Machining tool, machining system and machining method for handle part

A handle and parts technology, applied in the field of handle parts processing, can solve problems such as handle part opening deformation, achieve the effects of improving efficiency, ingenious and novel structural design, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

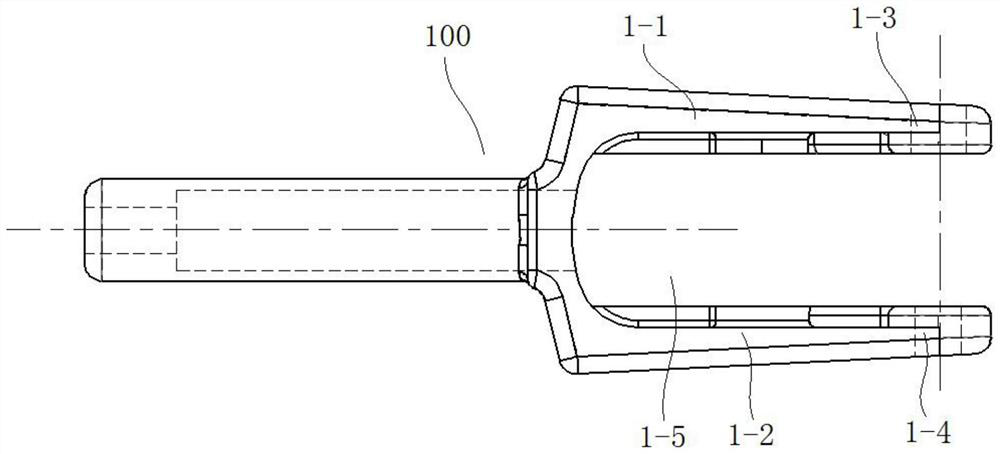

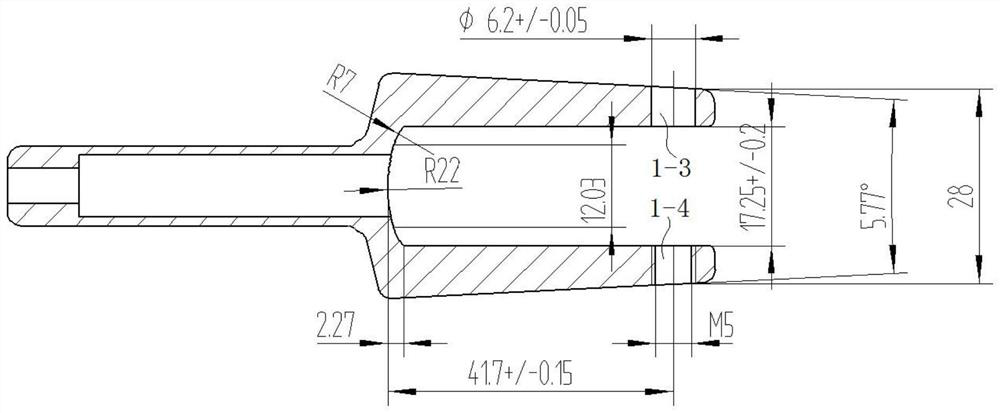

[0052] Such as Figure 4 As shown, this embodiment provides a processing tooling 100 for handle parts, which mainly includes a base plate 2, a positioning plate 4 and a part fixture 6. The upper surface of one side of the base plate 2 is provided with a first positioning surface 3; the positioning plate 4 is arranged on the base plate 2; the positioning plate 4 is located above the first positioning surface 3, and is spaced apart from the first positioning surface 3, and the upper surface of the positioning plate 4 is provided with a second positioning surface 5; the positioning plate 4 is used for fitting the handle part blank 1 Handle opening 1-5, wherein, handle opening 1-5 needs to process the side plate of threaded hole 1-4 (ie figure 1 The second opening side plate 1-2 shown) is located between the positioning plate 4 and the first positioning surface 3, and the side plate (ie, figure 1 The bottom surface of the shown second opening side plate 1-2) is veneered support; ...

Embodiment 2

[0065] This embodiment proposes a processing system for handle parts, including a machining center for machining a handle part blank 1 and a processing tool 100 for handle parts as described in Embodiment 1.

[0066] In this embodiment, as a preferred manner, the above-mentioned machining center adopts a three-axis machining center. The three-axis machining center can be used to process through holes 1-3 and threaded holes 1-4. It is an existing machining center. The specific structure and working principle will not be repeated here. It has high work efficiency and low cost, and can overcome the current situation. There are four-axis machining centers with four-axis repeated rotation, long auxiliary man-hours, low processing efficiency, and high cost.

Embodiment 3

[0068] This embodiment proposes a processing method for a handle part, which is implemented by using the processing tool for the handle part as described in Embodiment 1, and specifically includes the following steps:

[0069] Install the handle part blank 1 to be processed on the processing tool 100 of the handle part, and make the tail end of the handle part blank 1 cooperate with the part fixture 6, and the handle opening 1-5 is set on the positioning plate 4, and the handle opening 1-5 The side plate of the threaded hole 1-4 that needs to be processed is located between the positioning plate 4 and the first positioning surface 3, and is supported by the first positioning surface 3. The side of the handle opening 1-5 that needs to process the through hole 1-3 The plate is located above the positioning plate 4 and is veneered supported by the second positioning surface 5;

[0070] Process the through hole 1-3 on the side plate that needs to process the through hole 1-3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com