Patents

Literature

119results about How to "Reduce the number of tool changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

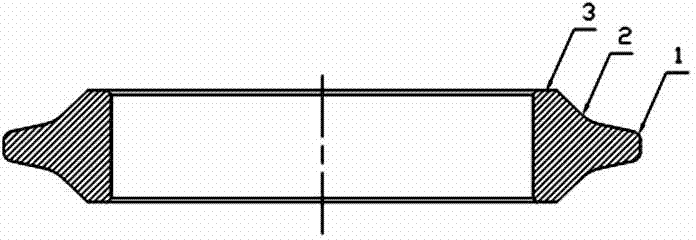

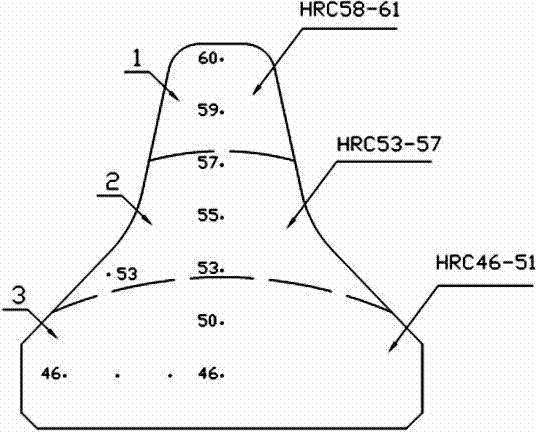

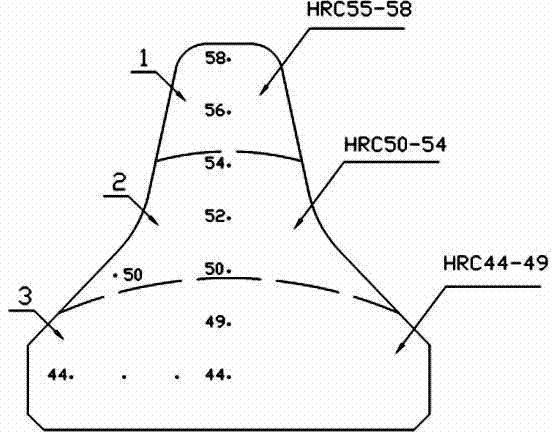

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Preparation method of high-toughness polycrystalline cubic boron nitride compound sheets

InactiveCN102505090AImprove like compatibilityImprove fracture toughnessUltra high pressureMixed materials

The invention relates to a preparation method of high-toughness polycrystalline cubic boron nitride compound sheets. The preparation method comprises the following steps that: various raw materials are respectively subjected to chemical acid-base treatment and physical vacuum treatment; micro powder of the treated raw materials is respectively mixed according to different mass percent ratios, mixed materials and base body material hard alloy base body sheets are pressed into test blocks according to a certain layer paving sequence; pressed and formed test blocks are put into a molybdenum cup separated by a salt tube shielding layer, then, filled salt tubes are put into a graphite mold, finally, the graphite mold is filled into a pyrophyllite cavity, ends are sealed, and synthesis blocks are obtained through assembling; and the synthesis blocks are sintered together at ultra-high pressure and high temperature to form the polycrystalline hard alloy compound sheets. The preparation method has the advantages that the toughness characteristic of the base body materials is fully utilized, the similar compatibility of the base body materials and polycrystalline layers of the prepared polycrystalline cubic boron nitride compound sheets is good, the fracture toughness property is good, the anti-impact performance is high, the knife breaking phenomenon can be greatly avoided, the knife change times are reduced, the service life is prolonged, and the processing efficiency and the processing precision of a knife tool are improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

