Natural gas high and low pressure integrated gas supply system for large dual-fuel power ship

A gas supply system and dual-fuel technology, which are applied in the fields of equipment loaded into pressure vessels, ship construction, ship propulsion, etc., to achieve the effects of high cost performance, simple maintenance and convenient start-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

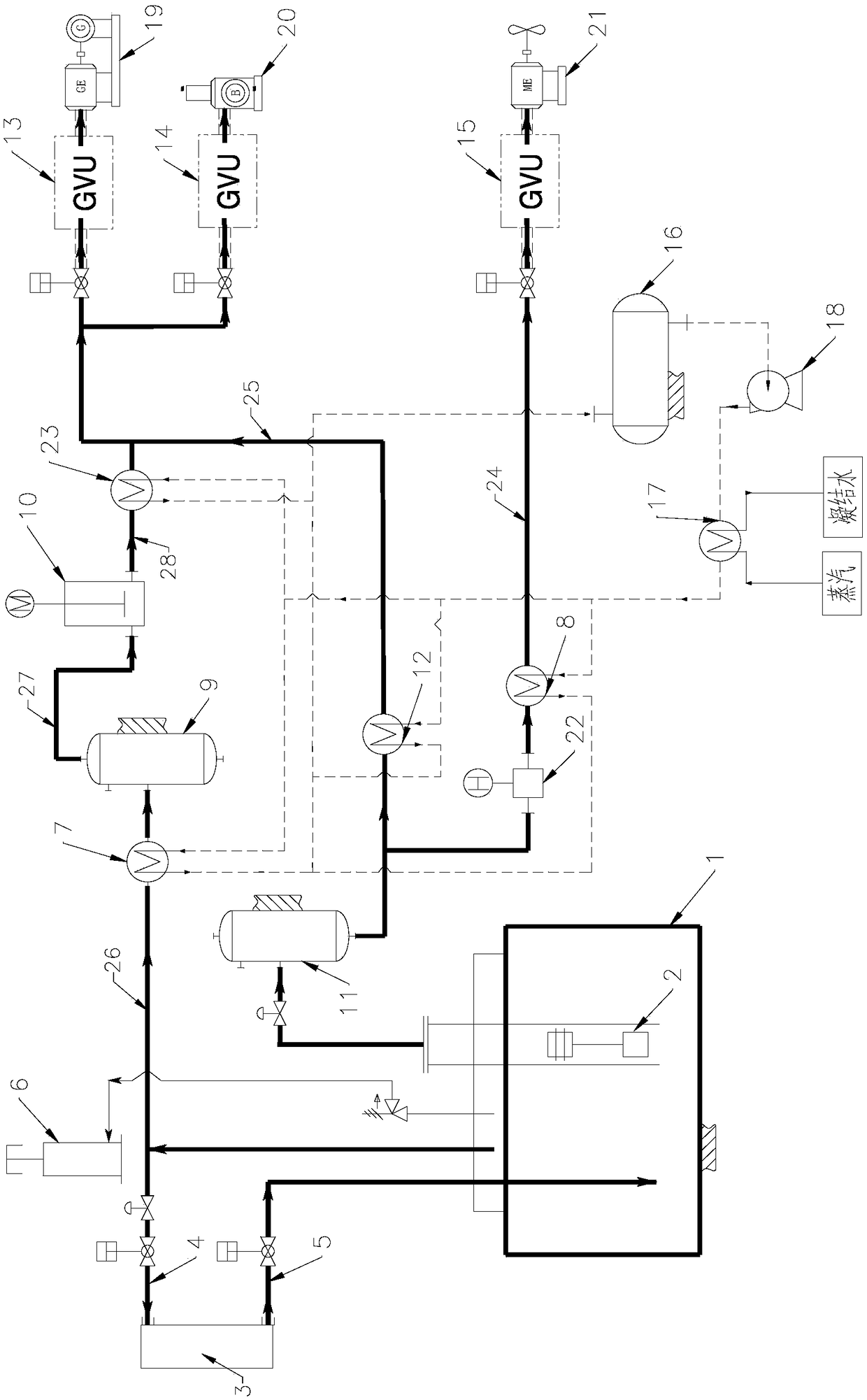

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] seefigure 1 , the natural gas high and low pressure integrated gas supply system of a large dual-fuel powered ship of the present invention is used to provide natural gas fuels of different pressures, temperatures and flows to the gas equipment on board; the gas equipment includes a ship host 21, a generator 20 and a boiler 19. The main engine 1 of the ship adopts the ME-GI engine of Mann Company, and the engine adopts low-speed two-stroke dual-fuel, the air supply pressure is about 300 bar, and the air supply temperature is 50°C; the generator 20 and the boiler 19 both use medium-speed four-stroke dual-fuel, The air supply pressure is about 6bar, and the air supply temperature is 50°C. Ship main engine 1, generator 20 and boiler 19 all can use marine fuel oil and LNG two kinds of fuels.

[0031] The natural gas high-low pressure integrated gas supply system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com