Stirring apparatus

A mixing device and mixing device technology, which is applied in the direction of cement mixing device, mixer with rotating stirring device, mixer accessories, etc., can solve the problem that the mixing device cannot mix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

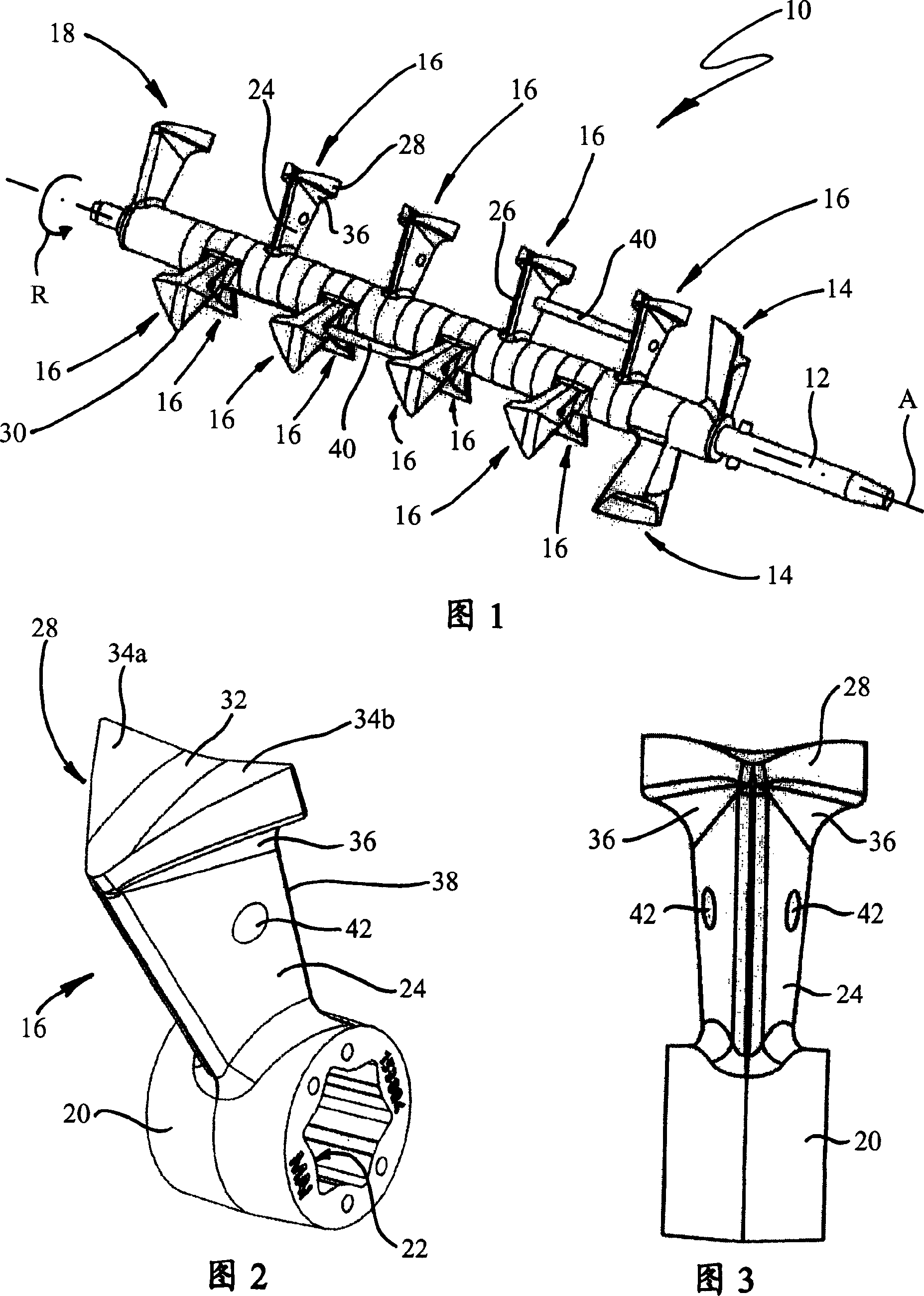

[0024] Fig. 1 shows a stirring device 10, which has a structure used in the continuous mixer. Using a continuous mixer, the added ingredients can be continuously made into the desired mixture, such as concrete. The stirring device 10 is provided in a mixing chamber (not shown in the figure) in a continuous mixer, and is rotatably provided in the mixing chamber by a shaft 12 provided on the rotation axis A.

[0025] As shown in the embodiment, viewed from the flow direction of the ingredients to be mixed, two conveying blades 14 are provided on the shaft 12. The two conveying blades 14 are used, for example, to quickly convey the solid ingredients to a powerful mixing zone behind the conveying blades 14, where the solid ingredients and liquid ingredients, such as water, are mixed. However, since the transmission blade 14 is not particularly important to the present invention, it will not be further elaborated.

