Flue gas oxidation garbage pyrolysis device with feeding function

A flue gas and garbage technology, applied in the field of flue gas oxidation garbage pyrolysis device, can solve the problems of energy waste, hinder the effect of garbage pyrolysis treatment, unfavorable enterprise development, etc., and achieve the effect of avoiding accumulation into blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

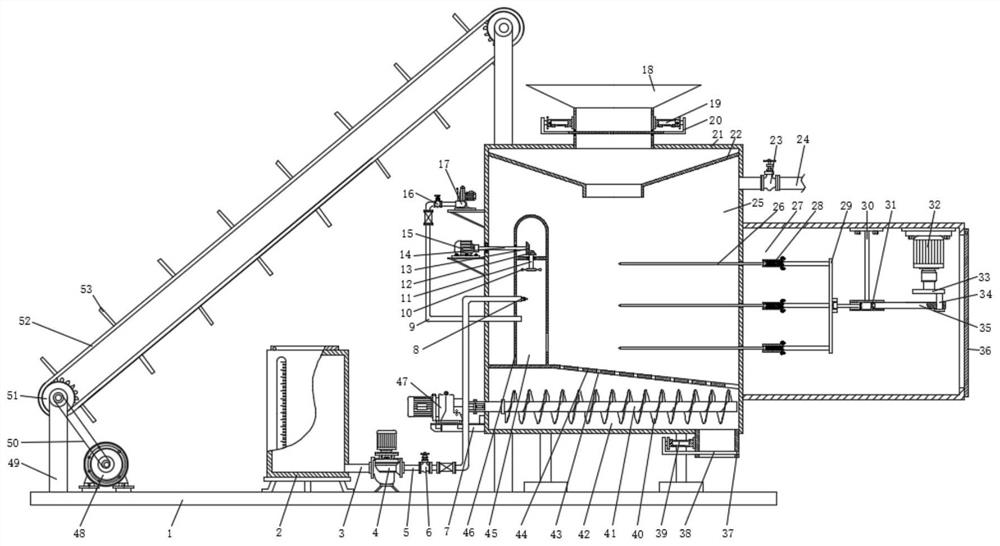

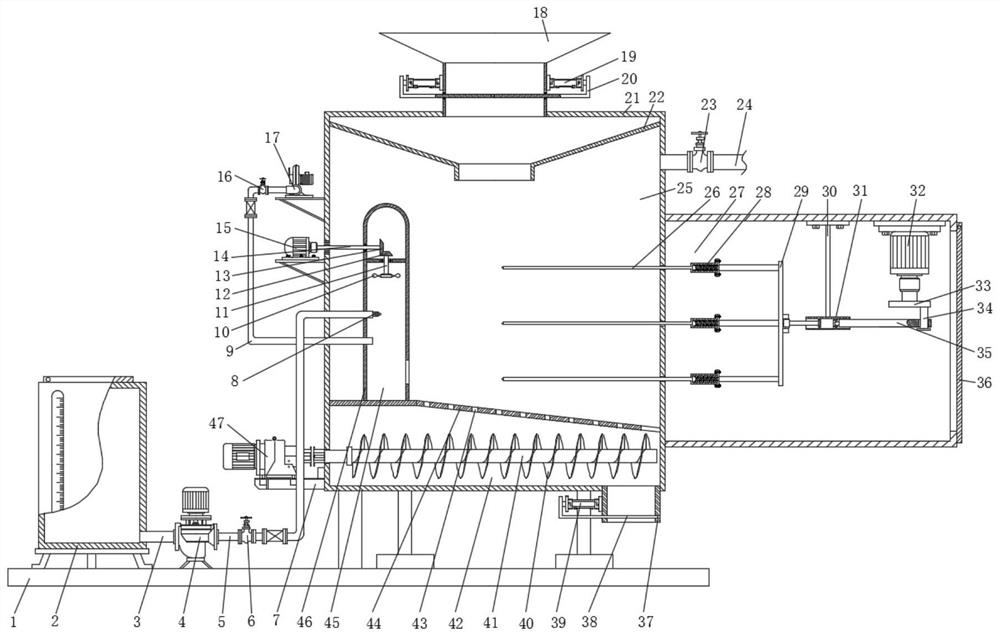

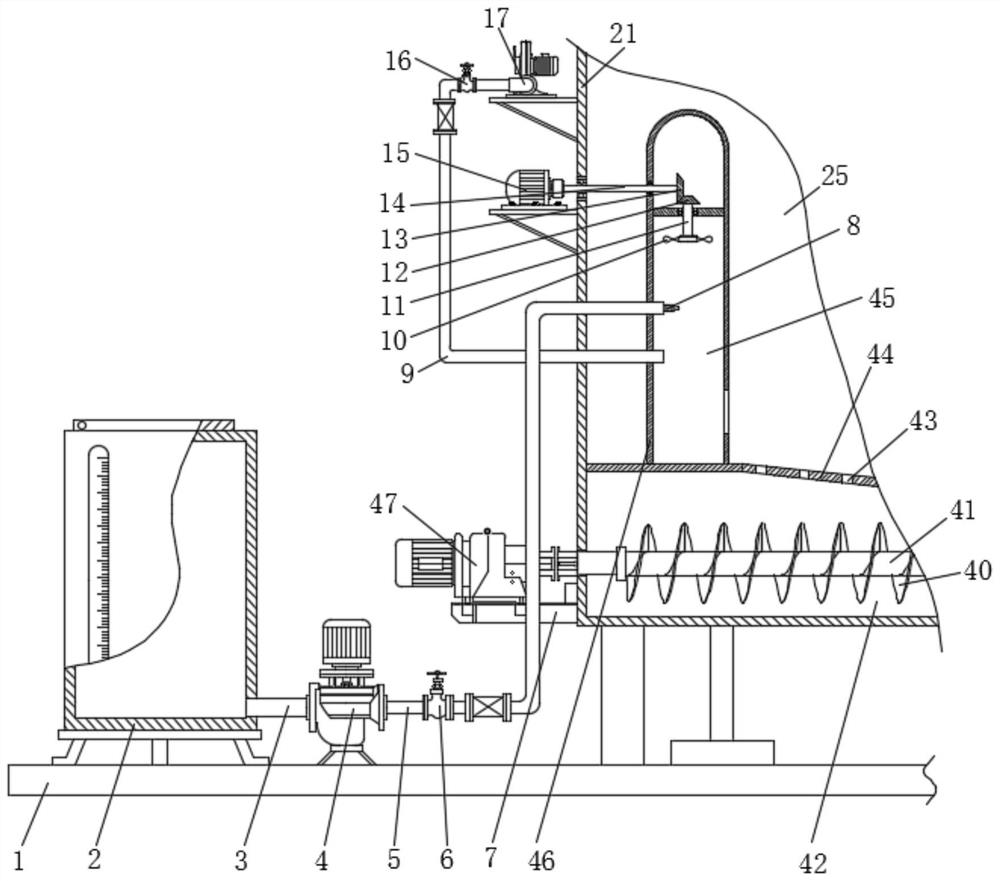

[0026] In order to better understand the technical solution of the present invention, the present invention will be described in detail below with reference to the accompanying drawings, and the description of this section is merely exemplary and interpretative, and no limitation should be made to the scope of the invention. .

[0027] like Figure 1 - Figure 7As shown, the specific structure of the present invention is: a flue gas oxidation waste parent-like device having a feed function, including a bottom plate 1, a housing 21, a third shut-off valve 23, an exhaust gas discharge pipe 24, and a transport motor 48, exhaust gas The discharge tube 24 can be an external exhaust gas treatment device, the exhaust gas treatment device is a technique conventionally selected by those skilled in the art, and the present invention is not in this portion, so this does not mean that the interior space of the housing 21 includes a waste heat release chamber 25, a transmission chamber 27, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com