Full automatic welding machine for arc finned tubes

A finned tube, fully automatic technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsatisfactory welding quality and production efficiency, not compact enough structure, weak welding, etc., and achieve structural Compactness, improved welding efficiency, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

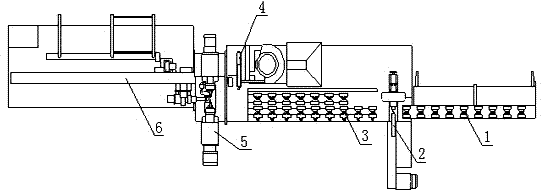

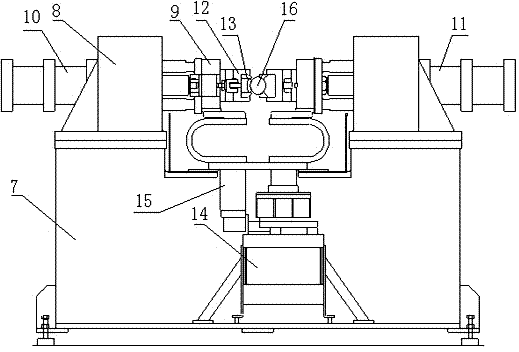

[0019] refer to Figure 1-Figure 2 , the arc fin tube automatic welding machine of the present embodiment, it comprises fin tube automatic feeding mechanism 1, automatic grinding tube mechanism 2, fin tube automatic turning mechanism 3, fin automatic feeding mechanism 4 and fin tube Automatic straightening mechanism 6, which also includes fin automatic welding mechanism 5, fin automatic welding mechanism 5 includes base 7, two pneumatic propulsion devices 8 symmetrically installed on the base 7, two pneumatic propulsion devices 8 symmetrically installed A welding head 9, a clamping device 13 symmetrically installed on the welding head 9, a welding cylinder 10 and a top-tightening cylinder 11 symmetrically installed on the pneumatic propulsion device 8.

[0020] The automatic fin welding mechanism 5 also includes a welding power source 14 installed on the base 7 , a conductor 15 connected to the welding power source 14 , and an electrode 12 connected to the conductor 15 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com