Preparation method of double-modified SnO<2>@C/graphene nano composite anode material

A nano-composite, double-modified technology, applied in the field of preparation of negative electrode materials, can solve the problems of poor cycle performance and lithium storage, and achieve the effects of high dispersion, good uniformity and dispersion, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

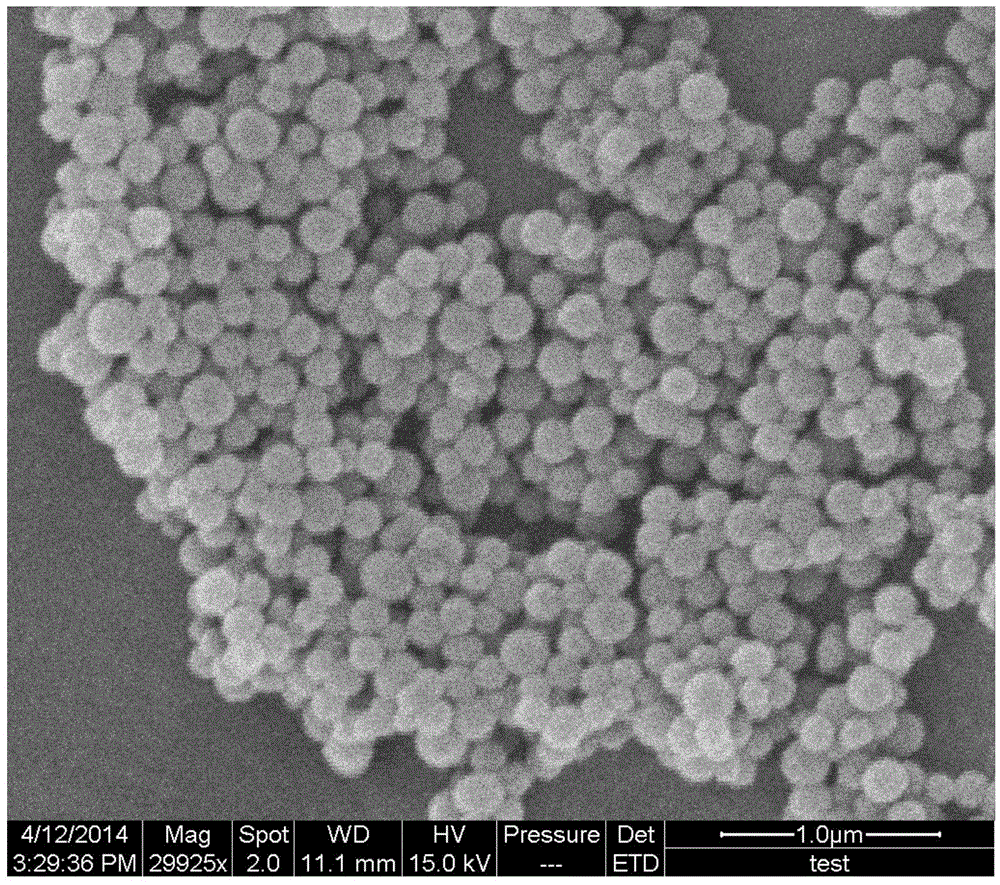

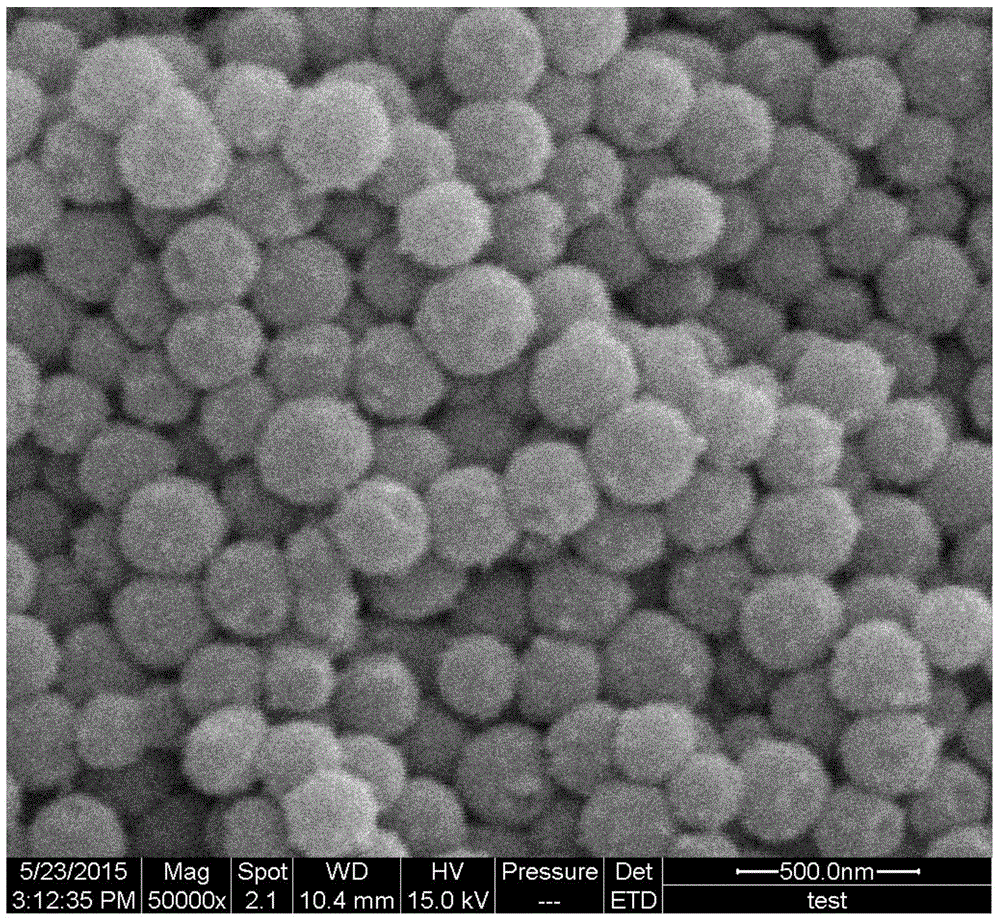

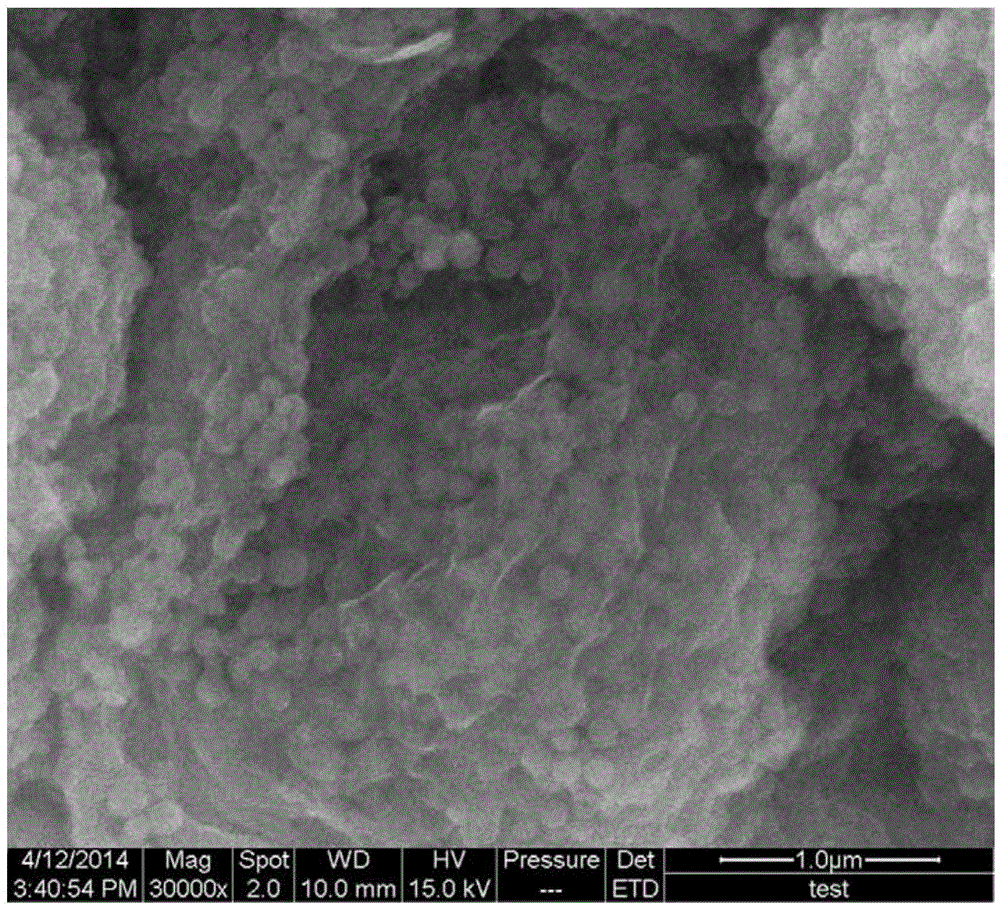

[0028] Specific embodiment 1: This embodiment is a double modified SnO 2 The preparation method of C / graphene nanocomposite negative electrode material is specifically completed in the following steps:

[0029] 1. Preparation of nano-carbon spheres: put the glucose powder into deionized water, and stir it magnetically for 10 minutes to obtain an aqueous glucose solution; pour the glucose solution into a polytetrafluoroethylene reactor in a microwave reactor and seal it, at a temperature of 120- React at 200°C and a pressure of 10bar to 30bar for 0.5h to 3h, centrifuge to obtain a solid product, and wash the solid product with centrifugal water until the filtrate is clear after washing to obtain a washed solid product. Vacuum drying at a temperature of 80°C for 8 hours, and then grinding to obtain nano-carbon sphere powder;

[0030] The mass of the glucose powder described in step 1 and the volume ratio of deionized water are (2~8) g:30mL;

[0031] 2. Two-step method to prepa...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of the glucose powder described in step 1 to deionized water is 4g:30mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: in step 1, react at a temperature of 180° C. and a pressure of 10 bar to 30 bar for 0.5 h to 3 h, and centrifuge to obtain a solid phase product. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com