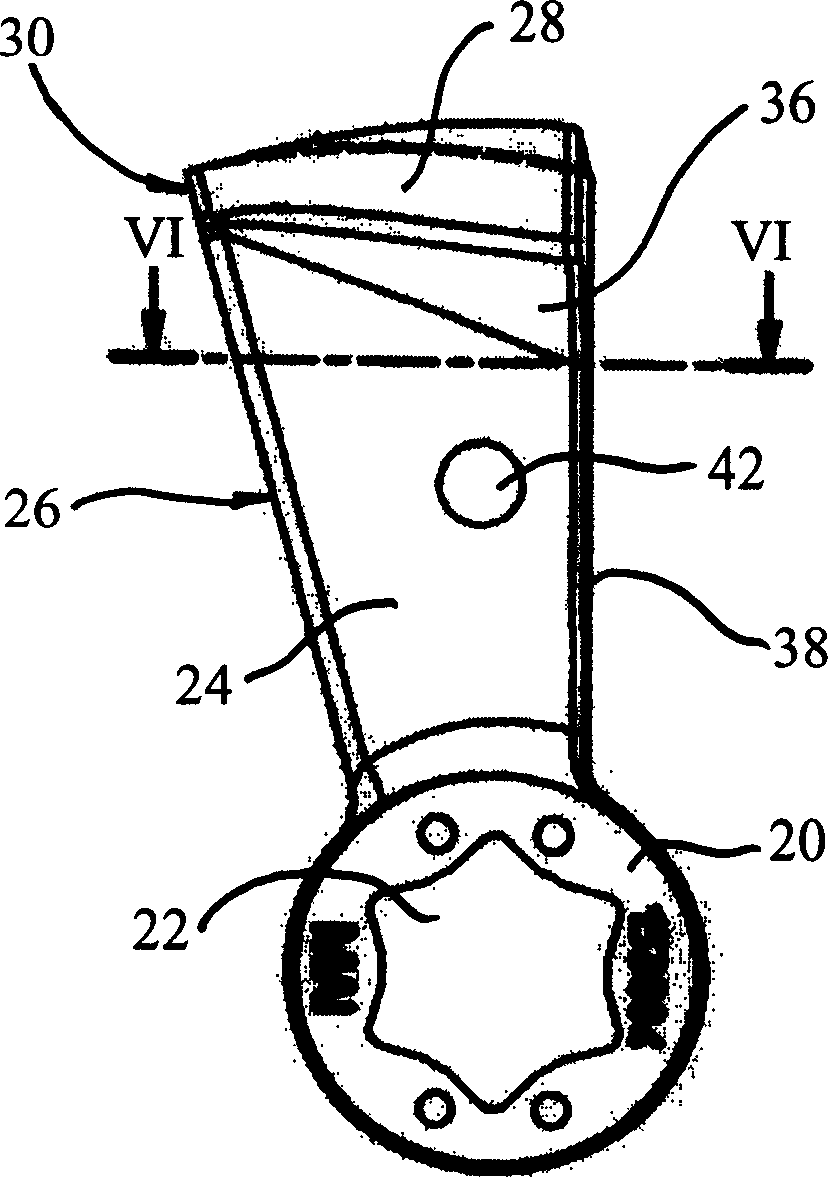

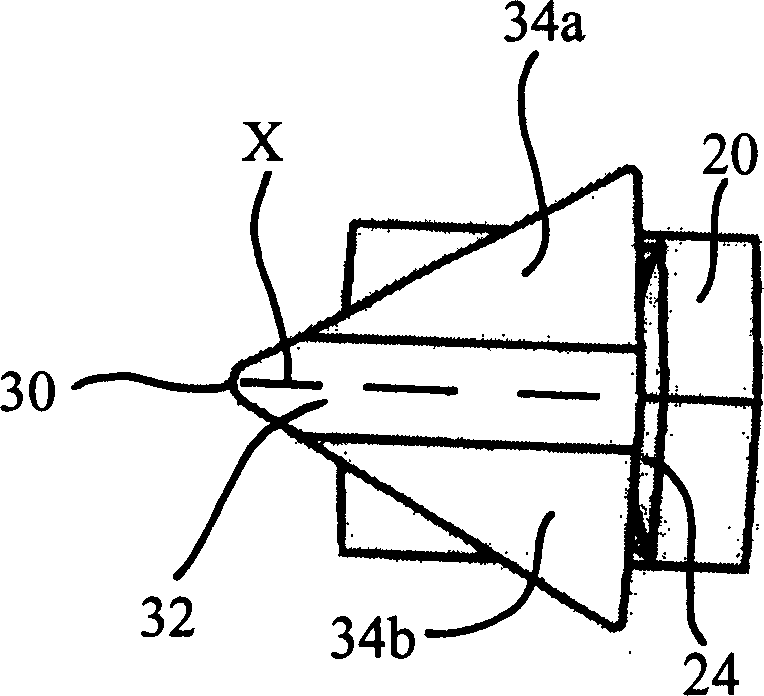

[0026] Downstream of the conveying blade 14, a plurality of mixing bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com