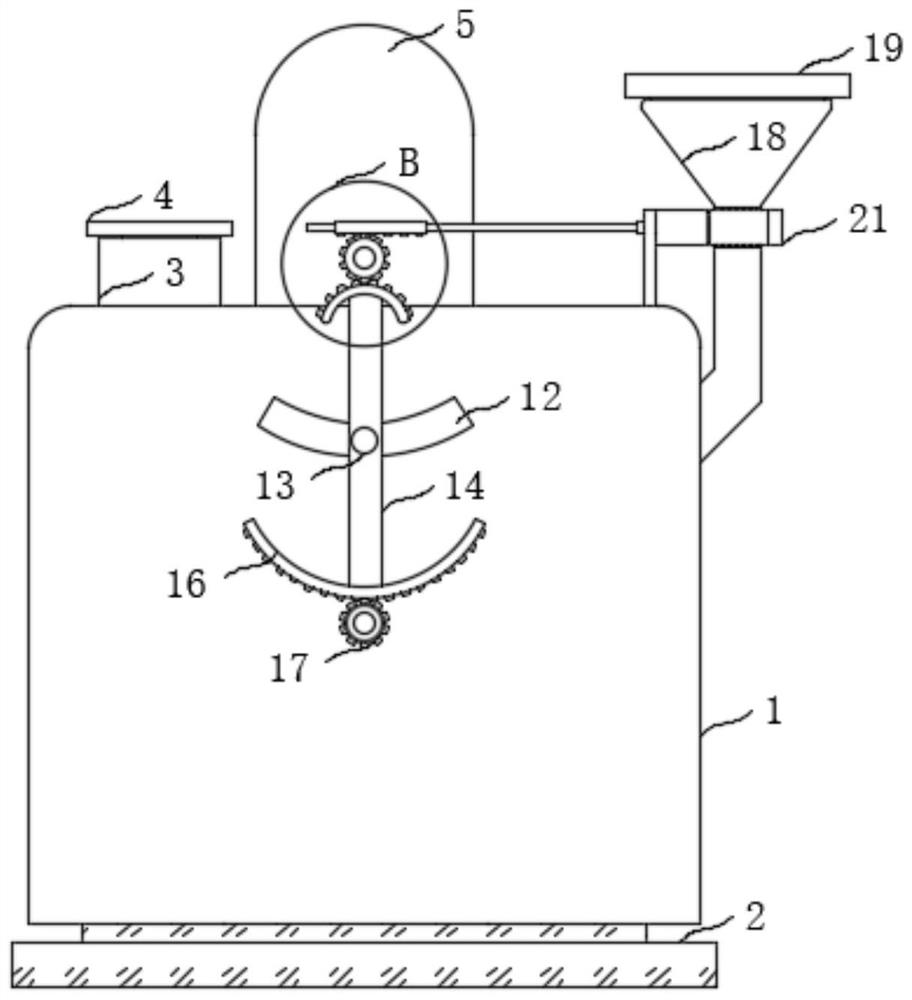

[0026] refer to Figure 1-4 , a wet garbage treatment device, including a sealing base 2 installed on an anaerobic tank 1, a feed seat 3 and a biogas discharge square pipe 5 are fixedly installed on the anaerobic tank 1, and a sealing plate is threaded on the feed seat 3 4;

[0027] Of note above are:

