Automatically controlled underground coal mine gas configuration experiment device

An experimental device and gas technology, applied in gas/liquid distribution and storage, gas and gas/steam mixing, transportation and packaging, etc., can solve the problem of low investment and achieve the effect of controllable precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

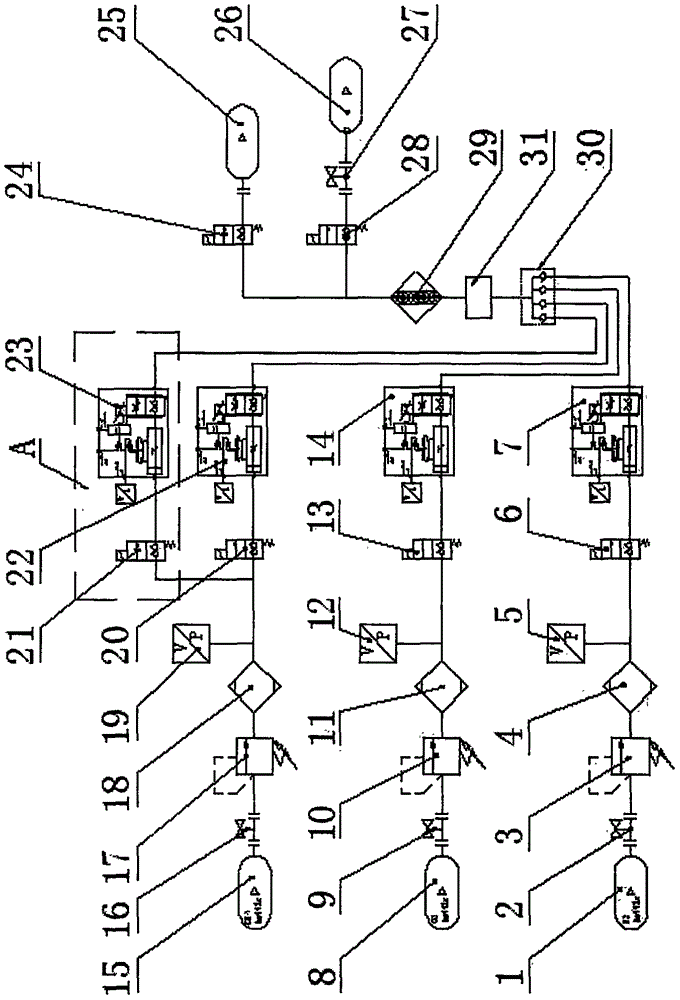

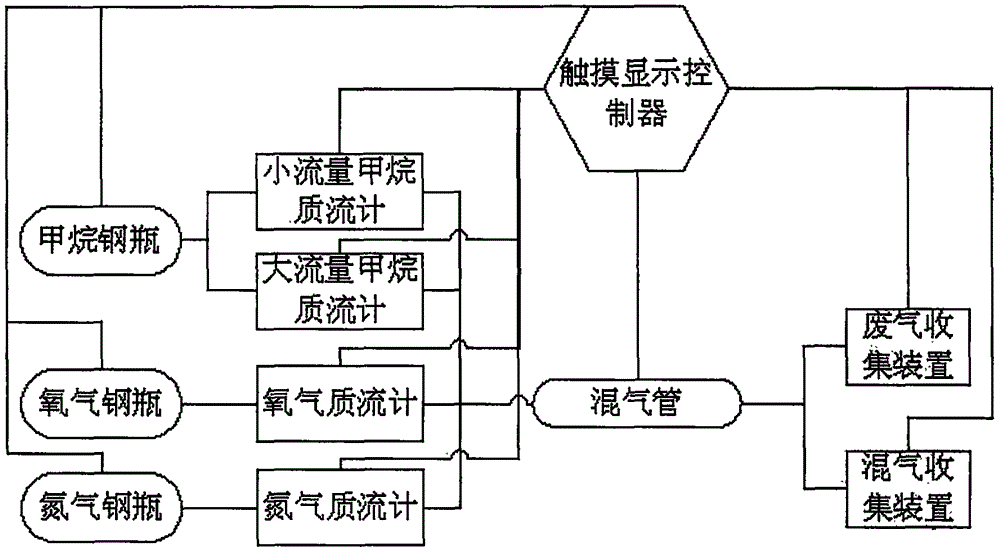

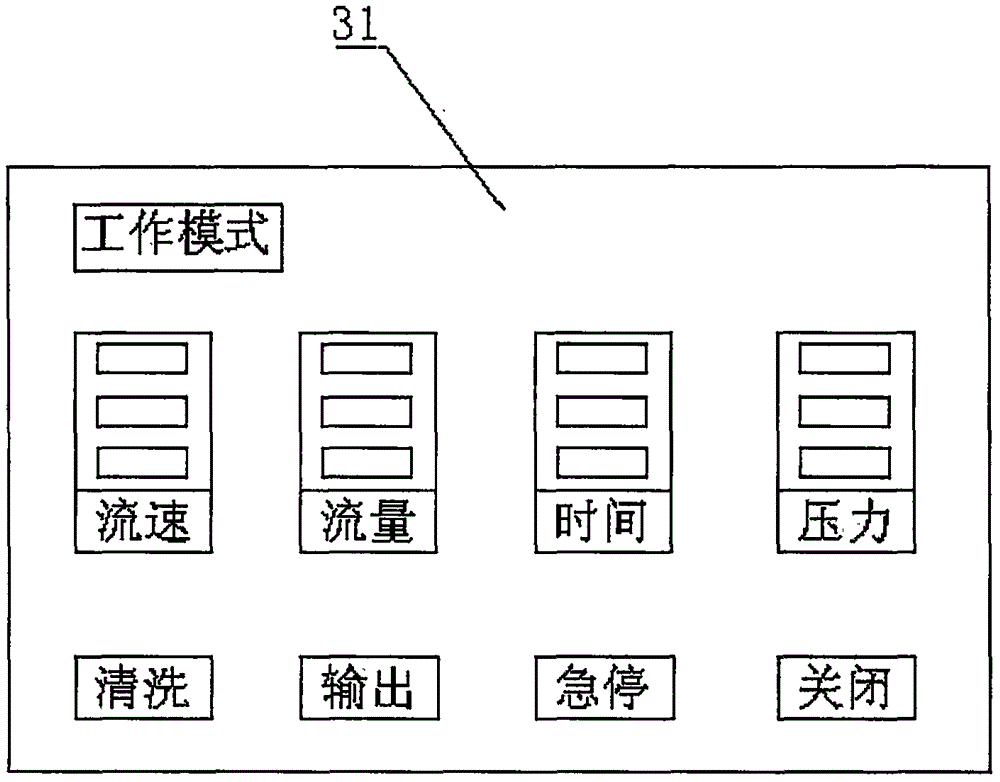

[0028] Such as Figure 1-10 As shown, in the touch display controller 31, after setting the cleaning time and the required nitrogen, oxygen, and methane concentration ratios, the cleaning button is opened, and the nitrogen solenoid valve 6 is powered, and the oxygen solenoid valve 13 is powered. A certain methane concentration makes the large-flow methane solenoid valve 20 and the small-flow methane solenoid correspondingly energized, the air intake path of the solenoid valve is opened, the exhaust gas zero-leakage switch solenoid valve 24 is energized, and the exhaust gas recovery pipeline is opened.

[0029] Nitrogen mass flow meter 7, oxygen mass flow meter 14, large flow methane mass flow meter 22 and small flow methane mass flow meter 23 are converted into mass flow meter spool opening amount by touching display controller 31 according to the set proportional parameters At this time, the gas in the steel cylinder is output to the exhaust gas recovery device through the pi...

Embodiment 2

[0031] Such as Figure 1-10 As shown, in the touch display controller 31, the proportion automatic mode is selected by the working mode button, and the gas mixture percentage of any two gases in the three gases is set, wherein the ratio of the methane concentration in the