Separating and cutting method and device for side surface lock catch type sheet

A plate and lock technology, applied in the field of mechanical processing, can solve the problems of material waste, repeated processing, etc., and achieve the effect of avoiding waste of working hours and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

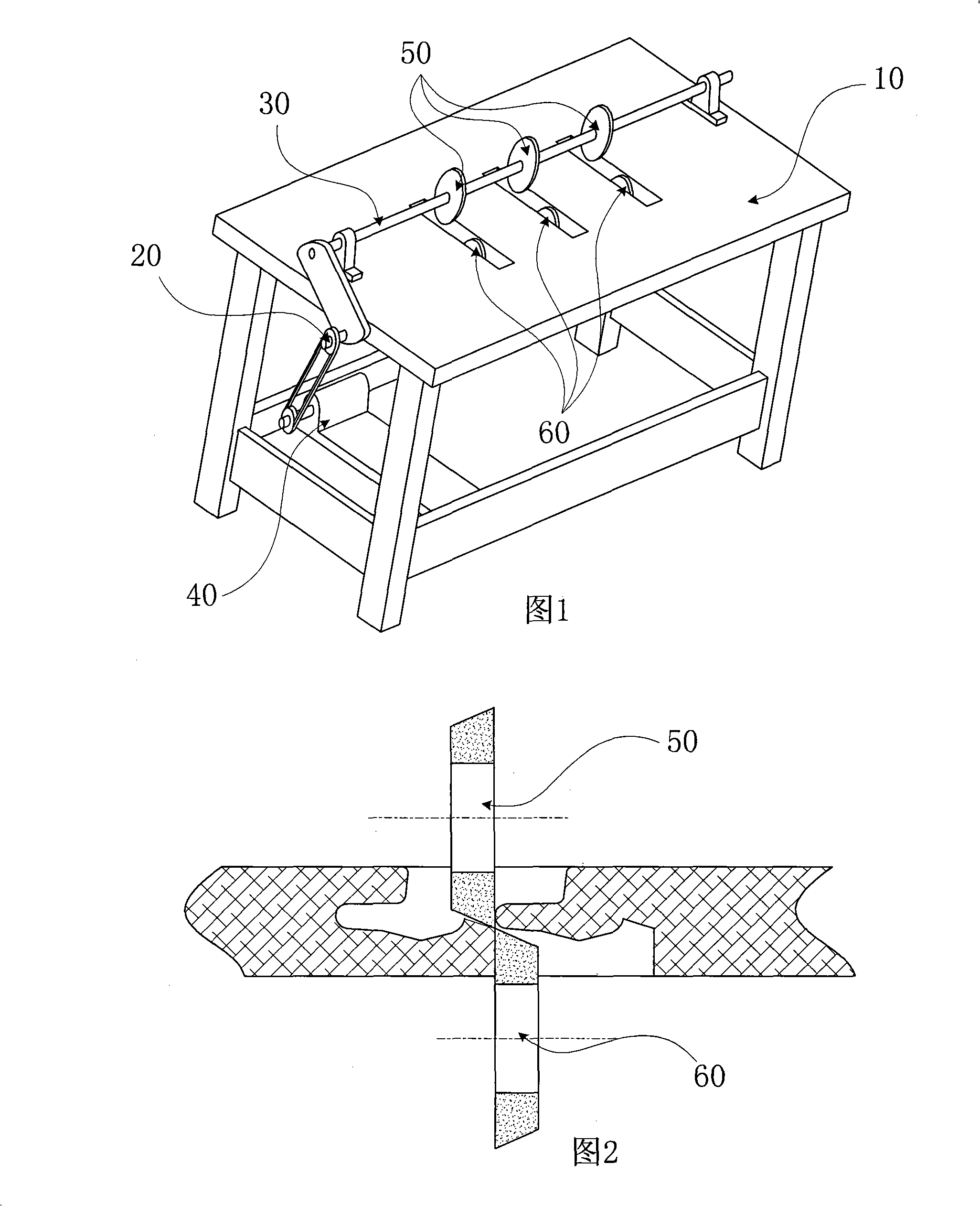

[0015] Specific embodiments of the present invention are described with reference to the above drawings.

[0016] As can be seen from Fig. 1 and Fig. 2, the cutting device of this type of side lock type plate includes a workbench 10, a power control and driving device 20 fixed on the workbench 10 and an upper drive shaft 30 connected thereto. and the lower drive shaft 40, the upper drive shaft 30 and the lower drive shaft 40 are equipped with an upper saw blade 50 and a lower saw blade 60 respectively, and the relative end faces between the upper saw blade 50 and the lower saw blade 60 are attached, Cutting edges at the contact points of the upper saw blade 50 and the lower saw blade 60 are radially connected. In the present invention, the cutting method for the side lock type plate includes: adjusting the position of the upper saw blade and the lower saw blade of the cutting device according to the orientation of the tongue and groove lip of the plate, the upper saw blade and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com