Method for evaluating corrosion in buried pipeline

A technology for buried pipelines and evaluation methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., and can solve technical difficulties in pipeline corrosion safety management, high risk of safe operation of pipelines, safety hazards and accidents that should not be discovered and handling issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

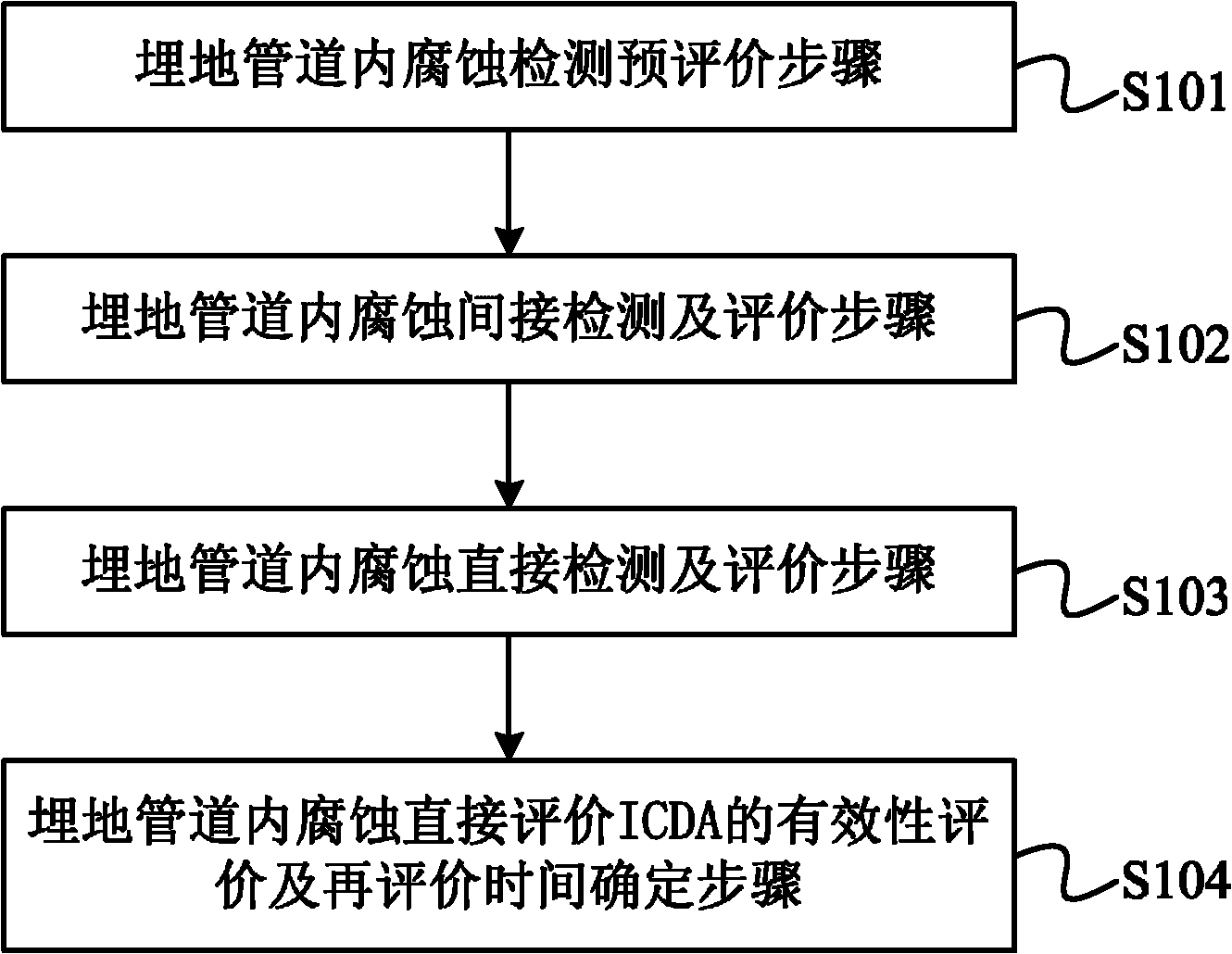

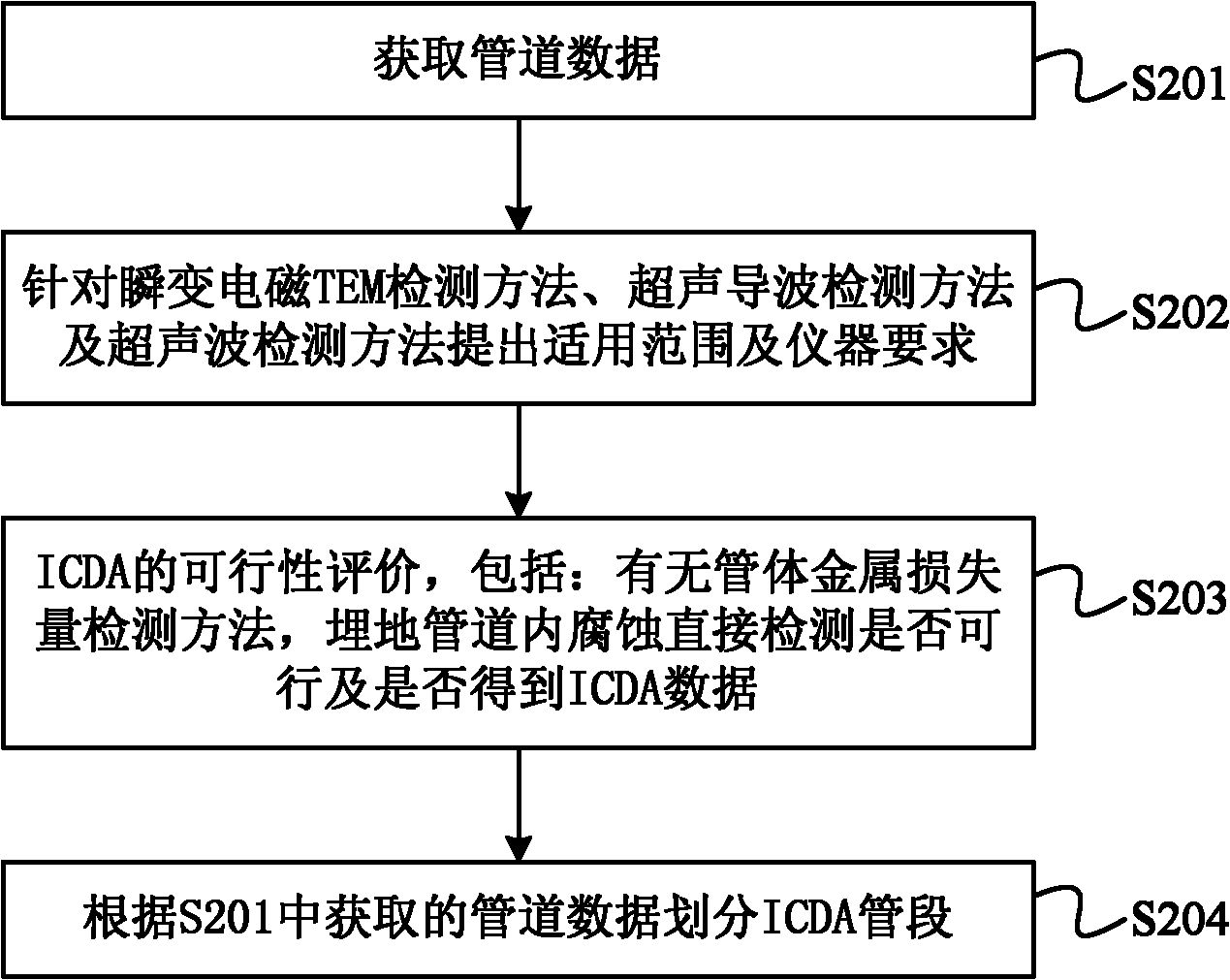

[0087] Such as figure 1 As shown, this embodiment provides a buried pipeline internal corrosion evaluation method, the evaluation method includes: buried pipeline internal corrosion detection pre-evaluation step S101; buried pipeline internal corrosion indirect detection and evaluation step S102; buried pipeline internal corrosion Step S103 of direct detection and evaluation; step S104 of determining the effectiveness of ICDA for direct evaluation of internal corrosion of buried pipelines and re-evaluation time.

[0088] The internal corrosion evaluation method of bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com