Heating control device for achieving package equipment by using Omron temperature control module

A heating control device and packaging equipment technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as uncontrollable temperature, product scrapping, temperature control accuracy cannot be guaranteed, etc., and achieve the goal of ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

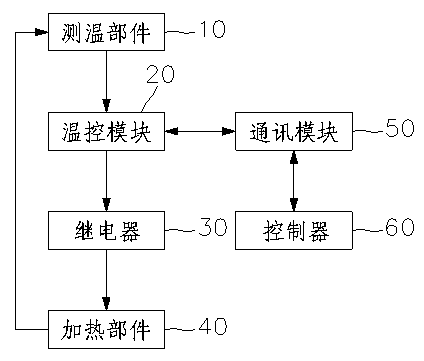

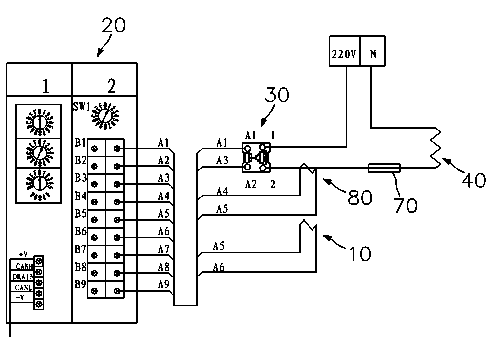

[0026] Such as figure 1 , 2 As shown, a heating control device for packaging equipment, the heating control device includes a temperature measuring component 10, the output end of the temperature measuring component 10 is connected to the input end of the temperature control module 20, and the output end of the temperature control module 20 is connected to the relay 30, and the power supply circuit at the control end of the relay 30 is provided with a heating element 40.

[0027] The input end of the temperature control module 20 is connected to the output end of the communication module 50 , and the input end of the communication module 50 is connected to the output end of the controller 60 .

[0028] Preferably, the temperature measuring component 10 is a thermocouple; the relay 30 is a solid state relay; and the controller 60 is a PLC controller.

[0029] Such as figure 2 As shown, further, a fuse 70 for short-circuit protection is connected in series in the power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com