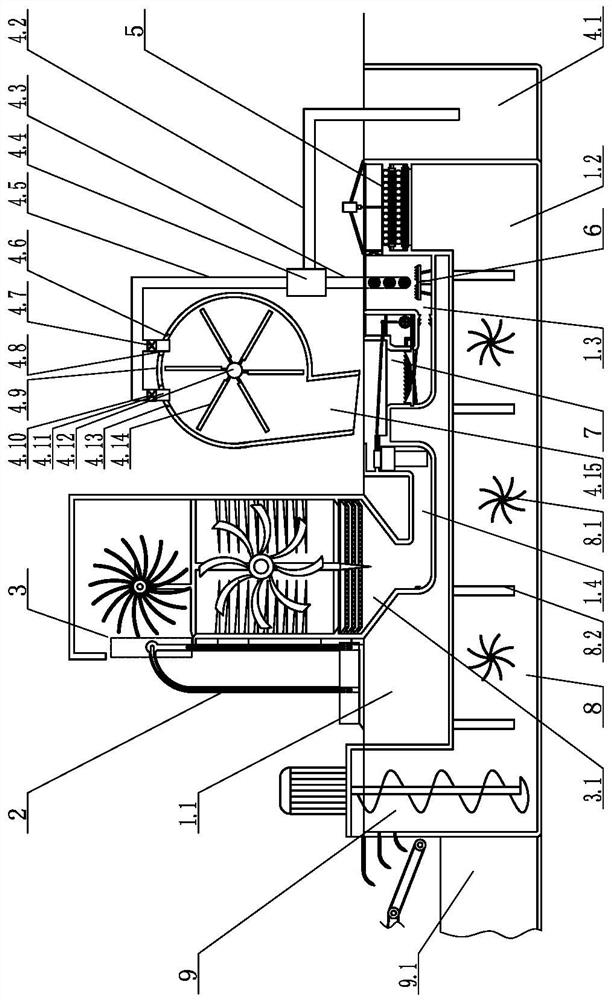

Full-automatic papermaking production equipment

A production equipment, fully automatic technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve problems such as high prices, unguaranteed paper quality, and inability to fully adapt to the production environment, reducing labor intensity and improving quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

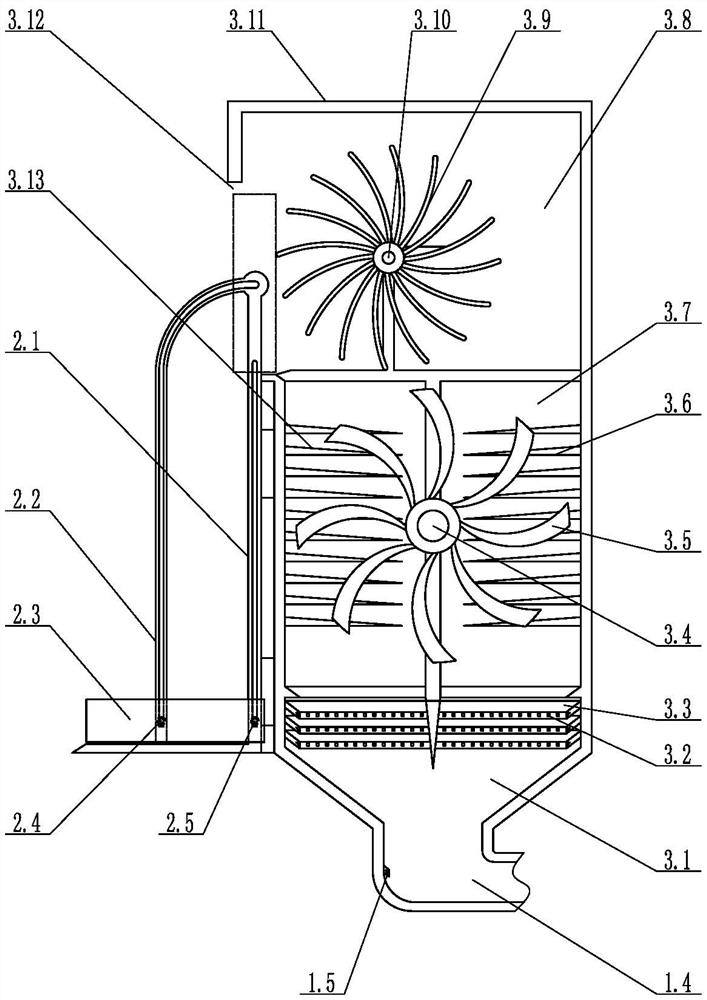

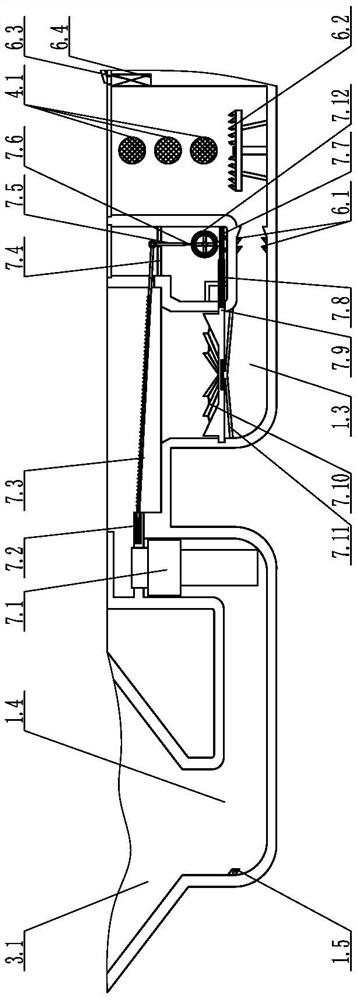

[0069] like figure 1 and 5 As shown, the present invention also includes a slurry flow device. The slurry flow device is arranged in the right end standpipe of the fine slurry channel; the slurry flow device includes a flow slurry stirring motor, and the motor shaft of the flow slurry stirring motor is connected to a lifting agitating channel, and the lifting agitating channel is vertically arranged In the standpipe at the right end of the fine slurry channel; on the left side wall of the standpipe at the right end of the fine slurry channel, the first flow bar hole, the second flow bar hole and the third flow bar hole are sequentially opened from top to bottom. The first flow slurry guide tube, the second flow slurry guide tube and the third flow slurry guide tube are installed in the right order of the first flow slurry bar hole, the second flow slurry bar hole and the third flow slurry bar hole; The slurry guide pipe, the second slurry guide tube and the third slurry guid...

Embodiment 3

[0074] In this embodiment, the first water source is a clean tap water source.

[0075] The second water source is a water source that is reused after filtration of recycled water in the papermaking process; the recycled water in the papermaking process includes filtered water after pulp washing and drained water from the papermaking net blanket. like figure 1 As shown, the draining water of the papermaking net blanket is temporarily stored in the draining recovery tank, and the draining outlet is opened in the draining recovery tank, and the water inlet end of the draining outlet pipe is installed at the draining outlet, and the draining outlet pipe is connected to the water spray pipe through the draining outlet pump. The water inlet, the water inlet of the power outlet pipe and / or the water inlet of the pulp wash flush pipe.

[0076] The filtered water after pulp washing is transported to the top of the vibrating sieve through the pulp washing and filtering water recycling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com