Patents

Literature

34results about How to "There will be no scrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

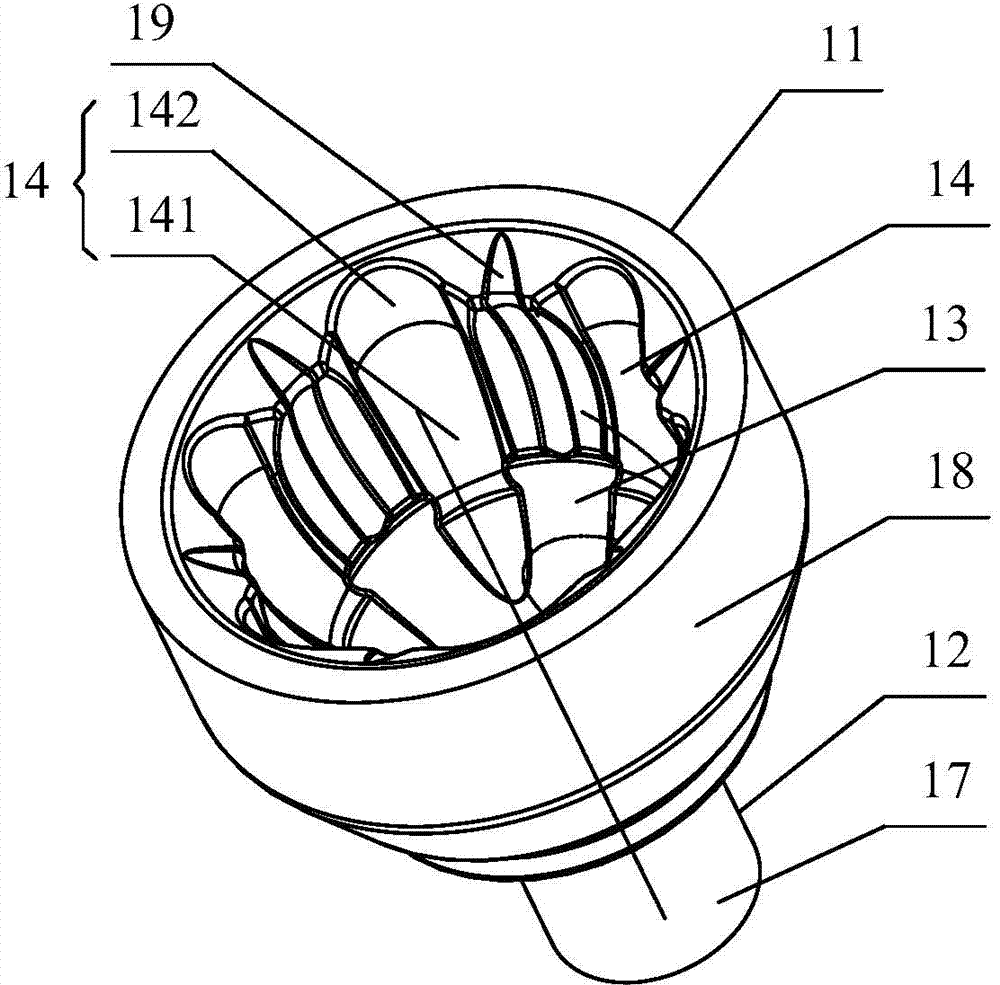

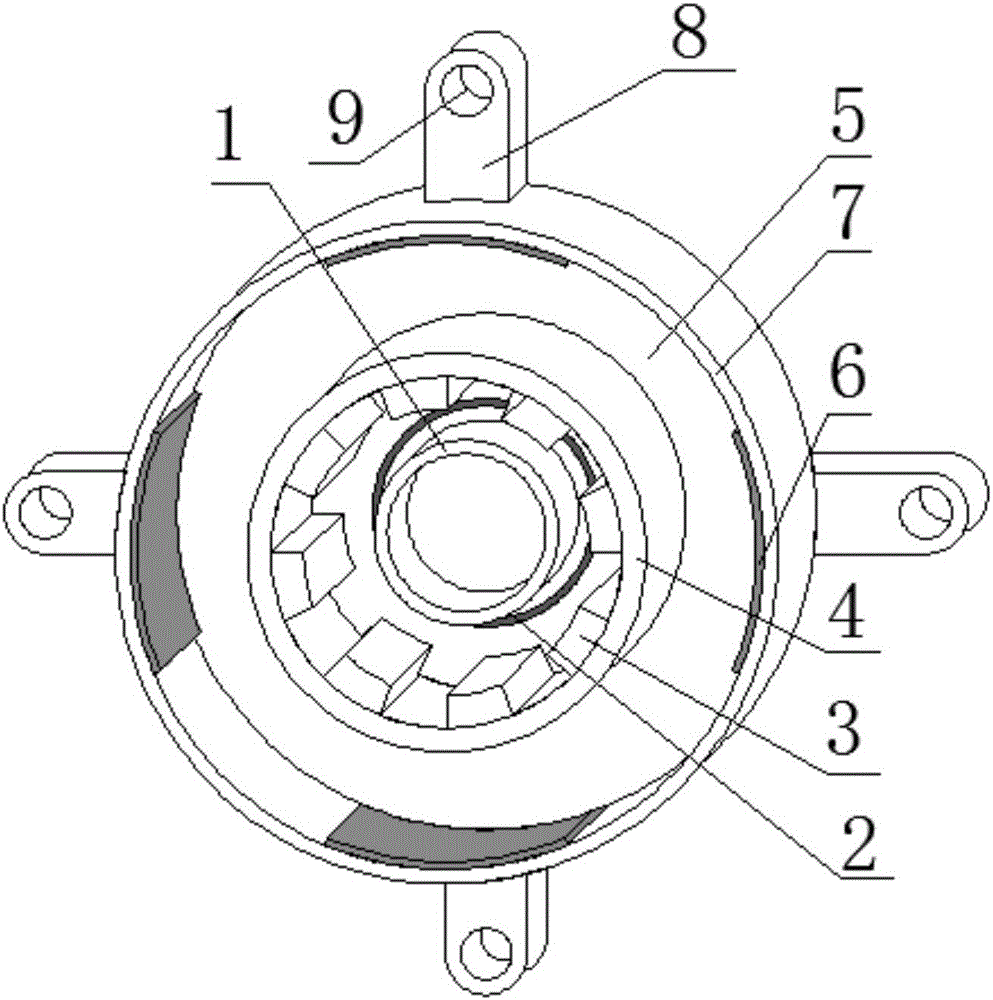

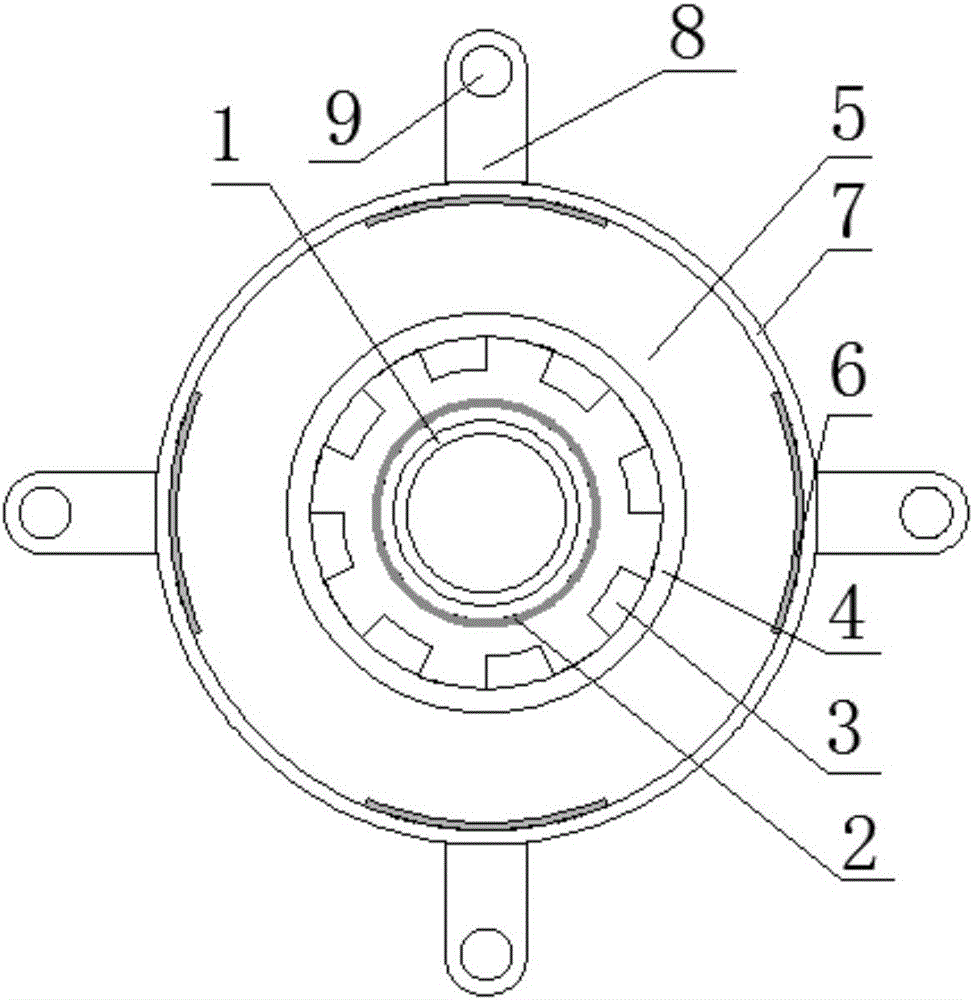

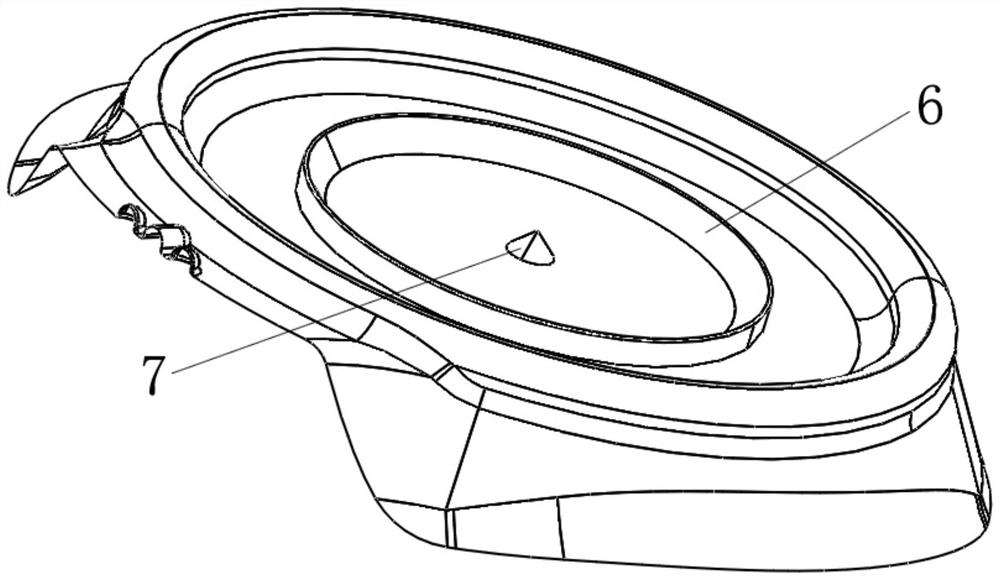

Motor end cover with good heat dissipation performance

InactiveCN105048693AGuaranteed uptimeSpeed up heat dissipationSupports/enclosures/casingsEngineeringGalvanization

The invention discloses a motor end cover with good heat dissipation performance. The motor end cover comprises a motor end cover body, wherein the inside and the outside of the motor end cover body are subjected to rust-proof treatment through a galvanization technology; the motor end cover body comprises a motor end cover bottom and an outer barrel of the motor end cover; at least two straight threaded sections which are not connected with each other are arranged on the inner wall of the outer barrel of the motor end cover; a through hole is formed in the center of the motor end cover bottom; at least one heat dissipation hole which is formed along the circumferential direction of the through hole is also formed between the through hole in the motor end cover bottom and the outer barrel of the motor end cover in a circular manner; a fixed structure is arranged on the outer wall of the outer barrel of the motor end cover; and a thread fixing hole is formed in the fixed structure. The defect that heat in the axial direction of a motor is not easy to dissipate along the axial direction in an accelerating manner during heat dissipation in the prior art is solved; and the motor end cover capable of further accelerating heat dissipation along the axial direction is designed, so that the motor can be subjected to heat dissipation along the circumferential direction during operation, and simultaneously can be subjected to heat dissipation along the axial direction; the heat dissipation is quickened; and a running fault of the motor is avoided.

Owner:CHONGQING ZHUHAO MACHINERY

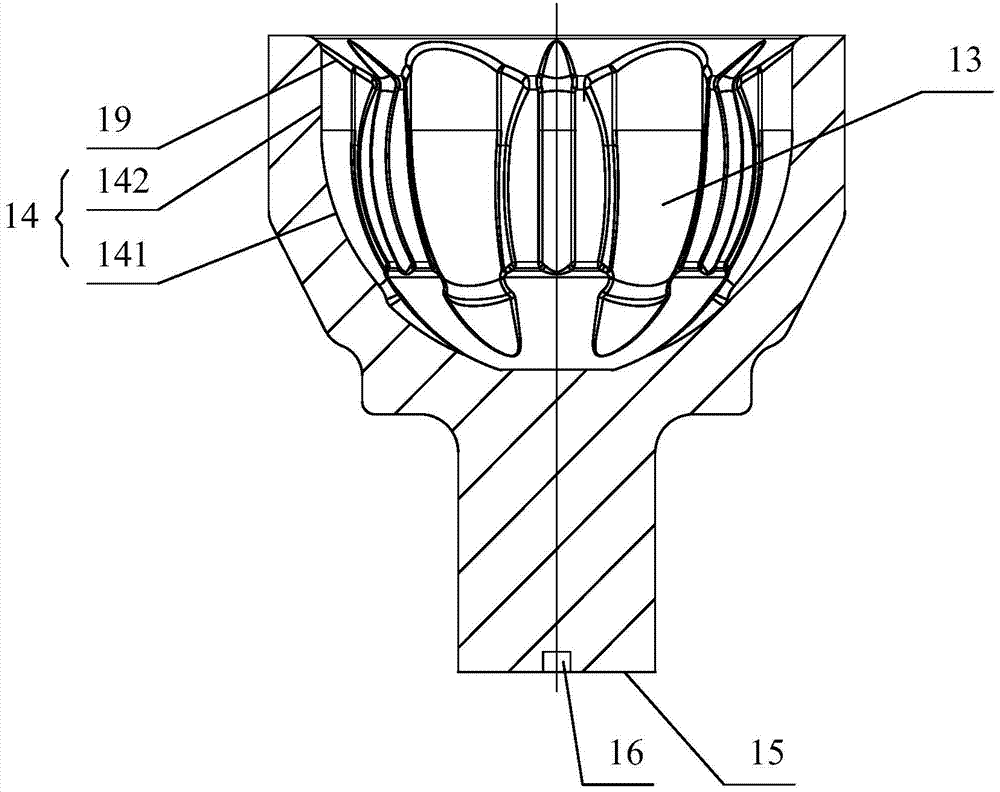

Method for manufacturing turbo-charger blower impeller mold

InactiveCN101480699AGood consistencyNot easily deformedFoundry mouldsFoundry coresImpellerPhysical model

The invention relates to a method for manufacturing a die of a compressor impeller of a turbocharger, which mainly comprises the following steps: firstly, a data model of the compressor impeller is designed: a computer three-dimensional data model of the compressor impeller of the turbocharger is designed through pro / engineer computer software; secondly, an impeller physical model is made by a digital control processing center: on a five-shaft digital control milling machine, an integrated impeller physical model is processed by metal materials, such as aluminum ally, and the like that are soluble in acid easily; thirdly, a metal layer is cast on the outer surface of the impeller physical model: an even nickel or copper layer with 2-7mm is cast on the outer surface of the impeller physical model by adopting an electroforming method; fourthly, the acid dissolution is carried out: the metal impeller physical model is molten by acid solution. The die of the compressor impeller of the turbocharger made through adopting the steps can be used for casting the compressor impeller of the rubber turbocharger.

