Grease nipple mounting structure

A technology of installation structure and grease nipple, which is applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve the problems of high labor intensity of operators, long installation time of grease nipple, and short service life, so as to shorten the installation time time, reduce labor intensity and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

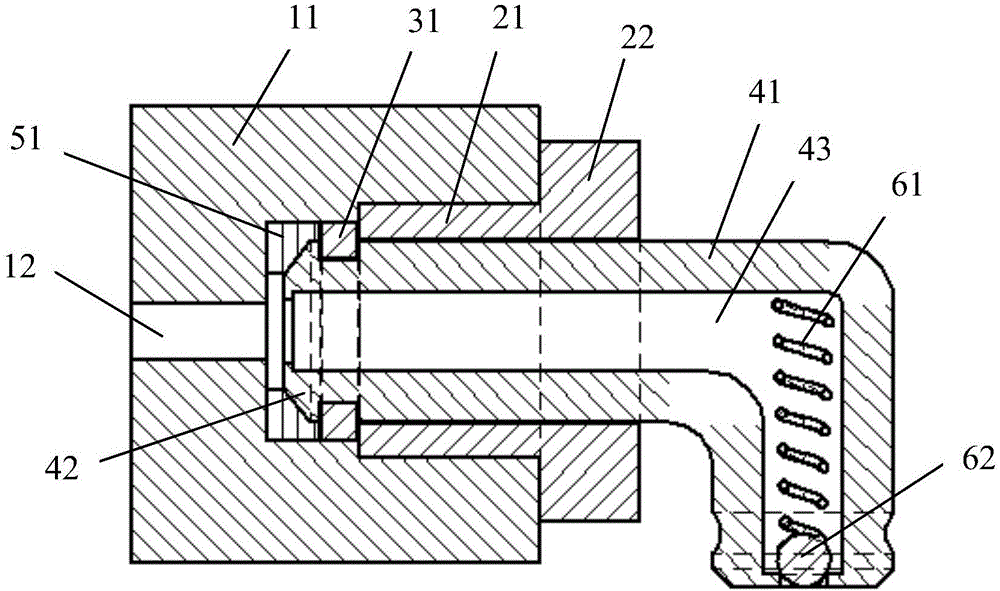

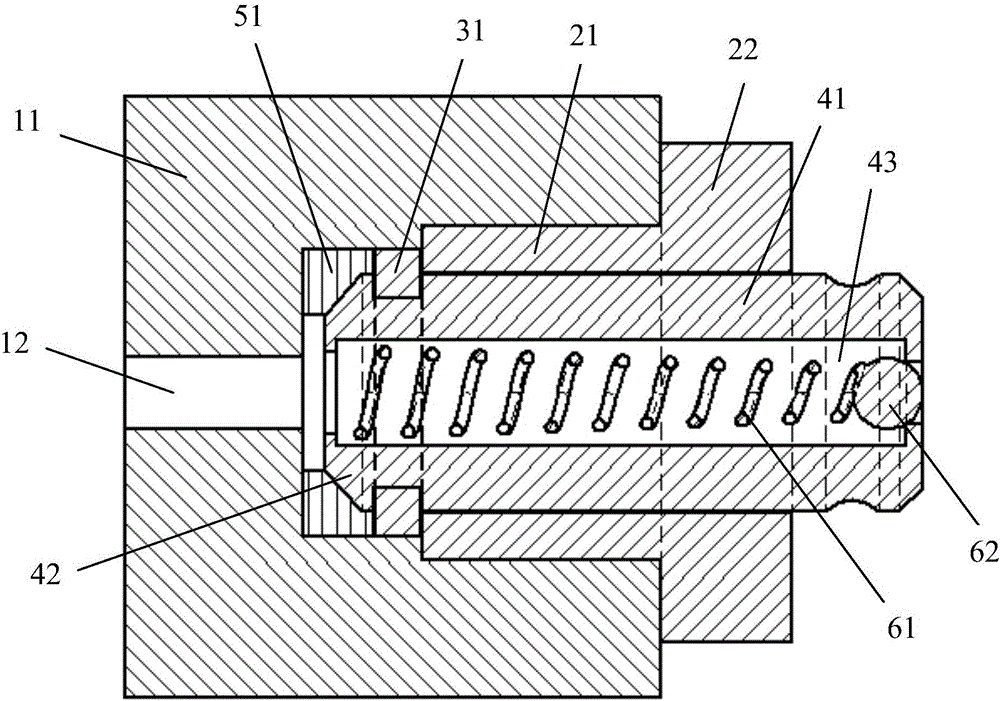

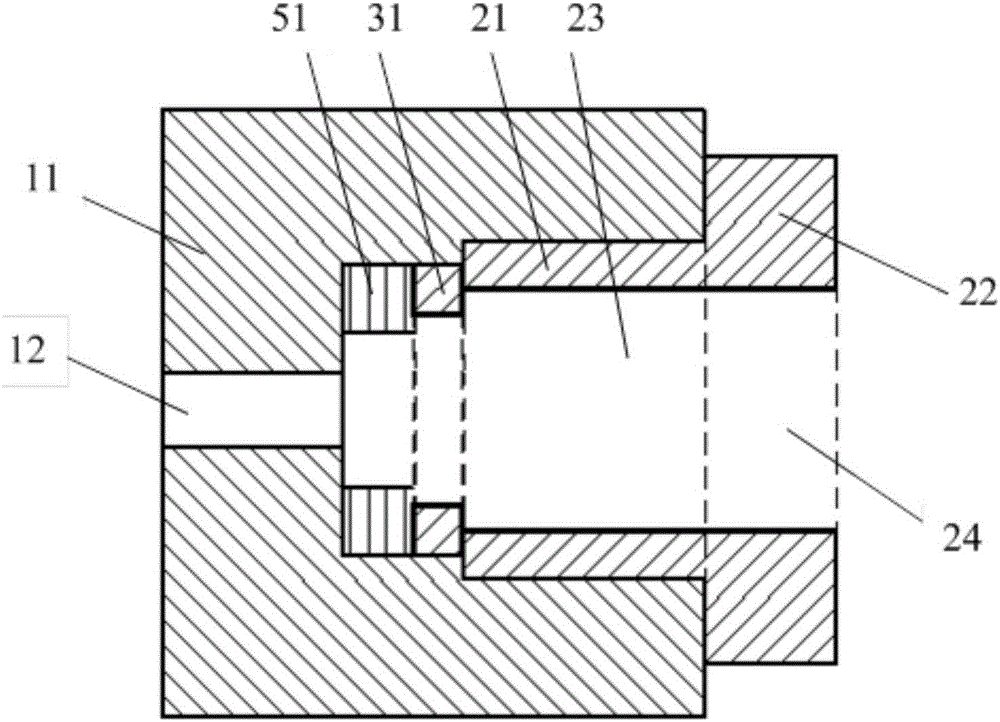

[0028] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a grease nipple installation structure, which includes a grease nipple 71 and a piece to be lubricated 11, the piece to be lubricated 11 has a lubricating hole 12, and it also includes a pressing block 21 and a lubricating The elastic snap ring 31 in the hole 12, the pressing block 21 matches the lubrication hole 12 and abuts against the elastic snap ring 31; the grease nipple 71 includes a hollow grease nipple body 41, the first end of the grease nipple body 41 is used To be connected with the grease supply pipe, the second end of the grease nipple body 41 is used to connect with the lubricating hole 12; Coaxial arrangement; the second end is a conical structure 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com