Liquid holding bath side-placed smoke gas desulfurization unit

A desulfurization device, side-mounted technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of large transportation power of absorbing liquid, difficult sealing, high reagent cost, etc., saving equipment investment and improving Residence time, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

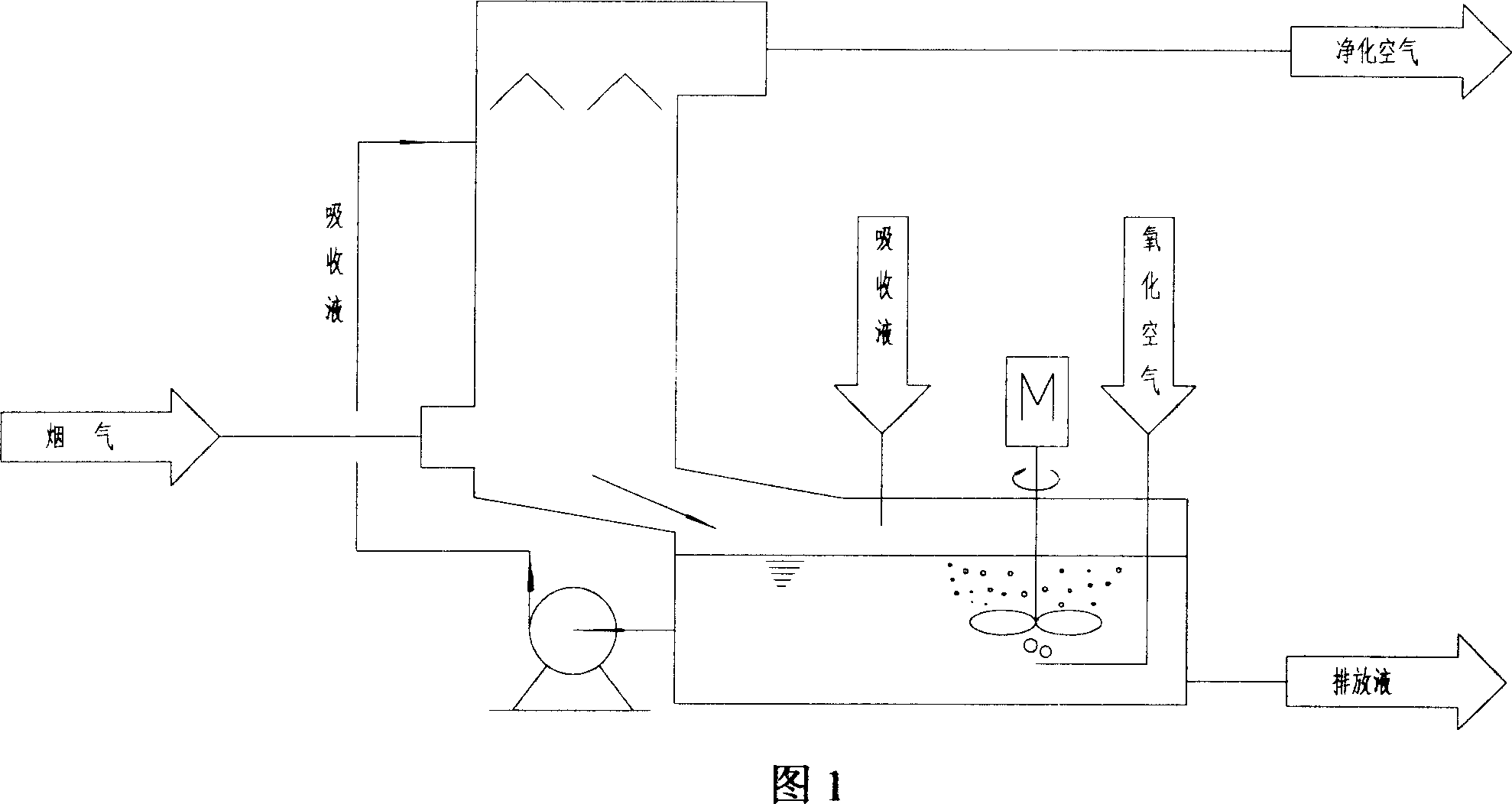

[0019] The structure and technical effects of the device of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] The liquid holding tank side-mounted flue gas desulfurization device of the present invention includes the following contents (see accompanying drawing 1):

[0021] (1) Flue gas desulfurization section (i.e. gas-liquid contact area);

[0022] (2) The liquid holding tank below the side of the flue gas desulfurization section (ie, the neutralization reaction zone);

[0023] (3) The circulation pump room directly below the flue gas desulfurization section.

[0024] Among them, the flue gas desulfurization section is installed on a platform constructed of concrete. The flue gas desulfurization section can use anti-corrosion concrete or anti-corrosion masonry structure, and can also use stainless steel or other metal materials with anti-corrosion lining (such as rubber lining), and anti-corrosion metal materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com