Hydraulic pressure floating hood type methane tank

A floating cover type biogas digester technology, applied in energy wastewater treatment, gas production bioreactors, biochemical instruments, etc., can solve the problems of increasing or decreasing the maximum output biogas pressure, unable to automatically discharge slag, and less gas storage, and achieve structural Simple, low cost, and the effect of increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

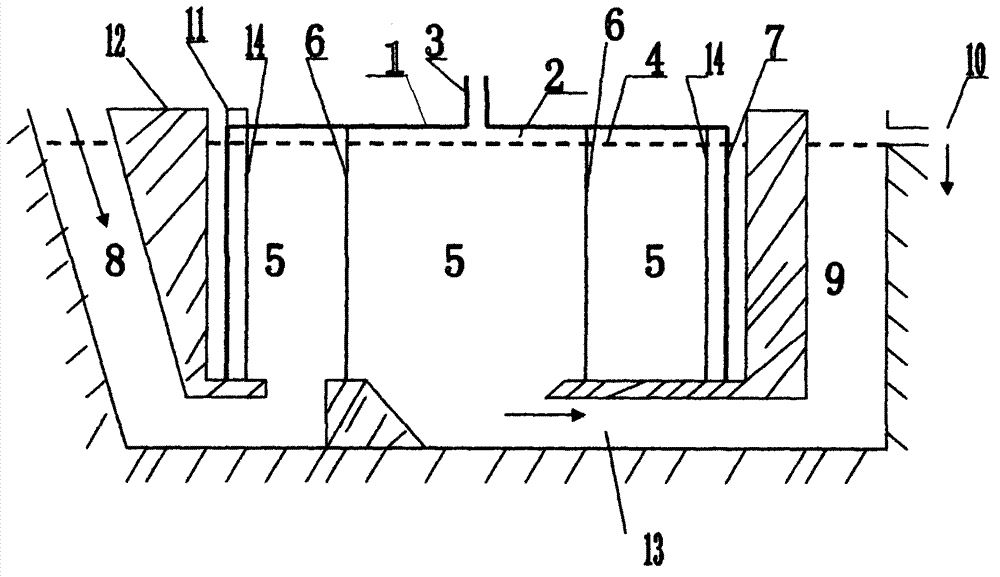

[0048] Hydraulic floating cover biogas digester, including cover, container, gas storage room, fermentation room, hydraulic room, feed liquid, feed pipe, discharge pipe, air guide pipe, overflow port, consisting of cover cover, cover wall, guide The cover body composed of air pipes is covered on the inner bottom of the container. There is a distance interlayer between the cover wall and the container wall. There is a device for introducing the material liquid into the cover, and there is a control gas storage room between the cover inner plane and the liquid surface. The device with a height greater than 0 is equipped with a positioning device that allows the cover body to sink and float freely, and a slag liquid discharge device. The feed inlet is higher than the zero pressure liquid level, and the height of the cover wall is at least equal to the vertical upward cross-sectional force area in the cover multiplied by The value obtained by dividing the maximum output biogas pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com