Motor end cover with good heat dissipation performance

A technology of motor end cover and heat dissipation performance, applied in the mechanical field, can solve the problems of difficult heat dissipation of motor heat, motor operation failure, and accelerated heat dissipation speed, and achieve the effects of avoiding accidents, ensuring positioning, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

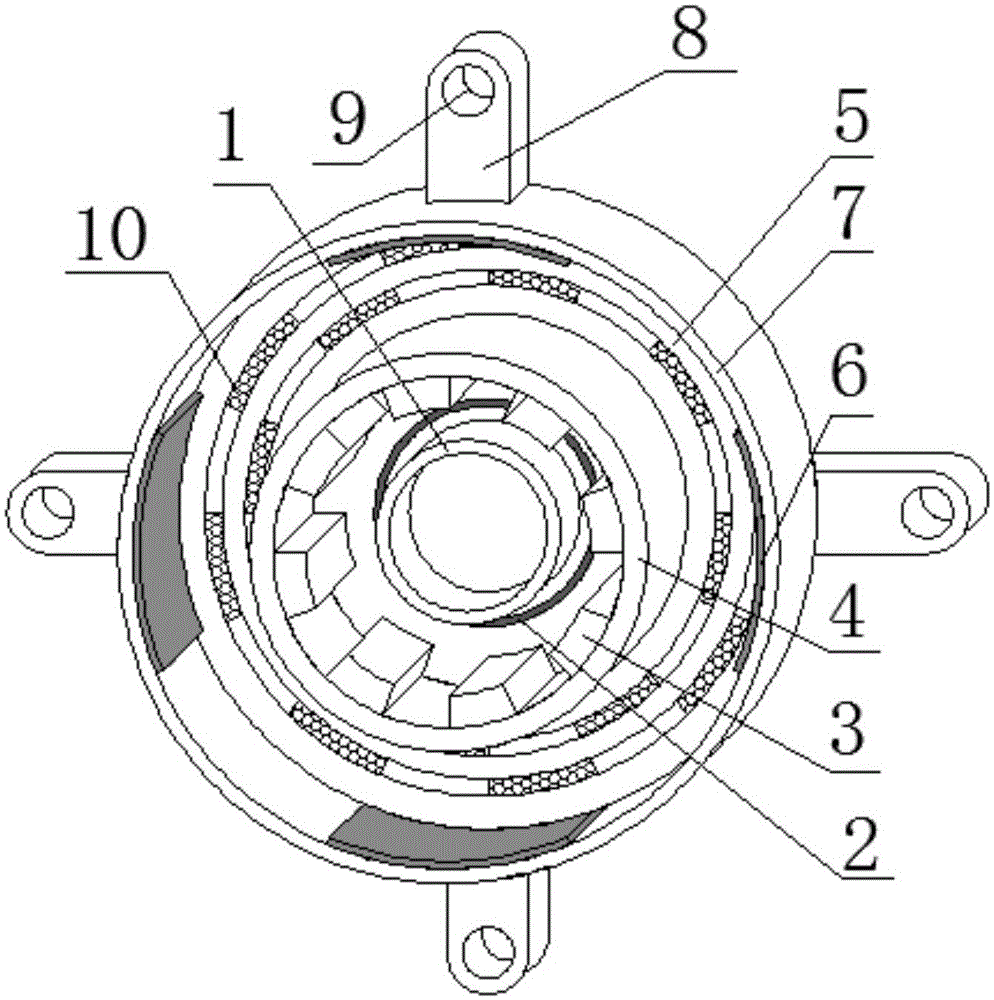

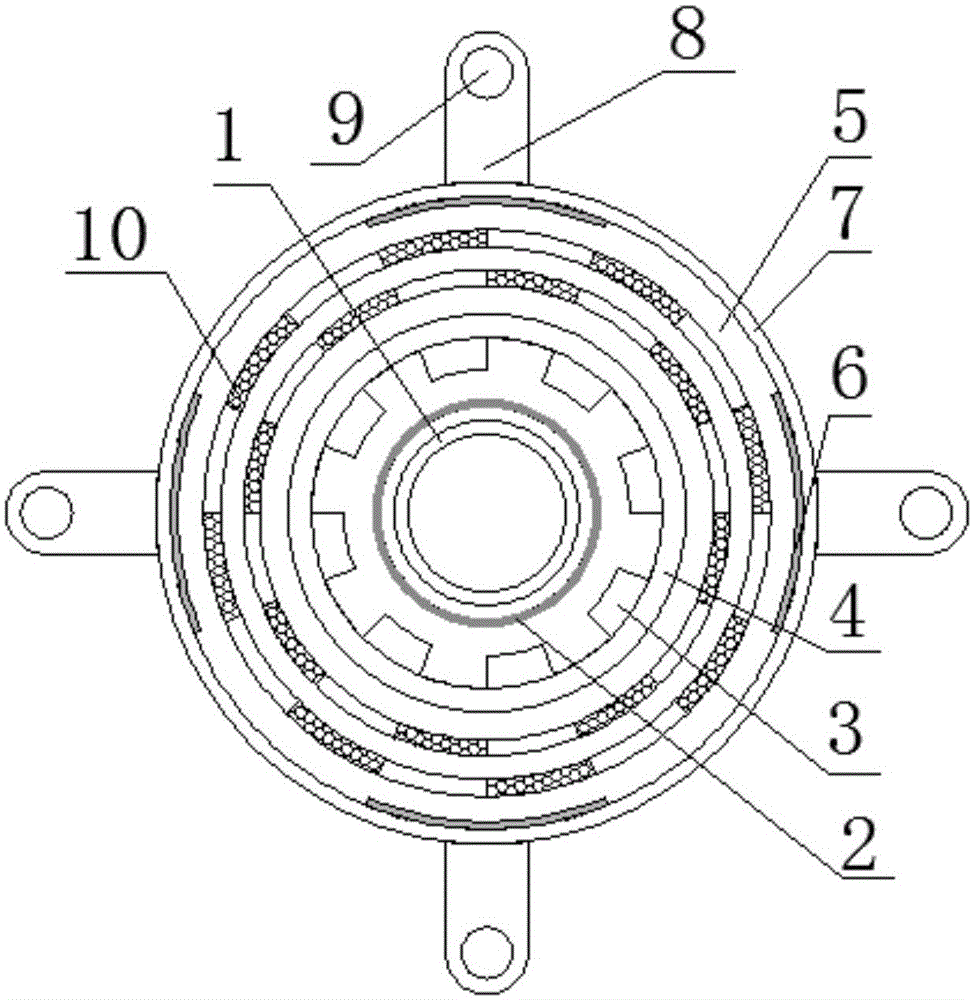

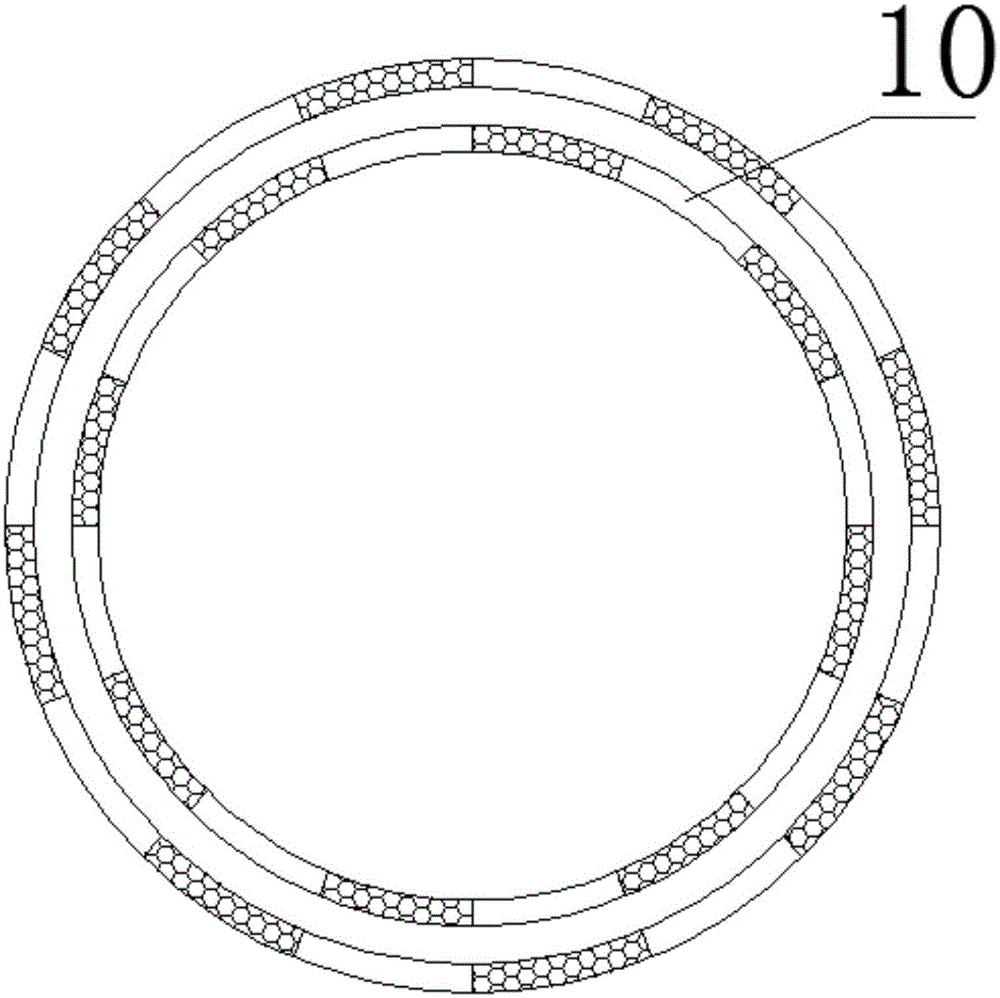

[0049]A motor end cover with good heat dissipation performance, which solves the problem that in the prior art, heat dissipation is often carried out from the side wall, and the heat in the axial direction of the motor is not easy to accelerate the heat dissipation along the axial direction, thus causing the failure of the motor to operate. Design a motor end cover that can further speed up