Owner:HUNAN TYEN MACHINERY

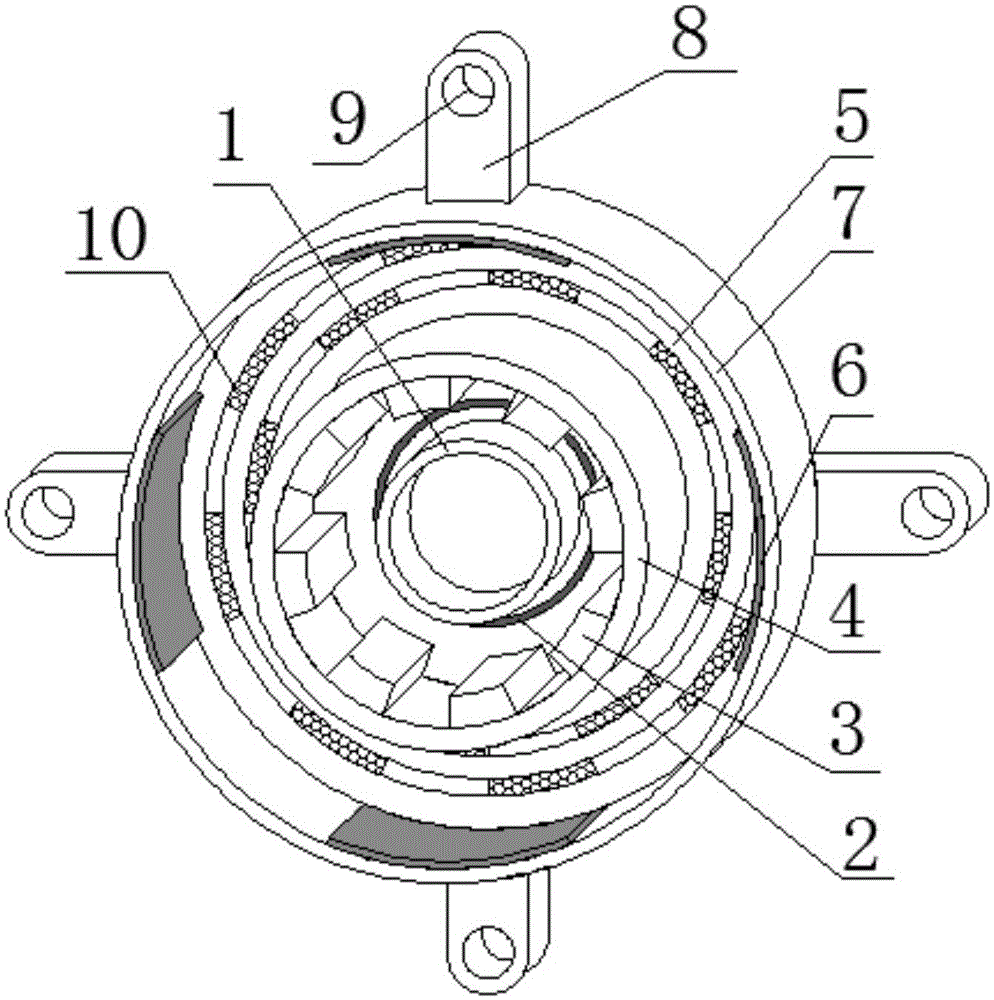

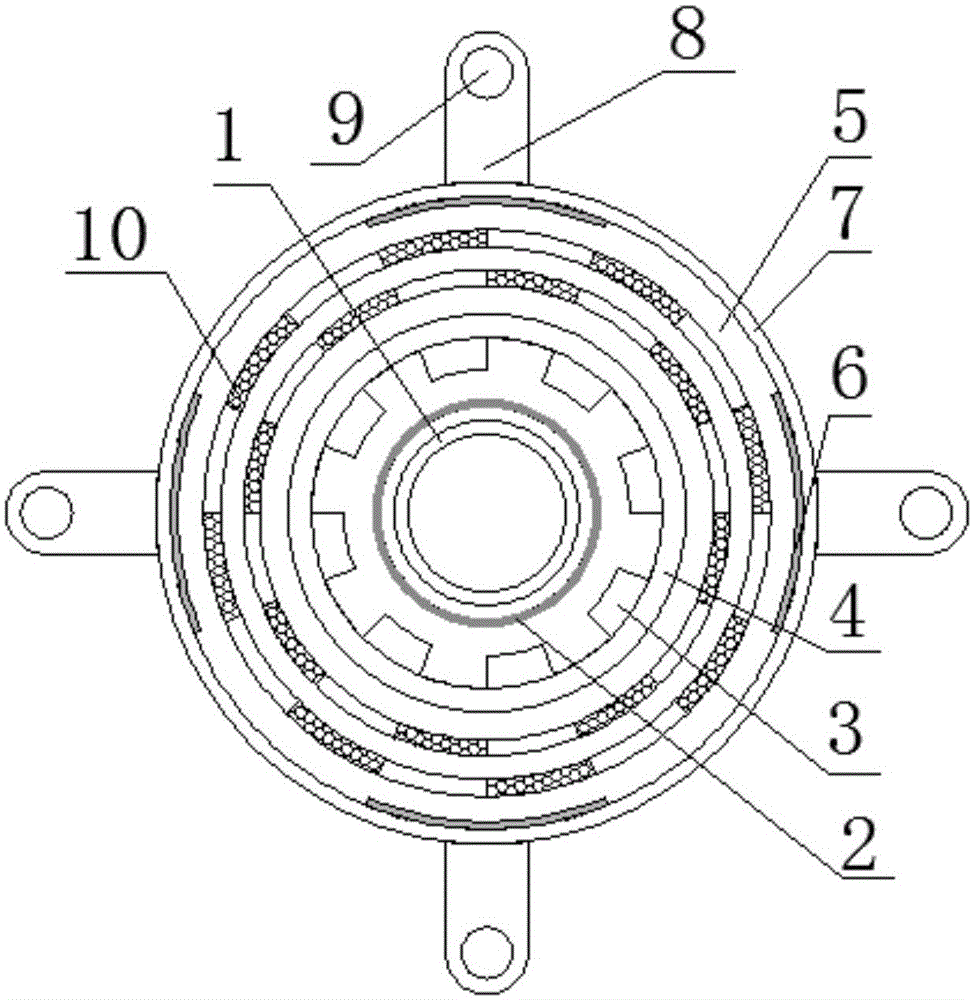

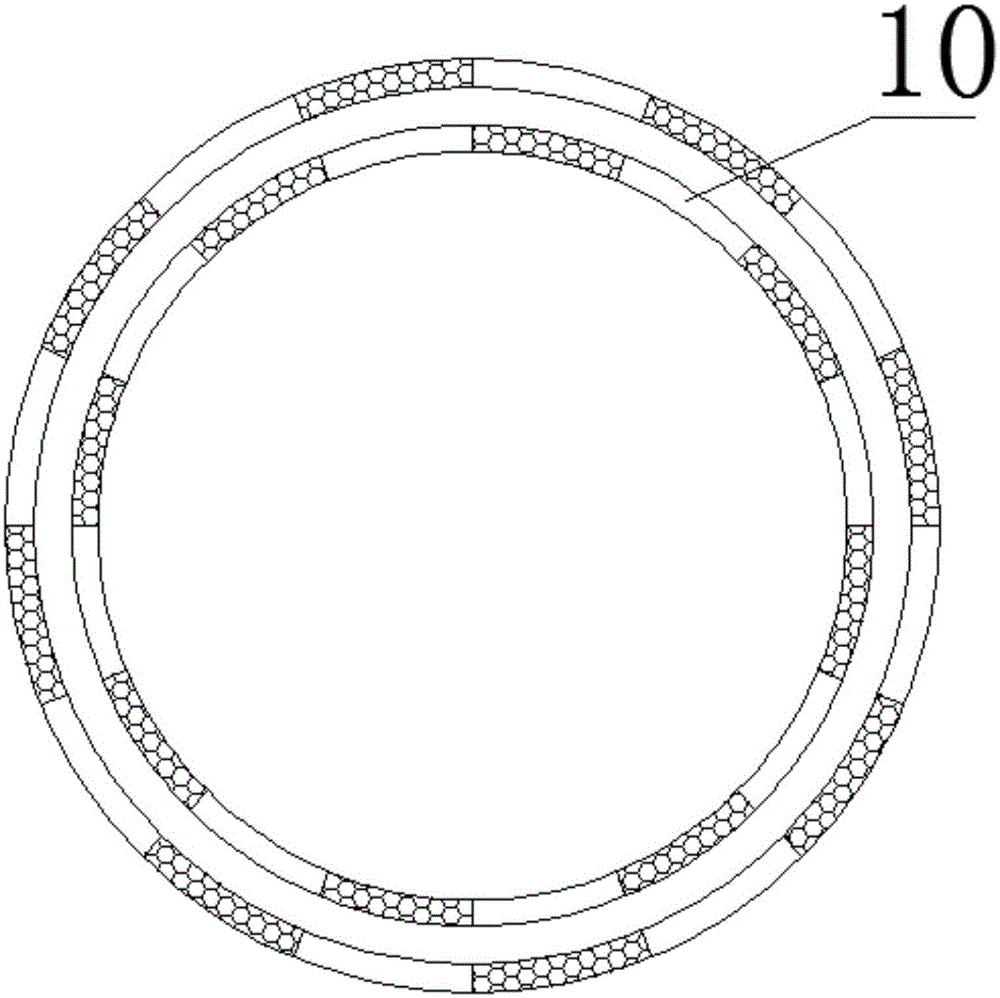

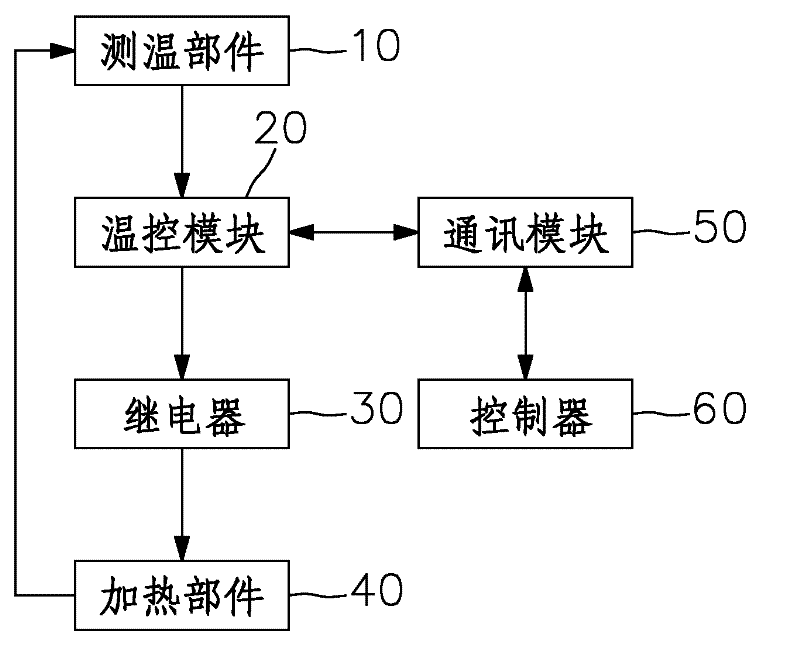

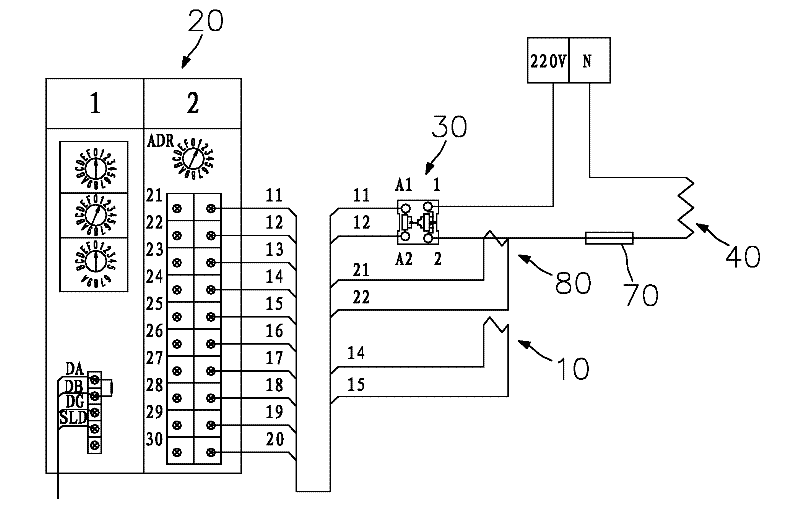

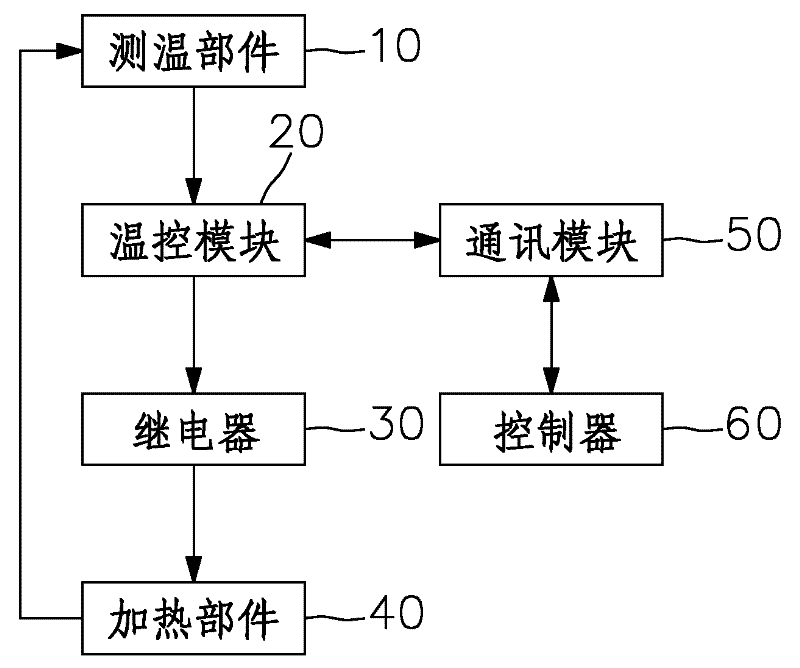

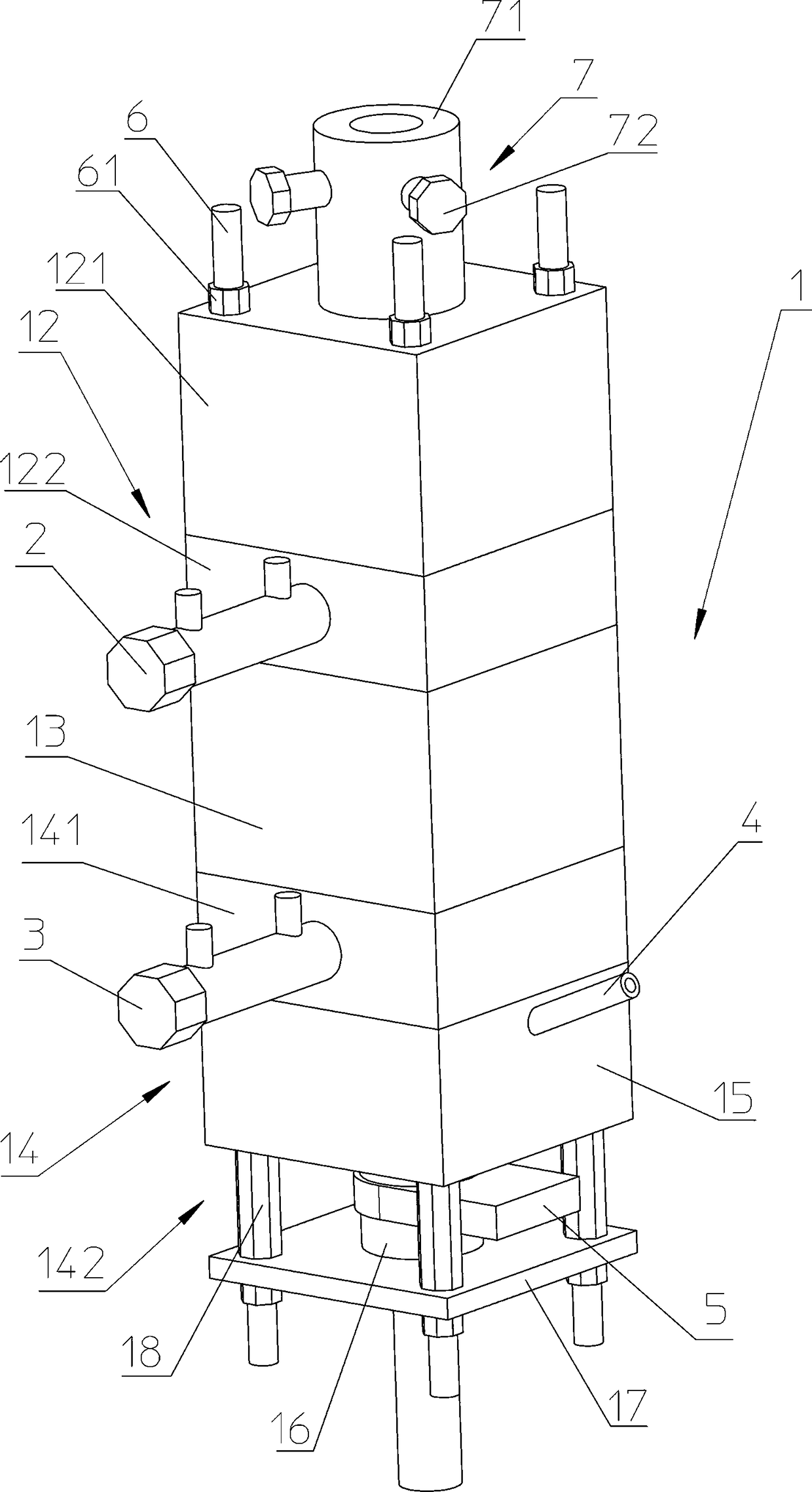

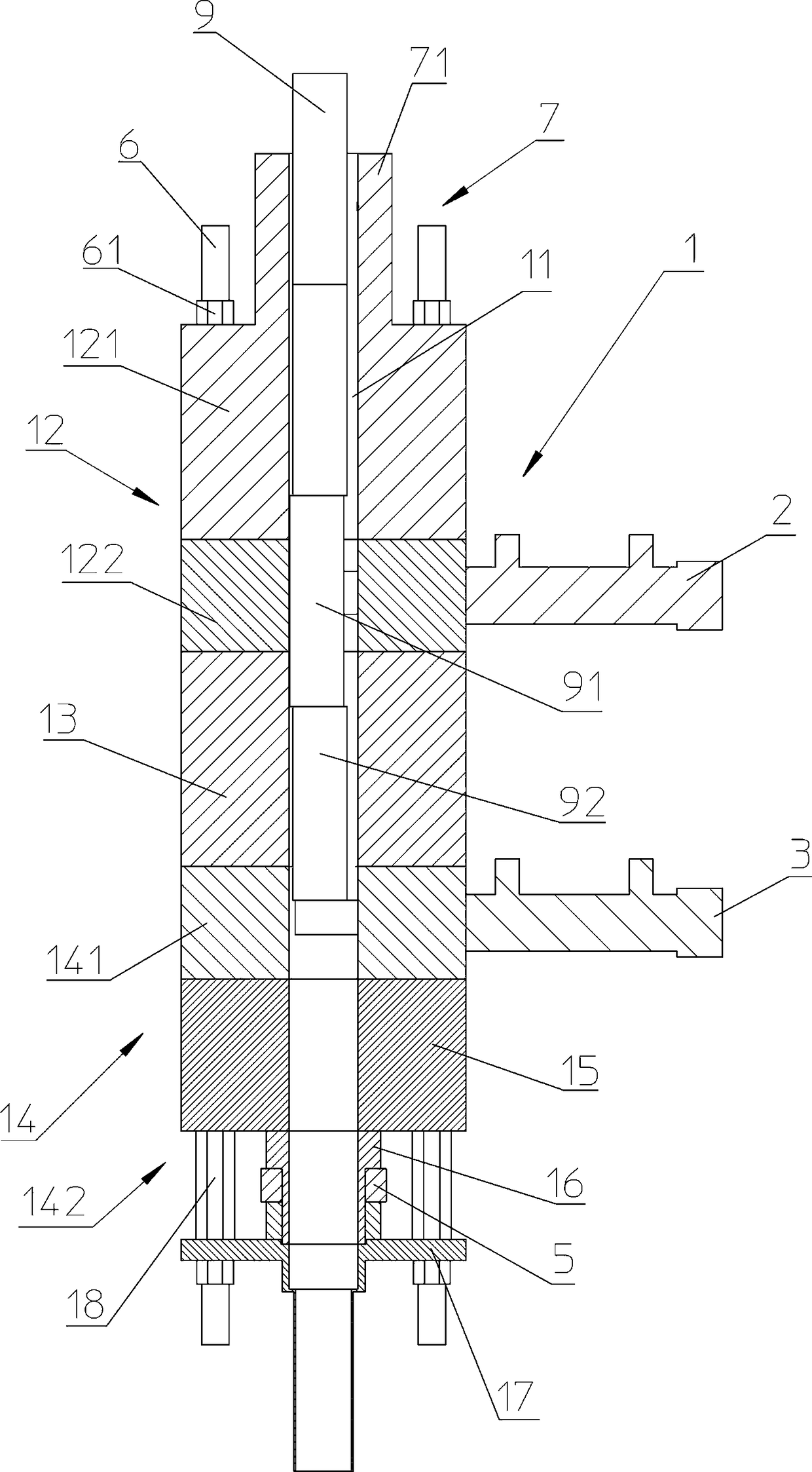

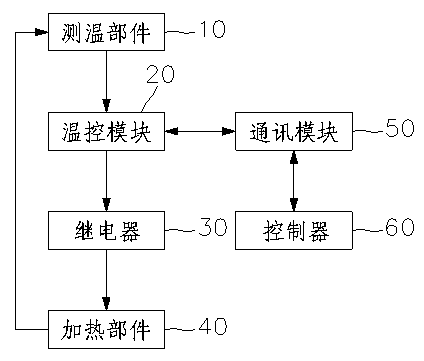

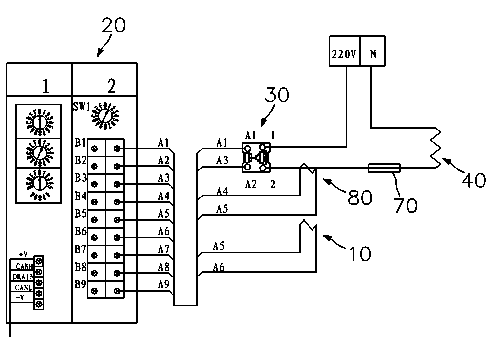

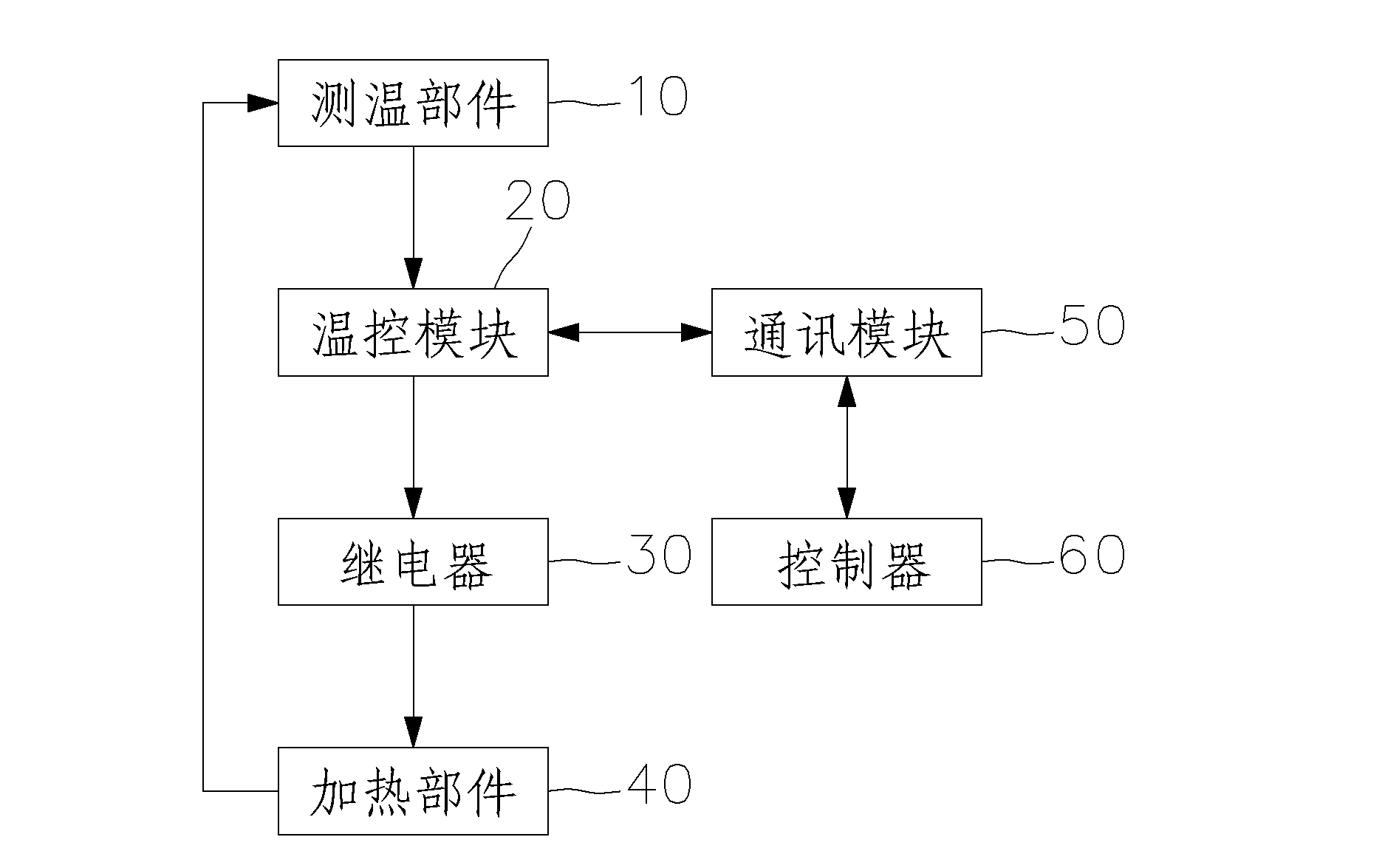

Heating control device used for packaging equipment

ActiveCN102412171AGuaranteed stabilityThere will be no scrappingSemiconductor/solid-state device manufacturingTemperature controlComputer module

The invention relates to a heating device in integrated circuit packaging equipment and especially relates to a heating control device used for packaging the equipment. The heating control device comprises a temperature measurement component. An output terminal of the temperature measurement component is connected with an input terminal of a temperature control module. The output terminal of the temperature control module is connected with a relay. A heating component is arranged in a power supply loop of a relay control terminal. In the heating device of the invention, the temperature control is separated from a processing scope of a system PLC controller so that the temperature control can not be interfered by factors, such as abnormity of the PLC controller. Therefore, stability and accuracy of the temperature can be guaranteed. Simultaneously, a short circuit protection function added in the invention is beneficial to protect hardware. And a broken line detection function contained in the invention can give alarm prompt in an initial failure stage so that the failure can be searched timely.

Owner:TONGLING FUSHI SANJIA MACHINE

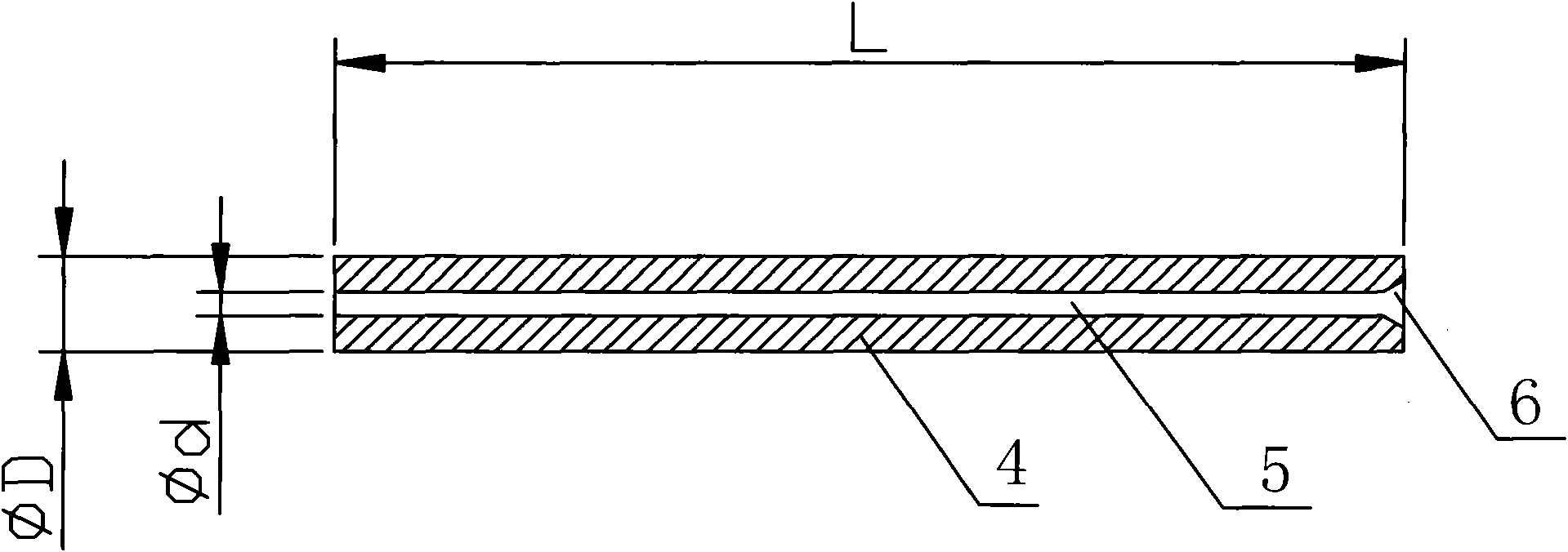

High-temperature cable for high-strength bearing detection

InactiveCN101299353AThere will be no scrappingGuaranteed temperature resistancePlastic/resin/waxes insulatorsInsulated cablesWell loggingEngineering

A high strength bearing detection high temperature cable, belongs to the cable technical field, characterized by being provided with a 1+6 stranding reinforce steel core, a double layer reverse outward armour steel wire and a plurality of insulated cores evenly and closely wound aroud the 1+6 stranding reinforce steel core to compose the cable core. Stuffed inorganic ropes are provided in the cable core, and a special macromolecule material sheath is coated on the cable core; the double layer reverse outward armour steel wire is wrapped at the cirumferential of the sheath; the surface of the steel wire armour is coated with a layer of soft mask rust preventive oil. The invention ahs reasonable and simple structure, easy manufacture, good utilization qualities, strong cable bearing ability, good corrosion-resisting properties, safety and long service life. The cable is the ideal cable in the well logging, the perforation, the river, the gulf, the irrigation works and the exploration and the like.

Owner:BAOSHENG SCI & TECH INNOVATION

Automatic processing adjustment fingerprint recognizer and recognition method thereof

ActiveCN106228123AThere will be no scrappingFast resolutionPrint image acquisitionMatching and classificationEmbedded systemDigital conversion

The invention discloses an automatic processing adjustment fingerprint recognizer, and solves the defects in the prior art. The technical scheme is that the recognizer comprises an induction surface, an analog-digital conversion unit, a processor, a random reading and writing storage unit, a bus interface, and a computer; the interior of the induction surface is provided with an induction element array; the induction element array is electrically connected with the processor through the analog-digital conversion unit; the processor is electrically connected with the computer through the bus interface, and the random reading and writing storage unit is electrically connected with the processor. The recognizer is smaller in size, is suitable to be used during fingerprint unlocking of a cellphone, just needs to add an induction surface at a specific part for achieving the purpose of the invention, can obtain higher recognition rate, is higher in recognition speed, and is smaller in size.

