Plunger for high abrasion-proof displacement pump

A volumetric pump, high wear-resistant technology, applied in the direction of plunger, variable volume pump components, pistons, etc., can solve the problems of difficult volumetric pumps to be popularized, easy to break the connection end, high manufacturing cost and other problems, and achieve simple manufacturing process , The connection terminal is firm and the material is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

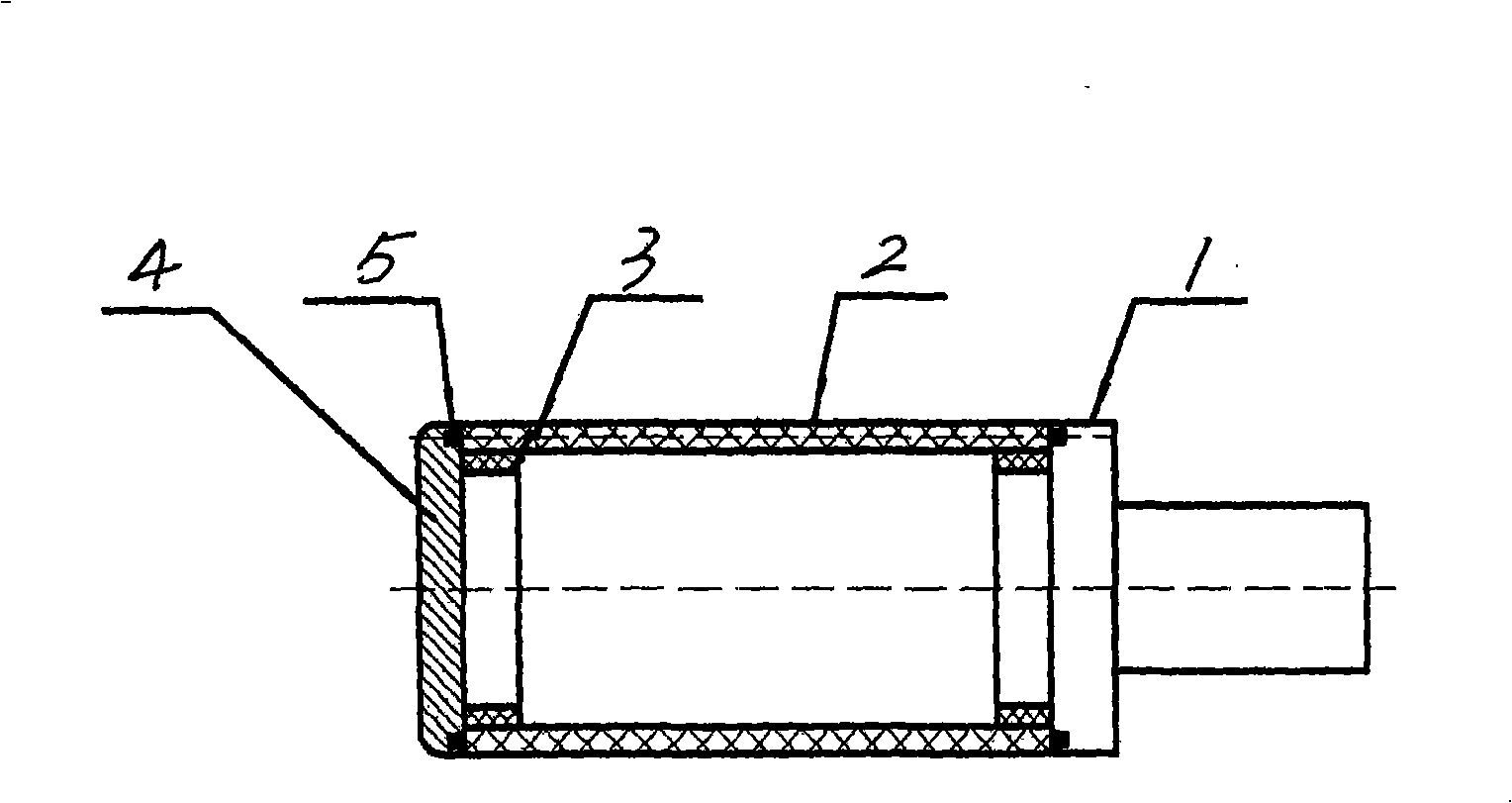

[0011] refer to figure 1 , a plunger for a high-wear-resistant volumetric pump, including a plunger core 1 made of chromium-nickel stainless steel with a connecting end, and the SIC The material is inlaid on the outer surface of the plunger core 1, so that the plunger core 1 is covered with a shell 2 with high hardness (physical and mechanical properties: density 3.0-3.2g / cm 3 , bending strength 350~500mpa, strength 9.2Mohs, elastic modulus 300~420GPa, thermal conductivity 40~81W / (m k), thermal expansion coefficient 4~4.5*10 -6 / °C). In order to ensure the airtightness of the plunger, a sealant layer 3 made of nitrile rubber is provided between the contact surface of the plunger core body and the SIC shell 2; the end of the plunger core body 1 is provided with The plug 4 made of 316L material seals the connecting end, and a sealing ring 5 is arranged between the shell 2 and the plug 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com