heat dissipation in the axial direction, so that the motor can not only dissipate heat in the circumferential direction, but also dissipate heat in the axial direction during operation, so that the heat dissipation speed is accelerated and motor failures are avoided, such as figure 1 , figure 2 , image 3 As shown, it includes the motor end cover body that has undergone anti-rust treatment by galvanizing process inside and outside. The motor end cover body includes the bottom 5 of the motor end cover and the outer cylinder 7 of the motor end cover. There are at least two disjointed straig...

Embodiment 2

[0055] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, the connection between the motor and the motor end cover can be more in line with mechanical stability, such as figure 1 , figure 2 , image 3 As shown, the following structure is especially provided: the crest width of the straight thread section 6 is 1.1-1.5mm; Evenly distributed around the circumference.

Embodiment 3

[0057] This embodiment is further optimized on the basis of the above embodiments, further to better realize the present invention, further ensure the stable connection with the stator or rotor in the motor, and also accelerate the heat dissipation in the axial direction, such as figure 1 , figure 2 , image 3 As shown, the following structure is particularly provided: the motor end cover body is also provided with a motor end cover inner cylinder 4, and the motor end cover inner cylinder 4 and the motor end cover outer cylinder 7 are concentrically arranged on the motor On the bottom 5 of the end cover; on the inner wall of the inner cylinder 4 of the motor end cover, there is a circle of bosses 3 that are geometrically evenly distributed; Between the inner walls of the outer cylinder 7 of the end cap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com