Multicore fiber inserting core body for gas tightness packaging of photoswitch

A fiber optic ferrule and multi-core fiber technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as aging, micromirror failure, and reflectivity reduction, and achieve high precision and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

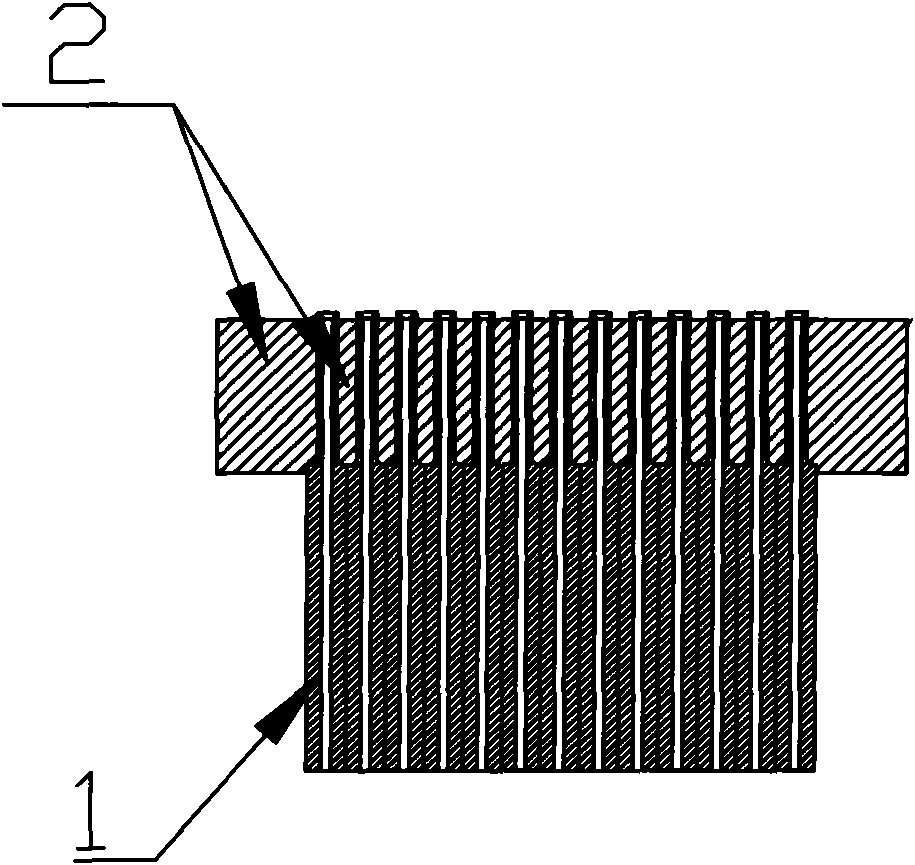

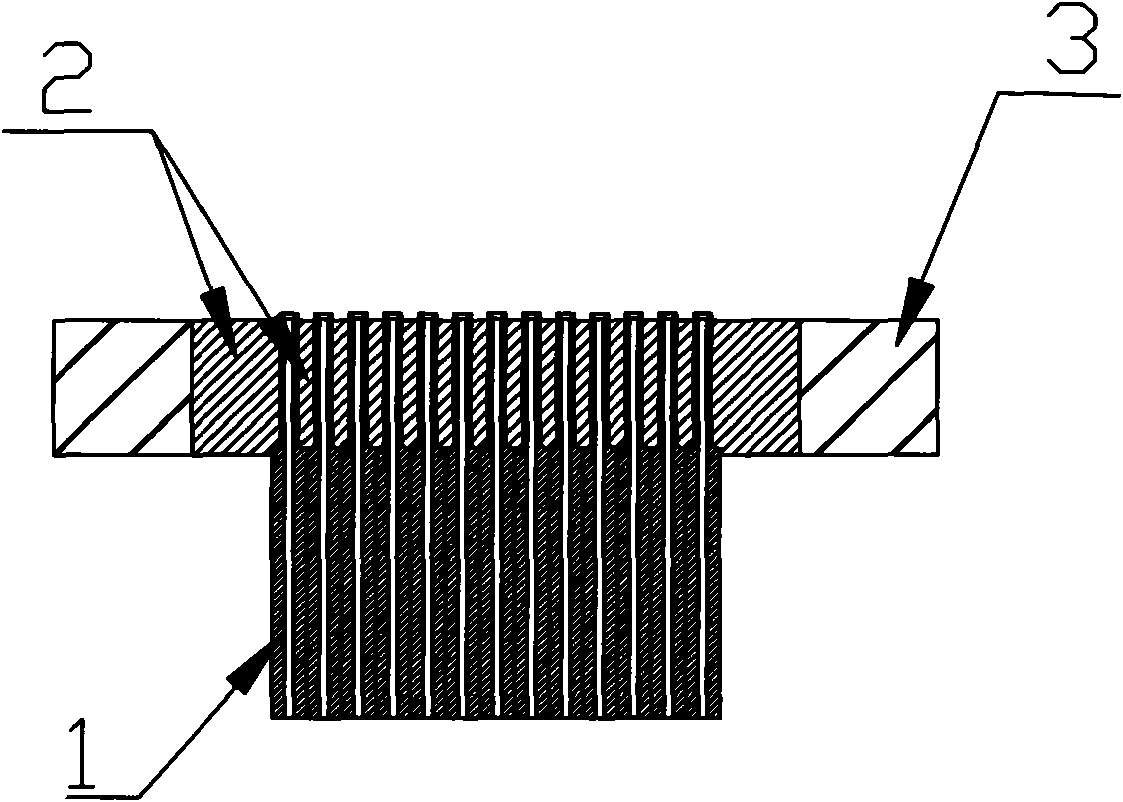

[0035] Such as figure 1 As shown, a multi-core optical fiber ferrule body for hermetic packaging of optical switches includes 13×13 optical fiber ferrules 1; the optical fiber ferrules are tubular, and the optical fiber ferrules are closely arranged in a The axes of the cores