Full-automatic quantitative glue dispensing mechanism

A dispensing mechanism and fully automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of affecting the yield, high labor intensity, large operation error, etc., and achieve accurate dispensing position and firm fixation , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

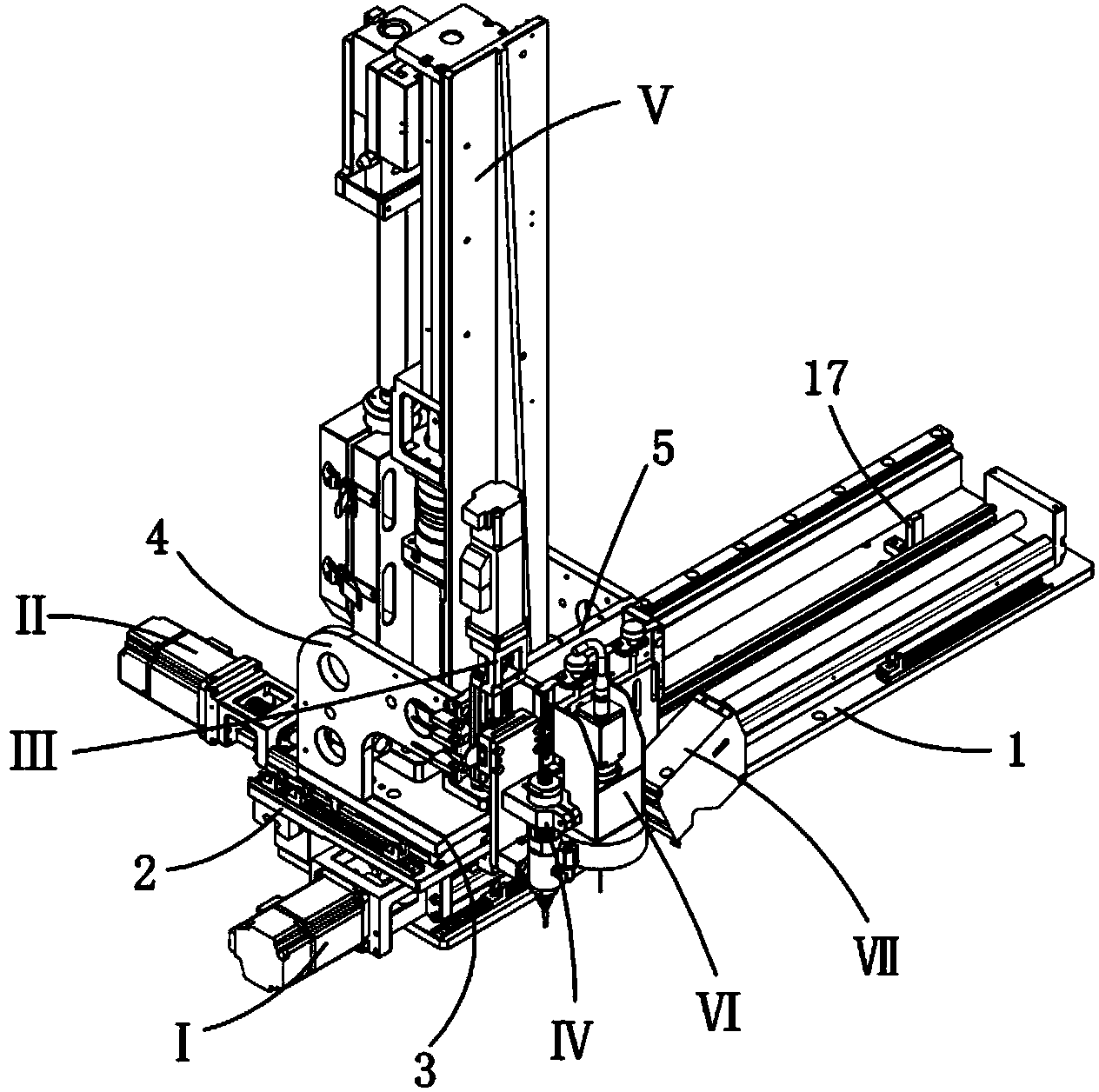

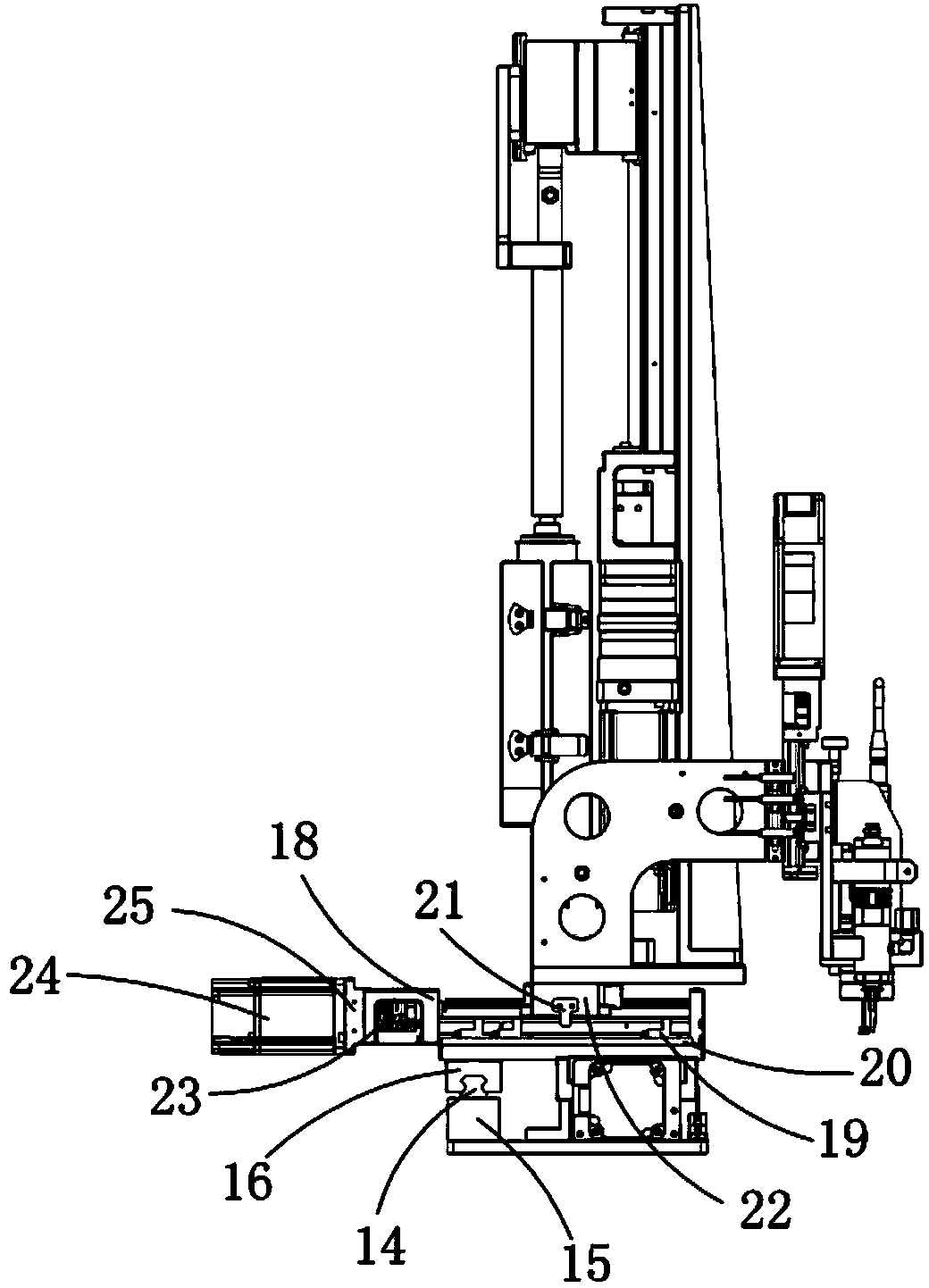

[0031] Examples, see attached Figure 1-9 , a fully automatic quantitative dispensing mechanism, which includes a base plate 1, an X-axis mechanism I, a Y-axis mechanism II, a Z-axis mechanism III, an XY connecting plate 2, a mounting plate 3, a Z-axis mounting connecting plate 4 and a Z-axis mounting plate 5. The X-axis mechanism is installed on the bottom plate; the Y-axis mechanism is installed on the X-axis mechanism through the XY connection plate; the installation plate is installed on the Y-axis mechanism; the Z-axis installation connection plate has two pieces, They are respectively installed vertically on both sides of the mounting plate; the Z-axis mounting plate is mounted on two Z-axis mounting connecting plates.

