A dual-interface smart card chip welding method and welding equipment

A double-interface smart card and chip welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting welding, affecting welding quality, card scrapping, etc., so as to facilitate dissipation and heat dissipation, improve welding quality, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

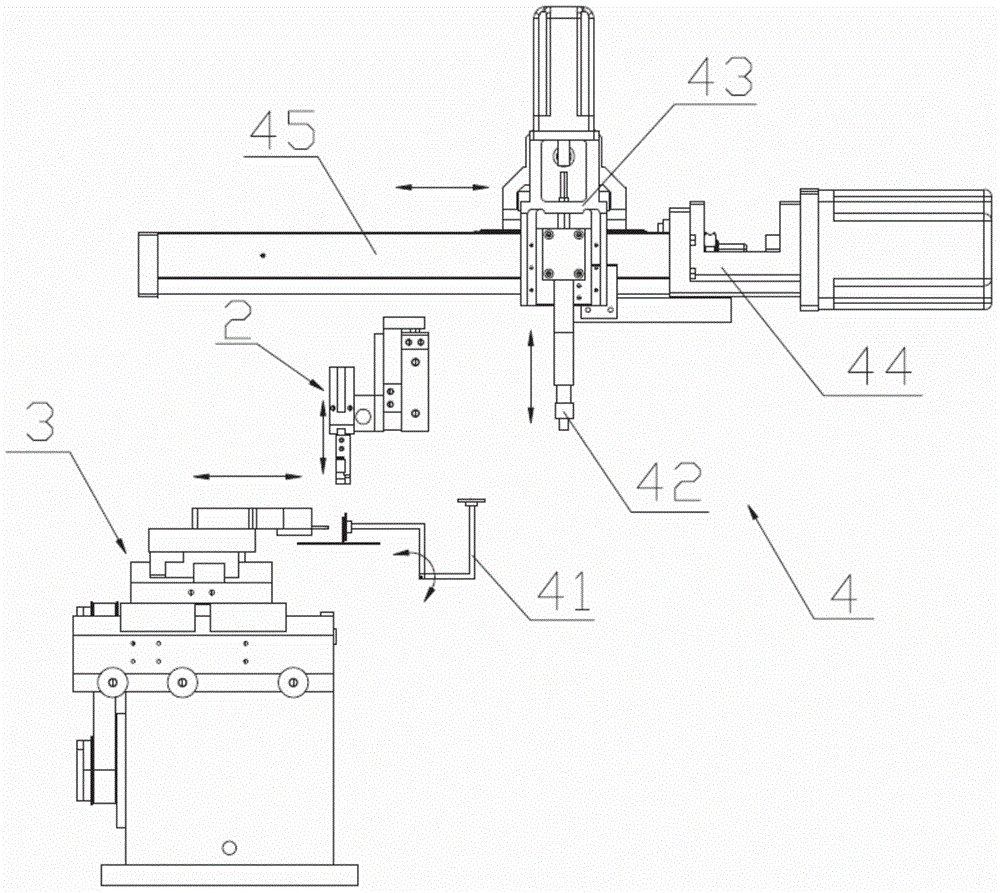

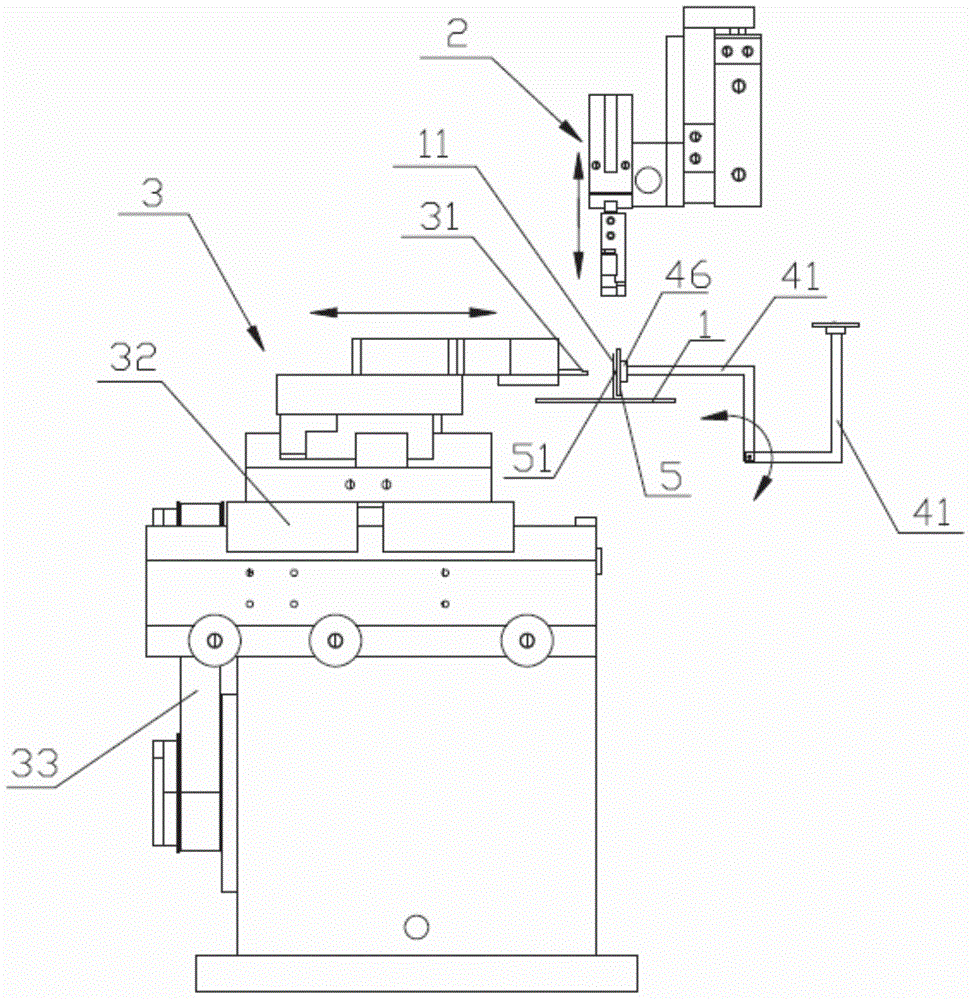

[0045] see Figure 1 to Figure 9 , the smart card chip 5 welding method of present embodiment 1 comprises the following steps:

