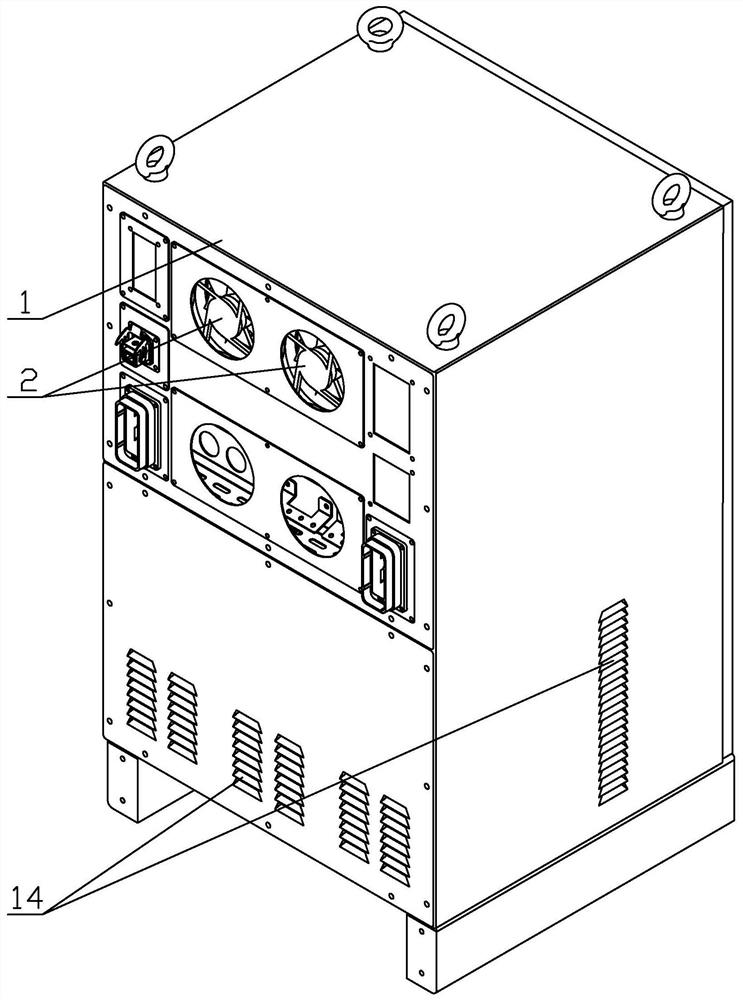

Robot control cabinet

A technology for robot control cabinets and cabinets, which is applied to cabinets/boxes/drawer parts, closed cabinets, electrical equipment casings/cabinets/drawers, etc. , the temperature rise in the cabinet, etc., to achieve the effect of improving dust resistance, ensuring heat exchange, and improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

