An automatic dispensing machine

A dispensing machine, automatic technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of high labor intensity, affecting the yield, large error, etc. Improve production efficiency and improve the effect of dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

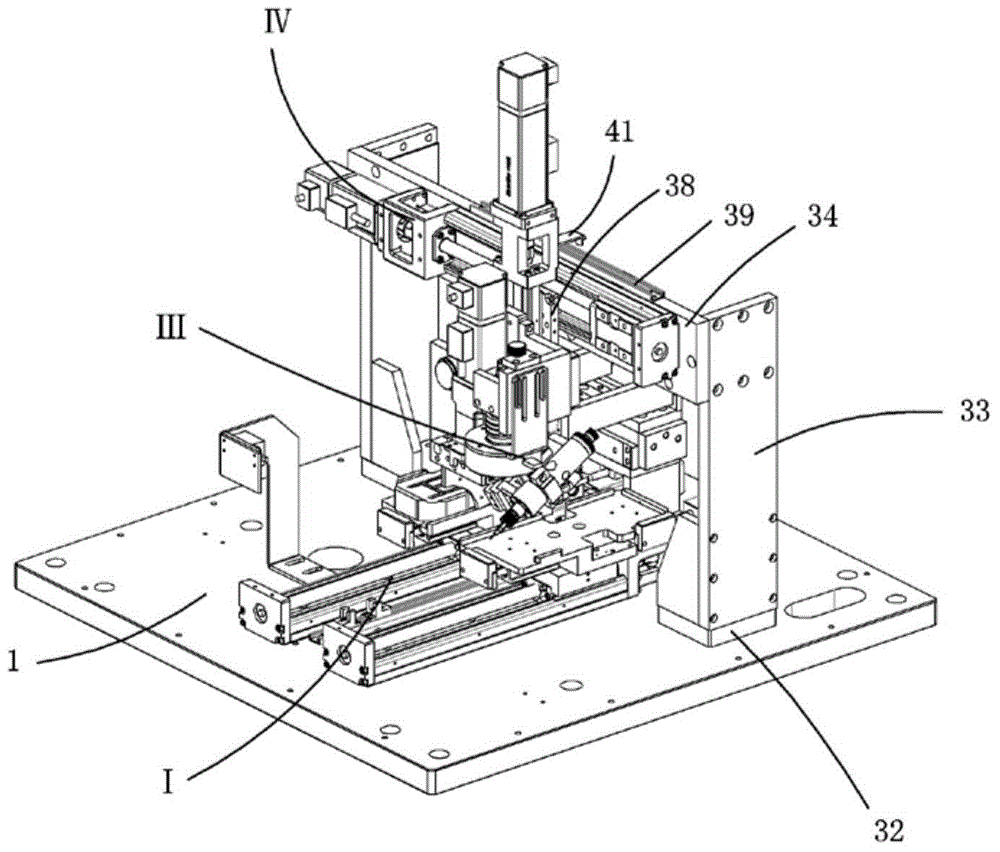

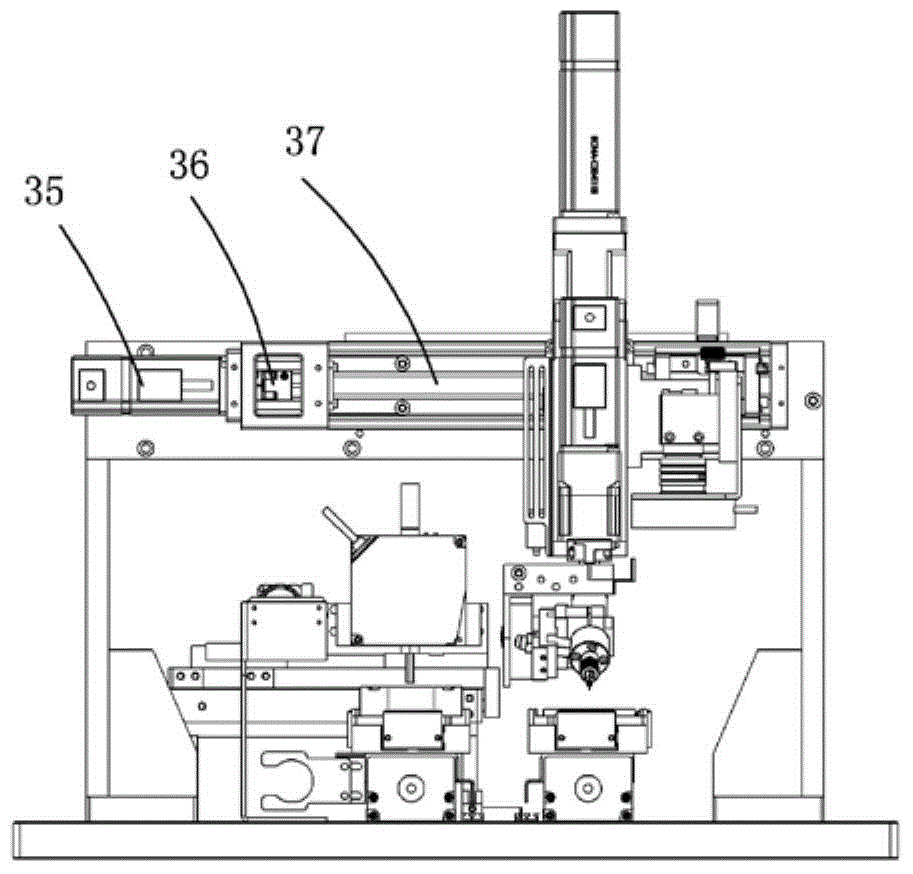

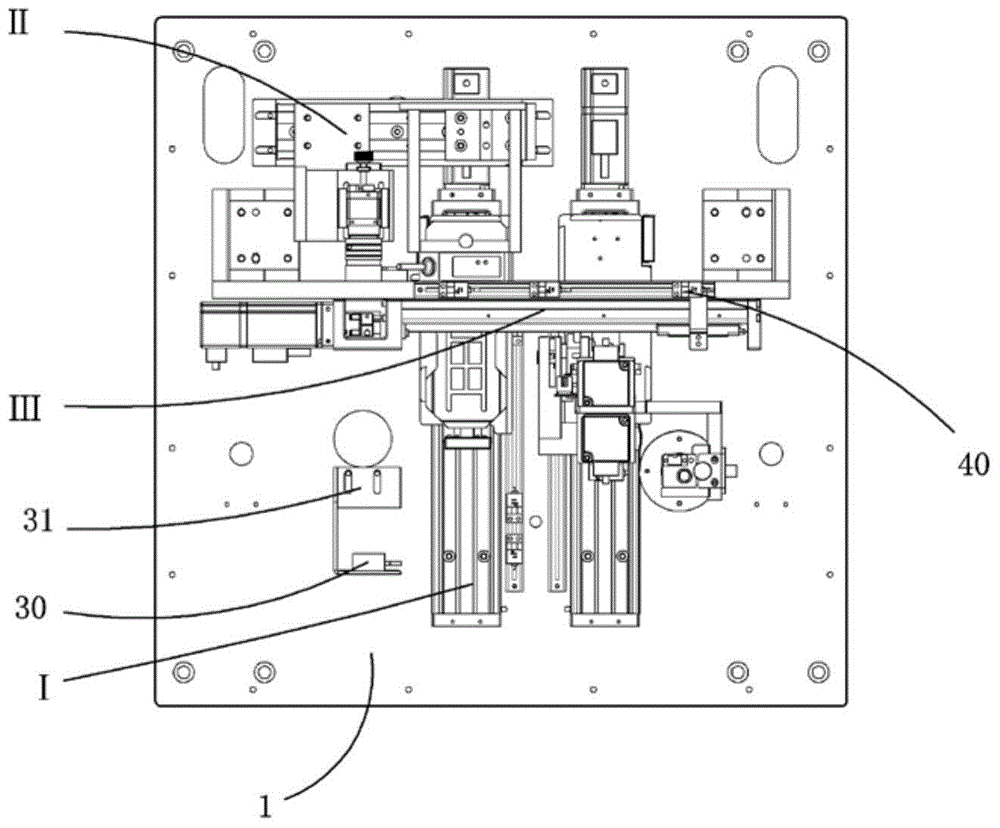

[0038] example, see attached Figures 1 to 11 , an automatic glue dispensing machine, which includes a base plate 1, a carrier transport mechanism I, a calibration mechanism II and a glue dispensing mechanism III, the carrier transport mechanism has two groups, which are respectively installed on the bottom plate; the calibration mechanism and the point The glue mechanism is respectively installed on the base plate, and the calibration mechanism is located below the glue dispensing mechanism.

[0039] The carrier transport mechanism includes a motor 2, a motor fixing seat 3, a coupling 4, a linear module 5, a linear module slider 6, a carrier mounting plate 7, a carrier 8, a mounting bar 9, a photoelectric sensor 10 and Induction sheet 11, the motor holder, the linear module and the mounting strip are respectively fixed on the bottom plate, and the linear module and the installation strip are installed in parallel; the motor is fixed on the motor holder, and the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com