Owner:世维人工智能(嘉兴)有限公司

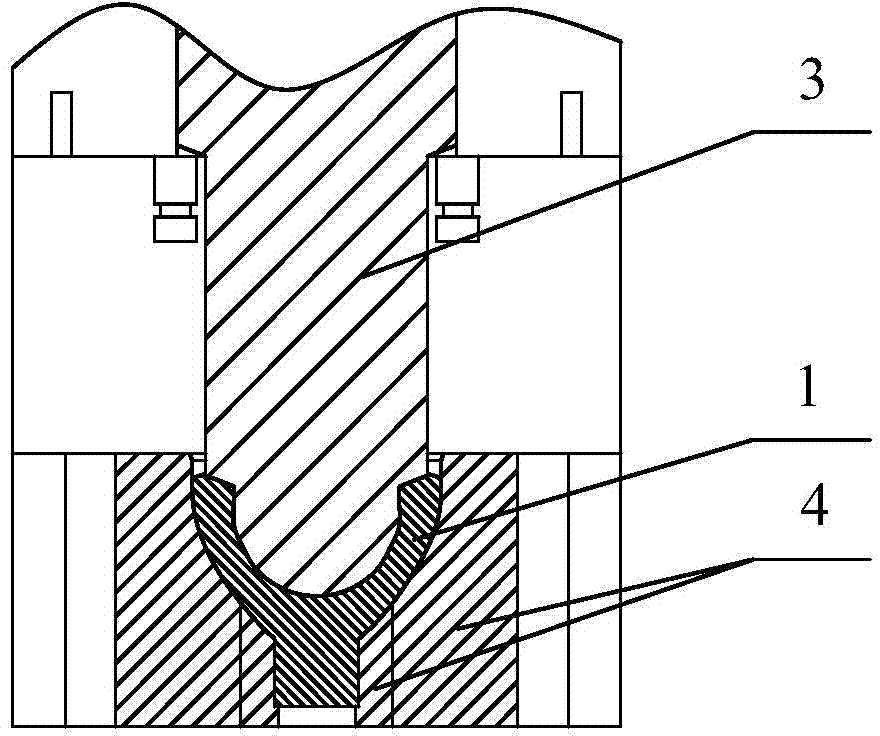

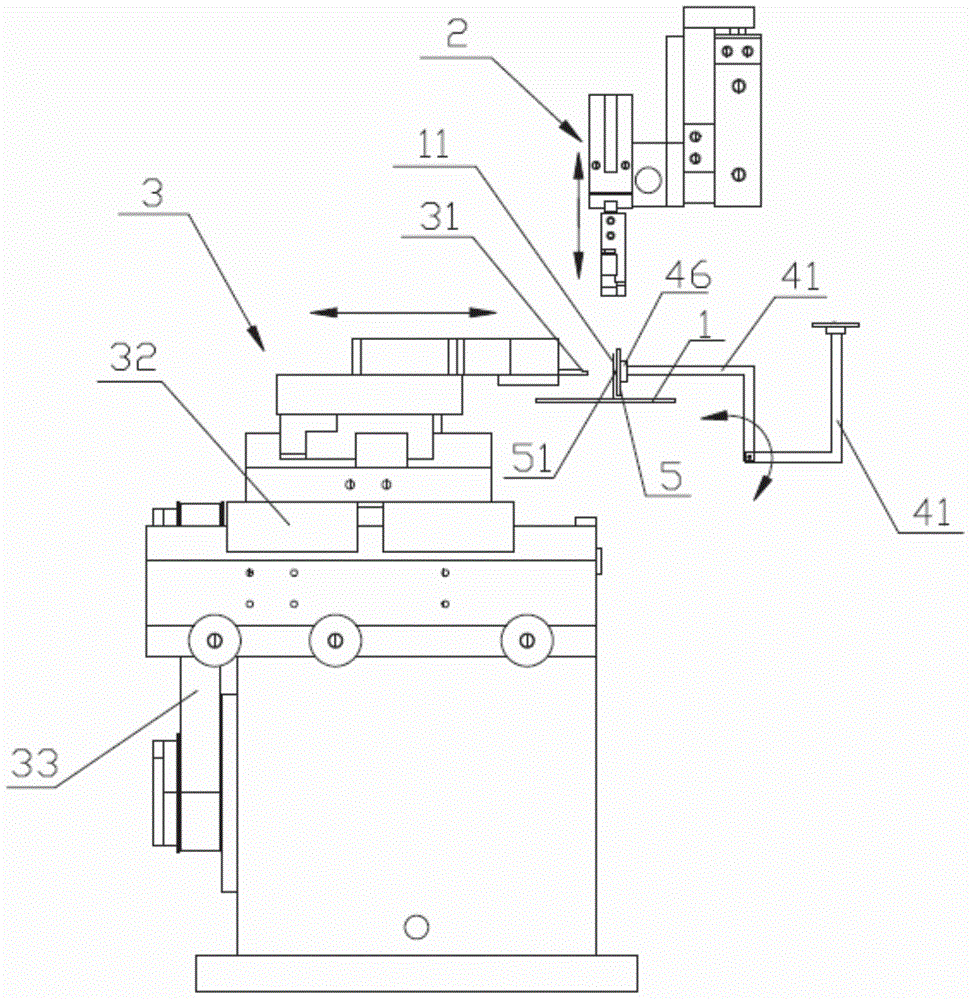

Servo bending machine for automobile connector terminal

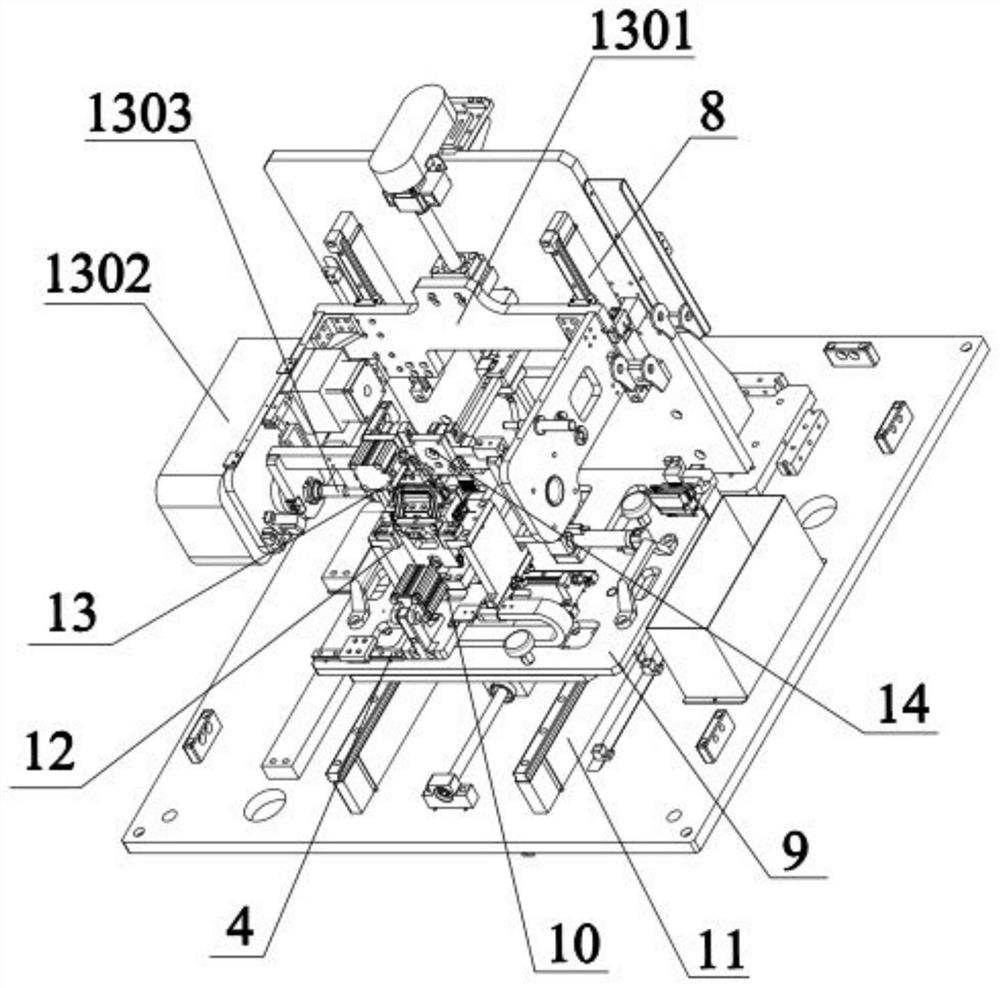

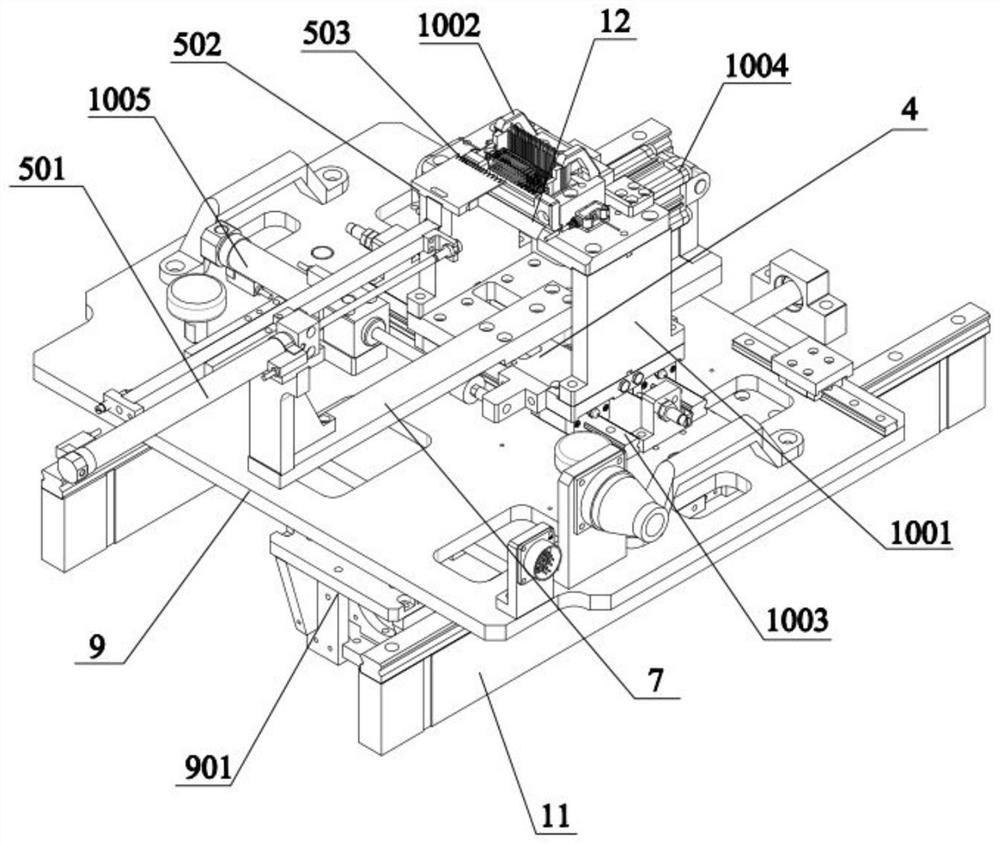

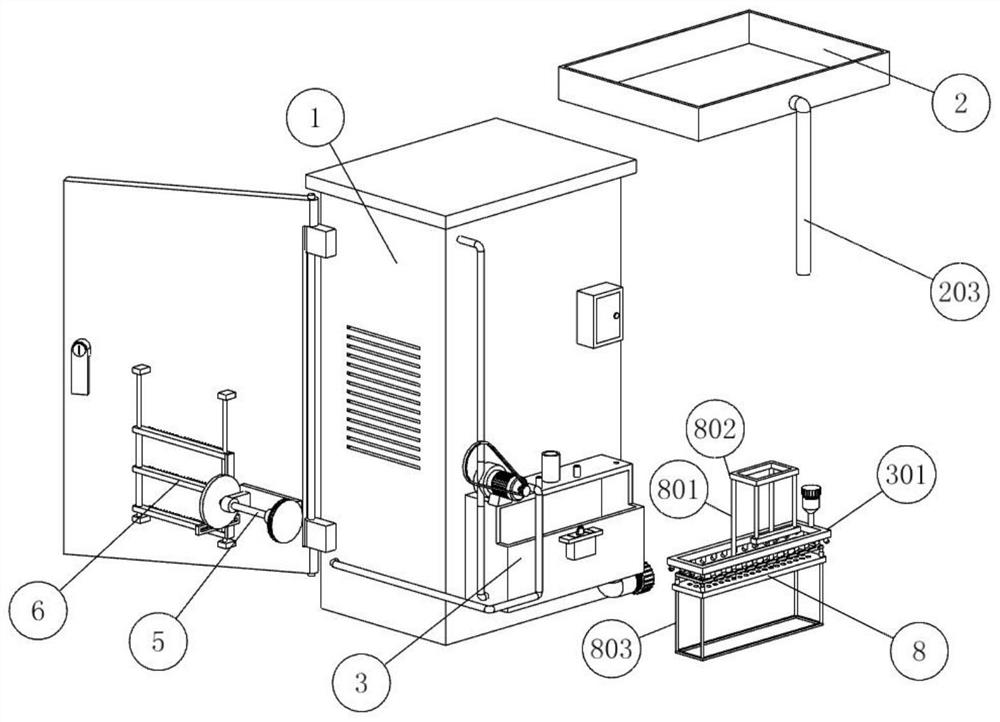

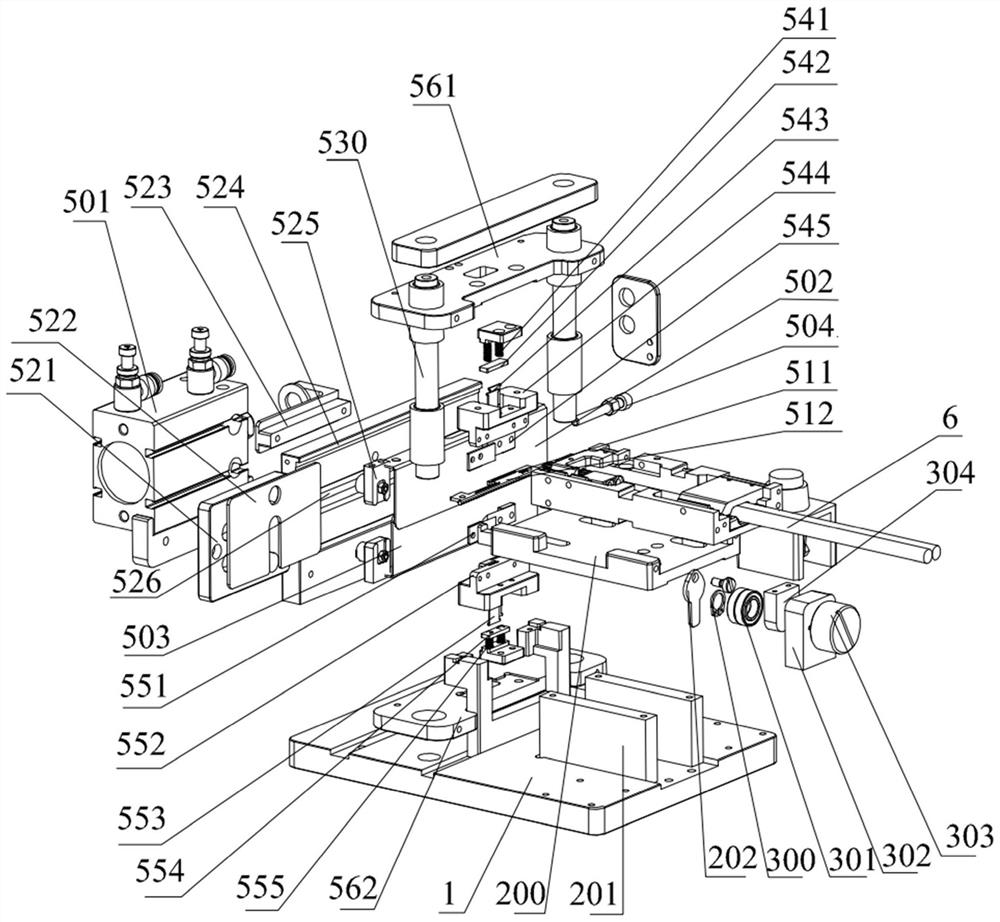

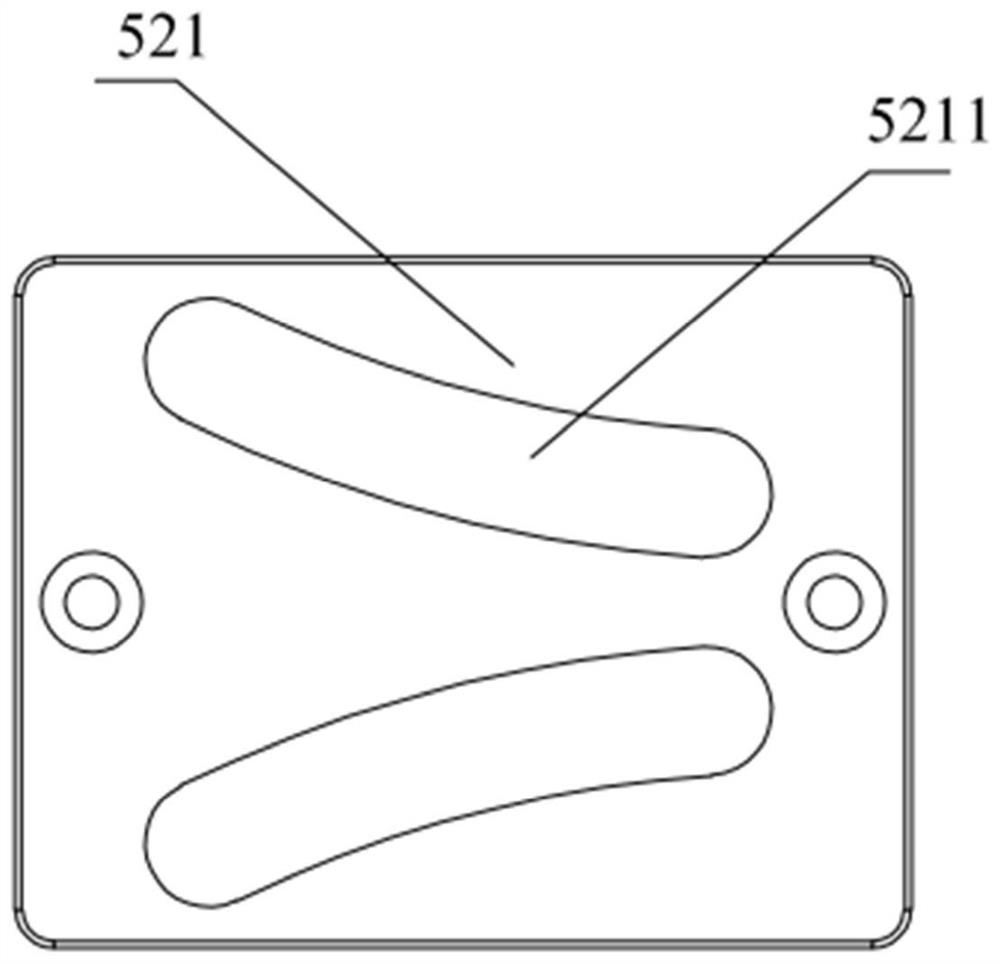

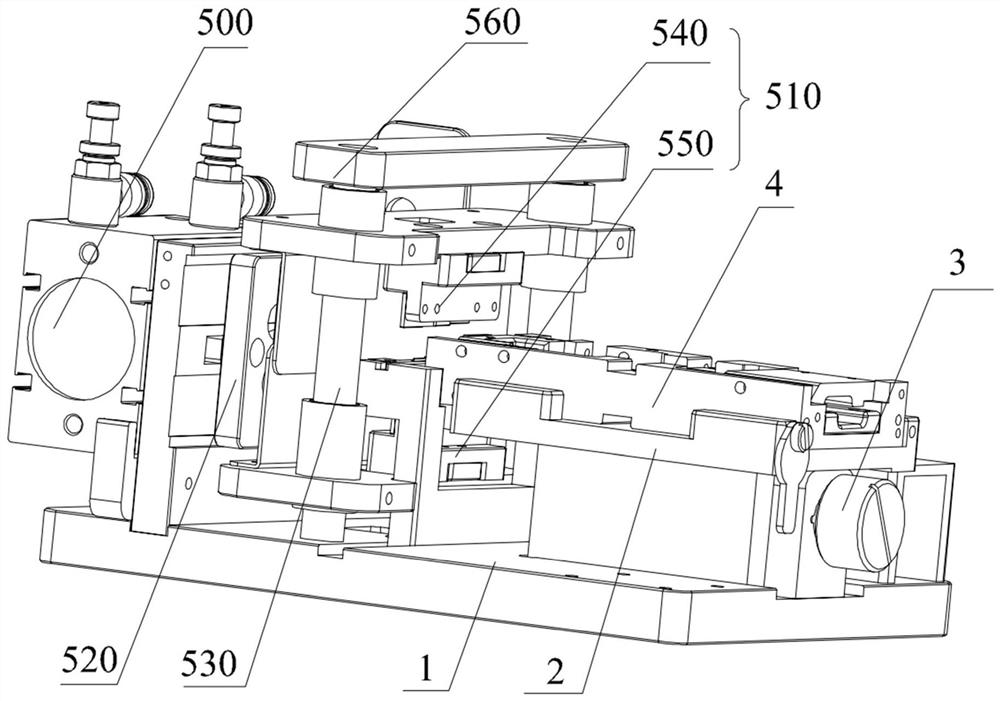

PendingCN112275946AImprove machining accuracyPrecise positioningContact member manufacturingRotational axisControl engineering

The invention discloses a servo bending machine for an automobile connector terminal. The servo bending machine for the automobile connector terminal comprises an upper machine frame, a lower machineframe and a bending machine body located between the upper machine frame and the lower machine frame, wherein the bending machine body comprises a positioning carrier device, a first bending device and a second bending device, the positioning carrier device comprises a positioning base and a carrier mechanism, the carrier mechanism comprises a support, a carrier and a pressing rod for fixing the connector terminal on the carrier, the first bending device comprises a first air cylinder and a horizontal bending knife arranged on the first air cylinder, the second bending device comprises a rotating mechanism and a rotating knife head arranged on the rotating mechanism, the rotating mechanism is arranged on a vertical sliding rail through a fixing frame, the rotating mechanism comprises a motor, a rotating shaft connected with the motor and a clamping and bending knife arranged on the rotating shaft, and the clamping and bending knife comprises a clamping plate, a fixed knife head arranged on the clamping plate and a rotating knife head. According to the servo bending machine for the automobile connector terminal, the bending knife is accurately controlled through the rotating mechanism, manual feeding and discharging are not needed, a workpiece can be accurately positioned, and the problem that the bending angle is not accurate is solved.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

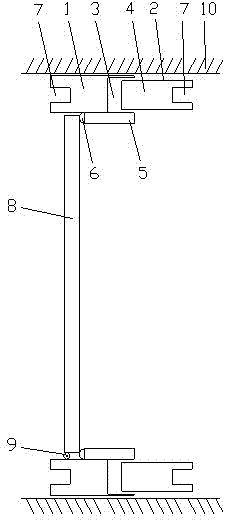

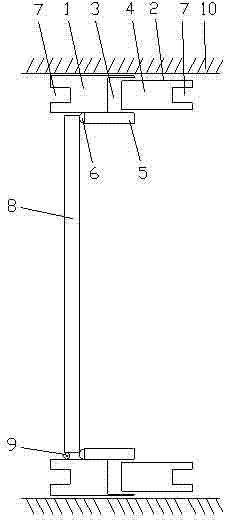

Self-adaptive suit door

InactiveCN102418456AImprove versatilityEasy to produce and sellWindow/door framesBatch productionStructural engineering

The invention discloses a self-adaptive suit door. The self-adaptive suit door comprises door sleeve plates and a door leaf, wherein the door sleeve plates comprise a left door sleeve plate and a right door sleeve plate which are assembled in a splicing way; a regulating slot is formed on an inner end face of the left door sleeve plate facing the right door sleeve plate; a regulating part which can be inserted into the regulating slot in a matching way is arranged on an inner end face of the right door sleeve plate facing the left door sleeve plate; and the door leaf is arranged on one of the left door sleeve plate and the right door sleeve plate. The widths of the door sleeve plates can be adaptively regulated along the thickness of a door hole, so that the generality of the door sleeve plates and the suit door is improved; the customized production of the door sleeve plates is changed into the preproduction, so that the batch production of the integral suit door can be realized, the production and the marketing are facilitated, and the production cost is reduced; the defect that the thickness of the door hole is required to be measured in advance in the prior art is overcome; the working procedure and the time are saved; and the construction progress is quickened.

