Continuous melting metal electroplating equipment

A molten metal and metal plating technology, applied in metal material coating process, hot dip plating process, device for coating liquid on the surface, etc., can solve the problem of large installation space, long plate temperature holding chamber, and poor response of strip steel plate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described below with reference to the drawings.

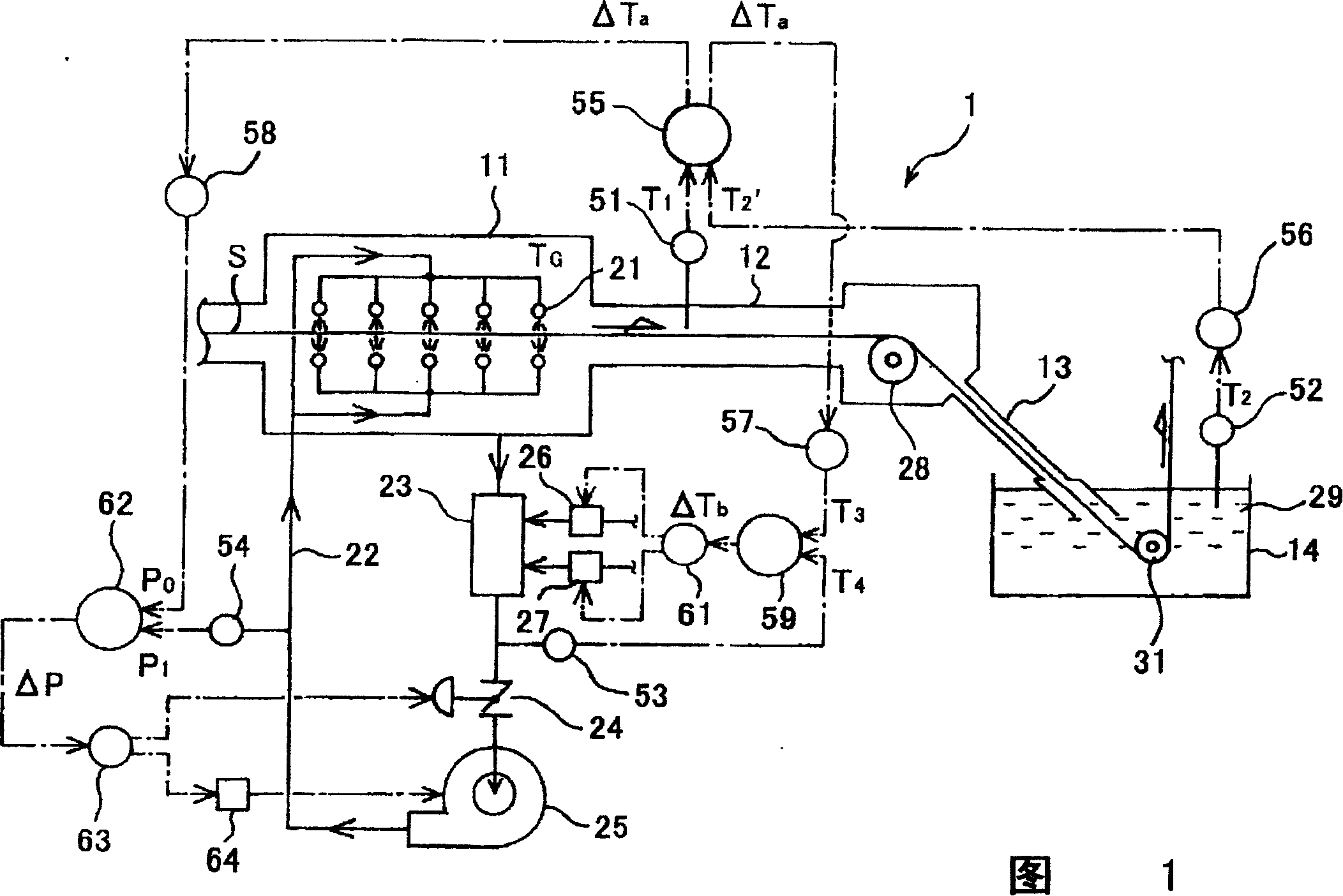

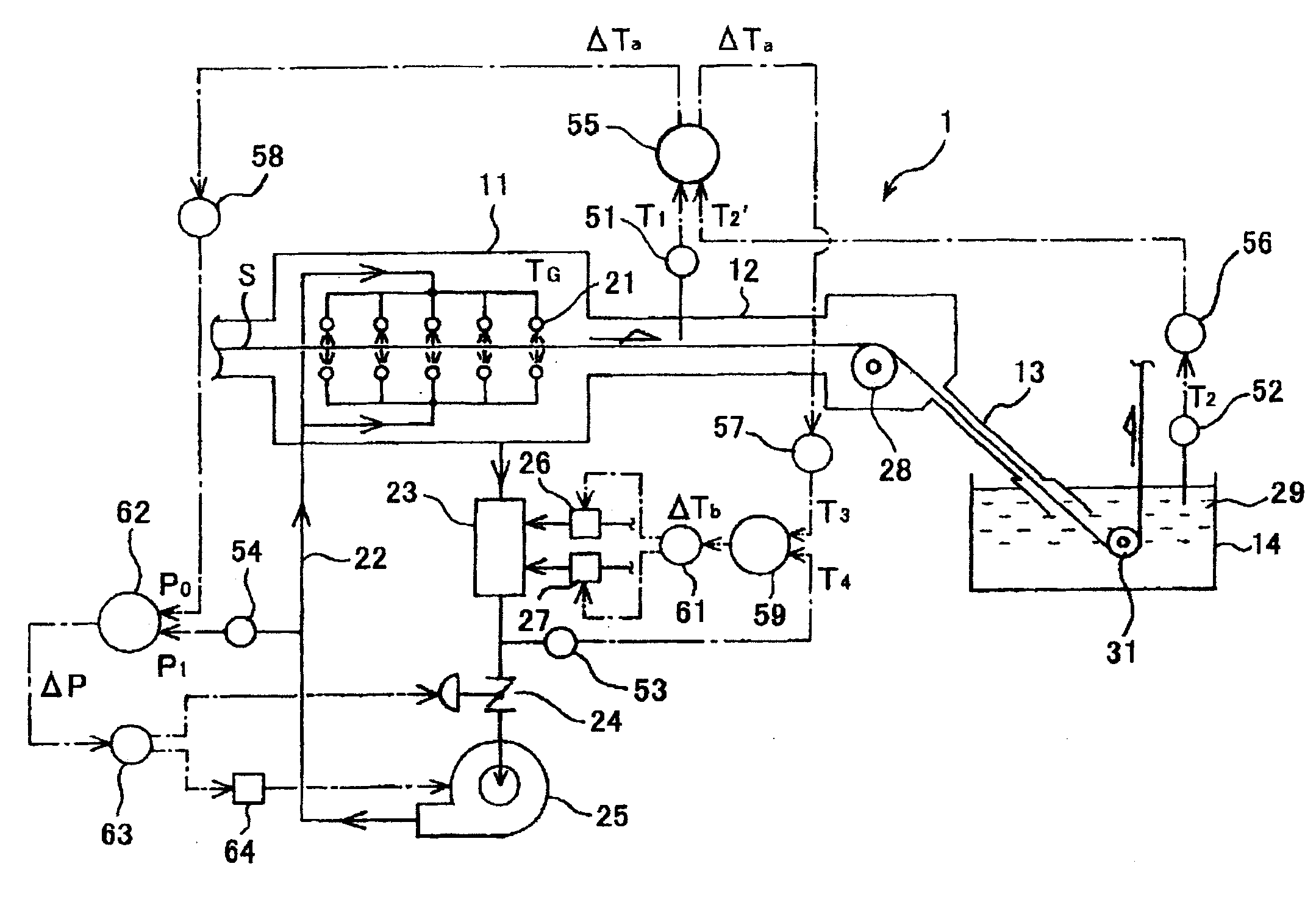

[0011] Fig. 1 shows the continuous molten metal plating equipment 1 of the present invention, and this continuous molten metal coating equipment 1 is for example arranged behind the heating zone of the annealing furnace, the back of the cooling zone, has the strip-shaped steel plate S, such as cold-rolled steel plate to press continuously The plate temperature holding chamber 11 , the plating solution tank introduction space 12 , the mouth 13 (snaut) and the plating solution tank 14 pass sequentially.

[0012] In the inside of the plate temperature maintaining chamber 11, a plurality of nozzles 21 arranged laterally at intervals are arranged in two rows opposite to each other at intervals above and below the steel plate S in the form of spraying gas to the strip-shaped steel plate S. The gas is forced to convect in the chamber 11 . In addition, the gas circulation channel 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com