Low-temperature propellant storage tank with pressure control device

A low-temperature propellant and storage tank technology, applied in the direction of fixed-capacity gas storage tanks, pressure vessels, container discharge methods, etc., can solve the problems of low heat exchange efficiency, no consideration of exhaust cold energy utilization, heat exchange efficiency limitations, etc. , to achieve good heat transfer efficiency, good application value and promotion prospects, and good control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

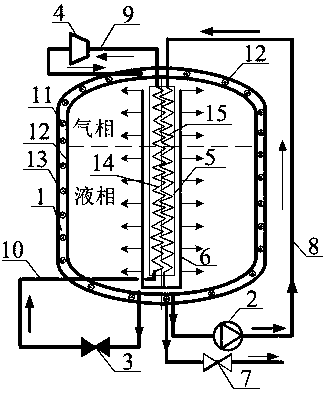

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] refer to figure 1 , the low-temperature propellant storage tank with a pressure control device proposed by the present invention, the low-temperature propellant storage tank body 1, the low-temperature circulation pump 2, the throttle valve 3, the expander 4, the counterflow casing heat exchanger 5, the exhaust Cooling coil 11 , fluid injection rod 6 and exhaust valve 7 , bulk fluid circulation circuit 8 , high-temperature gas exhaust circuit 9 , throttling refrigeration circuit 10 .

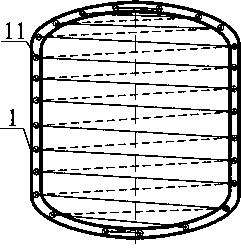

[0037] The low-temperature propellant storage tank 1 includes an inner tank 12 and an outer tank 13. The fluid in the tank is a low-temperature propellant, which is composed of a gas phase and a liquid phase, which can be liquid hydrogen, liquid oxygen or liquid methane. Insulation material is filled between the inner and outer tanks, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com