Display screen module attaching and assembling assembly line

A technology for assembly lines and display modules, applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve problems such as position deviation of dispensing, loose assembly of display modules, dripping, etc., to achieve The effect of accurate dispensing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

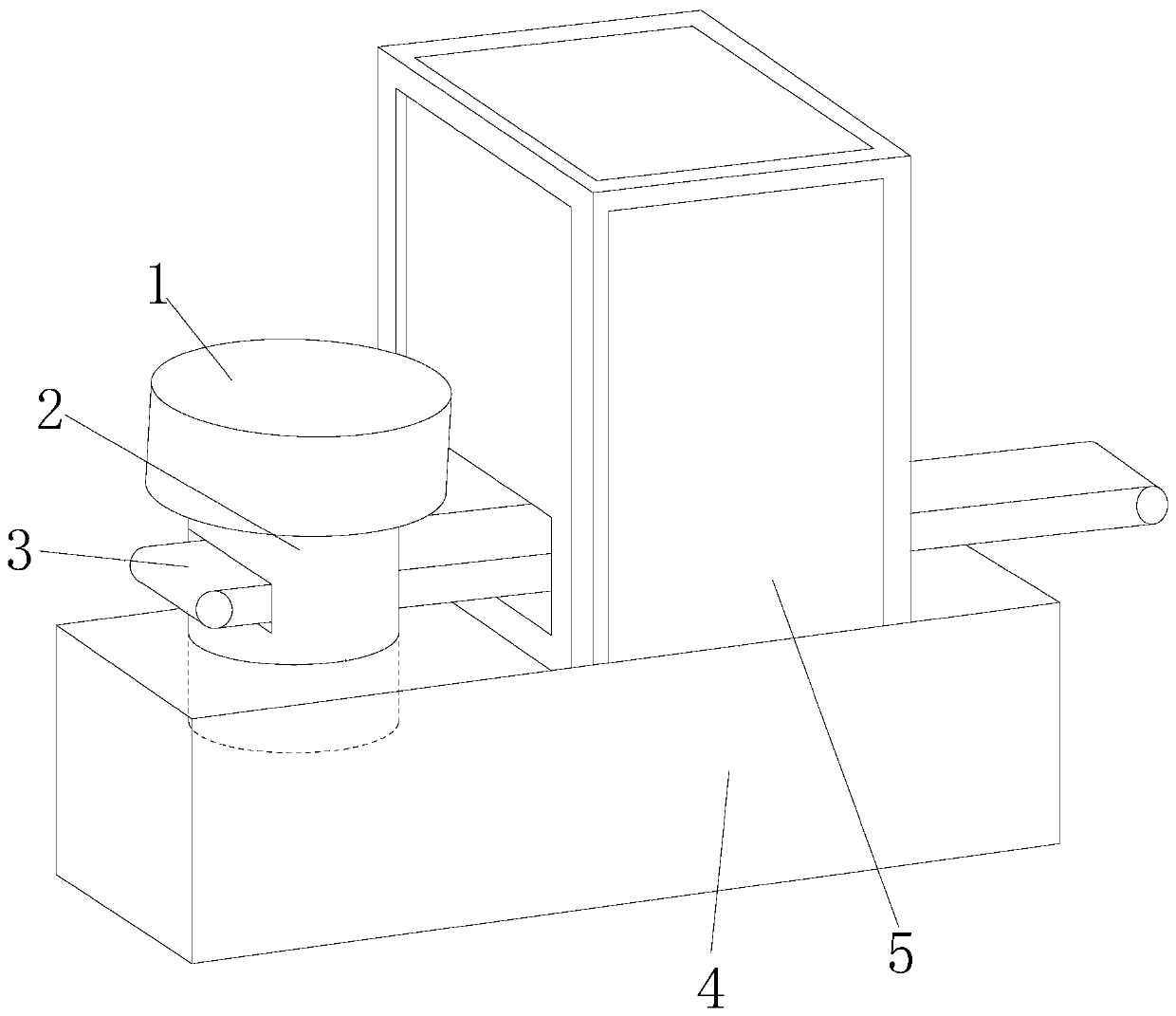

[0024] see Figure 1-Figure 6 , the present invention provides a display module bonding assembly line, the structure of which includes a fixed block 1, a cutting device 2, a conveyor belt 3, a fixed base 4, and an assembly cavity 5, the fixed block 1 is installed on the fixed base 4, the An assembly cavity 5 is provided on the fixed base 4, and the assembly cavity 5 is penetrated by the conveyor belt 3, and the conveyor belt 3 cooperates with the cutting device 2, and the cutting device 2 is installed in the fixed block 1;

