Fully-automatic quantitative and energy-saving material dispatching system

A scheduling system, fully automatic technology, applied in waste fuel, specific purpose bioreactor/fermenter, biomass post-processing, etc., can solve the problem of reducing the production efficiency of the process system, increasing the fixed cost of the process system, and consuming external energy of the system and other issues to achieve the effect of reducing fixed investment, reducing complexity, and improving environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

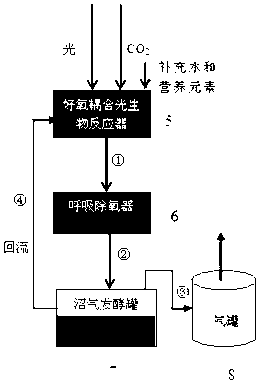

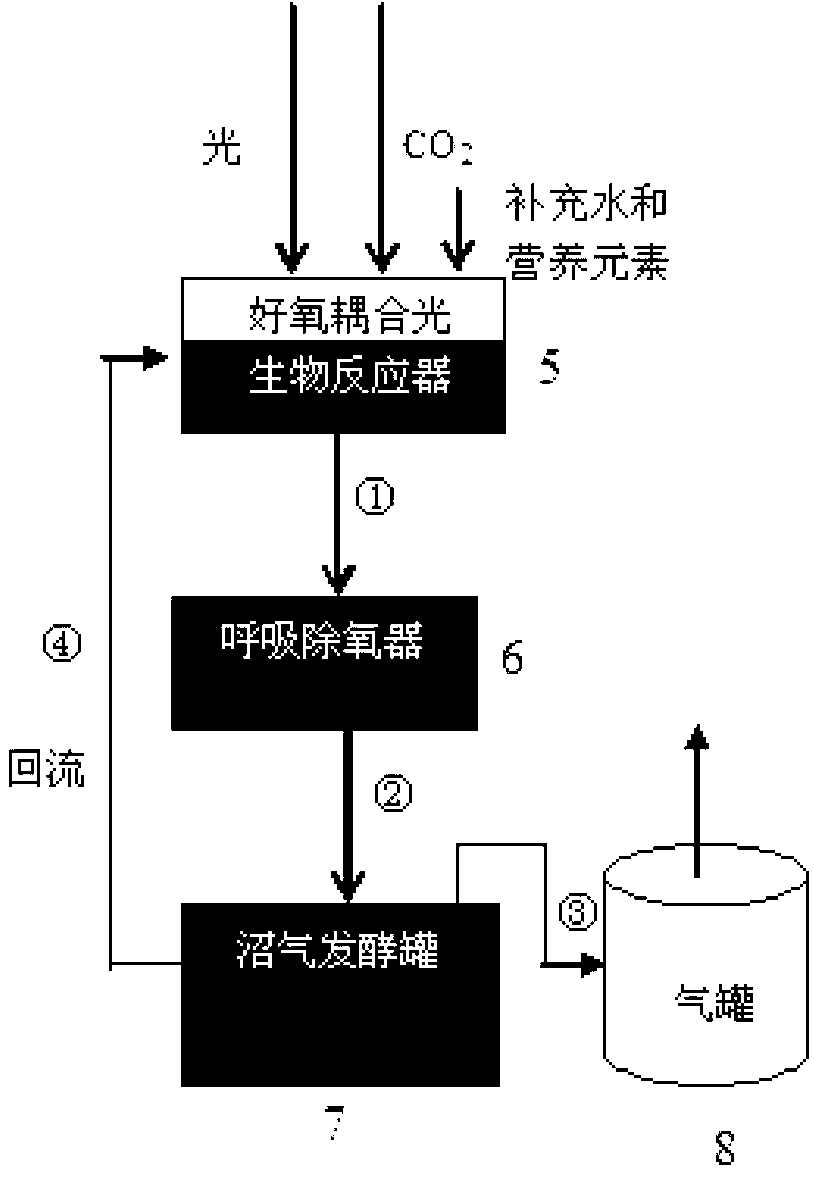

[0028] Such as Figure 1~2 As shown, the fully automatic quantitative and energy-saving material dispatching system includes a good-yang coupling photobioreactor 5, a respiratory deaerator 6, and a biogas fermentation tank 7 arranged up and down in sequence. The good-yang coupling photobioreactor 5 passes through the tube The road a1 is connected to the respiratory deaerator 6, and the respiratory deaerator 6 is connected to the biogas fermentation tank 7 through the pipeline b2, and the biogas fermentation tank 7 is connected to the gas storage tank 8 through the pipeline c3, and connected to the coupling photobiology through the return pipeline d4 Reactor 5; the pipeline a1, pipeline b2, pipeline c3, and return pipeline d4 are all connected to the liquid level control mechanism;

[0029] Wherein, the aerobic coupled photobioreactor 5 is established by coupling a photobioreactor with an aerobic bioreactor. The eutrophic coupled photobioreactor contains water, nutrients and a...

Embodiment 2

[0039] Such as figure 1 As shown, the equipment used in this embodiment includes an independently set aerobic coupled photobioreactor, a respiratory deaerator, an anaerobic fermentation tank and a liquid level control mechanism.

[0040] The above-mentioned equipment is used to realize the automatic quantitative energy-saving material scheduling problem of the technical process in the patent 201310151302.4, and specifically includes the following steps (such as figure 1 shown):

[0041] Step 1: Open pipeline a1, pipeline b2 and pipeline c3, and close return pipeline d4. The suspension of microalgae and aerobic bacteria in the aerobic coupling photobioreactor with an effective volume of 60000L enters the breathing deaerator with a volume of 30000L through the pipeline a1 under the action of its own gravity, and at the same time the Under the action of its own gravity, the suspension also enters the biogas fermentation tank with an effective volume of 90000L through the pipeli...

Embodiment 3

[0047] Such as figure 1 As shown, the equipment used in this embodiment includes an independently set aerobic coupled photobioreactor, a respiratory deaerator, an anaerobic fermentation tank and a liquid level control mechanism.

[0048] The above-mentioned equipment is used to realize the automatic quantitative energy-saving material scheduling problem of the technical process in the patent 201310151302.4, and specifically includes the following steps (such as figure 1 shown):

[0049] Step 1: Open pipeline a1, pipeline b2 and pipeline c3, and close return pipeline d4. The suspension of microalgae and aerobic bacteria in the aerobic coupled photobioreactor with an effective volume of 5000L enters the respiratory deaerator with a volume of 4500L through the pipeline a1 under the action of its own gravity, and at the same time the Under the action of its own gravity, the suspension also enters the biogas fermentation tank with an effective volume of 8000L through the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com