Ground methane tank capable of regulating methane pressure and manufacturing method thereof

A biogas digester, an adjustable technology, is applied in the fields of biochemical equipment and methods, building construction, and building material processing, etc., and can solve the problems of inconvenient production and living, complicated manufacturing methods, unstable output and pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

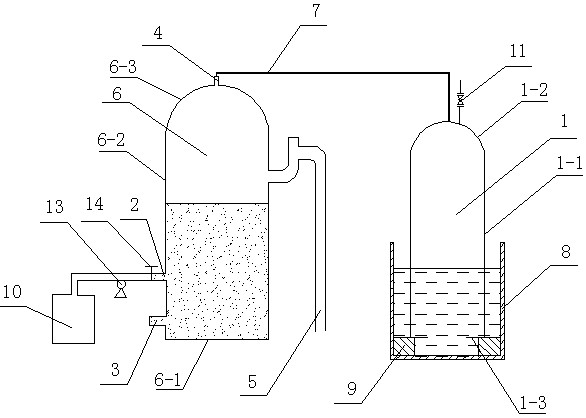

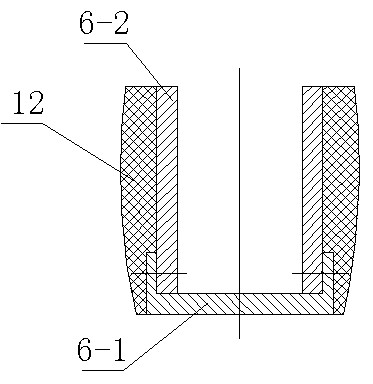

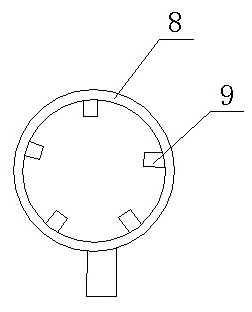

[0036] Such as figure 1 , figure 2 and image 3 As shown, an above-ground biogas digester with adjustable biogas pressure includes a gas storage tank 1 and a fermentation tank 6 with a feed port 2, a discharge port 3, a gas outlet 4, and a water outlet 5. The gas storage tank 1 It is a split structure with the fermentation tank 6, the two are connected through the air pipe 7, the upper end of the gas storage tank 1 is provided with an exhaust port 11, and the lower end is placed in the pool 8, and the bottom of the gas storage tank 1 is communicated with the pool 8; the fermentation The pool 6 is divided into three parts, including a concave pool bottom 6-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com