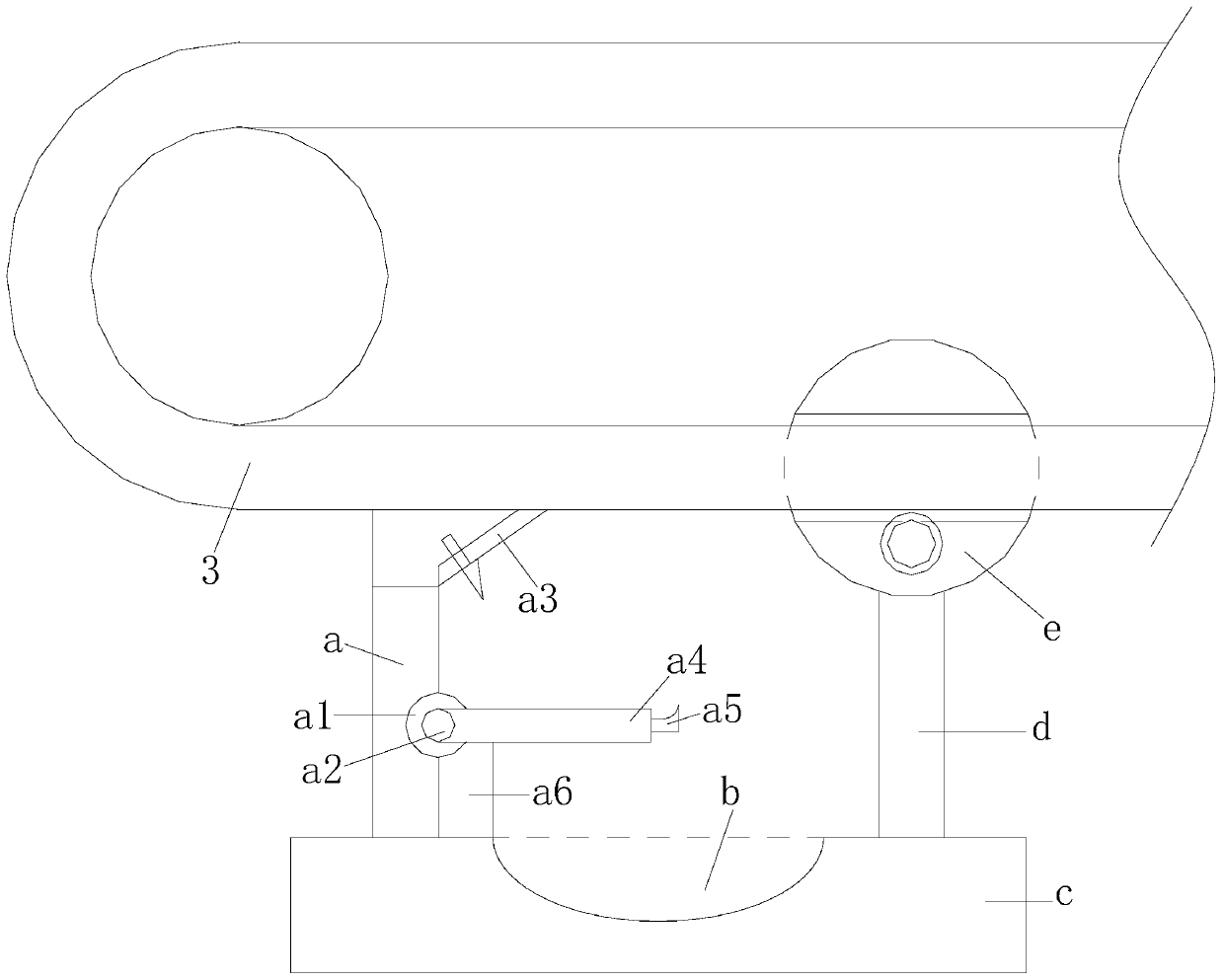

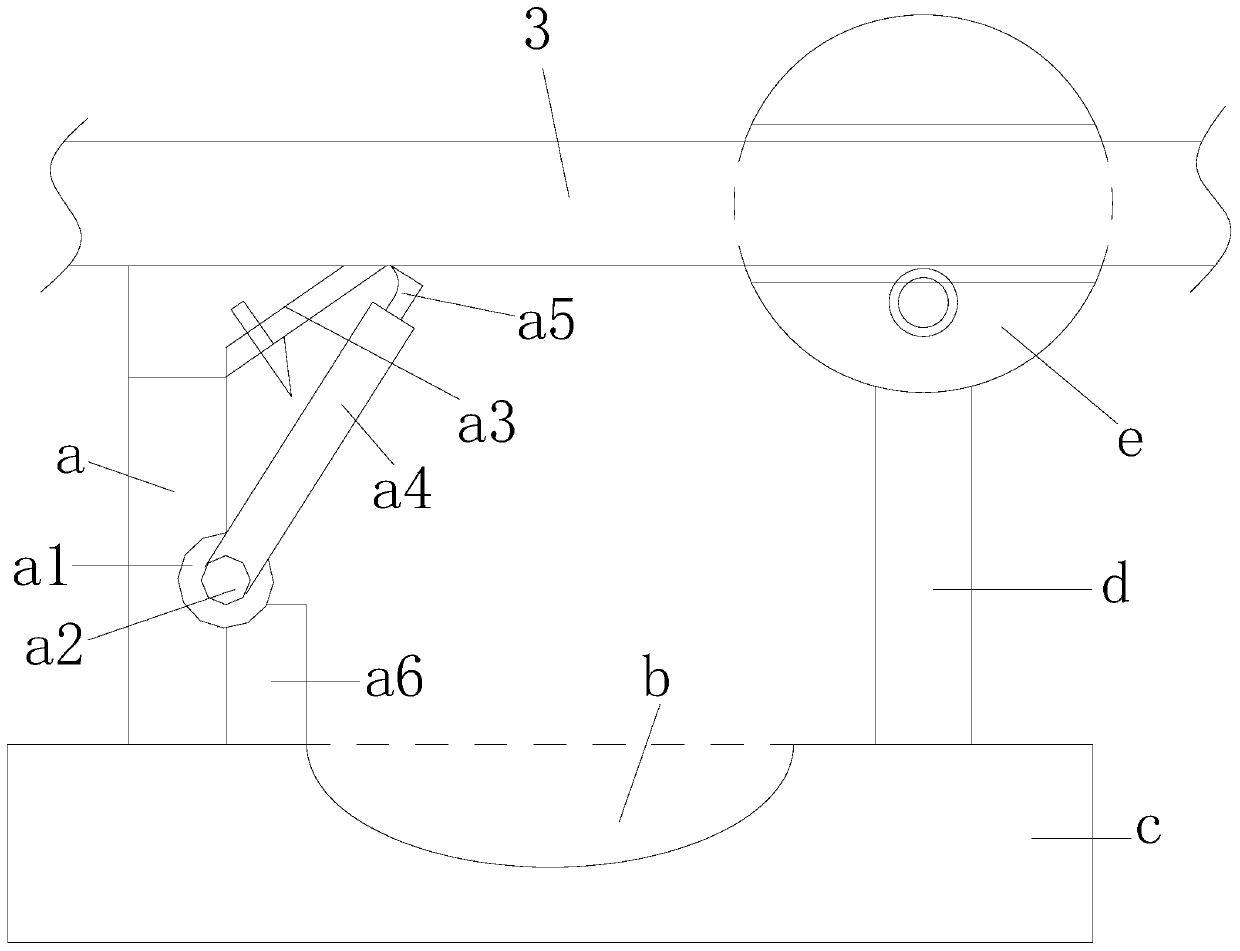

[0025] The cutting device 2 is composed of No. 1 column a, slag collection tank b, fixed seat c, No. 2 column d, and cleaning ball e. The No. 1 column a and No. 2 column d are set up in a symmetrical structure. The column a and the No. 2 column d are both fixed on the fixed seat c, and the fixed seat c is provided with a slag collection tank b, and the slag collection tank b is set up in a downward concave shape, and the slag collection tank b is embedded ...

Embodiment 2

[0032] see figure 1 , Figure 4-Figure 5 , the present invention provides a display module bonding assembly line, the structure of which includes a fixed block 1, a cutting device 2, a conveyor belt 3, a fixed base 4, and an assembly cavity 5, the fixed block 1 is installed on the fixed base 4, the The fixed base 4 is provided with an assembly cavity 5, the assembly cavity 5 is penetrated by the conveyor belt 3, the conveyor belt 3 is matched with the cutting device 2, and the cutting device 2 is installed in the fixed block 1; the cutting device 2 is composed of The first column a, the slag collection tank b, the fixed seat c, the second column d, and the cleaning ball e are composed of the first column a and the second column d in a symmetrical structure, and the first column a and the second column d are all fixed on the fixed seat c, the fixed seat c is provided with a slag collection tank b, the slag collection tank b is set up in a downward concave shape, and the slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com