gas mixture is required to be less than 10%, and the gas mixture is turned on. Gas manual shut-off valve 27, so that the gas path of the mixed gas collection device 26 is opened, and at this time, the nitrogen solenoid valve 6, the oxygen solenoid valve 13 and the small flow methane solenoid valve 21 are energized, and the air intake path of each solenoid valve is opened, and the gas mixture is zero. The leakage switch solenoid valve 28 is powered, the mixed gas collection pipeline is opened, and the nitrogen mass flow meter 7, the oxygen mass flow meter 14 and the small flow methane mass flow meter 23 are set by the touch display controller 31 according to the proportional parameters. The parameter is conver...

Embodiment 3

[0034] As shown in 1-9, in the touch display controller 31, the proportional automatic mode is selected by the working mode button, and the gas mixture percentage of any two gases in the three gases is set, wherein the ratio of the methane concentration in the mixed gas is required to be between Between 10% and 90%, open the mixed gas manual stop valve 27 to open the gas path of the mixed gas collection device 26. At this time, the nitrogen solenoid valve 6, the oxygen solenoid valve 13 and the large flow methane solenoid valve 20 are energized, and the solenoid valves of each circuit The valve intake gas path is opened, the mixed gas zero leakage switch solenoid valve 28 is energized, the mixed gas collection pipeline is opened, the nitrogen mass flow meter 7, the oxygen mass flow meter 14 and the large flow methane mass flow meter 22 , is converted into the opening amount of the mass flow meter by the touch display controller 31. At this time, the gas in the steel cylinder pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com