[0046] (1) Transport the card 1 that has been picked up by the antenna 11 to the welding station, and then the antenna slapping device 2 moves to the station to slap the two antennas 11 so that the two antennas 11 are located on the vertical plane, And the distance between the two antennas 11 is equal to the distance between the centers of the two solder joints 51 on the chip 5. After the beating is completed, the antenna line shooting device 2 leaves the welding station;

[0047] Specifically, the antenna line shooting device 2 moves from top to bottom to the welding station, and after the line shooting is completed, the antenna line shooting device 2 moves upward to reset;

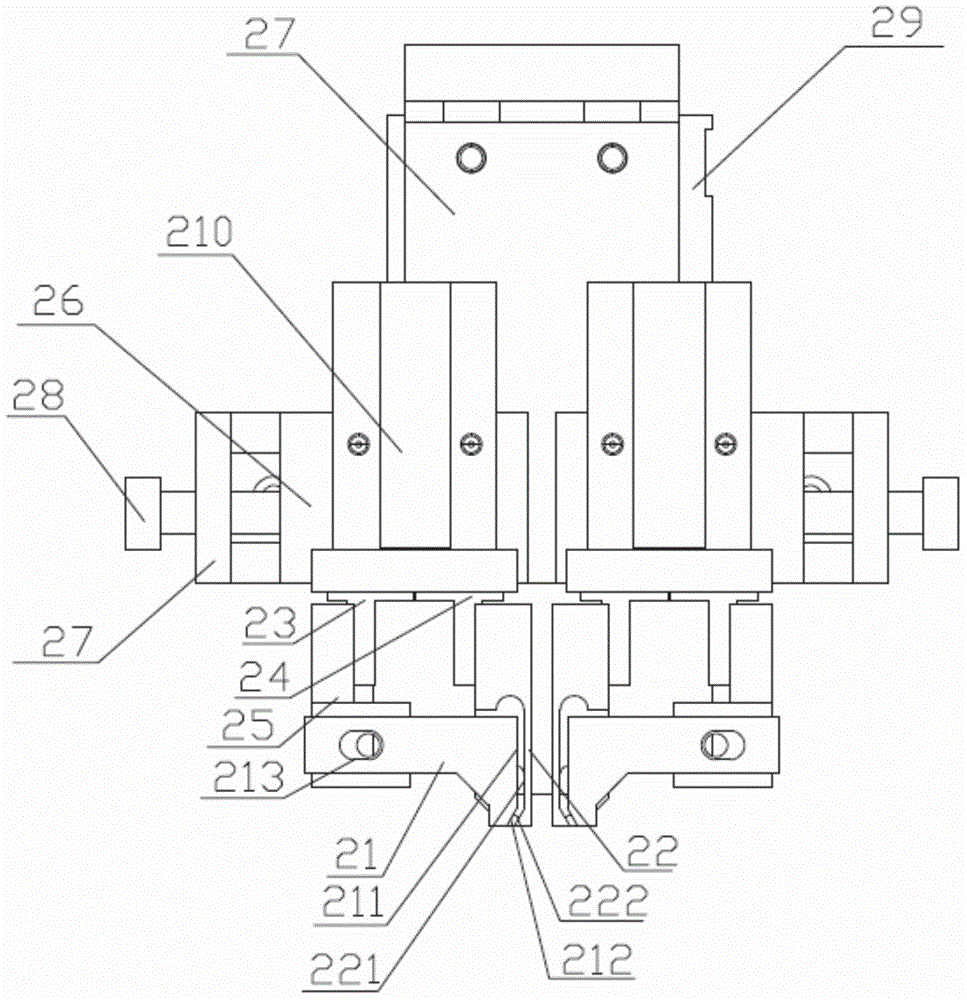

[0048] Further, see Figure 6 ~ Figure 9 , the line shooting action of the antenna shooting line device 2 is realized by two pairs of claws, and both pairs of claws can be cl...

Embodiment 2

[0060] In Example 1, since the wire surface of the claw is located on the vertical plane, after the wire is completed, the antenna may be shifted to the outside by a certain distance, so that it cannot be completely vertical, thereby offsetting the solder joint. May affect welding quality. The reason is: see Figure 10 ~ Figure 12 , before performing the wire shooting process of the present invention, the card 1 needs to go through the following processing process: first, the chip groove 12 is milled out on the card 1 corresponding to the two antennas 11, so that the antenna 11 hidden in the card 1 is exposed , when milling the chip slot 12, when the antenna 11 is exposed, it is necessary to bend the two antennas 11 to both sides of the chip slot 12 (equivalent to reverse bending the antenna 11 along its extending direction in the card), Make it close to the state of lying flat on the card surface, so as not to cut off the antenna 11 when milling the groove; then it is necess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com