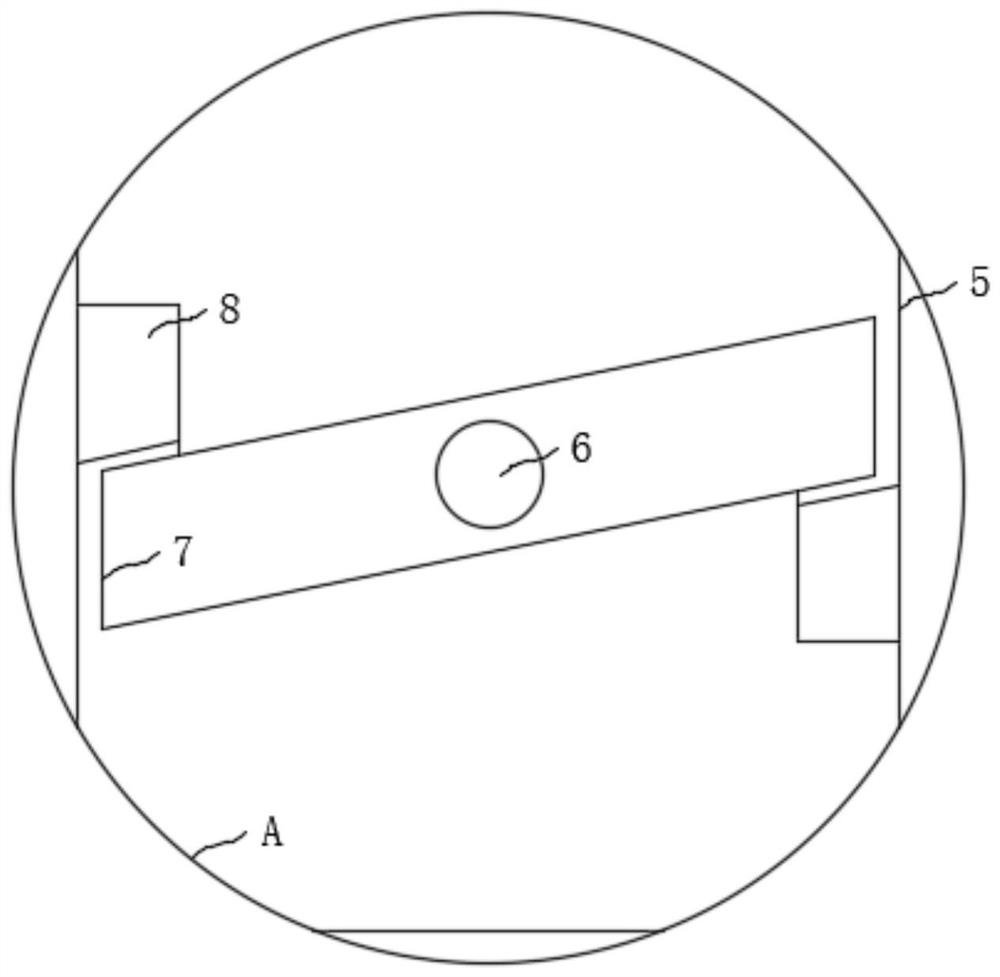

[0028] 1. A baffle 7 is connected to the biogas discharge square pipe 5 through the rotation of the rotating rod 6. A torsion spring is installed between the baffle 7 and the two ends of the biogas discharge square pipe 5. When the biogas generated in the anaerobic tank 1 is When it is small, due to the elastic force of the torsion spring, the position and angle of the baffle plate 7 in the biogas discharge square pipe 5 can be kept unchanged, and the biogas discharge square pipe 5 is kept in a sealed state.

[0029] 2. There are two magnetic blocks 8 fixedly installed in the biogas discharge square pipe 5, and the two magnetic blocks 8 are attached to the left upper end and ...

Embodiment 2

[0038] refer to figure 1 , figure 2 , Figure 4 , Figure 5 , the difference between embodiment two and embodiment one is: an additive feed hopper 18 is fixed in the shape of a rod on the anaerobic tank 1, and the additive feed hopper 18 is threadedly connected with a dust cover 19, and on the anaerobic tank 1 A support rod 20 is fixedly installed on the support rod 20, and a positioning frame 21 matched with the additive feed hopper 18 is fixedly installed on the support rod 20. One end of the positioning frame 21 close to the support rod 20 is slidably connected with a push rod 22, and the push rod 22 is fixedly installed. There is a push block 23, a rubber hose 24 corresponding to the position of the push block 23 is fixedly installed on the additive feed hopper 18, a spring 25 is installed between the push block 23 and the positioning frame 21, and a push rod 22 and the driving gear 11 Installed with an opening mechanism;

[0039] The opening mechanism is made up of chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com