Owner:唐米

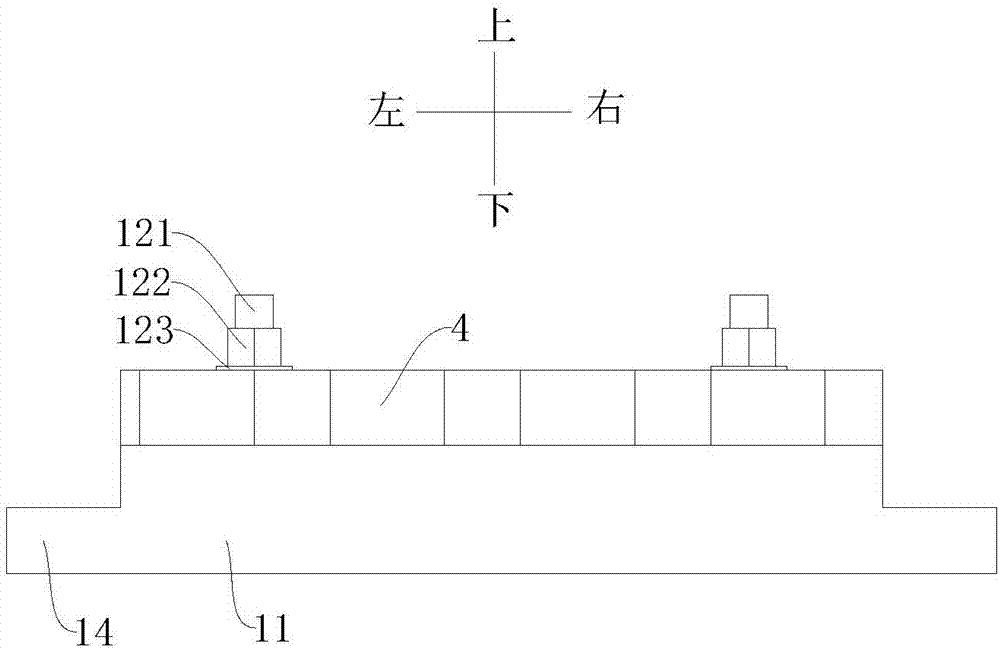

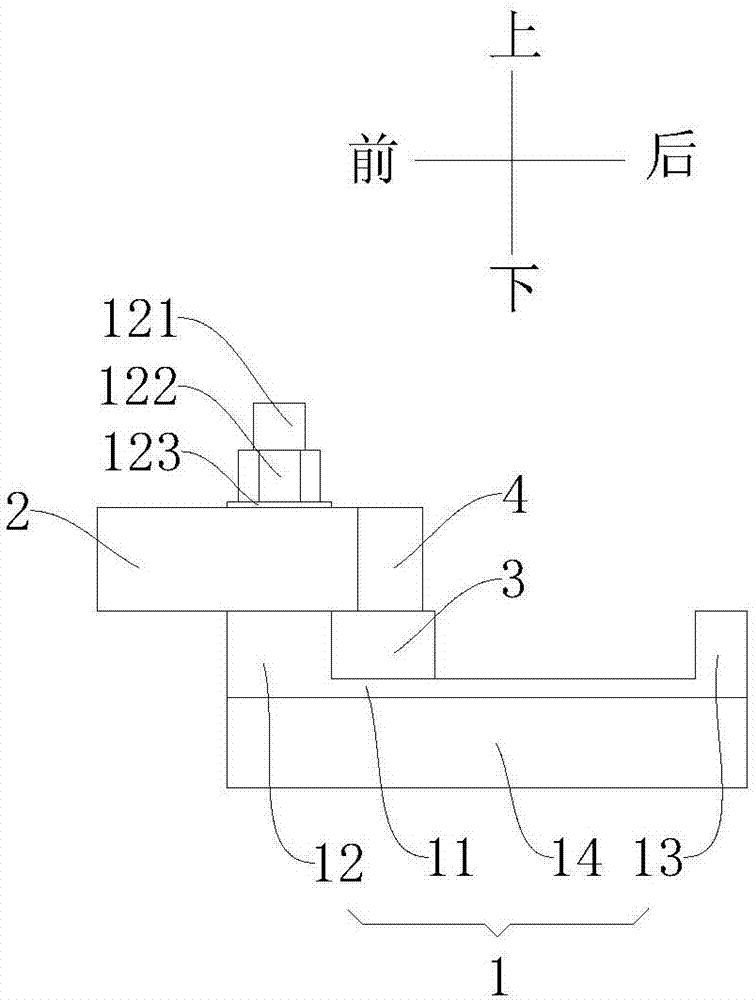

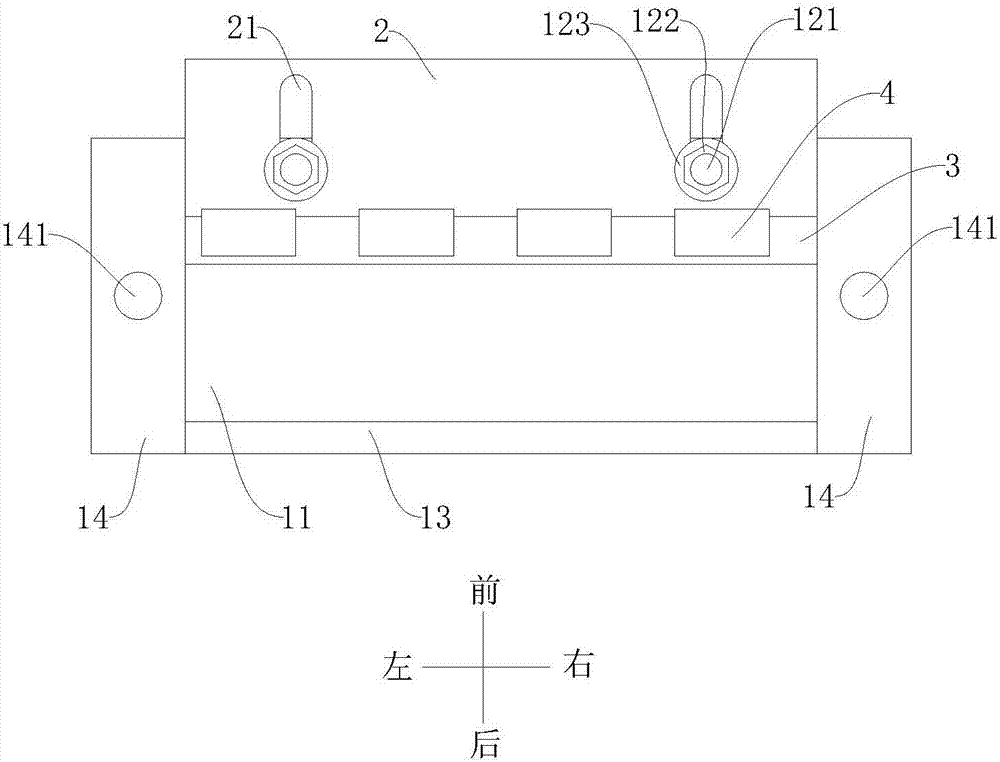

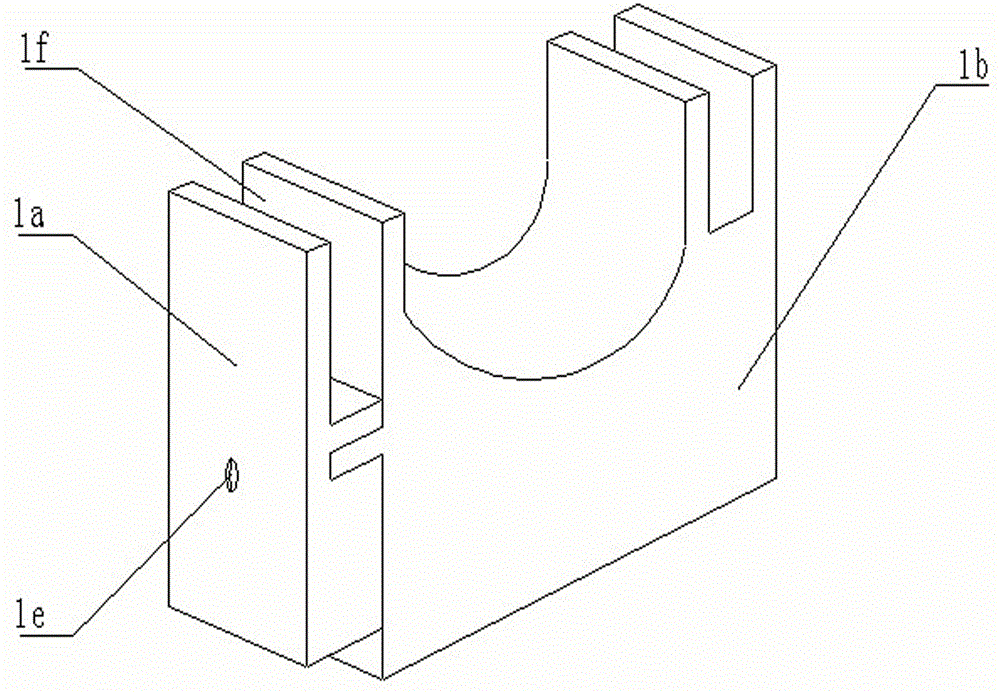

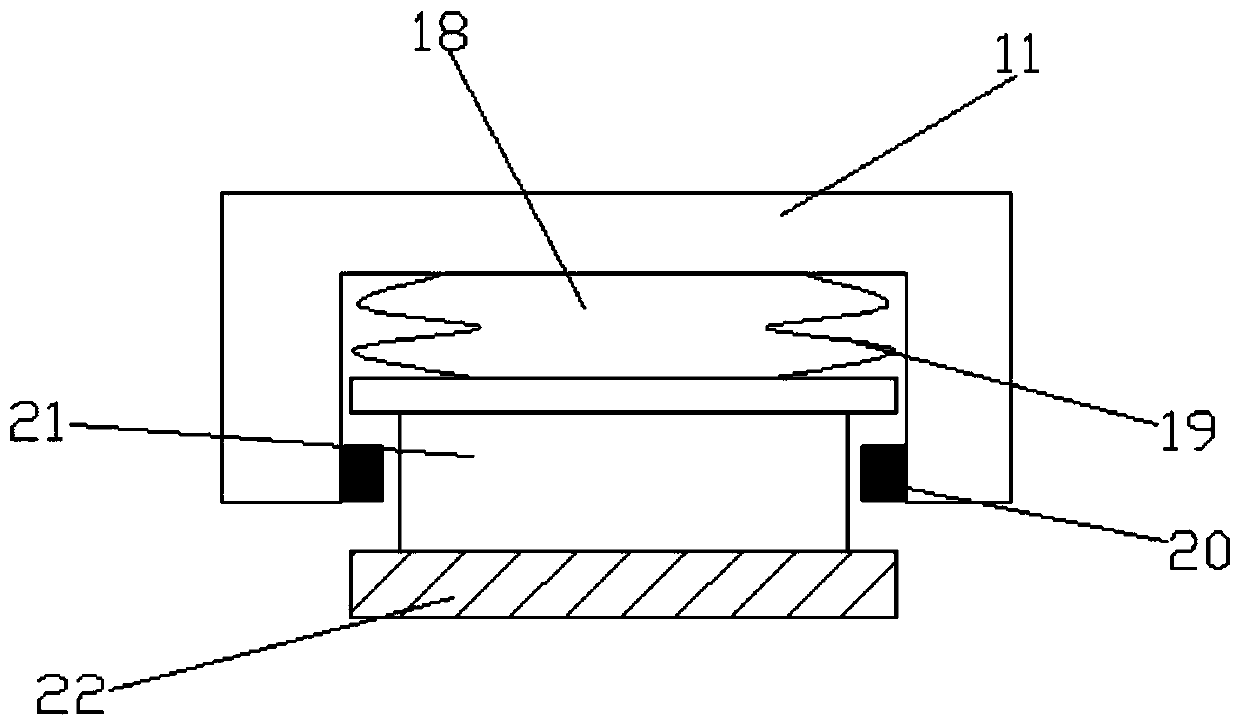

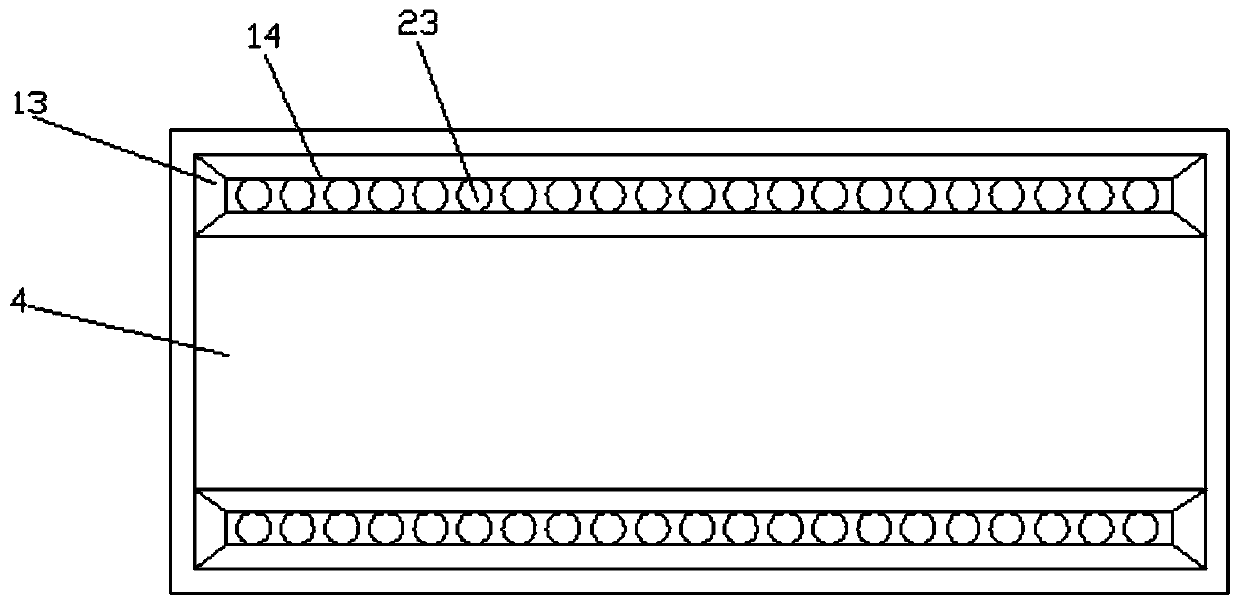

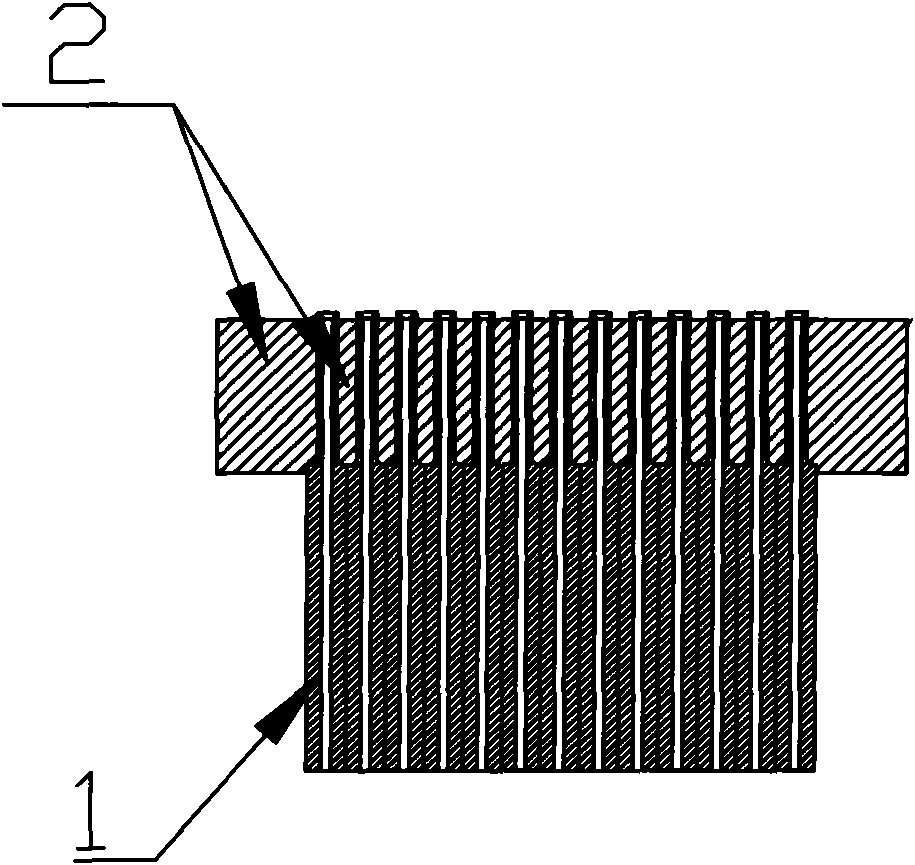

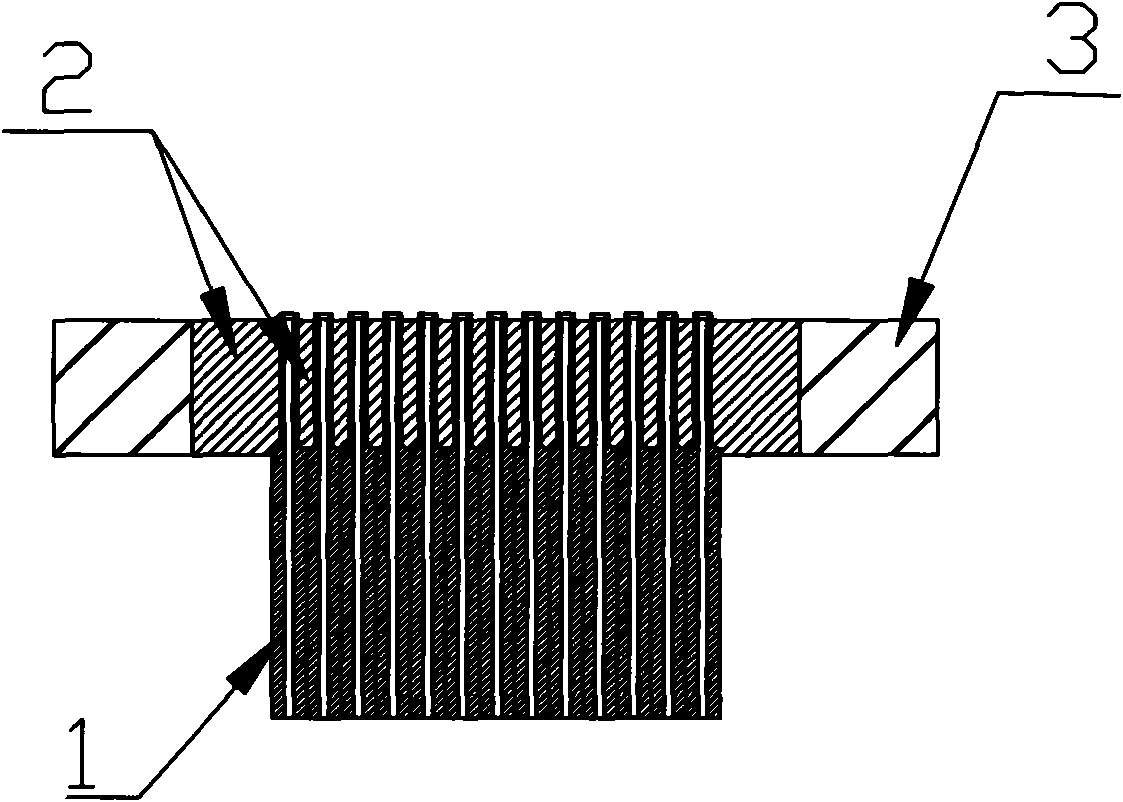

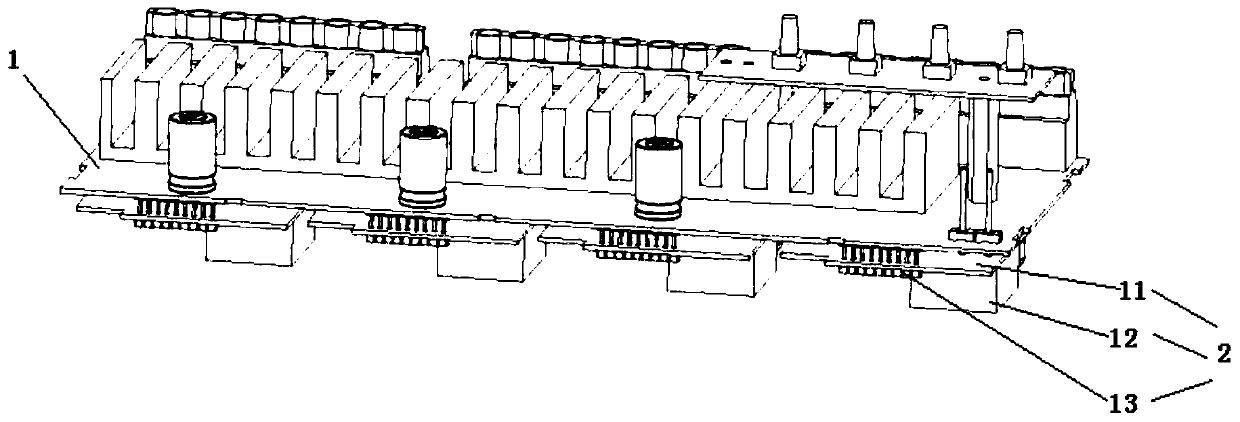

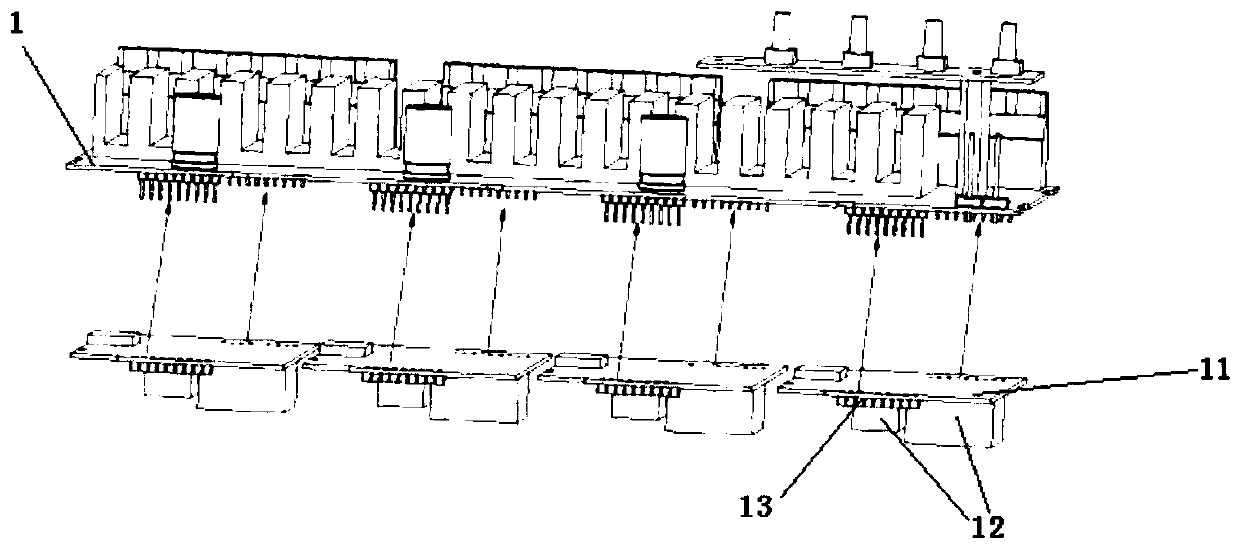

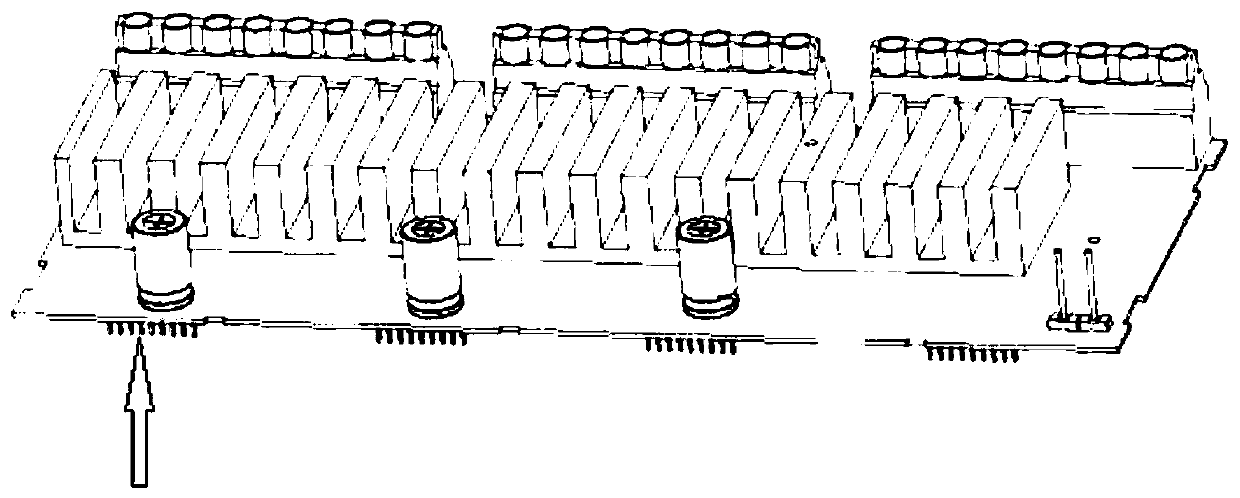

Positioning device for processing of motor magnetic sheets

PendingCN107297552APrecise positioningHigh precisionManufacturing stator/rotor bodiesElectrical-based auxillary apparatusElectric machineStructural engineering

The invention discloses a positioning device for processing of motor magnetic sheets. The positioning device is mounted on a workbench and comprises a lower support, an upper support and a processing plate. The lower support is of a square grooved structure and comprises a bottom plate, a first side board and a second side board; the first side board and the second side board are formed on two sides of the bottom plate integrally. The upper support is of a rectangular block structure. The upper support is fixedly connected with the lower support. The back end surface of the upper support is parallel to the internal side surfaces of the first side board and the second side board of the lower support, and is provided with clamp slots at intervals along the left to right direction. The processing plate is of a cuboid structure disposed in the square groove of the lower support; the front side surface and the back side surface of the processing plate are parallel with the internal side surfaces of the first side board and the second side board; the vertical height of the processing plate is not higher than the height of the first side board; the front side surface of the processing plate is abutted against the first side board. By the positioning device, the motor magnetic sheets can be positioned on the processing plate accurately; the products have high precision, scrap is avoided, resources are saved, and production cost is reduced.

Owner:徐州给力磁业有限公司

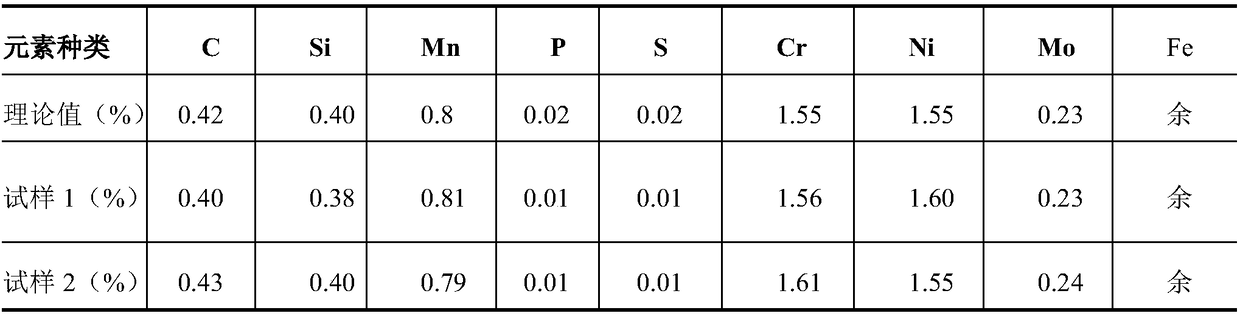

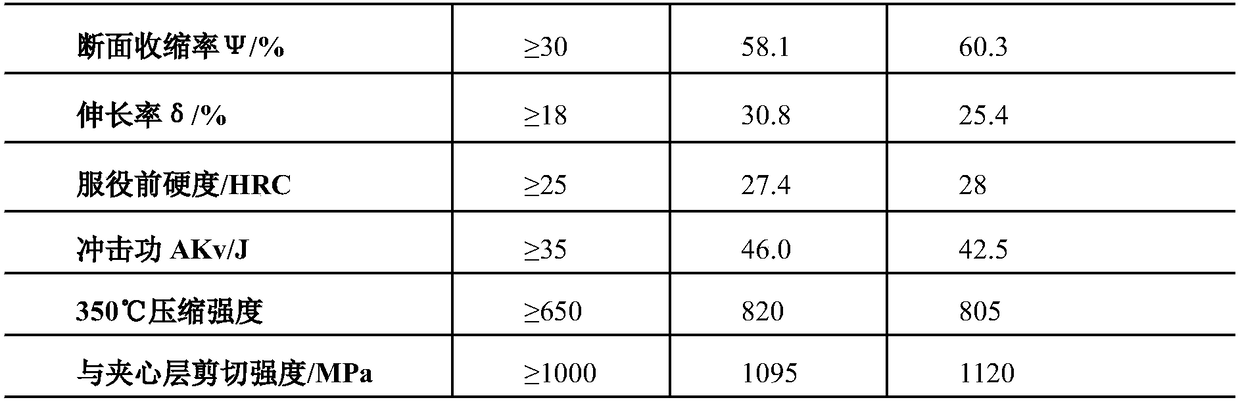

A special cast steel for preparing large hot forging dies under high temperature and heavy load conditions and its preparation method