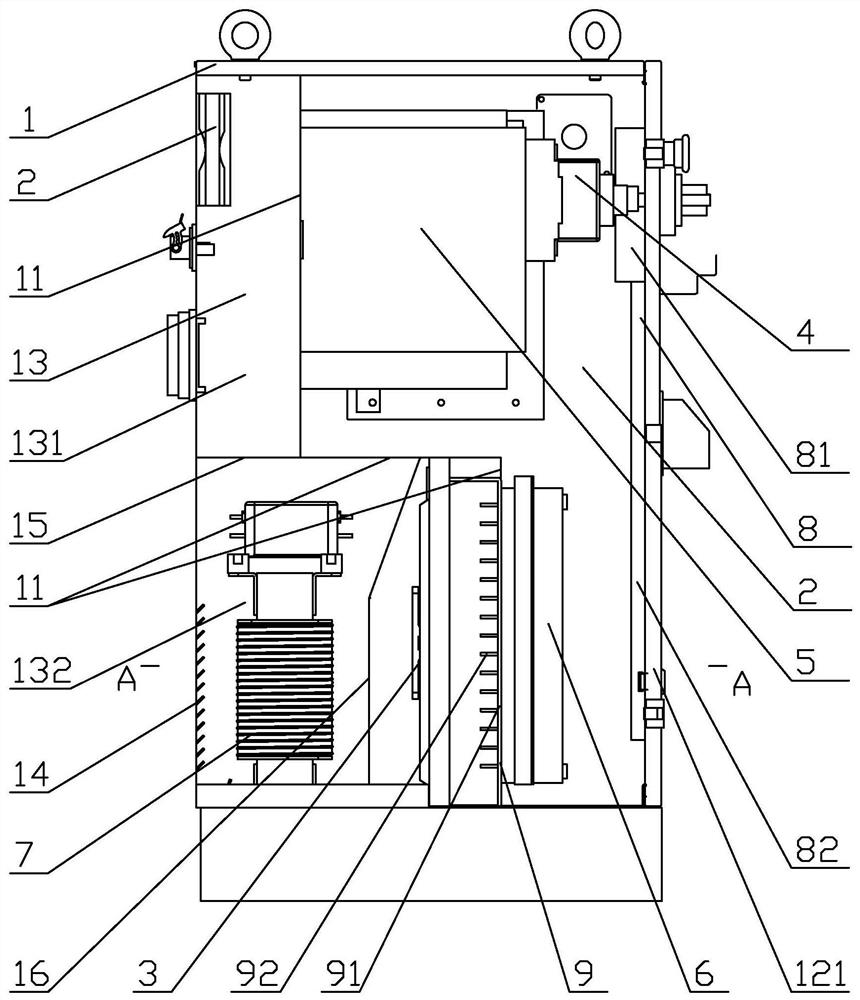

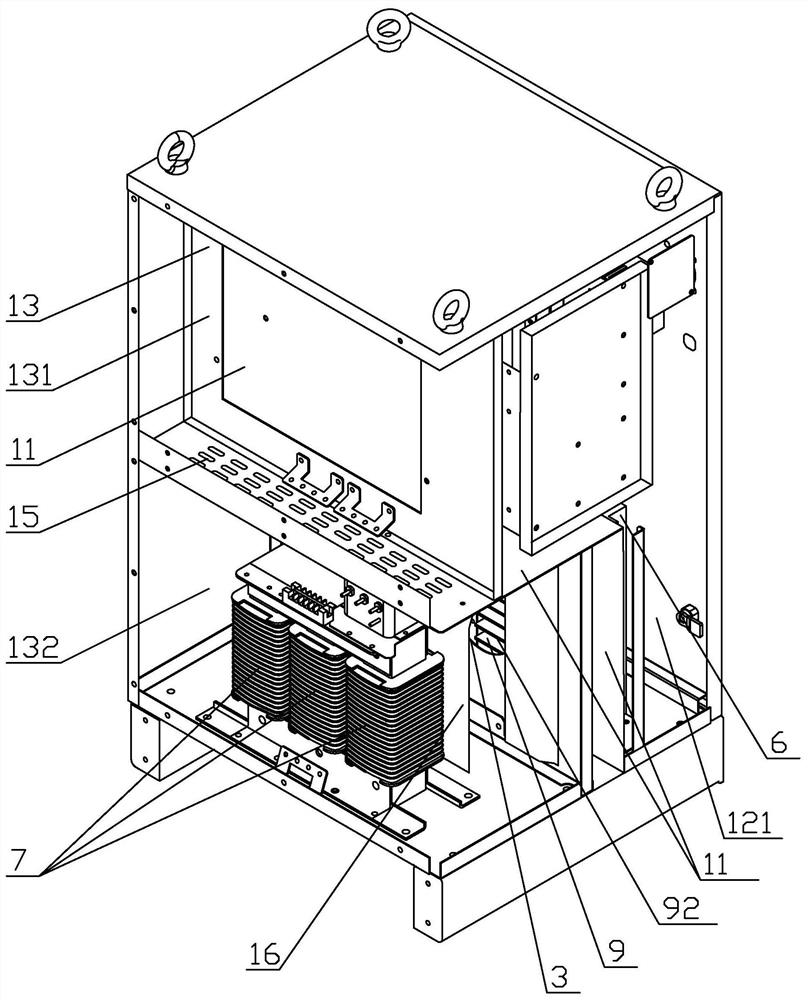

[0048] As a specific embodiment, when the orifice plate 15 is a ring with a through hole in the middle or is only a mark used to mark the boundary between the upper cavity 131 and the lower cavity 132 , the function of the orifice plate 15 is only for the semi-open space 13 Divide space. As a specific implementation manner, the orifice plate 15 is a plate or filter screen provided with several through holes, and the orifice plate 15 can filter the air flowing from the upper cavity 131 to the lower cavity 132, such as filtering large particles of dust, so that It is safer to place electronic components in the lower cavity.

[0049] When this embodiment is in use, the axial direction of the cooling fan 3 is horizontal and the partition plate 11 is arranged vertically. The cooling fan 3 can promote the air flow in the lower cavity 132 and enhance the heat dissipation capability of the partition plate 11 at the lower cavity 132. The cooling fan 3 reaches the baffle 11 and spreads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com