Recovery power generation technology of methane generated by paper-making wastewater treatment

A technology for papermaking waste water and biogas, which is applied in the direction of gas fuel, petroleum industry, engine components, etc., can solve problems such as not considering the value of biogas utilization, and achieve considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

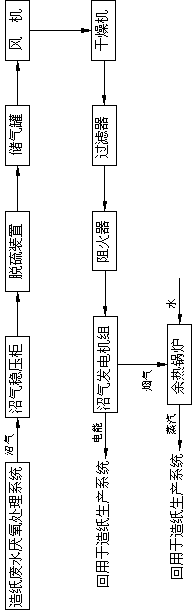

[0015] The recovery and power generation process of biogas produced by papermaking wastewater treatment in the present invention firstly sends the biogas generated by the anaerobic treatment system of papermaking wastewater into the biogas stabilizing cabinet for voltage stabilization; since the H2S content in the biogas is about 200g / L, the biogas needs to be sent to the desulfurization system After desulfurization treatment, the H2S in the biogas is reduced to below 0.05g / L; the desulfurized biogas is sent to the gas storage tank for collection, and then sent to the dryer for dehydration and drying through the fan, until there is no free in the biogas State of water (moisture content below 40g / Nm 3 ); the dried biogas is filtered through a filter to filter out large particles of impurities in the biogas. The filtration accuracy is 5 μm. 3 ; The filtered biogas is sent to the biogas generator set for power generation, and a flame arrester device is installed at the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com