Owner:CHONGQING UNIV +3

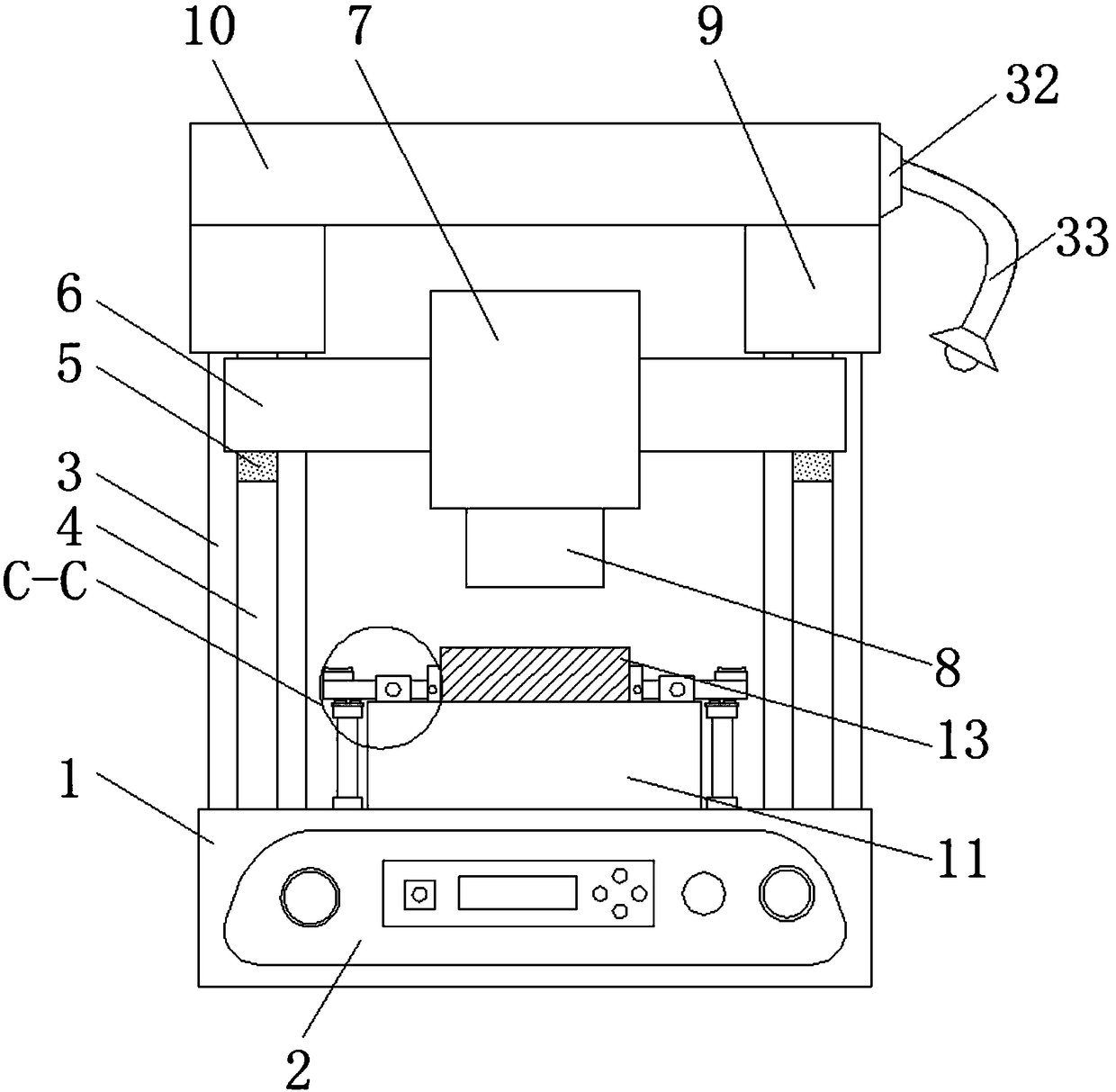

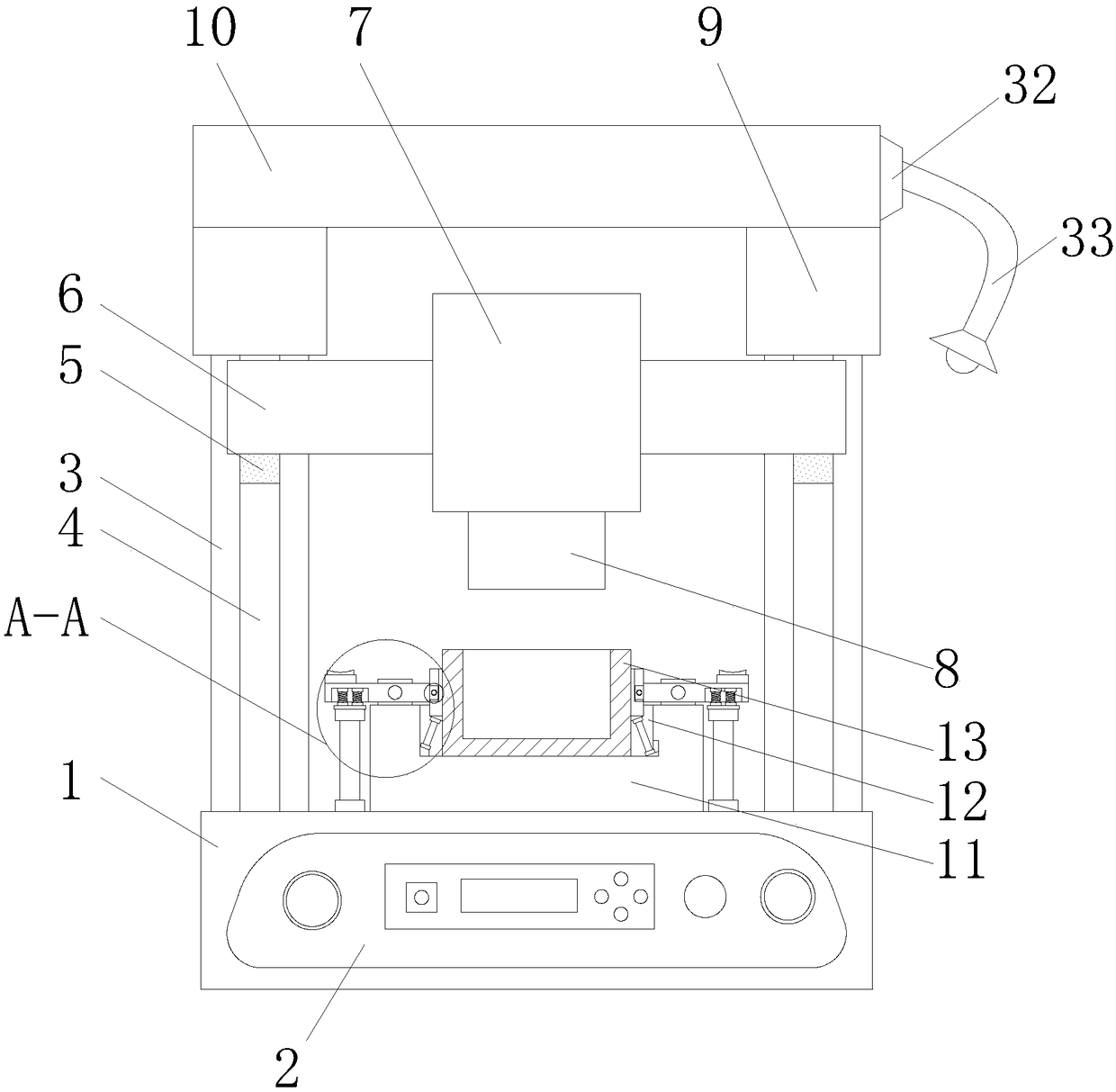

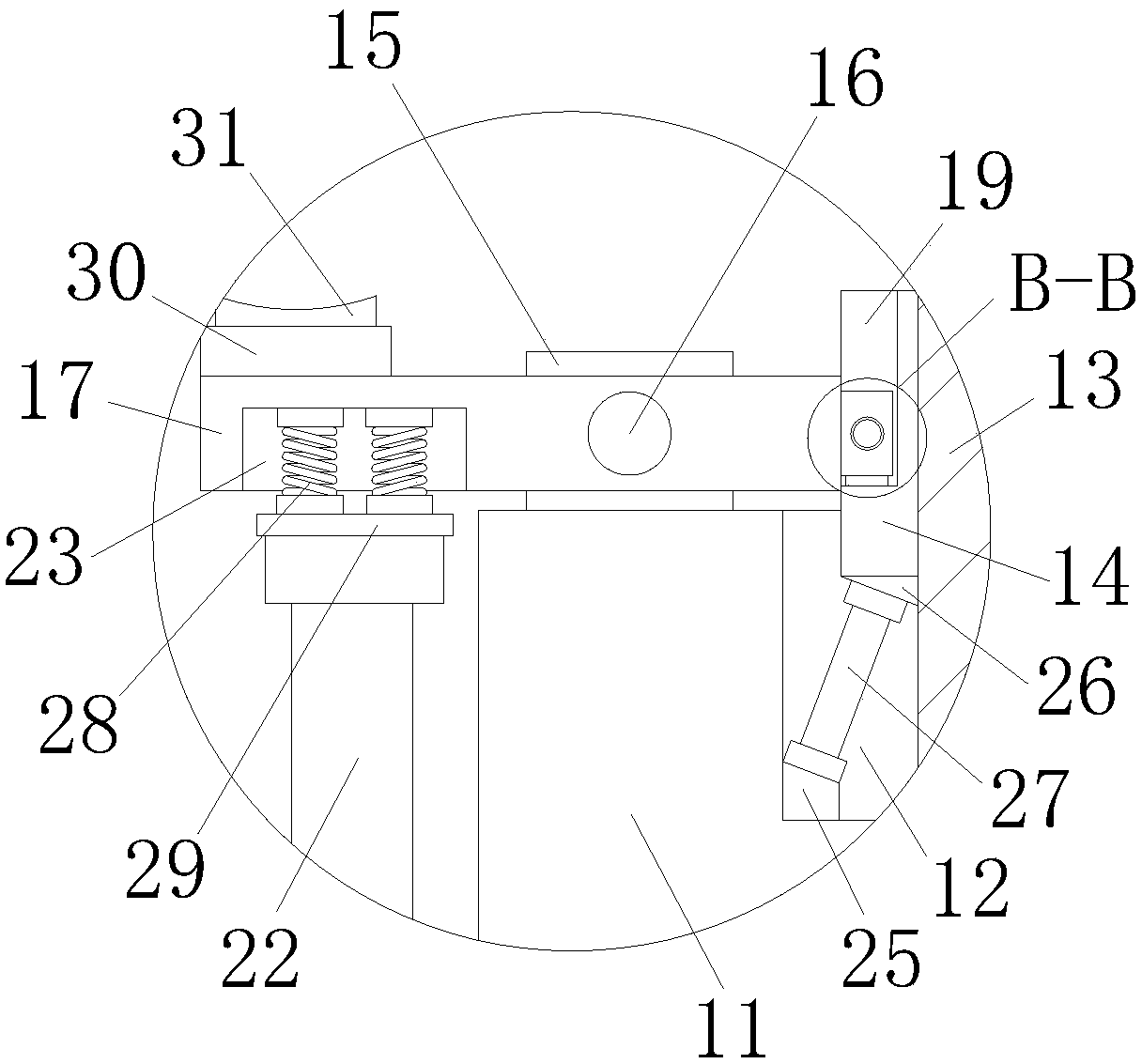

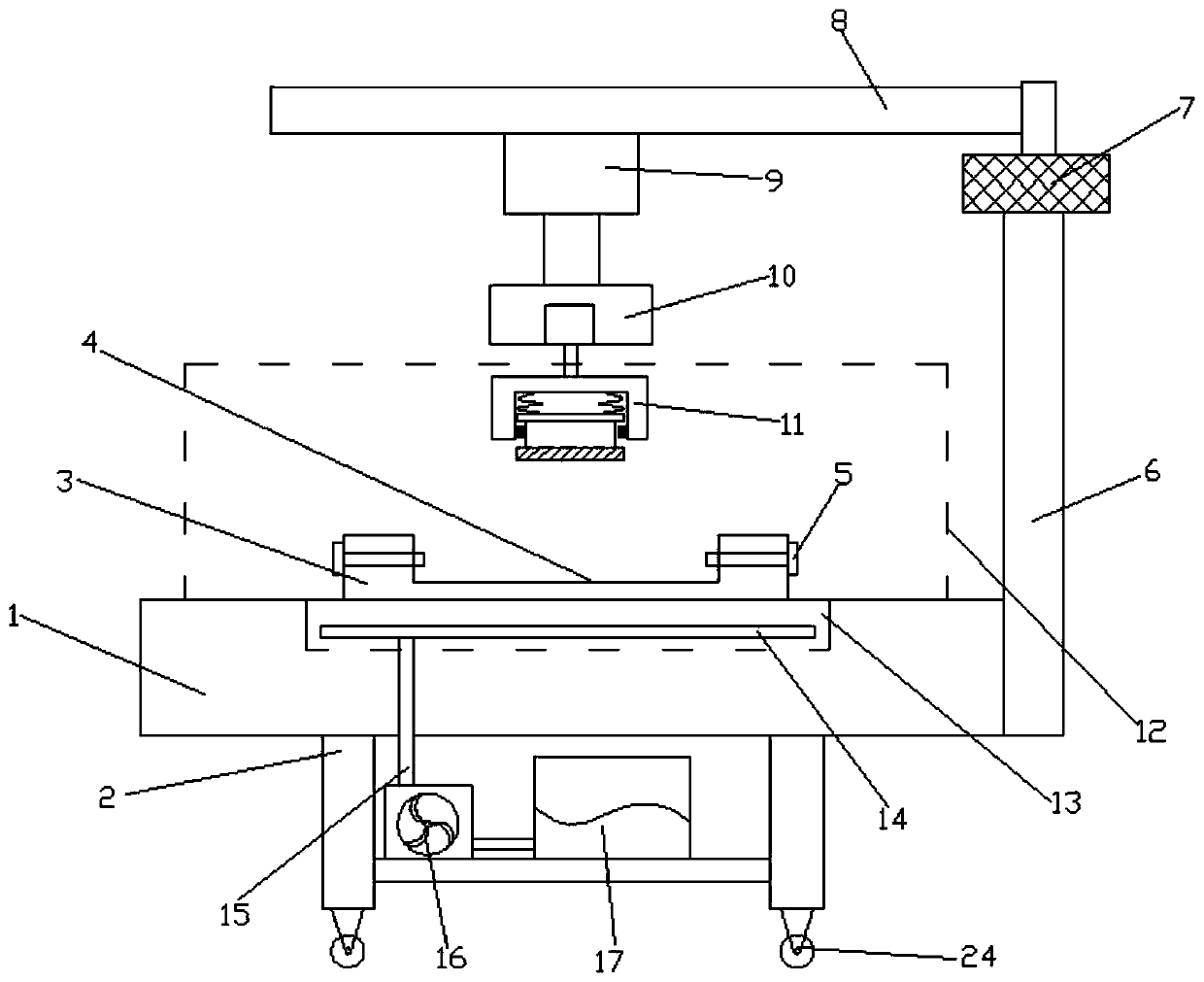

Automatic hot-press molding machine capable of conveniently replacing mold

InactiveCN108381984ASolve the very inconvenient problem when changing the moldEasy to replaceMetal working apparatusPressesHydraulic cylinderMolding machine

The invention discloses an automatic hot-press molding machine capable of conveniently replacing a mold. The automatic hot-press molding machine comprises a base, a control panel is arranged on the front side of the base, and supporting columns are fixedly connected to the two sides of the rear side of the top of the base; and sliding grooves are formed in the front sides of the supporting columns, sliding blocks are arranged inside the sliding grooves, the front sides of the sliding blocks penetrate through the sliding grooves and extend to the outside of the sliding grooves, and the front sides of the two sliding blocks are fixedly connected through a pressing plate. According to the automatic hot-press molding machine, inserting blocks, fixing plates, fixing shafts, rotating blocks, inserting plates, inserting grooves, bolts, first hydraulic cylinders and pressing grooves are arranged, so that the problem that a common automatic hot-press molding machine in the market is very inconvenient when the mold is replaced is solved, a lot of time is saved, furthermore, personnel who perform replacement do not need high professional knowledge, and the phenomenon that the mold is scrappeddue to operation errors is avoided; and the loss is reduced, the normal use in a workshop can be met, the fixing performance of the machine to a hot-press mold is good, and improvement on the rate offinished products is facilitated.

Owner:浙江斯菲诺电气有限公司

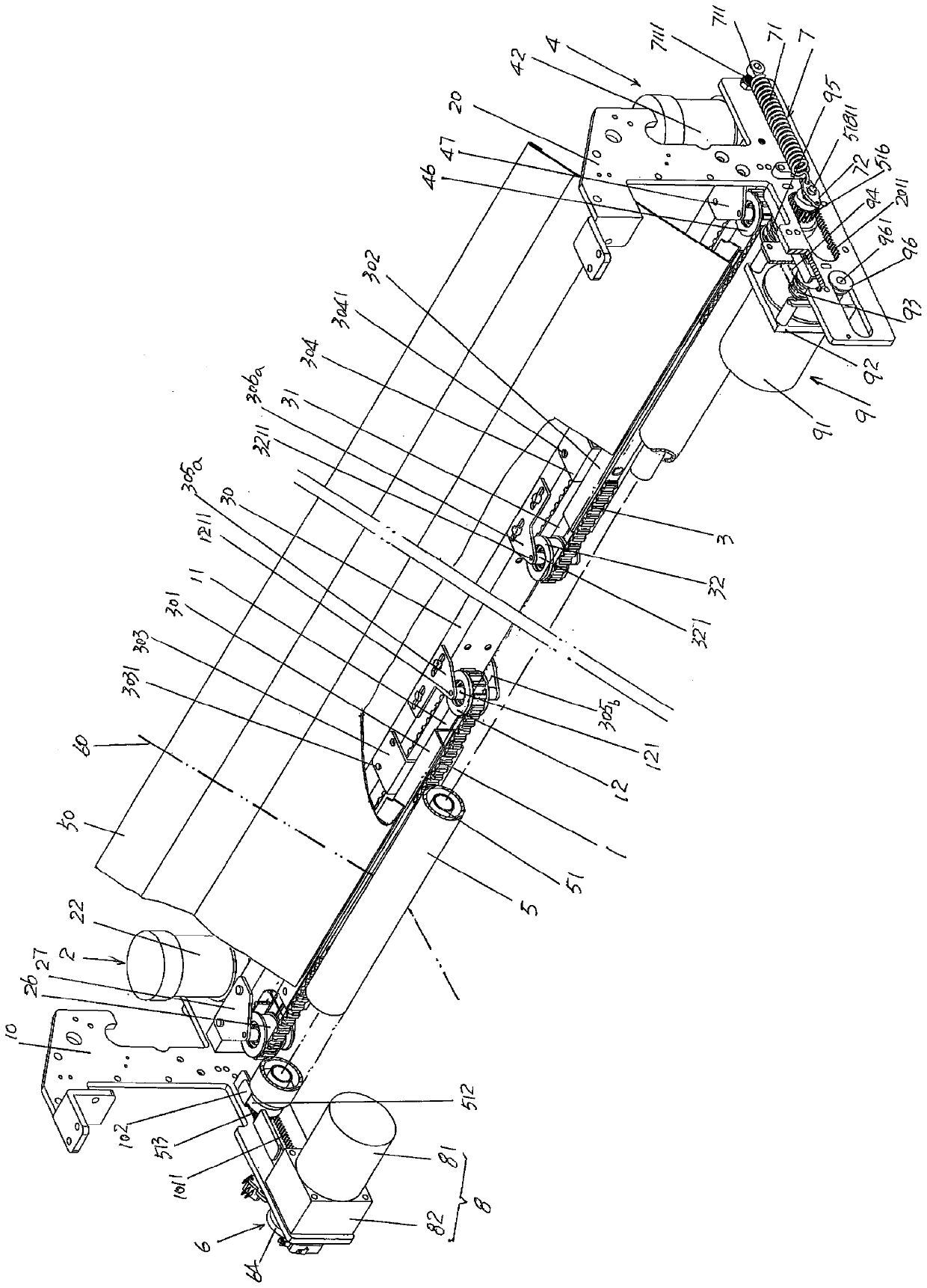

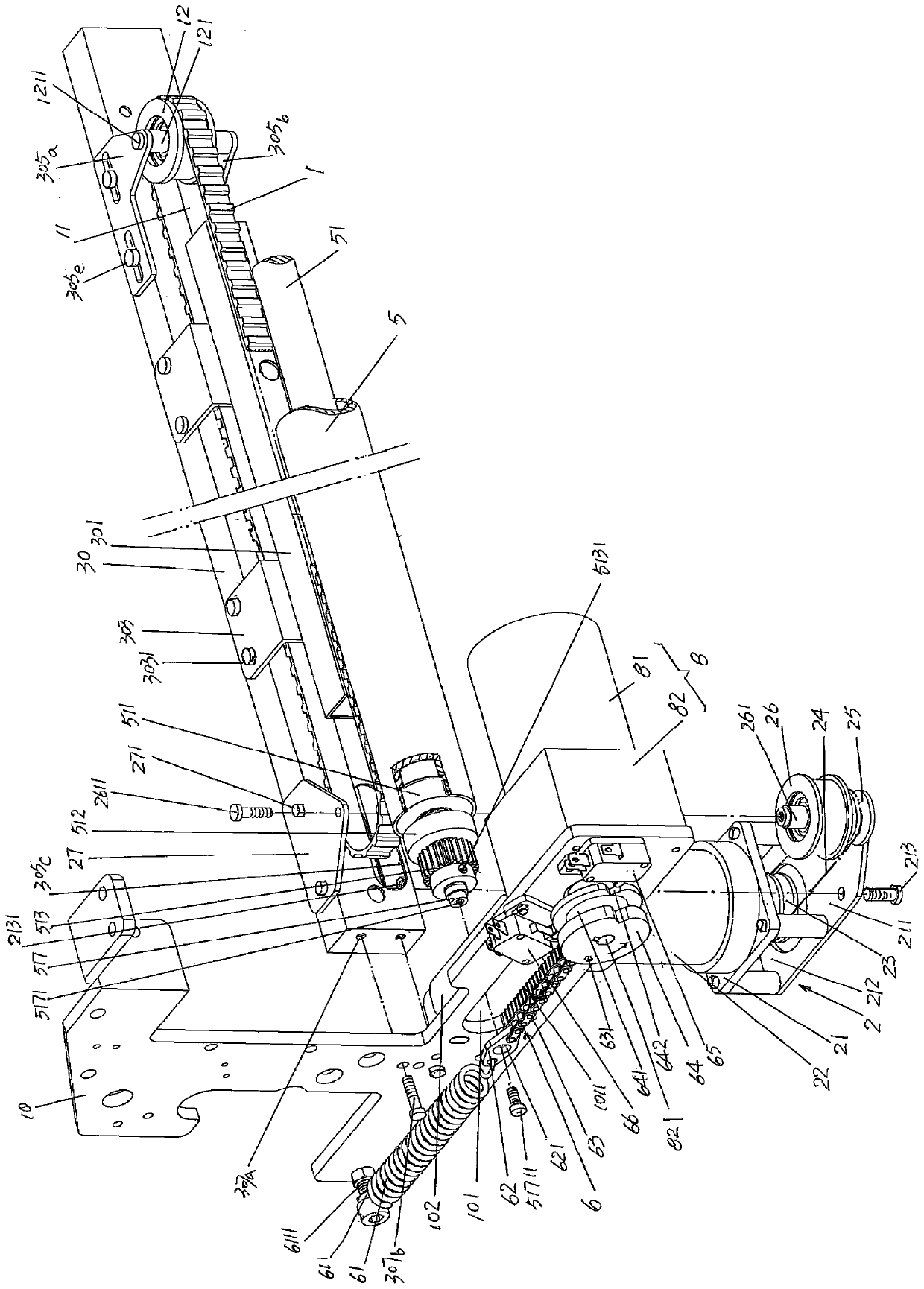

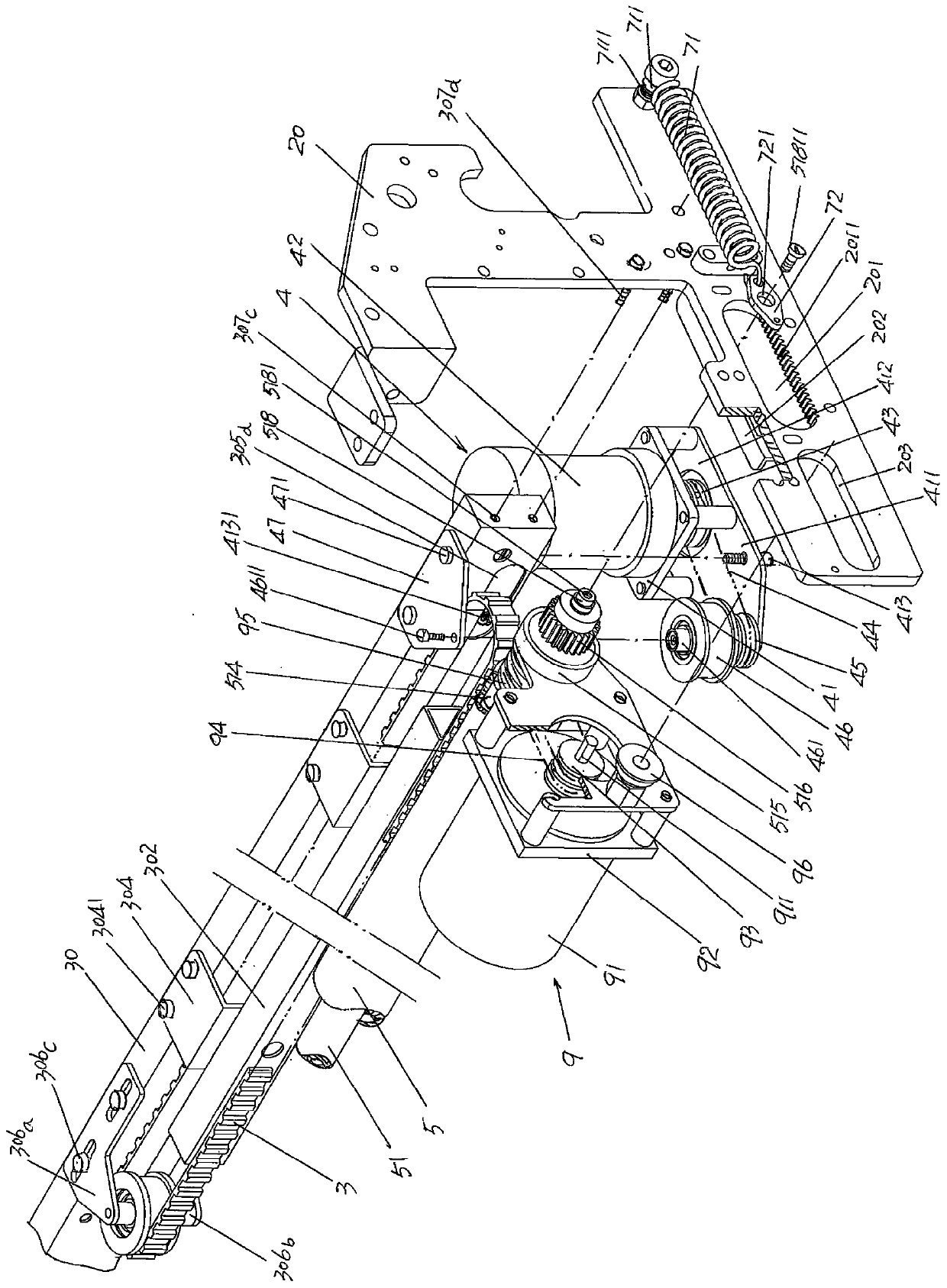

Lower edge unfolding device of spreading machine with cloth pressing function

PendingCN111170052AThere will be no scrappingFull stripping flat strippingUnfolding thin materialsWebs handlingChain linkIndustrial engineering

The invention discloses a lower edge unfolding device of a spreading machine with a cloth pressing function, and belongs to the technical field of clothing machinery. The lower edge unfolding device of the spreading machine with the cloth pressing function comprises a tenter left wallboard, a tenter right wallboard, a tenter, a left edge unfolding toothed belt, a left edge unfolding toothed belt driving mechanism, a right edge unfolding toothed belt and a right edge unfolding toothed belt driving mechanism, and is characterized by further comprising a cloth pressing roller, a cloth pressing roller shaft left tensioning and loosening mechanism, a cloth pressing roller shaft right tensioning and loosening mechanism, a chain reel driving mechanism and a cloth pressing roller driving mechanism. The cloth pressing roller is arranged on a cloth pressing roller supporting shaft, the cloth pressing roller shaft left tensioning and loosening mechanism is arranged on the left side of the left wallboard of the tenter, the cloth pressing roller shaft right tensioning and loosening mechanism is arranged on the right side of the right wallboard of the tenter, the chain reel driving mechanism isarranged on the right side of the front end of the left wallboard of the tenter, and the cloth pressing roller driving mechanism is arranged at the front end of the right wallboard. The hemming edgeson the two sides of cloth are fully unfolded and flattened, and the situation that subsequent processes are affected or even the cloth is scrapped is avoided.

