Landfill gas separating and purifying process and device

A landfill gas and process technology, which is applied in separation methods, dispersed particle separation, absorption purification/separation, etc., can solve problems such as inability to obtain high purity, and achieve the effects of reducing emissions, facilitating utilization, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

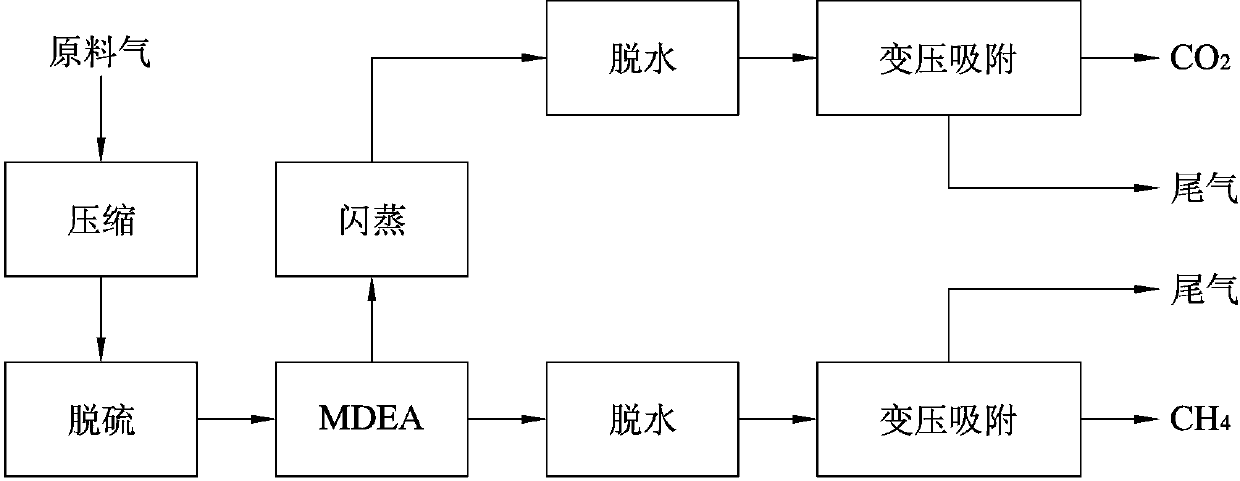

[0027] Embodiment one: see attached figure 1 As shown, a process for realizing the separation and purification of landfill gas includes the following steps: firstly, the landfill gas is separated into methane-rich gas and carbon dioxide-absorbed solution by using methyldiethanolamine method (MDEA); Then, the methane-rich gas is dehydrated and separated by pressure swing adsorption to obtain methane product gas; the solution that absorbs carbon dioxide is flashed to release the gas containing carbon dioxide, and the gas containing carbon dioxide is dehydrated and then subjected to pressure swing adsorption And separation obtains carbon dioxide product gas.

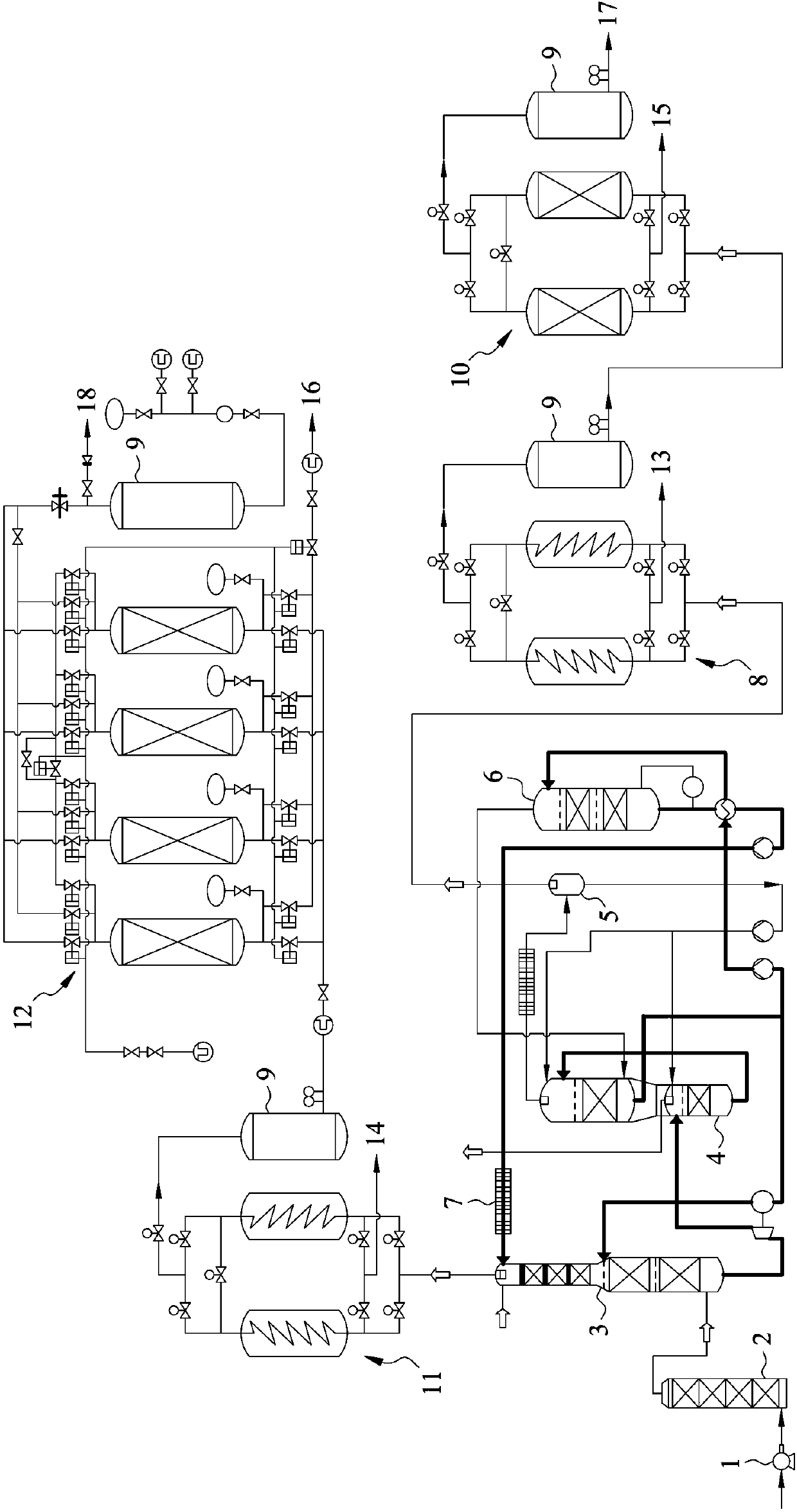

[0028] The above separation and purification process is carried out through the attached figure 2 The separation and purification device shown is realized. In this figure, the wider lines represent the passages of liquids, while the narrower lines represent the passages of gases. The landfill gas separation and purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com