Compound-type aluminium alloy frication-stir-welding main shaft

A technology of friction stir welding and aluminum alloy, which is applied in welding equipment, welding equipment, non-electric welding equipment, etc., to achieve the effect of simple structure, controllable insertion depth and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

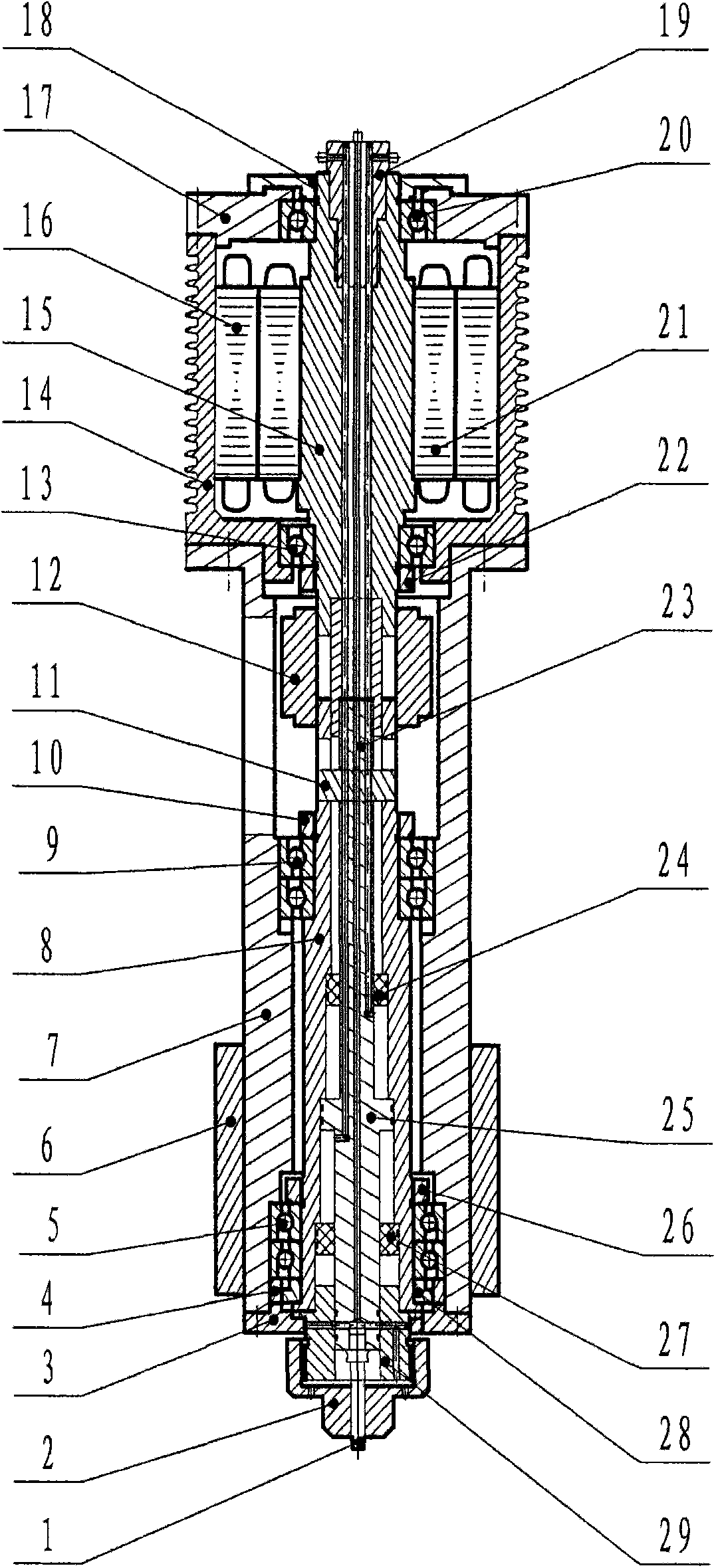

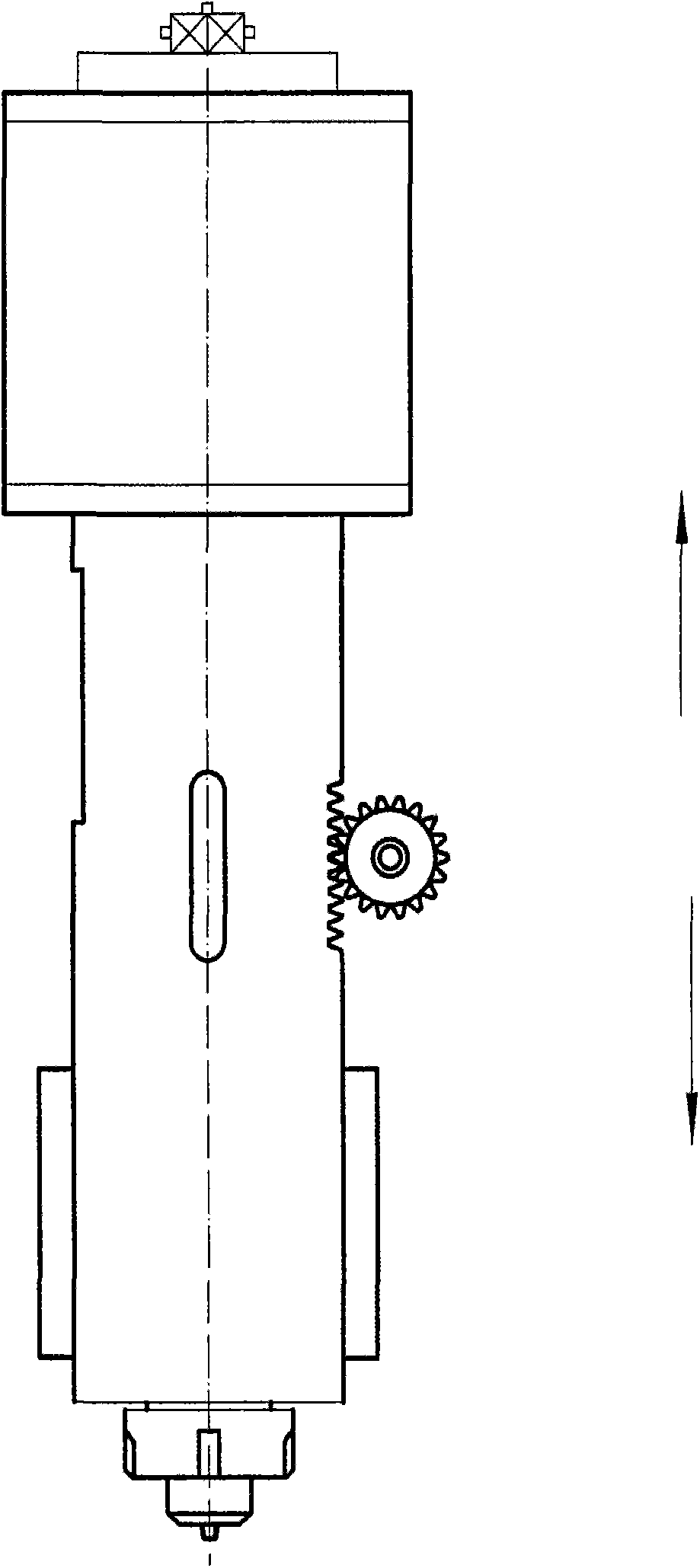

[0011] Combine below figure 1 and figure 2 The composite aluminum alloy friction stir welding spindle of the present invention will be described in more detail through specific implementation methods.

[0012] figure 1 , 2 As shown, a composite aluminum alloy friction stir welding spindle of the present invention includes a stirring pin 1, a locking stirring head 2, a front end cover 3, a shaft sleeve 7, a rotating shaft 8, a retracting shaft 25, a motor casing 14, and a motor shaft 15. Motor stator 16, motor rotor 21, rear cover 17, shaft coupling 12, upper and lower transmission rings 24 and 27, coupling pin 11, the motor shaft 12 is set in the motor housing 14 through the front and rear motor bearings 13 and 20, Locked and fixed by the motor nut 22 and the compression nut 18, a motor stator 16 and a motor rotor 21 are arranged between the motor shaft and the motor casing, the periphery of the motor casing 14 is provided with a cooling rib structure, and the periphery of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com