Owner:苏州比阳特服装设备有限公司

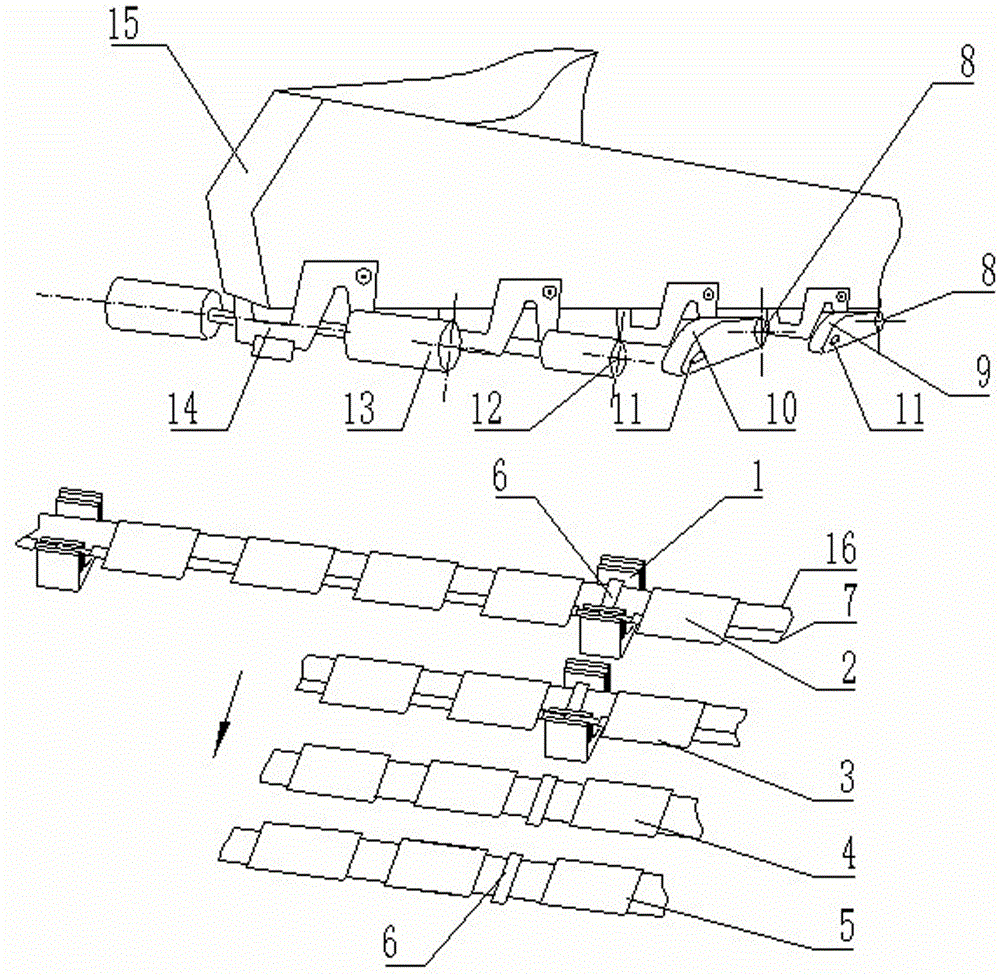

Turning method and turning positioning device for UF outer spider short-shanked precision forgings

ActiveCN103921062AEliminate deviations caused by misalignmentSmooth millingPositioning apparatusMetal-working holdersEngineeringJitter

The invention provides a turning method for UF outer spider short-shanked precision forgings. The method includes the sequential steps of sleeving a turning positioning device, which comprises a fixed base and a connecting part, with a UF outer spider short-shanked precision forging, providing the outside of the connecting part with a plurality of lanes which radially protrude, which face first lanes and which have center lines parallel to the center axis of the turning positioning device; by using the center axis of the turning positioning device as a positioning reference, turning the end face of a shank of a UF outer spider short-shanked blank, drilling a center hole in the end face of the shank, and turning the outside of the shank and the outside of a head of the UF outer spider short-shanked blank. The turning method has the advantages that the center axis of the turning positioning device is used as the positioning reference constantly during turning the UF outer spider short-shanked blank, jitter of the outside of the head of a turned UF outer spider is never out of tolerance, and subsequent smooth milling of all first lanes of the UF outer spider is facilitated.

Owner:SHANGHAI GKN DRIVE SYST

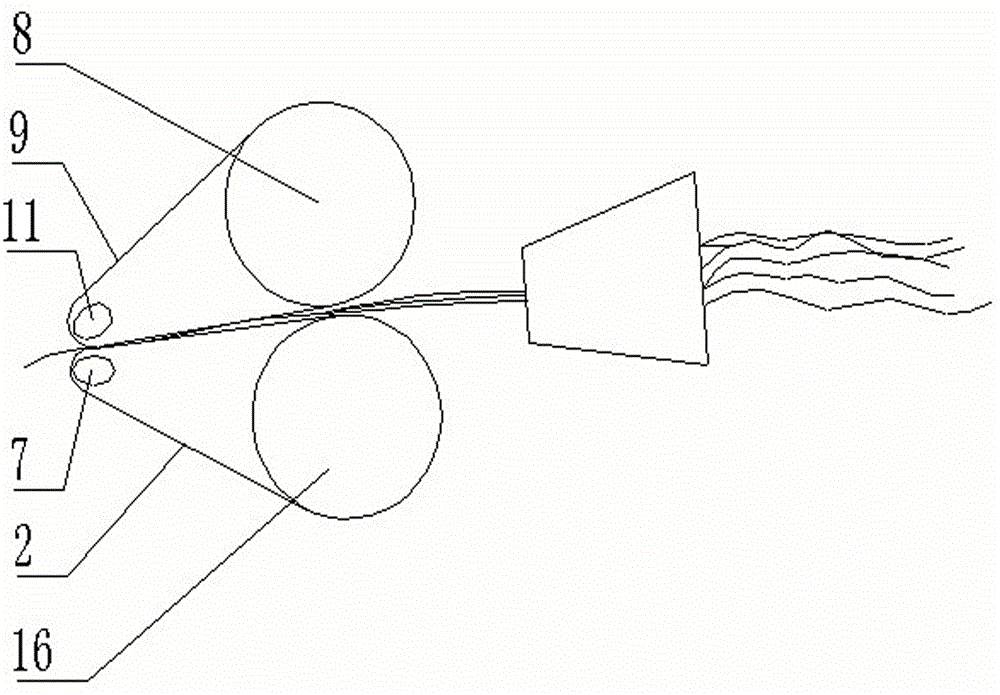

Roving frame draft gear applicable to high draft

InactiveCN104313737AIncrease production capacityReduce manufacturing costDrafting machinesEngineeringMechanical engineering

Owner:ANHUI HUAMAO TEXTILE

Wiper motor end cover employing chrome-plating rust-proof technology

InactiveCN105048686AFirmly connectedEffective positioningSupports/enclosures/casingsEngineeringScrew thread

The invention discloses a wiper motor end cover employing a chrome-plating rust-proof technology. The wiper motor end cover comprises a wiper motor end cover body, wherein the inside and the outside of the wiper motor end cover body are treated by the chrome-plating rust-proof technology; the wiper motor end cover body comprises a wiper motor end cover bottom and a wiper motor end cover barrel; at least two segments of straight thread segments which are not connected with one another are arranged on the inner wall of the wiper motor end cover barrel; the crest widths of the straight thread segments are 1.1-1.5mm; a through hole is formed in the center of the wiper motor end cover bottom; and four straight thread segments are arranged and are evenly distributed along the circumferential direction of the wiper motor end cover barrel. By a segment design mode, the condition that the whole threaded part is not scrapped even if one segment of thread slips can be ensured. Various thread segments are not interfered with one another, so that when one segment of thread slips, the whole threaded part is not scrapped; and an ordinary thread is replaced with a straight thread, so that the threaded part is relatively stable; and the problem of deformation is avoided.

Owner:CHONGQING ZHUHAO MACHINERY

Grinding device for automobile accessory production

InactiveCN111002170AThere will be no scrappingAvoid flyingGrinding drivesGrinding machinesElectric machineryMotronic

The invention discloses a grinding device for automobile accessory production. A base is inccluded. Supporting legs are welded and fixed to a periphery of a bottom of the base. A workbench is arrangedin a center of a top of the base. The workbench is provided with a clamping groove. Threaded holes are arranged in a peripheral outer wall of the clamping groove. Fastening bolts are connected to thethreaded holes. A supporting rod is arranged on the outer wall of one side of the base, a stepping motor is fixed to the top end of the supporting rod through a screw, an output shaft of the steppingmotor is connected with a horizontally-arranged transverse rod through a coupler, an electric telescopic rod is arranged in the center of the transverse rod, a grinding motor is arranged at a lower end of the electric telescopic rod, and a grinding disc is arranged on the output shaft of the grinding motor. Baffle plates are arranged on peripheral edges of the base, U-shaped grooves are arrangedin two side edges of the workbench, dust suction pipes are embedded in the U-shaped grooves and are connected with a dust collector through a connecting pipe, and the dust collector is connected witha dust collection box. When the grinding device is used for grinding automobile accessories, a situation that finished products are damaged is avoided, grinding is more convenient, a dust collectionfunction is achieved, and the structure is simple.

Owner:江西大杰科技产业有限公司

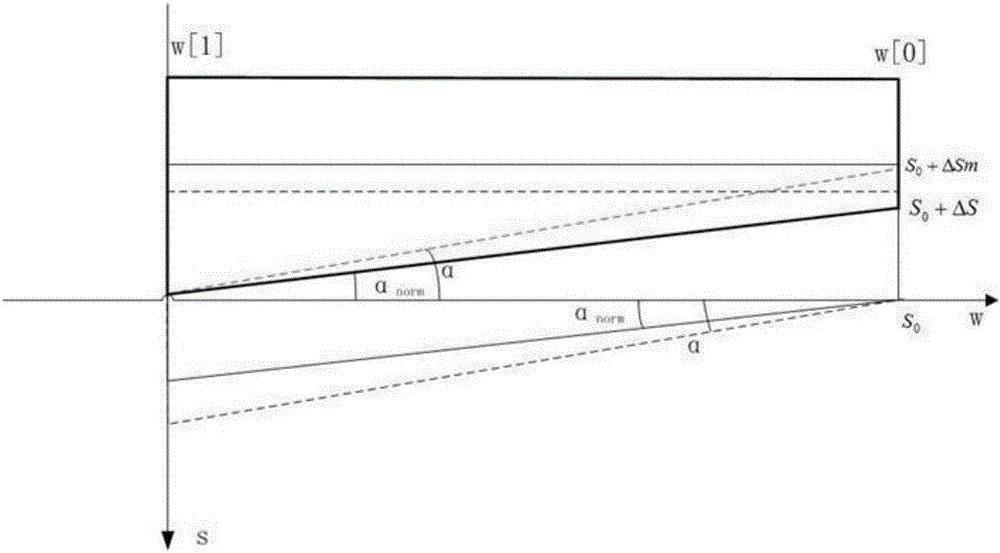

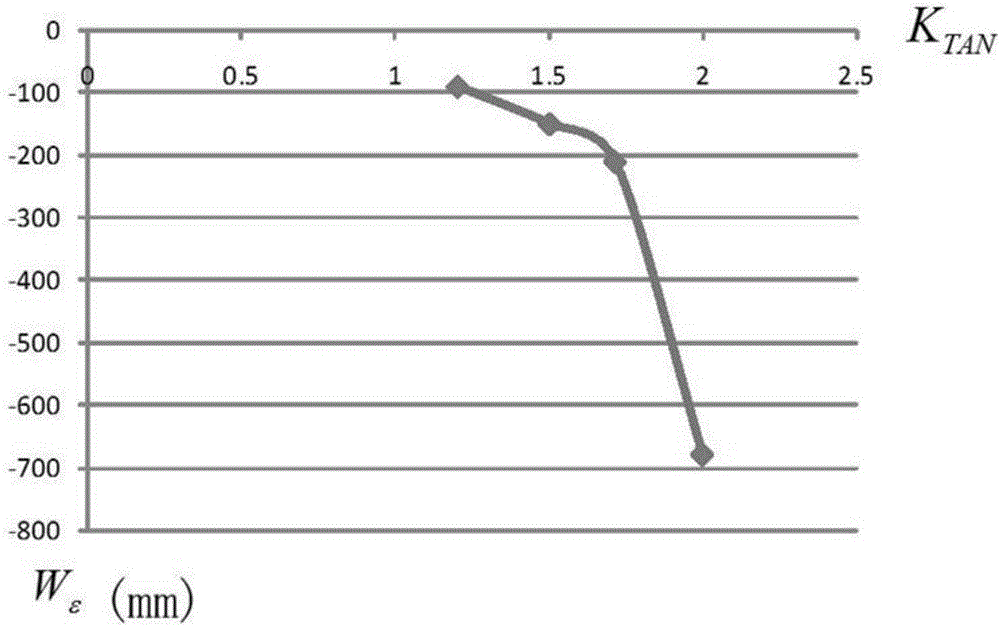

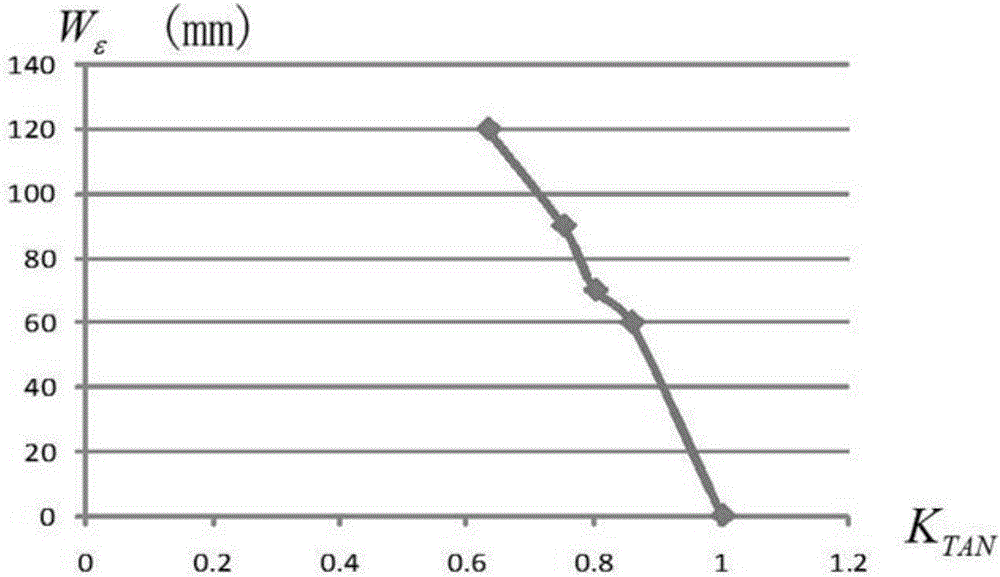

Shearing stroke control method for plate shearing machine based on plate width

ActiveCN106270751AMeet the needs of useEasy to useProgramme controlComputer controlEngineeringEnergy consumption

The invention discloses a shearing stroke control method for a plate shearing machine based on the plate width. A potentiometer is used for collecting voltage, and the shearing stroke of a tool rest in the vertical direction is mapped into the shearing plate width in the horizontal direction. At any shearing angle, the current shearing plate width can be deduced through voltage feedback of the potentiometer. The beforehand stopping shearing plate width is set for offsetting the influence of the motion inertia of the tool rest on the shearing stroke control. After the plate shearing machine is corrected through the algorithm in the method, at any shearing angle, the shearing plate width error can reach the shearing precision the same as the error under the calibrated shearing angle, the using requirement of a user is met, the error range is a positive value, and it is ensured that due to the too short shearing stroke, plates are scraped cannot happen. Meanwhile, the shearing efficiency is improved, energy consumption is reduced, and due to the fact that the user does not need to conduct repeated calibration on the shearing plate width or angle, usage is facilitated for the user, and the work efficiency is improved.

Owner:NANJING ESTUN AUTOMATION CO LTD

Method for manufacturing turbo-charger blower impeller mold

InactiveCN101480699BGuaranteed accuracyImprove consistencyFoundry mouldsFoundry coresImpellerTurbocharger

The invention relates to a method for manufacturing a die of a compressor impeller of a turbocharger, which mainly comprises the following steps: firstly, a data model of the compressor impeller is designed: a computer three-dimensional data model of the compressor impeller of the turbocharger is designed through pro / engineer computer software; secondly, an impeller physical model is made by a digital control processing center: on a five-shaft digital control milling machine, an integrated impeller physical model is processed by metal materials, such as aluminum ally, and the like that are soluble in acid easily; thirdly, a metal layer is cast on the outer surface of the impeller physical model: an even nickel or copper layer with 2-7mm is cast on the outer surface of the impeller physical model by adopting an electroforming method; fourthly, the acid dissolution is carried out: the metal impeller physical model is molten by acid solution. The die of the compressor impeller of the turbocharger made through adopting the steps can be used for casting the compressor impeller of the rubber turbocharger.

Owner:HUNAN TYEN MACHINERY

Adjustable-type nail feeding device in stud welding machine

The invention discloses an adjustable-type nail feeding device in a stud welding machine. The adjustable-type nail feeding device comprises a nail feeding shell. A nail feeding channel is formed in the nail feeding shell. The side wall of the nail feeding shell is further provided with a nail stopping air cylinder and a nail falling air cylinder from top to bottom. A spraying-blowing opening is further formed in the position, below the nail falling air cylinder, of the nail feeding shell. An annular proximity switch is further arranged at the position, between the spraying-blowing opening andthe nail feeding channel, of the nail feeding shell. The nail feeding shell is formed by stacking of an upper module, a middle module and a lower module. Locking rods sequentially penetrate through the upper module, the middle module and the lower module from top to bottom, and after pair-lock nuts are tightly screwed correspondingly at the two ends of the locking rods, the upper module, the middle module and the lower module can be stacked and tightly locked to form the nail feeding shell. The upper module is provided with a nail feeding channel inlet and the nail stopping air cylinder, and the lower module is provided with the nail falling air cylinder, the spraying-blowing opening, the annular proximity switch and a nail feeding channel outlet. The adjustable-type nail feeding device can be applied to conveying of studs with different heights and different diameters by replacing the middle modules with different heights and wear-proof sleeves with different inner diameters.

Owner:SUZHOU MENGZHIJIE WELDING TECH

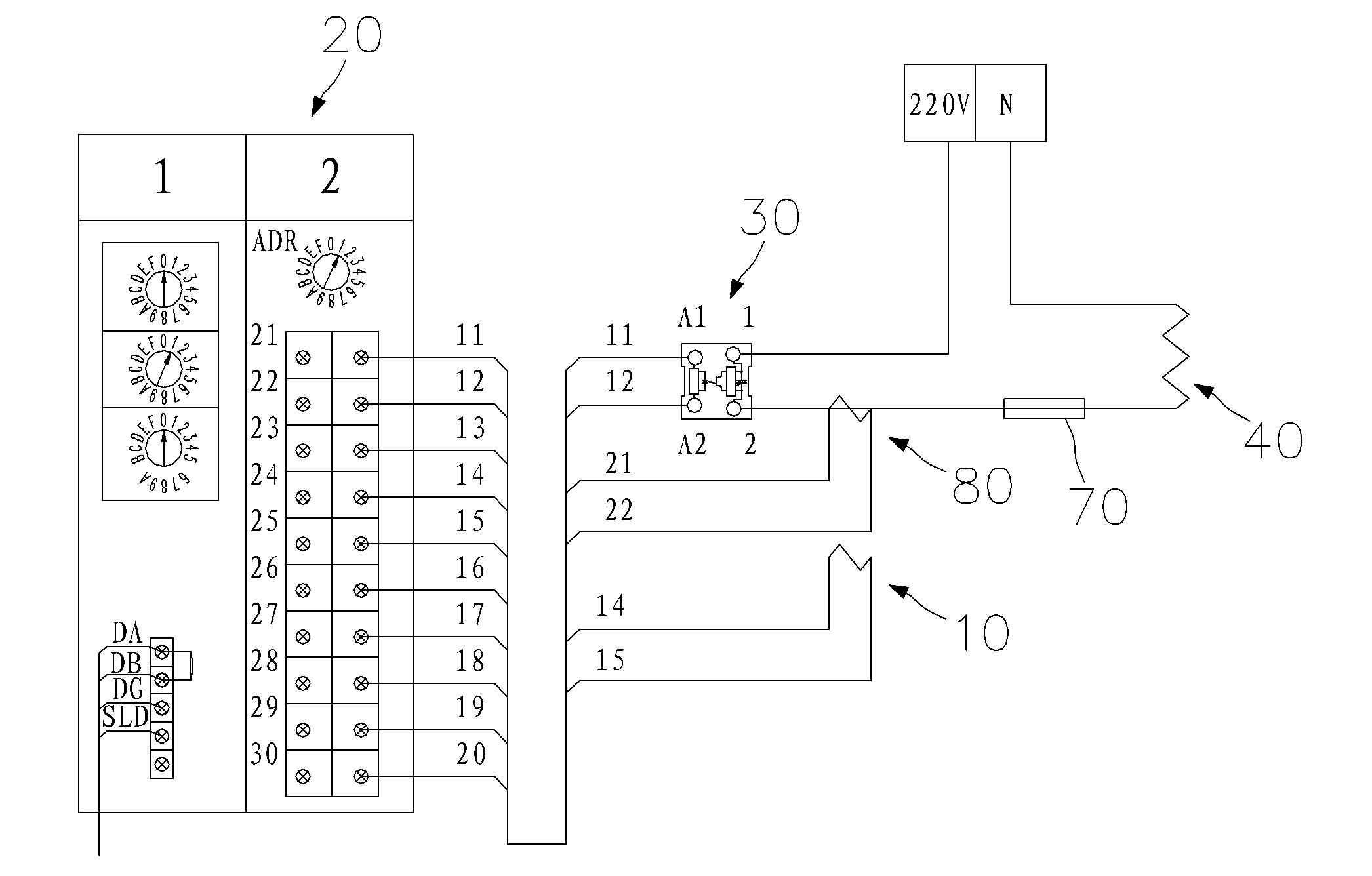

Heating control device for achieving package equipment by using Omron temperature control module

InactiveCN103399596AGuaranteed stabilityThere will be no scrappingTemperatue controlSemiconductor/solid-state device manufacturingTemperature controlProgrammable logic controller

The invention relates to a heating device in integrated circuit package equipment, in particular to a heating control device used for package equipment. The heating control device comprises a temperature measurement component, wherein an output end of the temperature measurement component is connected with an input end of a temperature control module; an output end of the temperature control module is connected with a relay; and a heating component is arranged in a power supply return circuit of a control end of the relay. According to the heating device, temperature control is separated from a processing range of a system PLC (Programmable Logic Controller), so that the temperature control is not interfered by factors such as PLC abnormity any more, and the stability and the precision of a temperature are ensured; in addition, an added short-circuit protection function facilitates protecting hardware; and a broken line detection function of the heating control device can give an alarm prompt at an early fault stage, so that a fault can be found conveniently and timely.

