Hot film biogas hot air utilization control system and its operation control method

A control system and biogas technology, applied in biochemical equipment and methods, transportation and packaging, gas production bioreactors, etc., can solve the problems of biogas discharge and utilization, high energy consumption, etc., to reduce production costs and save electricity , the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

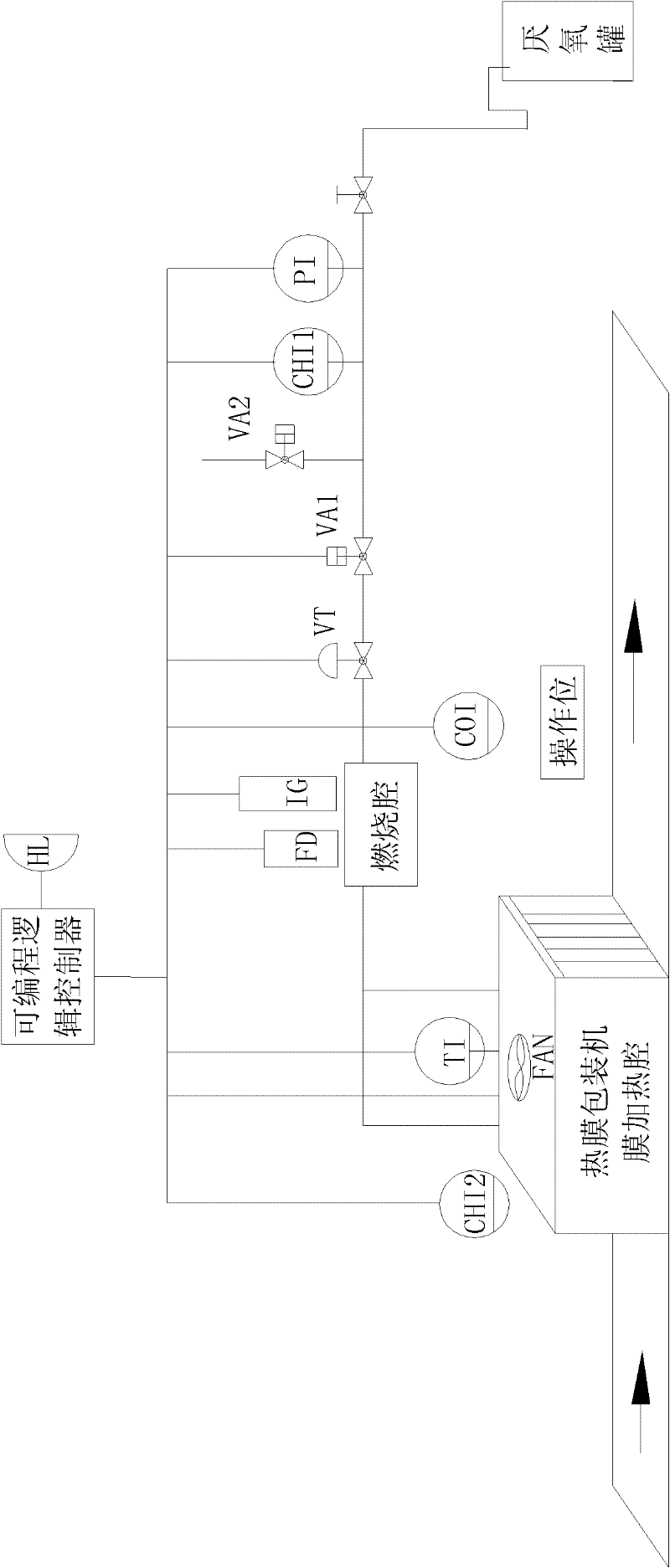

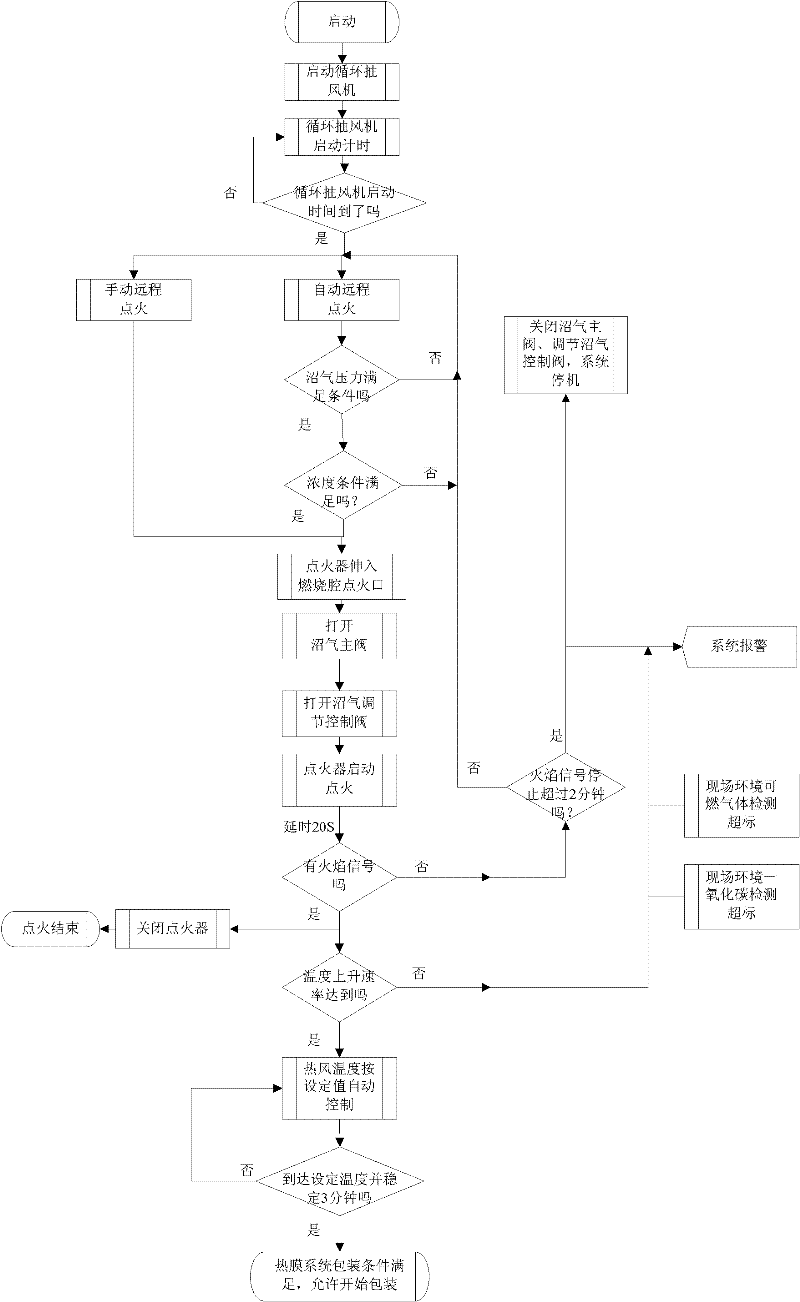

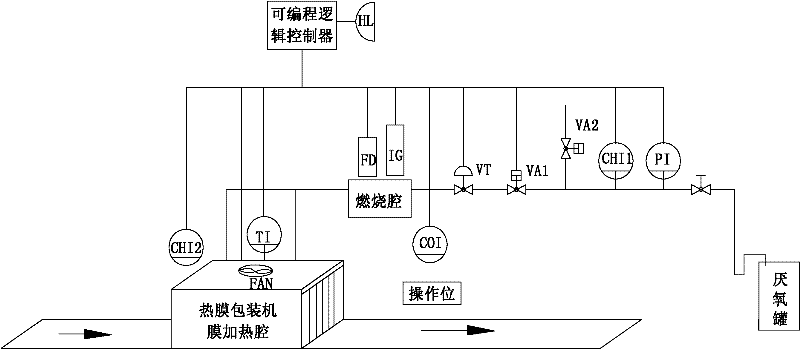

[0025] see figure 1 , is a hot film biogas hot air utilization control system of the present invention, which is mainly composed of a hot film packaging machine, an anaerobic tank that generates and stores biogas, a combustion chamber, an igniter IG, a flame detector FD, a biogas pipe, and a hot air pipe , biogas main valve VA1, biogas regulating valve VT, biogas emptying valve VA2, biogas pressure sensor PI, biogas concentration sensor CHI1, circulating exhaust fan FAN, hot air temperature sensor TI and programmable logic controller. The hot film packaging machine is equipped with a film heating chamber. The combustion chamber is provided with an ignition port, a biogas inlet and a hot air outlet. The biogas inlet of the combustion chamber communicates with the biogas outlet provided on the anaerobic tank through the biogas pipe, and the hot air outlet of the combustion chamber communicates with the hot air inlet provided on the membrane heating chamber through the hot air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com