Cam-type sealing machine for cylindrical batteries

A cylindrical battery and sealing machine technology, which is used in the manufacture of primary batteries, secondary batteries, circuits, etc., can solve the problems of excessively fast bending deformation of the sealing, easy burrs at the sealing, and increased gas consumption, and achieves easy operation and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

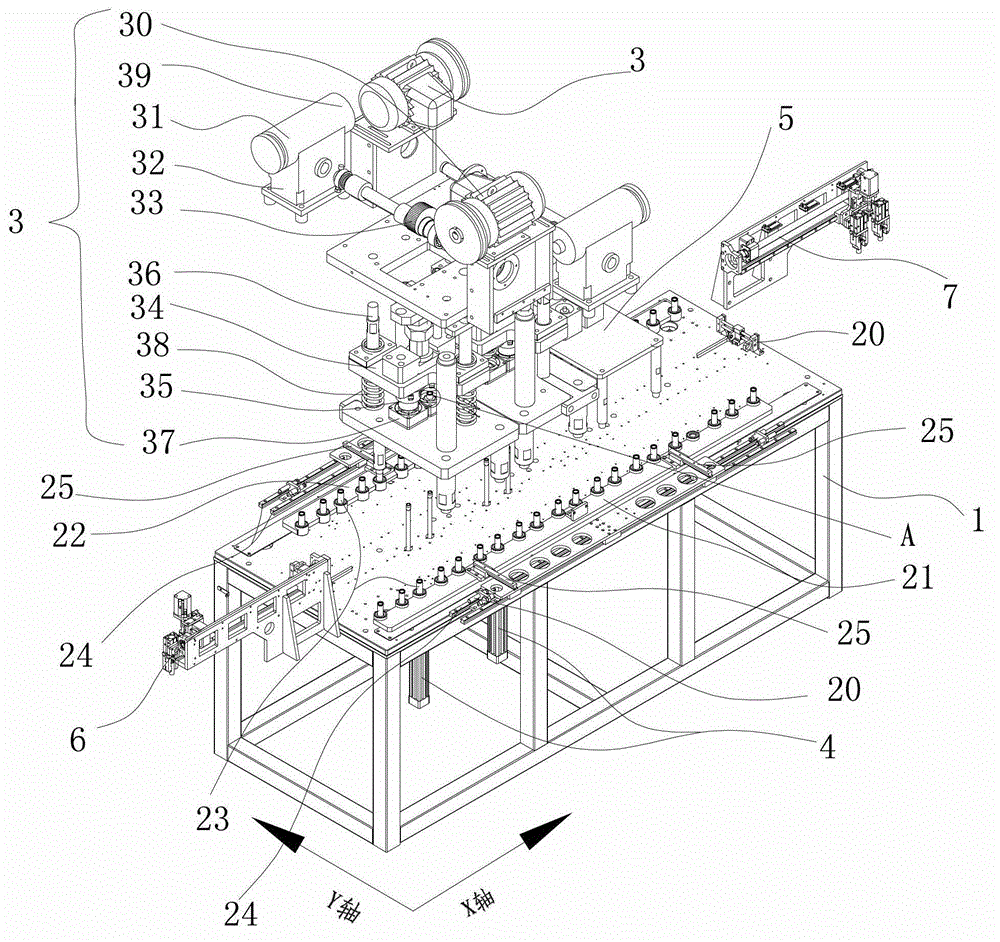

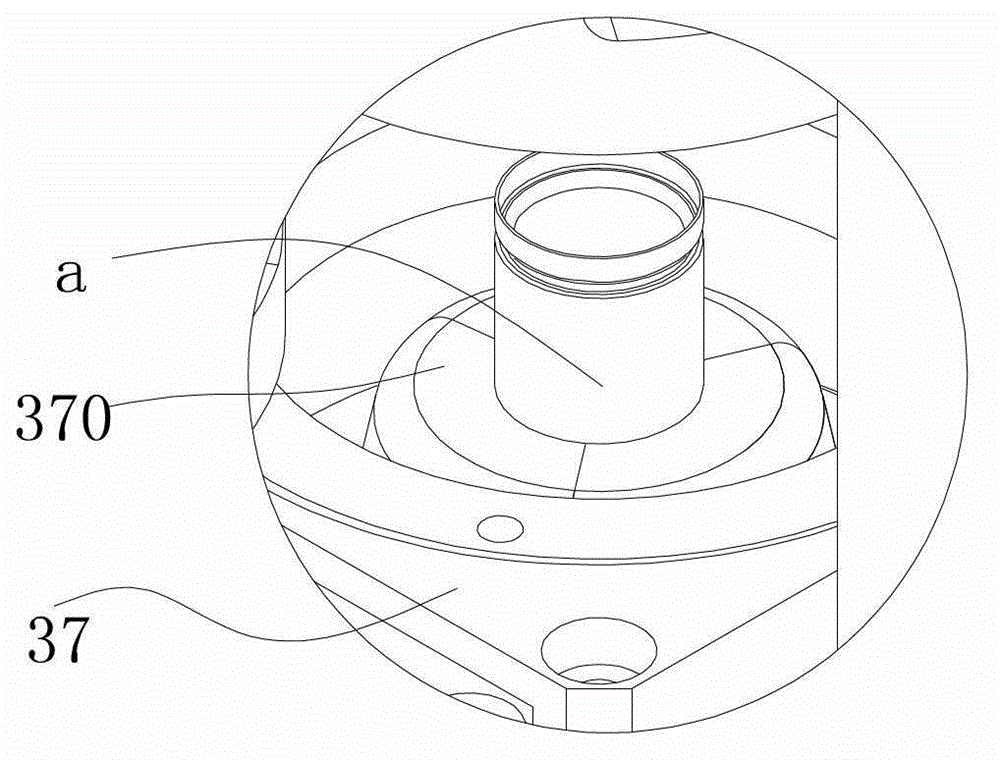

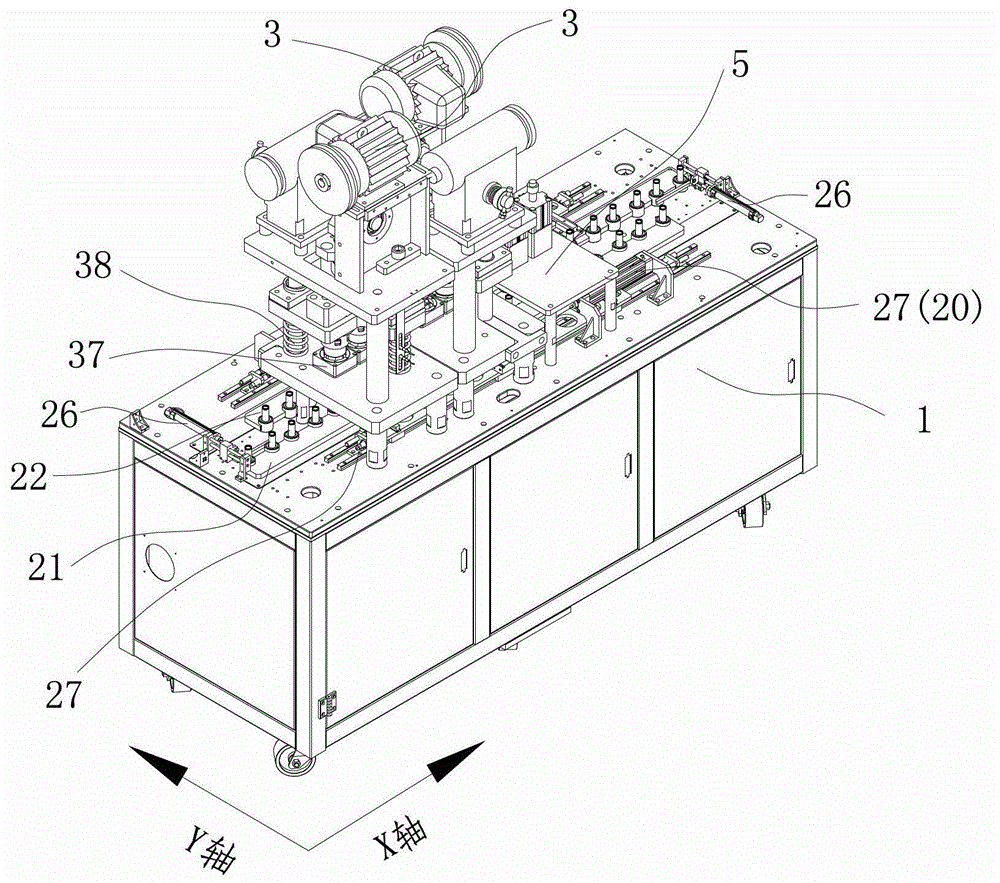

[0025] A cam type cylindrical battery sealing machine, such as Figure 1 to Figure 6 As shown, it includes a machine base 1, a rail transfer device 2 and two sets of sealing die devices 3, the linear transfer track of the rail transfer device 2 is arranged on the platform of the machine base 1, and two sets of sealing die devices 3 are sequentially arranged along the transfer rails; The track transfer device 2 includes a transfer drive device 20 and a pair of front and rear transfer grippers (21, 22) symmetrically arranged along both sides of the transfer track, and the butt joints of the pair of front and rear transfer grippers (21, 22) are respectively spaced and misaligned. A plurality of clamping columns 23 for laterally shifting the cylindrical batteries (not shown) are provided, and the platform of the machine base 1 is respectively provided with clamps for forward and backward transfer and laterally reciprocating displacement of the clamping plates (21, 22). Horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com