Owner:TONGLING FUSHI SANJIA MACHINE

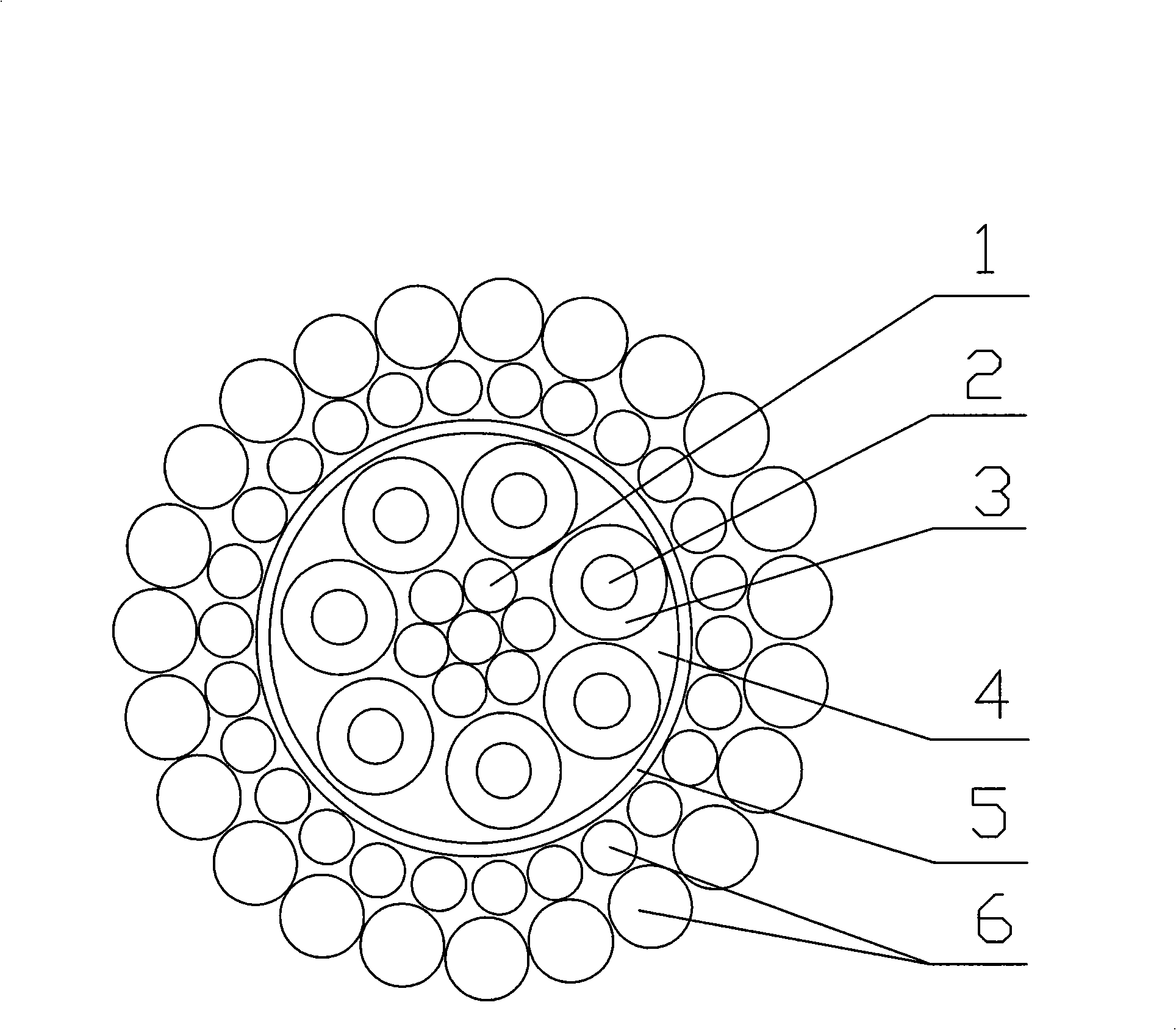

Multicore fiber inserting core body for gas tightness packaging of photoswitch

The invention relates to a multicore fiber inserting core body for gas tightness packaging of a photoswitch, comprising a plurality of fiber inserting cores; the fiber inserting cores are tubular and radically and tightly arranged, and the axes of the fiber inserting cores are mutually parallel; and adjacent fiber inserting cores are subjected to glass sealing so as to realize fixed connection and seal. The invention can effectively improve the sealing effect and lower the packaging cost, provides a brand new large chamber sealing solution for the packaging of MEMS (Micro-Electro-Mechanical System) photoswitches, and realizes that the inside optical path coupling is adjustable and the omniseal of the photoswitch is realized in the final packaging of an outside light input and output port, thereby improving the reliability of the photoswitch running for a long time.

Owner:CHAOZHOU THREE CIRCLE GRP

Multi-channel control device and mounting method thereof

PendingCN111142453AThere will be no scrappingReduce maintenance costsProgramme controlComputer controlMechanical engineeringEmbedded system

Owner:GUANGZHOU VIDEO STAR INTELLIGENT CO LTD

Enameled wire coil rack descending method

InactiveCN103413626ANot easy to damageEasy to operateCable/conductor manufactureEngineeringUltimate tensile strength

The invention discloses an enameled wire coil rack descending method. The method includes the following steps that after take-up reels are filled, a special tool car is pushed below the take-up reels, wherein the special tool car comprises a base plate, a wheel, a liftable plate, a hydraulic lifting arm and a car pushing handle, the wheel is arranged on the lower portion of the base plate, the lower end of the hydraulic lifting arm is arranged on the base plate, and the upper end of the hydraulic lifting arm is connected with the liftable plate; a sliding chute is formed in the car pushing handle, and one end of the liftable plate is arranged in the sliding chute and can move up and down along the sliding chute; the hydraulic lifting arm of the special tool car is ascended, the liftable plate is ascended, and then wire coils are jacked up; after the special tool car is pushed to a set position, the hydraulic lifting arm is descended, the liftable plate is descended, and the wire coils roll down. The method is convenient to operate, labor cost is saved, labor intensity is also relieved, the wire coils are not prone to being damaged, and the situation that all wires in the wire coils are scrapped due to the fact that the wire coils are damaged is completely avoided.

Owner:JIANGSU JURONG UNITED COPPER MATERIAL

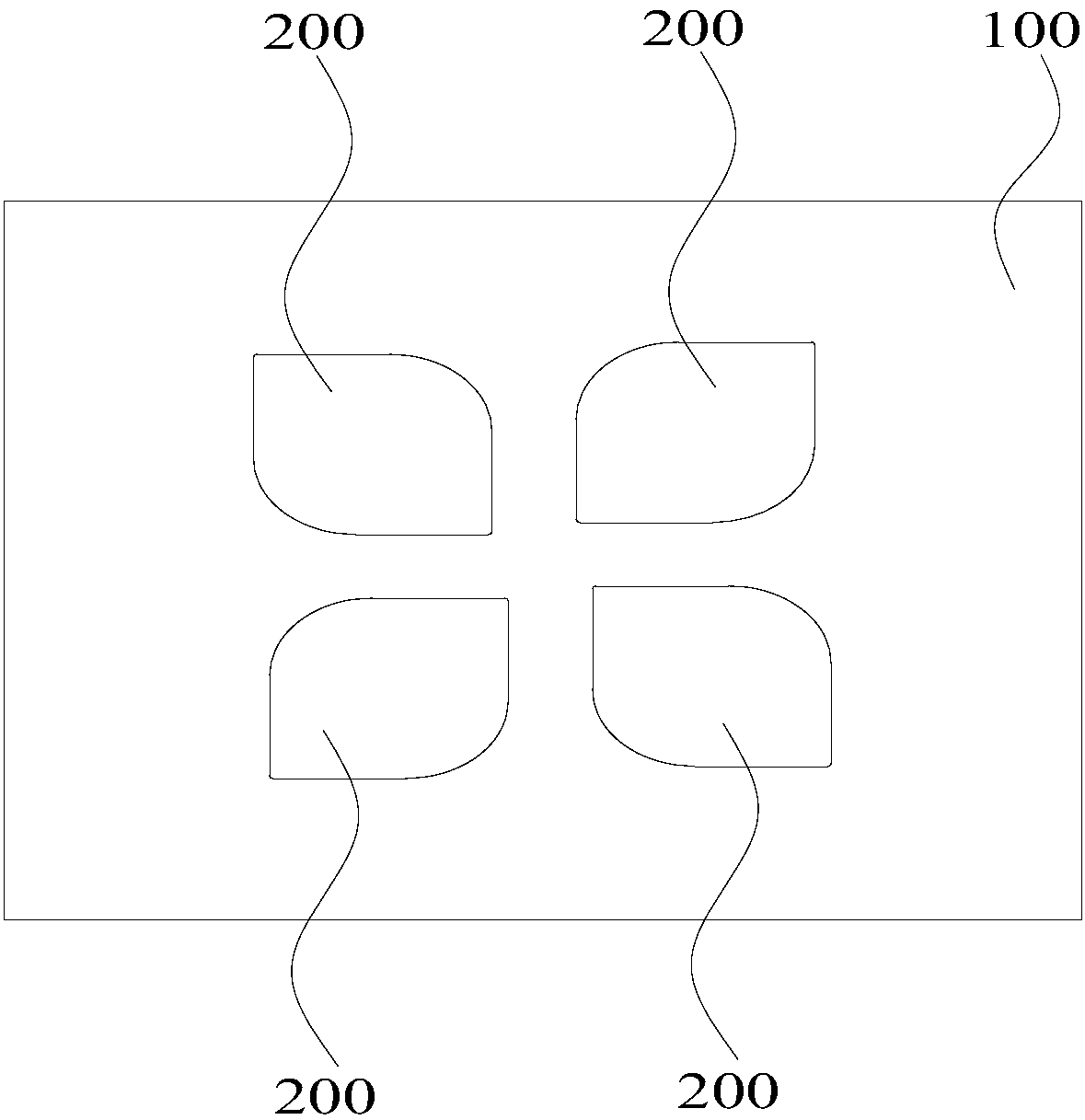

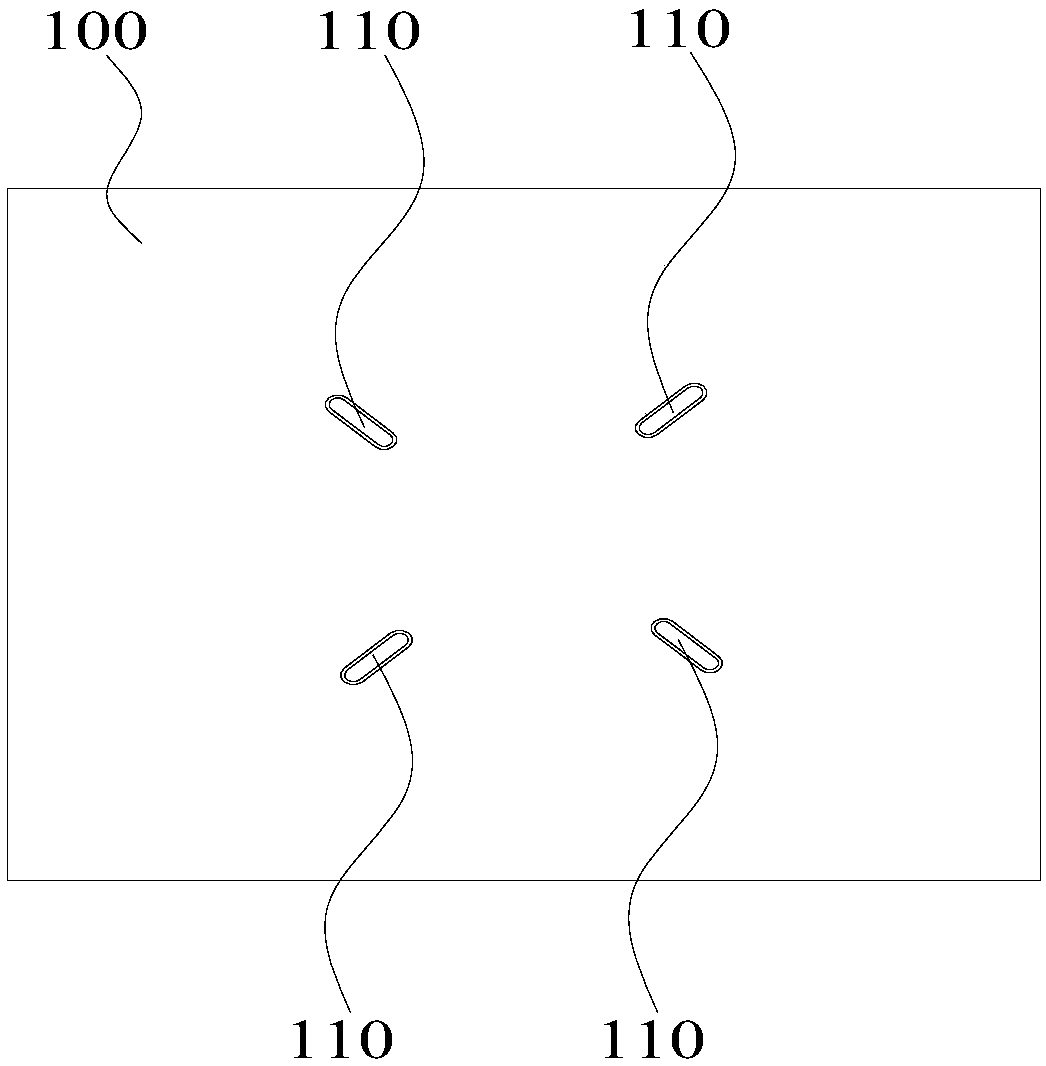

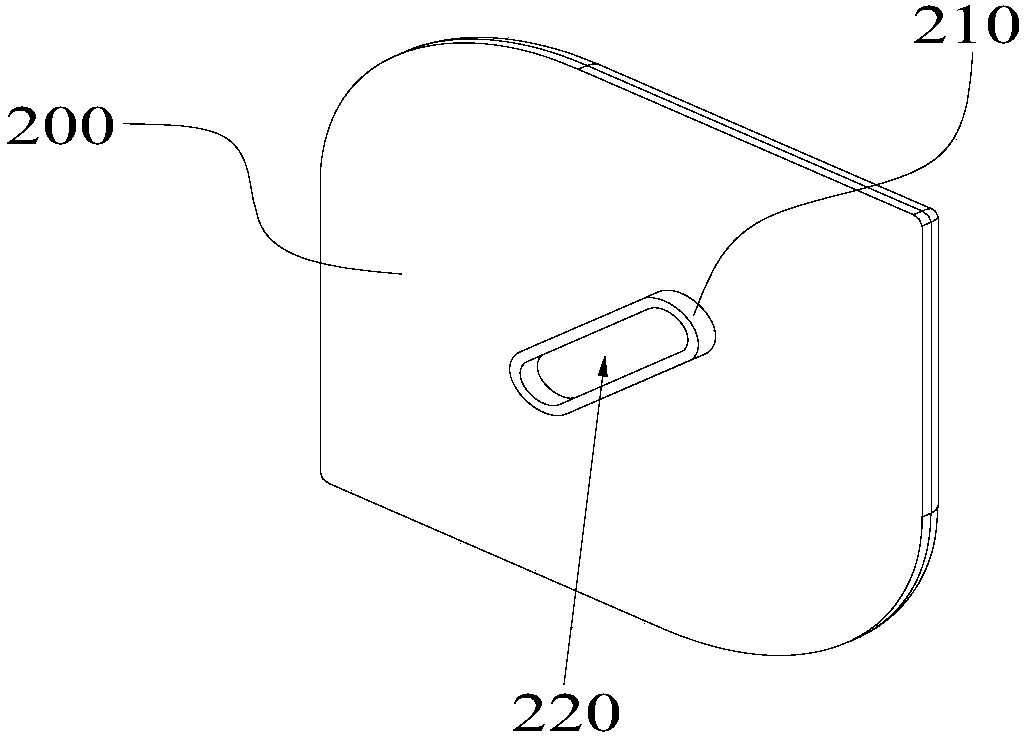

Decorating part and production method thereof

PendingCN108162665AEasy to operateIncrease productivityDecorative surface effectsSpecial ornamental structuresEngineeringScrap

The invention relates to a decorating part. The decorating part comprises a substrate body and a plurality of blade units; the substrate body is provided with a plurality of first clamping position parts; the blade units are arranged in a plate shape, the side surfaces of the blade units are provided with second clamping position parts, and the second clamping position parts are arranged to face the substrate body; and the second clamping position parts and the first clamping position parts are clamped and fixed in a matched mode, so that the blade units are attached to the substrate body. Thefirst clamping position parts and the second clamping position parts are connected in a clamping and fixing mode, so that the substrate body and the blade units are directly attached and fixed; meanwhile, the first clamping position parts and the second clamping position parts are further used for positioning, so as to improve the assembly accuracy of the substrate body and the blade units; and compared with a traditional method of glue bonding, not only are the problems of reworking and scrap due to the poor adhesion precision avoided, but also the production cost is reduced, and the production efficiency is further improved as the assembly operation is simple and convenient.

