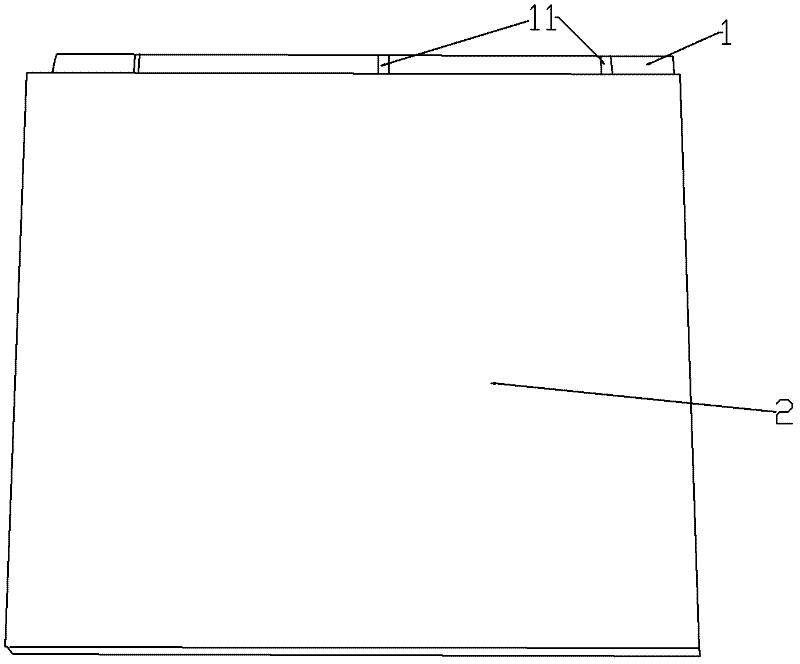

Solid wood foor

A technology of solid wood boards and floors, applied in the direction of wood layered products, layered products, buildings, etc., can solve the problems of easy aging, short service life, easy to get dirty, etc., achieve good elasticity and impact resistance, and humanize the living environment , maintenance of environmental protection and renewable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

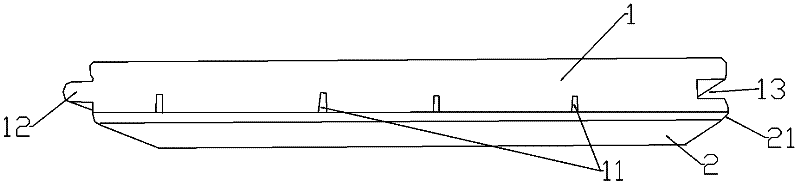

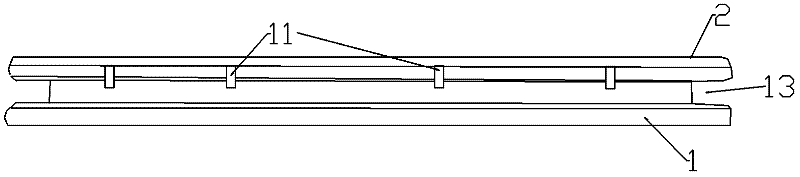

[0041] Embodiment 1: The solid wood board 1 has a thickness of 10mm, the PVC board has a thickness of 2mm, the groove depth of each groove is 3.0-3.5MM, and the groove width is 2MM.

Embodiment 2

[0042] Embodiment 2: The thickness of the solid wood board is 12mm, the thickness of the PVC board is 2mm, the groove depth of each groove is 6MM, and the groove width is 3MM.

Embodiment 3

[0043] Embodiment 3: The thickness of the solid wood board is 13 mm, the thickness of the PVC board is 4 mm, the groove depth of each groove is 5 or 6 mm, and the groove width is 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com