Forage for improving later-period production performance of laying hens and eggshell quality

A production performance and feed technology, applied in the field of laying hen feed, can solve the problems of insufficient eggshell quality improvement, failure to improve hormone secretion, follicular development limitation, etc., to enhance the carrying and oxidation energy supply, and improve egg production efficiency and feed utilization, and the effect of promoting egg protein and egg fat deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

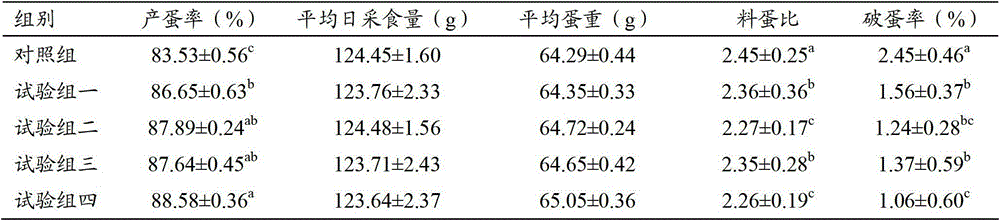

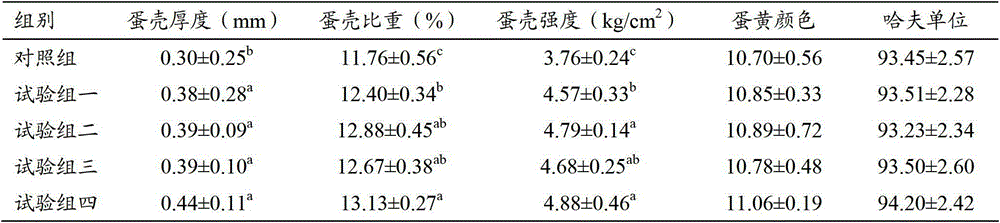

Examples

Embodiment 1

[0017] Accurately weigh the following raw materials (kg): corn 45, soybean meal 10, wheat 8, corn germ cake 5, alfalfa grass powder 3, calcium grains 4, brewer's grains 4, calcium powder 3, corn gluten meal 2, calcium hydrogen phosphate 0.5 , bentonite 0.1, vegetable oil 0.2, betaine 0.0005, salt 0.2, lysine 0.2, multivitamin (commercially available) 0.1, choline 0.1, complex trace element (commercially available) 0.1, sodium bicarbonate 0.1, methionine 0.1, vegetable Acidase 0.002.

[0018]First mix alfalfa powder, calcium hydrogen phosphate, bentonite, betaine, table salt, lysine, multivitamins, choline, complex trace elements, sodium bicarbonate, methionine, phytase, and then fully mix with calcium powder for 15 -20 minutes, mix well and set aside. Pulverize corn through a 6.0-7.0mm sieve, soybean meal, wheat, corn germ cake, and brewer's grains are pulverized and pass through a 4.0mm sieve, and put into the premixer with corn gluten meal, calcium particles, and vegetable ...

Embodiment 2

[0020] Accurately weigh the following raw materials (kg): corn 50, soybean meal 15, wheat 12, corn germ cake 10, alfalfa meal 6, calcium grains 6, brewer's grains 6, calcium powder 5, corn gluten meal 4, calcium hydrogen phosphate 1 , bentonite 0.2, vegetable oil 0.4, betaine 0.0008, salt 0.4, lysine 0.4, multivitamin (commercially available) 0.2, choline 0.2, complex trace element (commercially available) 0.2, sodium bicarbonate 0.2, methionine 0.2, vegetable Acidase 0.006.

[0021] First mix alfalfa powder, calcium hydrogen phosphate, bentonite, betaine, table salt, lysine, multivitamins, choline, complex trace elements, sodium bicarbonate, methionine, phytase, and then fully mix with calcium powder for 15 -20 minutes, mix well and set aside. Pulverize corn through a 6.0-7.0mm sieve, soybean meal, wheat, corn germ cake, and brewer's grains are pulverized and pass through a 4.0mm sieve, and put into the premixer with corn gluten meal, calcium particles, and vegetable oil in ...

Embodiment 3

[0023] Accurately weigh the following raw materials (kg): corn 50, soybean meal 10, wheat 8, corn germ cake 10, alfalfa meal 5, calcium granules 6, brewer's grains 4, calcium powder 3, corn gluten meal 4, calcium hydrogen phosphate 0.5 , bentonite 0.1, vegetable oil 0.3, betaine 0.0007, salt 0.4, lysine 0.35, multivitamin (commercially available) 0.15, choline 0.15, complex trace element (commercially available) 0.2, sodium bicarbonate 0.2, methionine 0.15, phytochemicals Acidase 0.004.

[0024] First mix alfalfa powder, calcium hydrogen phosphate, bentonite, betaine, table salt, lysine, multivitamins, choline, complex trace elements, sodium bicarbonate, methionine, phytase, and then fully mix with calcium powder for 15 -20 minutes, mix well and set aside. Pulverize corn through a 6.0-7.0mm sieve, soybean meal, wheat, corn germ cake, and brewer's grains are pulverized and pass through a 4.0mm sieve, and put into the premixer with corn gluten meal, calcium particles, and veget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com