Anaerobic biological desulfurization method and device for methane

A biogas desulfurization and biogas technology, which is applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of difficulty in controlling oxygen supply for oxygenated biological desulfurization, high labor intensity for desulfurizer replacement, and high operating cost of chemical desulfurization, so as to avoid biogas The effect of reducing calorific value, reducing energy consumption and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

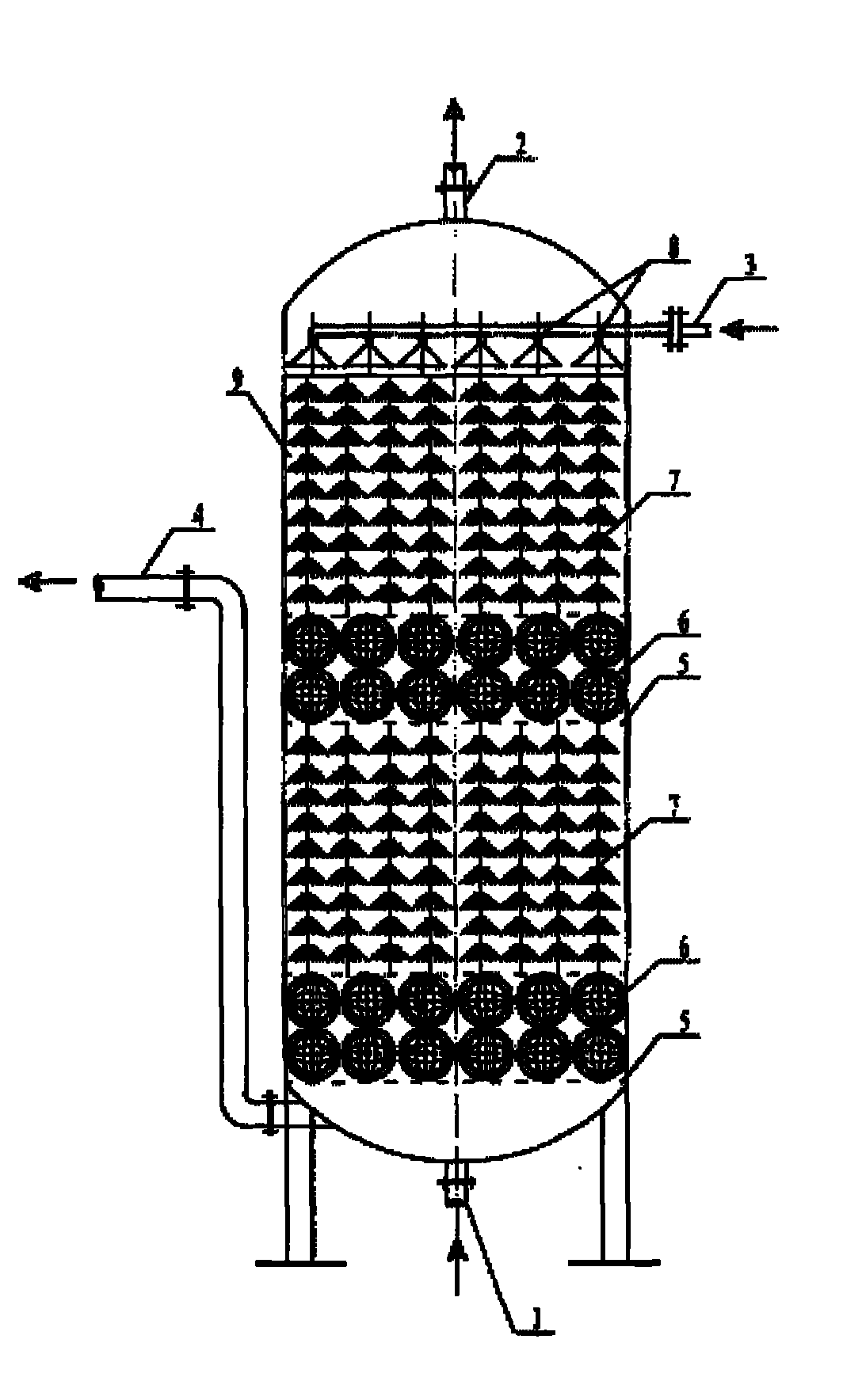

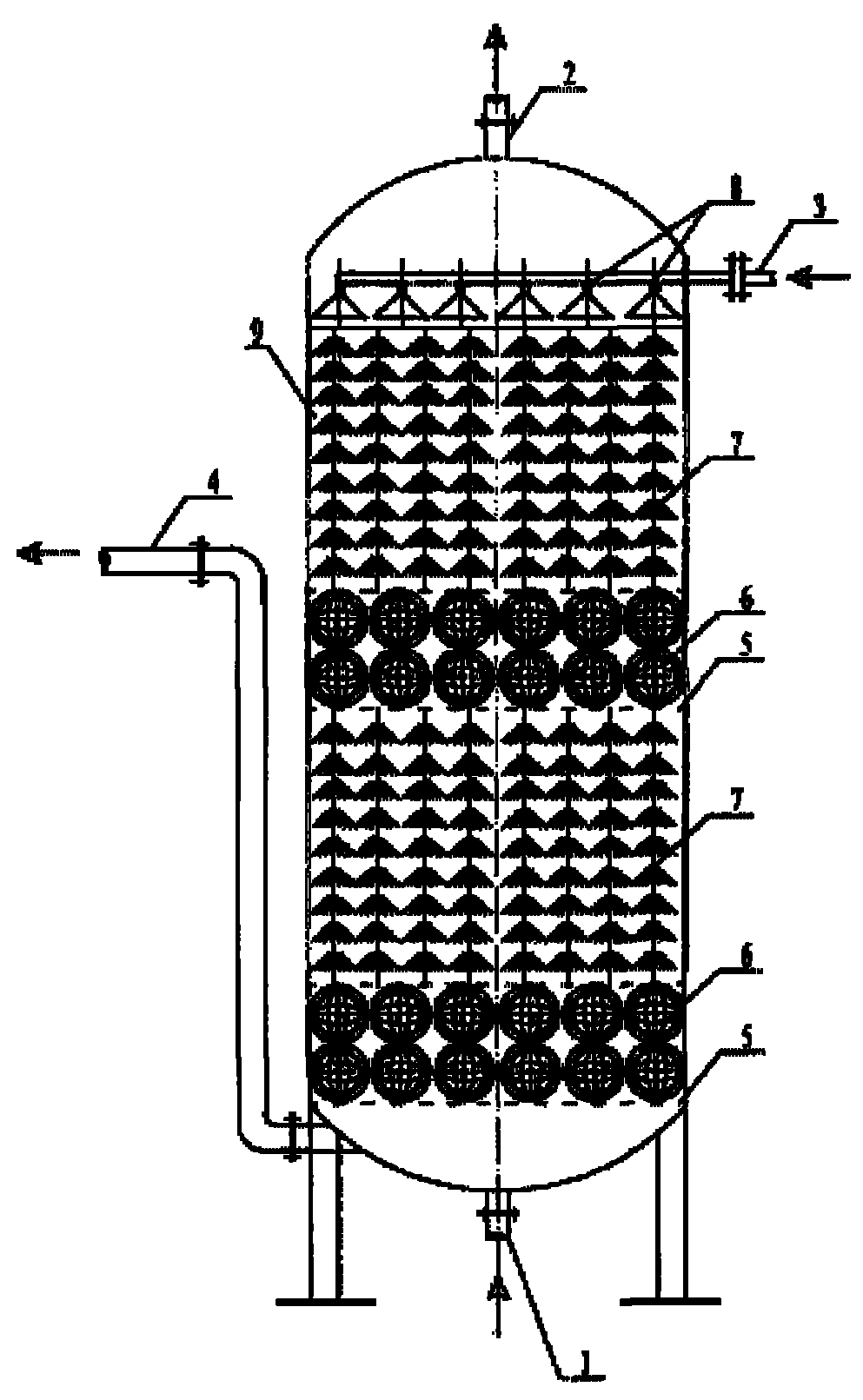

[0016] Example 1. See figure 1 , The biogas anaerobic biological desulfurization device of the present invention is a vertical packed tower. The biogas inlet 1 and the biogas outlet 2 are respectively arranged at the top and the bottom of the tower. Plastic air balls 6 with a high specific surface area of φ25-50mm and elastic packings 7 are placed in the tower. The two types of packings are placed alternately. . A spray nozzle 8 is arranged above the top layer of packing, and is connected with the spray liquid inlet 3 . The spray liquid outlet 4 is located in the middle and upper part of the outer side of the tower and communicates with the bottom of the tower to ensure that a desulfurization liquid section with a height of 30-50 cm is formed in the tower. The height of the vertical pipe connecting the bottom of the tower and the spray liquid outlet 4 is about 2 times of the biogas pressure (water column).

[0017] Implementation steps of the present invention are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com