are parallel to each other; adjacent fiber ferrules are sealed with glass 2 to achieve fixed connection and sealing. The radial periphery of the optical fiber ferrule body can also be provided with a metal frame 3, and the metal frame 3 and the adjacent optical fiber ferrule 1 are sealed with glass 2 to achieve fixed connection and sealing, such as figure 2 shown. The outer shape of the metal frame 3 can be almost all geometric shapes such as rectangle, circle, ellipse or rhombus. The metal frame can be made of stainless steel, such as SS446 alloy.

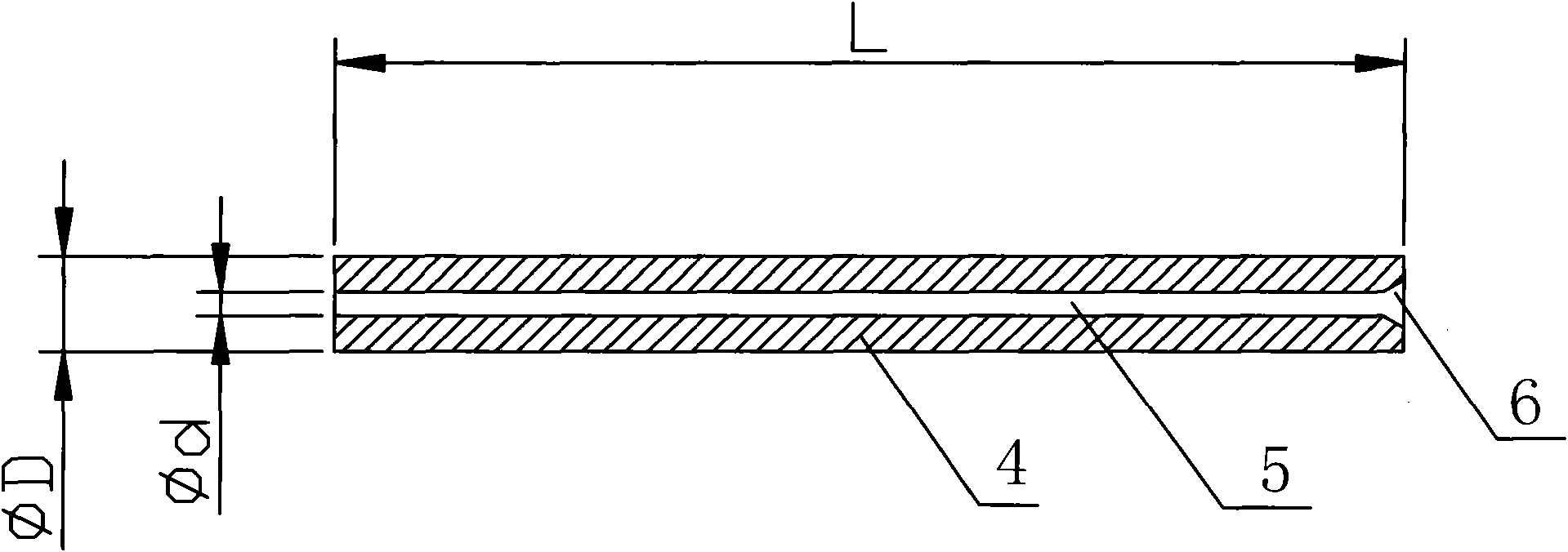

[0036] Such as image 3 As shown, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com