Owner:清远欧派集成家居有限公司

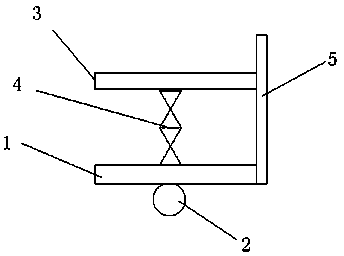

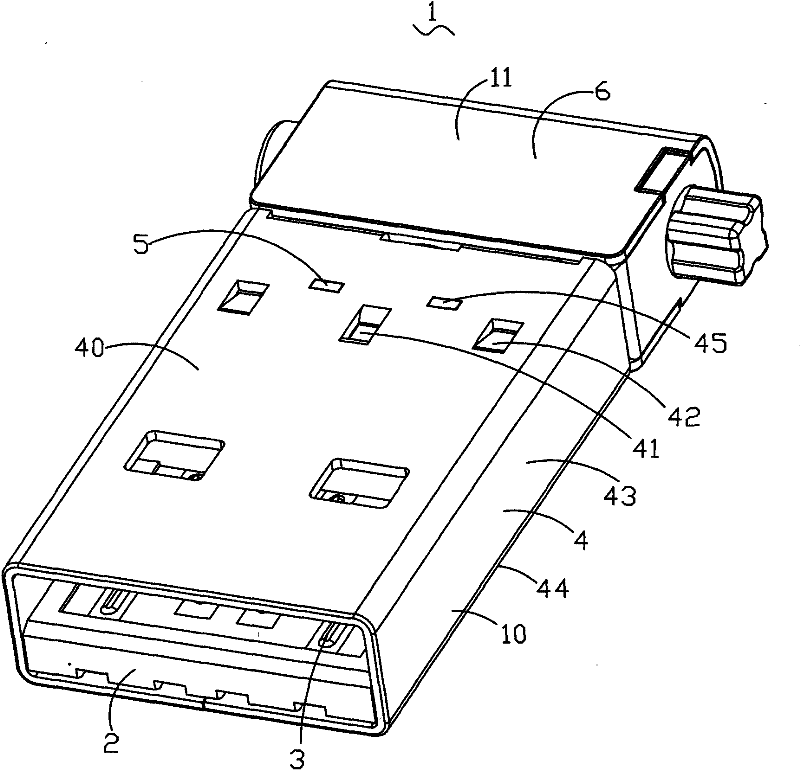

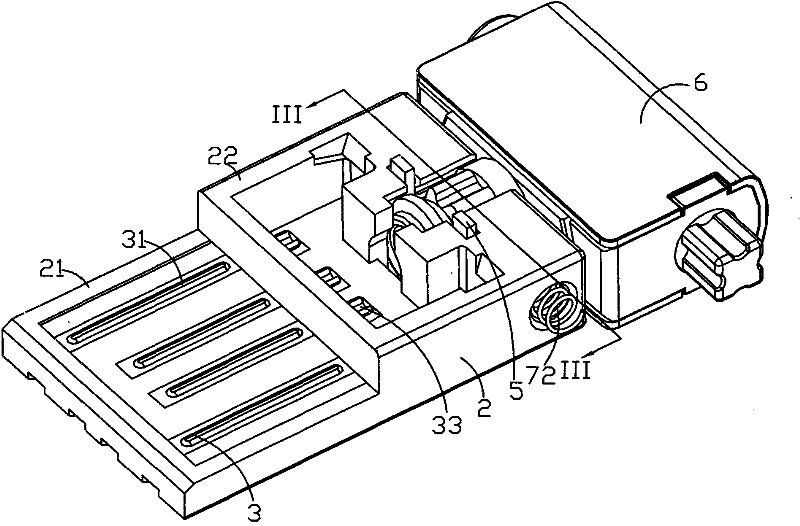

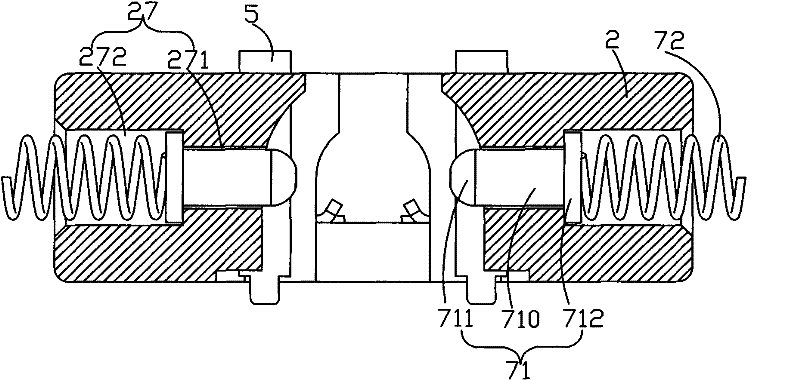

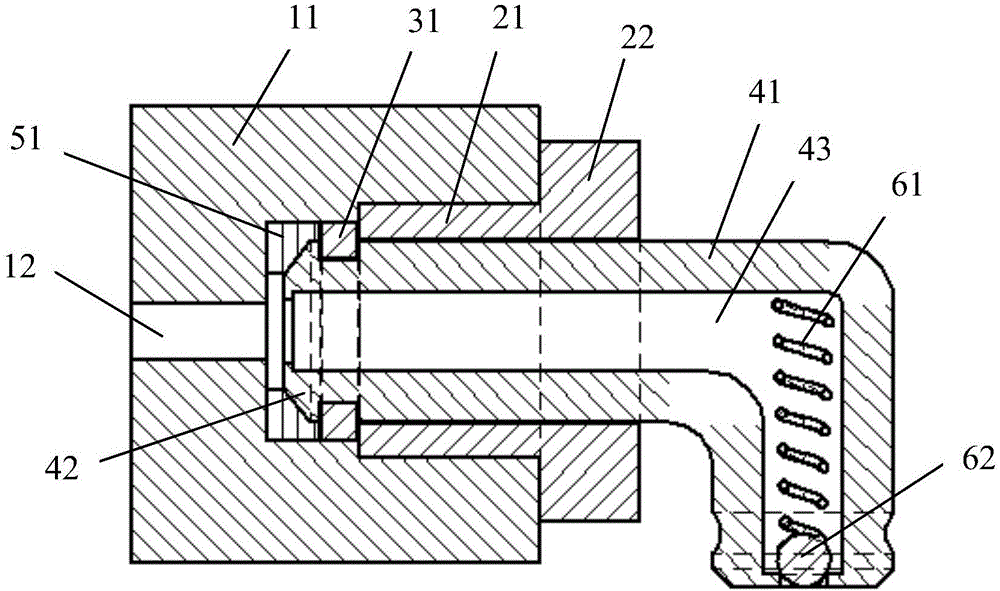

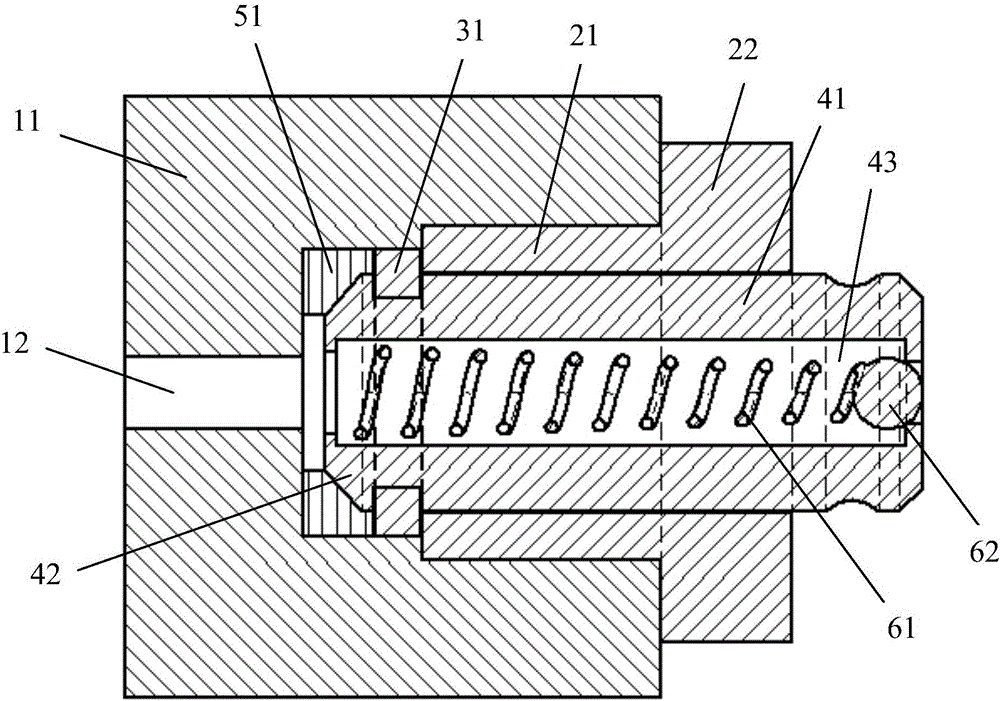

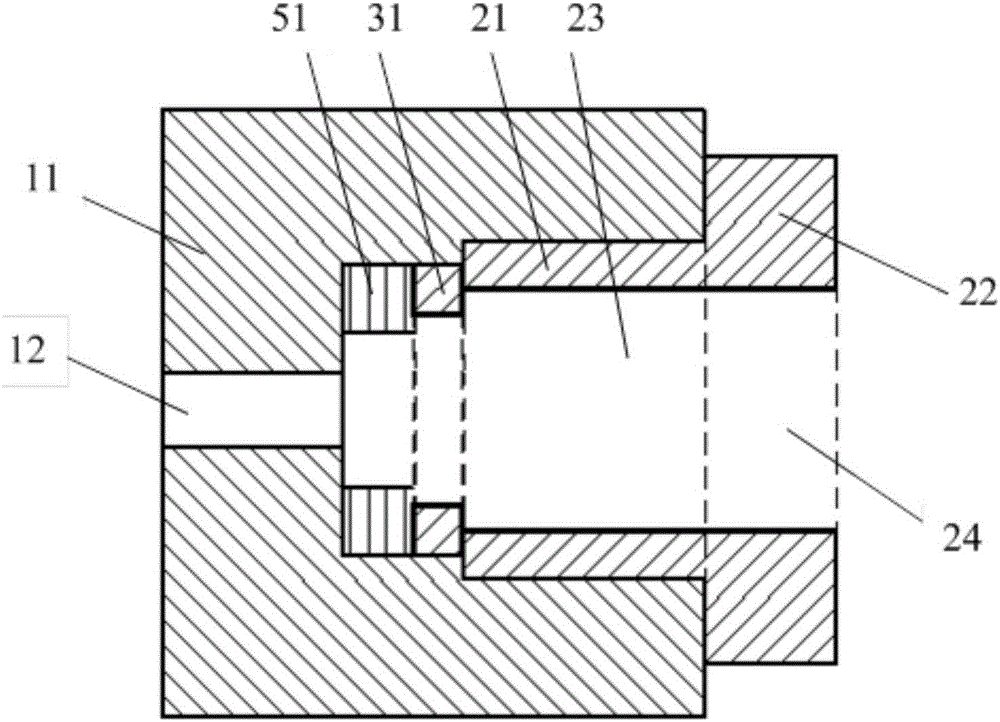

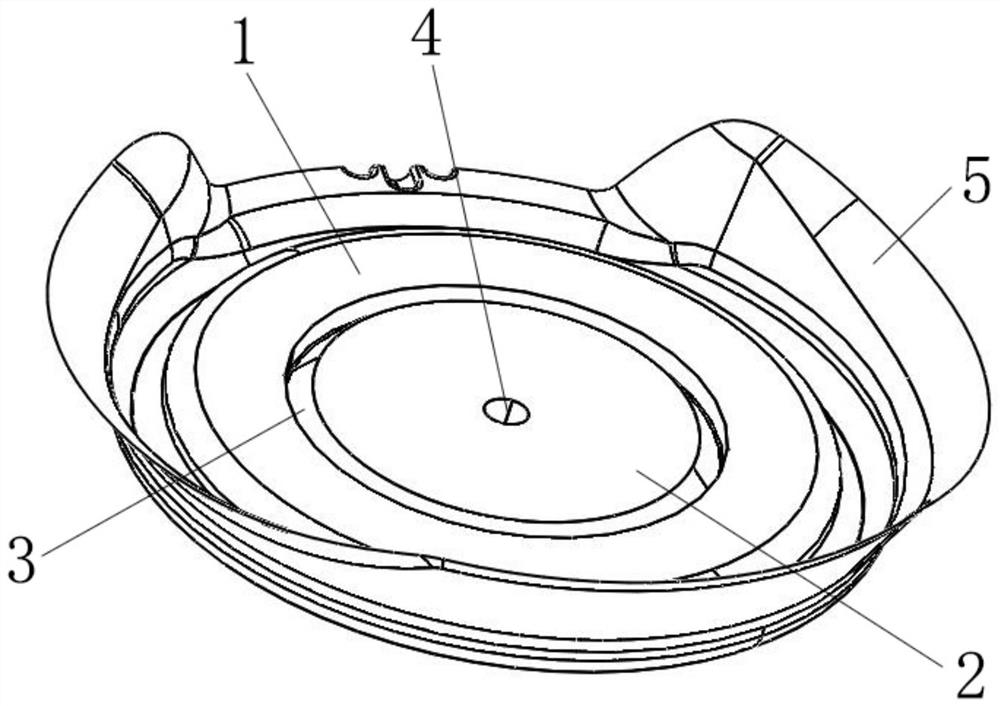

Electric connector with rotatable interface

InactiveCN101609952BIncrease elasticityEasy to useFlexible/turnable line connectorsState of artHobbing

An electric connector with a rotatable interface comprises an interface part and a rotating mechanism, the interface part comprises an insulation body provided with a conductive terminal; and the rotating mechanism comprises a mechanism part with a rotating shaft provided with a circle of hobbing, an assembly groove which is arranged at the rear of the insulation body and used for assembling the rotating shaft of the mechanism part, and a pair of elastic parts which are arranged at the rear part of the insulation body and cooperatively rotates with the rotating shaft of the mechanism part to locate the shaft; wherein, the elastic parts consist of a carrier rod and a spring which abuts on the carrier rod, and the carrier rod props against tooth groove positions between the hobbing on two sides of the rotating shaft. Compared with the prior art, the electric connector with a rotatable interface is characterized in that the cooperation of the elastic parts formed by the combination of the carrier rod and the spring with the rotating shaft of the mechanism part to realize relative rotation of the interface part and the rotating mechanism, thus good elasticity of the elastic parts can be kept by the spring even in frequent use, influencing no service performance.

Owner:SHENZHEN TECHASER TECH

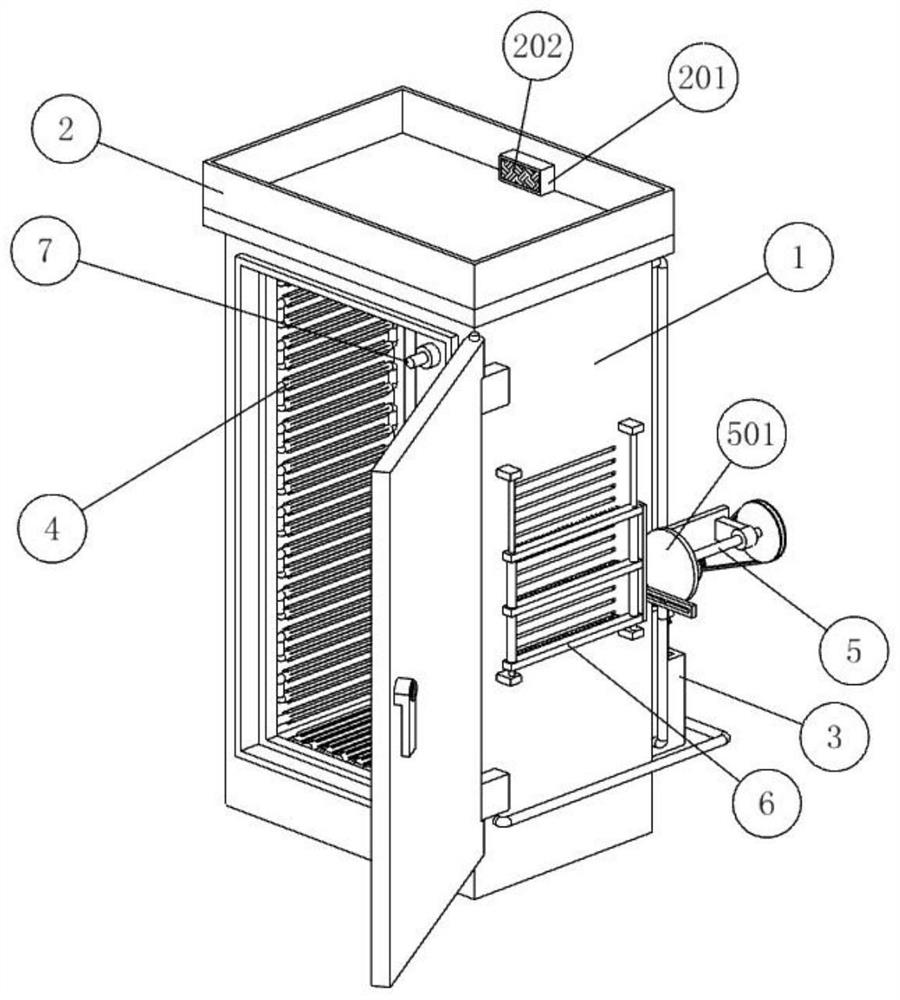

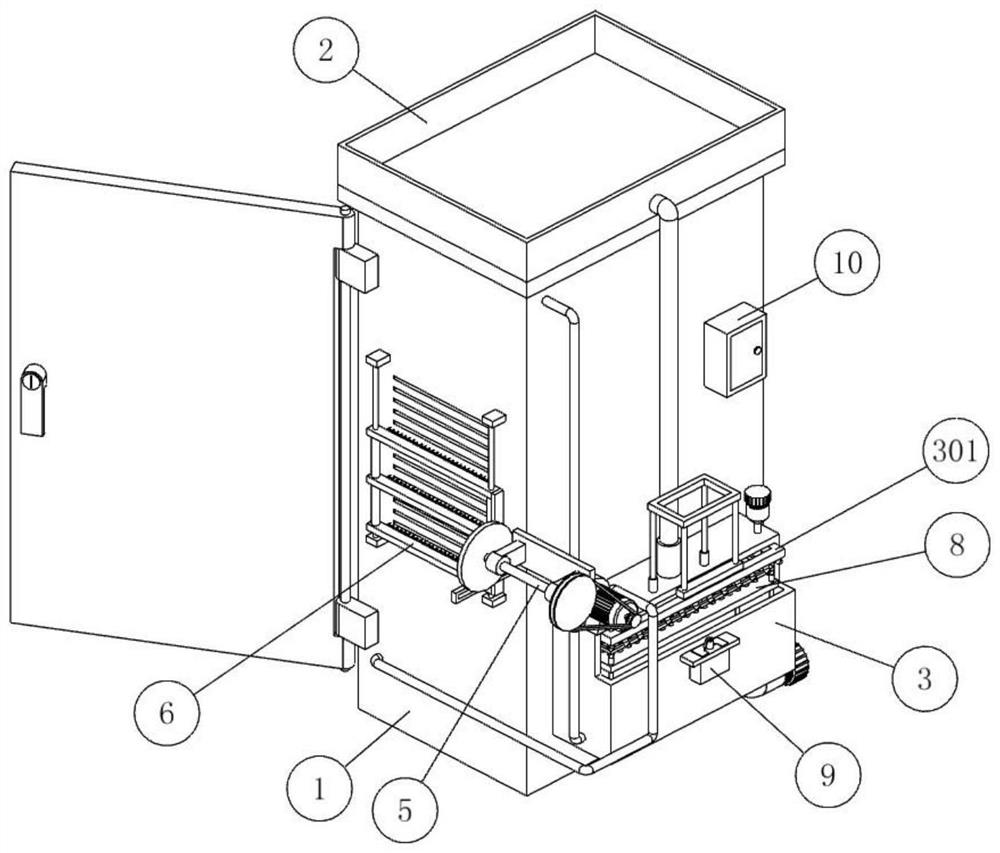

Power distribution cabinet and use method thereof

InactiveCN113659474ARapid and effective cooling effectExtended service lifeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsThermodynamicsWater storage tank

The invention provides a power distribution cabinet and a use method thereof. The use method of the power distribution cabinet is realized by using a special power distribution cabinet, thereby prolonging the service life of the power distribution cabinet. The power distribution cabinet comprises a cabinet body; the top of the cabinet body is provided with a rainwater collecting part, and the rear side of the rainwater collecting part is connected with a water storage tank installed on the lower portion of the rear end face of the cabinet body. A heat absorption part is arranged in the cabinet body; and the right rear part of the cabinet body is rotatably connected with a transmission member through a rotating support, and the right end surface of the cabinet body is provided with a cleaning part at a heat dissipation hole. Heat absorbed by the outer walls of four heat absorption pipes is brought into a second frame-shaped pipe through water in the water storage tank, then flows back into the water storage tank through a water return pipe, and is dissipated through the outer walls of the water storage tank, and the operation is repeated, so that the interior of the cabinet body can be rapidly and effectively cooled.

Owner:济南市中恒光机电技术中心

Multi-section bending, shaping and cutting-off mechanism for double-layer core wire

ActiveCN112547982AImprove processing productivityReduce labor costsWire cuttingStructural engineering

The invention discloses a multi-section bending, shaping and cutting-off mechanism for a double-layer core wire, and belongs to the field of machinery. The multi-section bending, shaping and cutting-off mechanism comprises a bottom plate, a shaping and cutting-off assembly and a driving assembly for controlling the shaping and cutting-off assembly to shape and cut off the double-layer core wire. The driving assembly is installed on the bottom plate, the shaping and cutting-off assembly is installed at the output end of the driving assembly, the shaping and cutting-off assembly comprises a cutter holder, a shaping cutter and a cutting-off cutter, and the shaping cutter and the cutting-off cutter are distributed and installed on the cutter holder from the length direction of the core wire toone end of the core wire cutting-off head. The multi-section bending, shaping and cutting-off mechanism for the double-layer core wire has the beneficial effects that the shaping and cutting-off mechanism is used for shaping and cutting off the core wire under the driving of the driving assembly, automation of shaping and cutting-off is achieved, combined operation of shaping and cutting-off steps is further achieved, the working efficiency is improved, the labor cost is reduced, and the automatically-machined core wire is more stable and superior in machining quality.

Owner:AMPHENOL (XIAMEN) HIGH SPEED CABLE CO LTD

Grease nipple mounting structure

InactiveCN106195601AExtended service lifeEasy to insertConduits/junctionsEngineeringUltimate tensile strength

The invention provides a grease nipple mounting structure. The grease nipple mounting structure comprises a grease nipple, a to-be-lubricated piece, a pressing block and an elastic snap ring, wherein a lubricating hole is formed in the to-be-lubricated piece; the elastic snap ring is arranged in the lubricating hole; the pressing block is matched with the lubricating hole and is abutted to the elastic snap ring; the grease nipple comprises a hollow grease nipple body; a first end of the grease nipple body is connected with a lubricating grease supply tube; a second end of the grease nipple body is connected with the lubricating hole; a through hole which allows the second end to penetrate through is formed in the pressing block; the through hole and the lubricating hole are coaxial; the second end has a conical structure; and an annular slot which is matched with the elastic snap ring is formed in the bottom of the conical structure. By the grease nipple mounting structure, the labor intensity of operators can be greatly reduced, mounting time is shortened effectively, and meanwhile, the service life of the grease nipple can further be prolonged.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

V-shaped groove fuel tank fuel filling port, and machining forming method of fuel tank fuel filling port finished product

The invention discloses a V-shaped groove fuel tank fuel filling port, and a machining forming method of a fuel tank fuel filling port finished product. The V-shaped groove fuel tank fuel filling portand a fuel tank body are of an integrally-formed structure. The fuel filling port comprises a fuelfilling port body, a guide hole coaxial with the fuel filling port body is formed in the fuel fillingport body, the upper surface of the fuel filling port body is sunken downwards to form an annular V-shaped groove coaxial with the guide hole, the side face, back to the guide hole, of the V-shaped groove is a vertical face, and the side face, facing the guide hole, of the V-shaped groove is an inclined face. By processing the V-shaped groove fuel tank fuel filling port, the final fuel tank fuelfilling port finished product is obtained, the obtained fuel filling port does not have the phenomena of single side of an open hole and scrapping of the open hole, and the phenomena of eccentricity and recession of the fuel tank after water cooling are avoided.

Owner:WUHU SHUNRONG AUTOMOBILE PARTS

Heating control device used for packaging equipment

ActiveCN102412171BGuaranteed stabilityThere will be no scrappingSemiconductor/solid-state device manufacturingTemperature controlHeat control

The invention relates to a heating device in integrated circuit packaging equipment and especially relates to a heating control device used for packaging the equipment. The heating control device comprises a temperature measurement component. An output terminal of the temperature measurement component is connected with an input terminal of a temperature control module. The output terminal of the temperature control module is connected with a relay. A heating component is arranged in a power supply loop of a relay control terminal. In the heating device of the invention, the temperature control is separated from a processing scope of a system PLC controller so that the temperature control can not be interfered by factors, such as abnormity of the PLC controller. Therefore, stability and accuracy of the temperature can be guaranteed. Simultaneously, a short circuit protection function added in the invention is beneficial to protect hardware. And a broken line detection function contained in the invention can give alarm prompt in an initial failure stage so that the failure can be searched timely.

Owner:TONGLING FUSHI SANJIA MACHINE

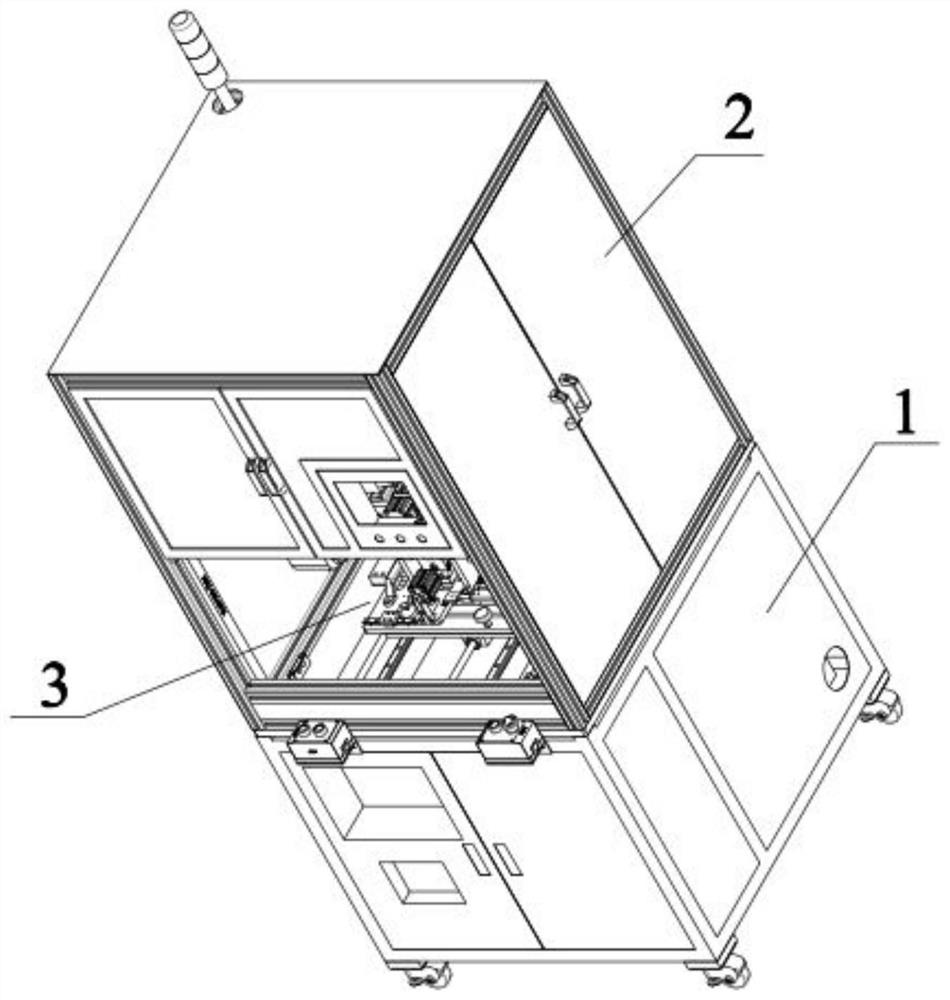

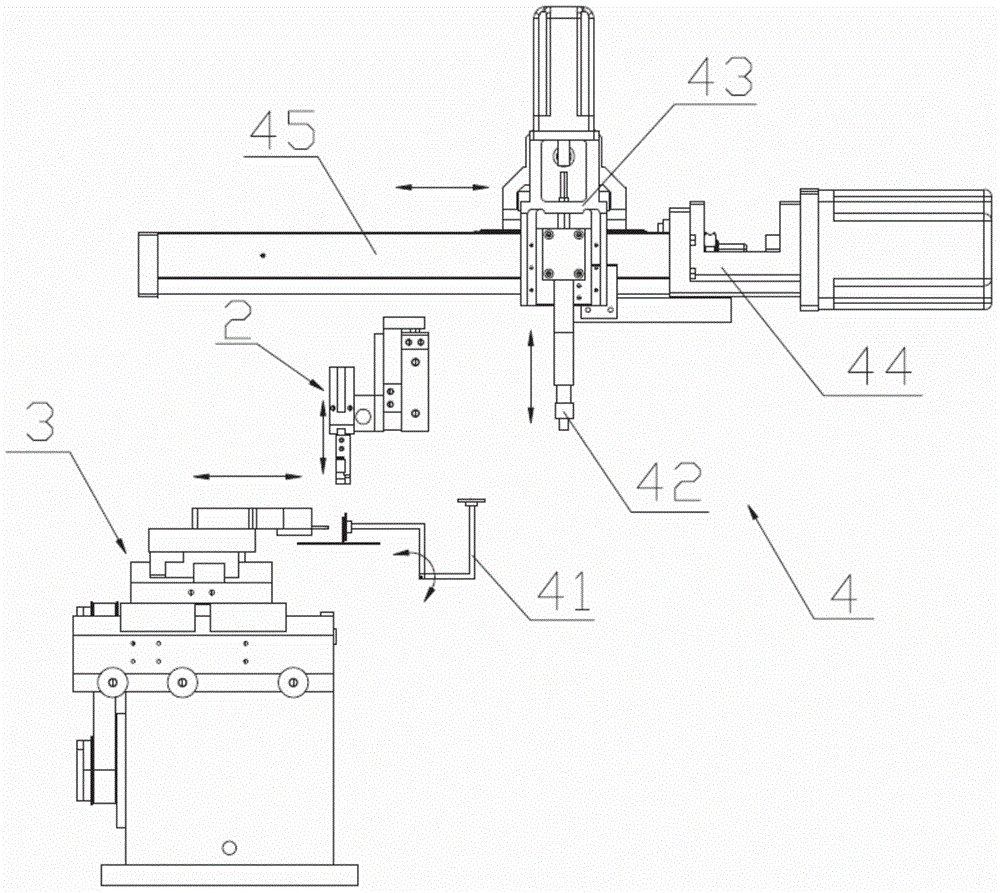

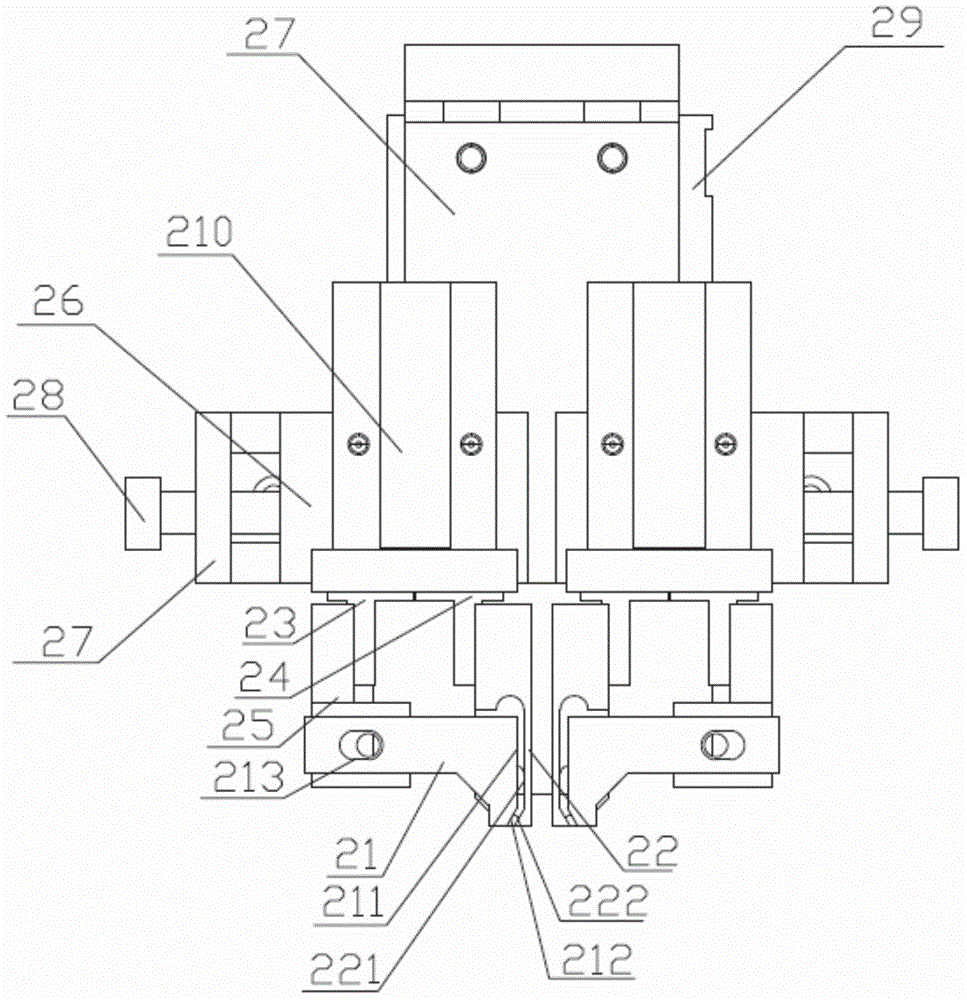

A dual-interface smart card chip welding method and welding equipment

ActiveCN104148833BThere will be no scrappingShorten the timeWelding/cutting auxillary devicesAuxillary welding devicesSmart cardEmbedded system

The invention discloses a double-interface smart card chip welding method and device. The double-interface smart card chip welding method includes steps of (1) conveying cards lifted up by two antennas to a welding workstation, then moving an antenna beating device to the workstation to beat the antennas so that the antennas are arranged on the same plumb surface, and after beating, removing the antenna beating device from the welding workstation, wherein the distance between the antenna is equal to that between the centers of two welding points on a chip; (2) conveying the chip to be welded to the welding workstation by a chip conveying device 2 and guaranteeing that the chip is vertically arranged and the two welding points on the chip are flush with the antennas; (3) enabling a welding head of the welding device to move towards the welding points and the antennas and welding the antennas on the welding points. During welding by the welding method, the antennas do not have to be continuously clamped, cleaning jaws are not needed to be cleaned, and the double-interface smart card chip welding method and device have the advantages high welding efficiency and quality and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com