Preparation method for high-entropy alloy

A technology of high-entropy alloys and alloying elements, applied in the field of preparation of high-entropy alloys, can solve problems that have not been reported, and achieve the effects of avoiding pollution, high reliability, and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

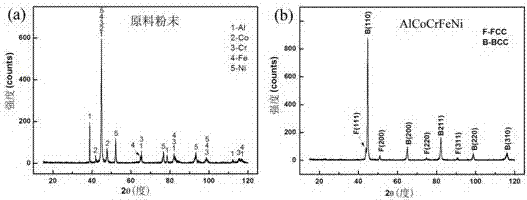

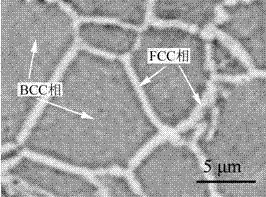

[0028]Adopt the method disclosed in the present invention to prepare high-entropy alloy AlCoCrFeNi, concrete steps are as follows:

[0029] (1) Measure pure Al powder, Co powder, Cr powder, Fe powder and Ni powder according to the converted mass percentage, the particle size of each powder should be less than 70 μm, and the purity should be greater than 99.5%;

[0030] (2) Put the powder into a polymer ball mill tank, put stainless steel balls into it, the ball-to-material ratio is 2:1, mix in a planetary ball mill, the speed of the ball mill is 150 r / min, and the powder has been mixed evenly after 4 hours of mixing , put the powder into the graphite mold after taking it out, and press it tightly;

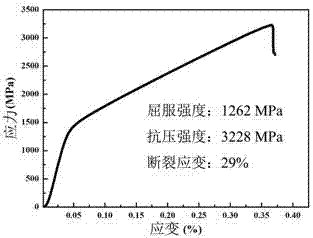

[0031] (3) Put the graphite mold filled with powder into the SPS sintering equipment for vacuum hot pressing sintering. The pulse cycle of the SPS equipment is set to 36 ms on and 6 ms off. At the beginning of sintering, a pre-pressure of 10 MPa was applied, and heating was starte...

Embodiment 2

[0038] In this example, the high-entropy alloy CoCrFeNiCu will be prepared by the preparation method disclosed in the present invention, and the specific steps are as follows:

[0039] (1) Measure Co powder, Cr powder, Fe powder, Ni powder and Cu powder according to the proportion, the purity of the powder is greater than 99.5%, and the particle size is less than 70 microns;

[0040] (2) Put the powder into a polymer ball mill tank, put stainless steel balls into it, the ball-to-material ratio is 2:1, mix in a planetary ball mill, the speed of the ball mill is 150 r / min, take out the powder after 4 hours of mixing Finally, put it into a graphite mold and press it tightly;

[0041] (3) Put the mold filled with powder raw materials into the SPS sintering equipment for vacuum reaction hot pressing sintering, the pulse mode of the SPS equipment is the same as that of Example 1. At the beginning of sintering, a pre-pressure of 10 MPa was applied, and heating was started when the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com