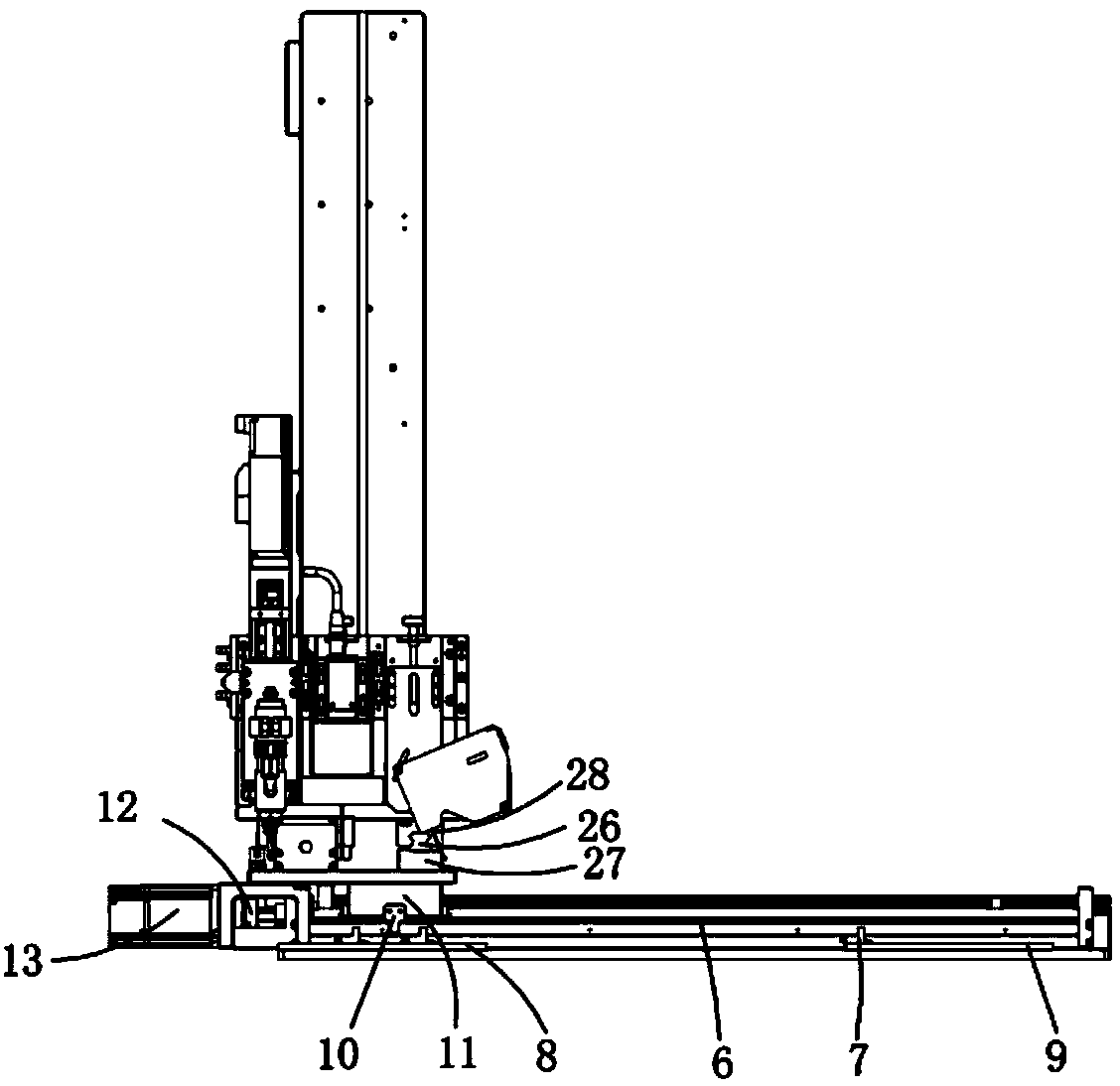

[0032] The X-axis mechanism includes an X-axis linear module 6, an X-axis photoelectric sensor 7, an X-axis mounting bar a8, an X-axis mounting bar b9, an X-axis sensing piece 10, an X-axis connecting block 11, an X-axis coupling 12, X-axis motor 13, X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com