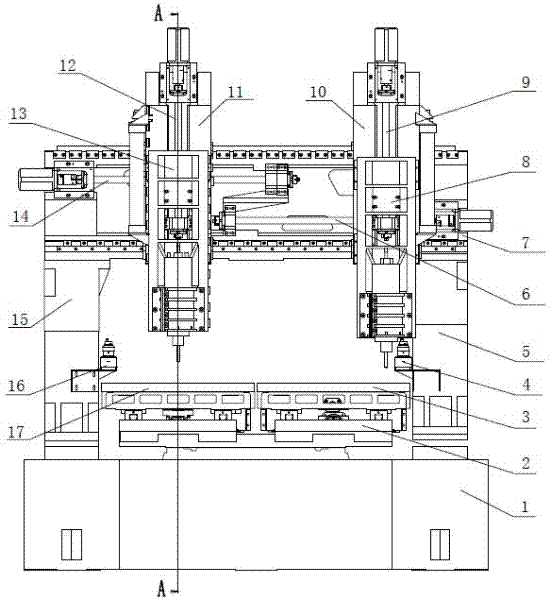

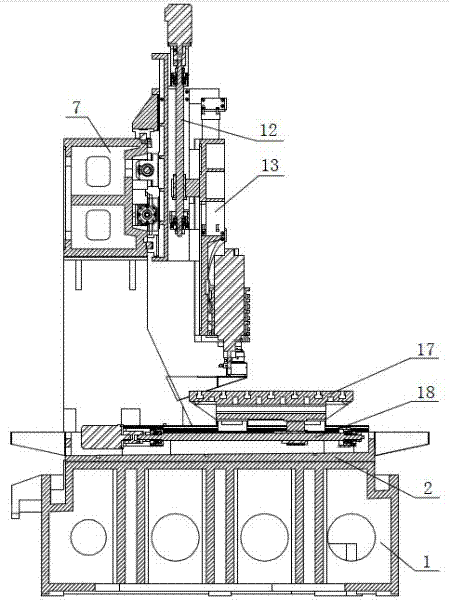

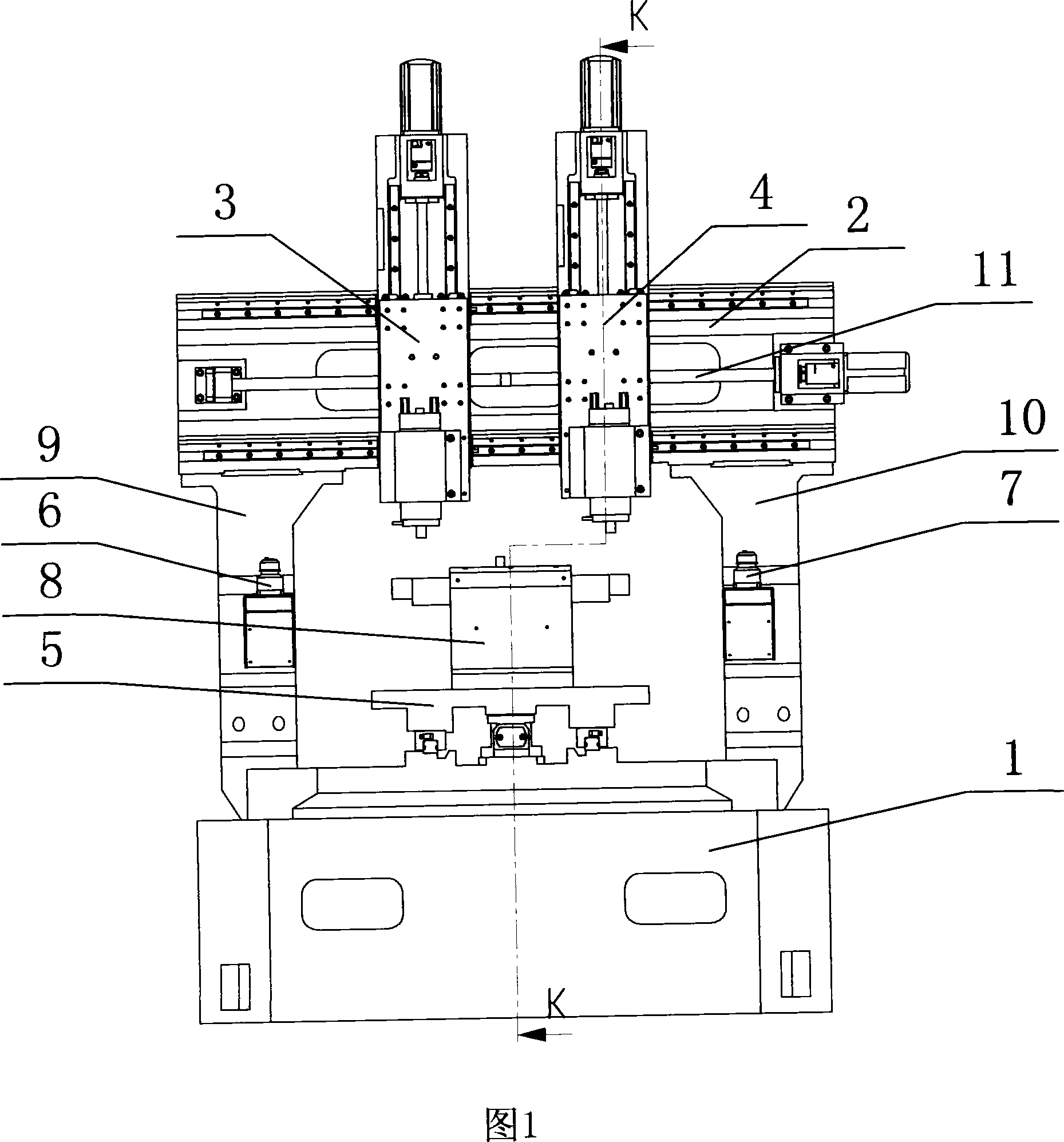

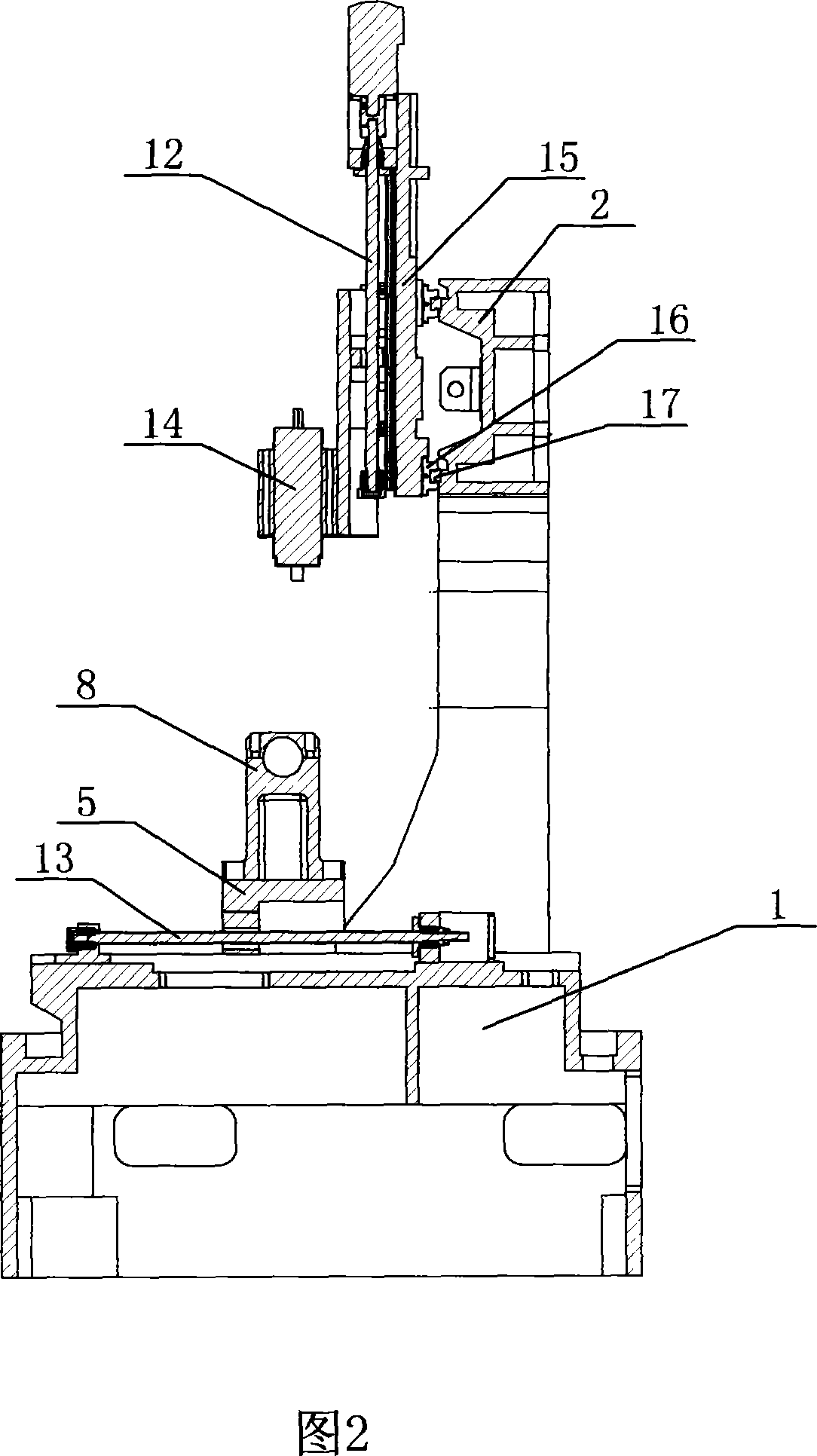

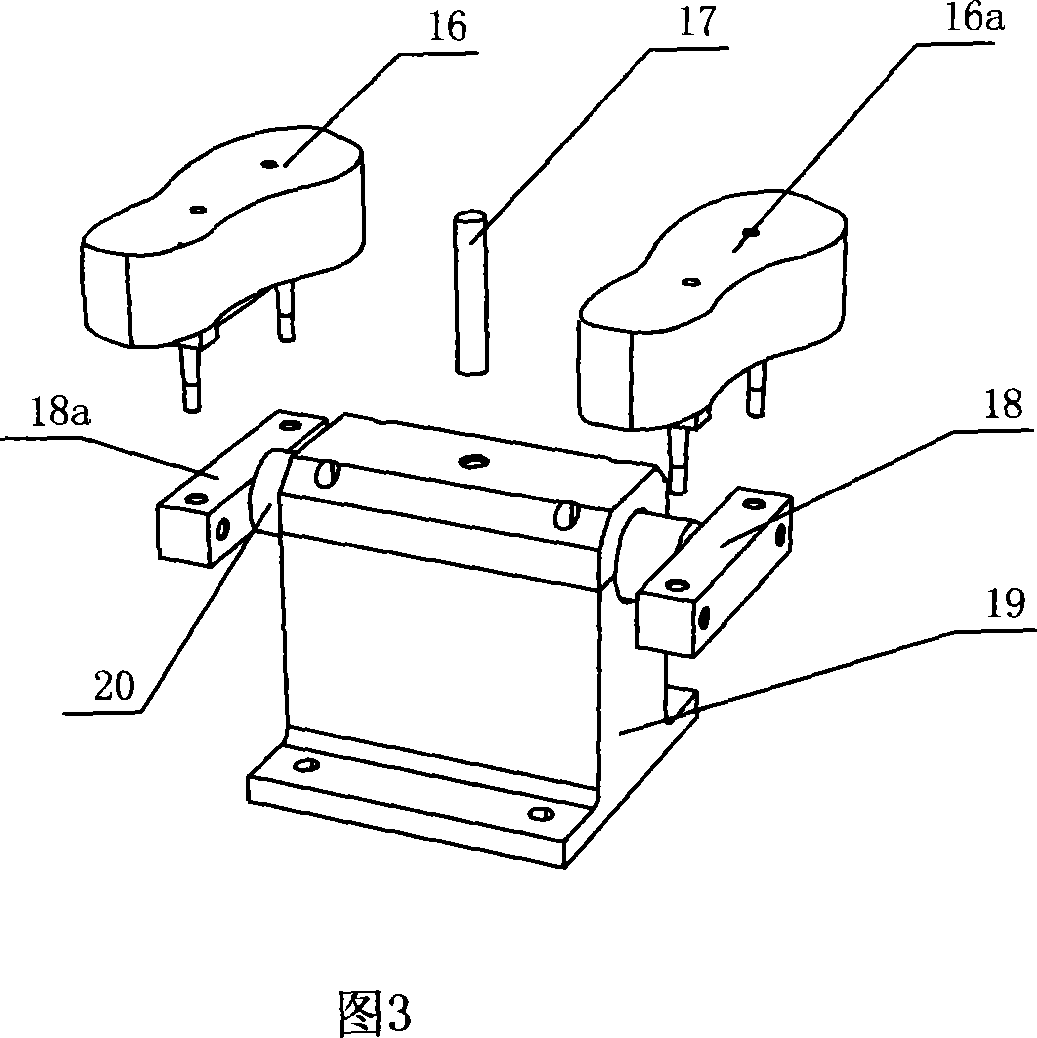

Numerical control double-station mould engraving and milling machine

InactiveCN102189288AIngenious structureSimple and fast operationMilling machinesLarge fixed membersNumerical controlBall screw

The invention relates to a machine tool, in particular to a numerical control double-station mould engraving and milling machine. A foundation, a left vertical shaft and a right vertical shaft are arranged on a frame body of the machine in a matched way; a beam is arranged above the left vertical shaft and the right vertical shaft in a matched way; the beam is connected with a left X-axle sliding table and a right X-axle sliding table through a left X-axle linear sliding block guide rail pair and a right X-axle linear sliding block guide rail pair in a matched way and the beam is in transmission fit with the left X-axle sliding table and the right X-axle sliding table through a left X-axle ball screw pair and a right X-axle ball screw pair; the foundation is connected with a left Y-axle sliding table and a right Y-axle sliding table through a left Y-axle linear sliding block guide rail pair and a right Y-axle linear sliding block guide rail pair in a matched way and the foundation is in transmission fit with the left Y-axle sliding table and the right Y-axle sliding table through a left Y-axle ball screw pair and a right Y-axle ball screw pair; and the left X-axle sliding table and the right X-axle sliding table are connected with a left Z-axle sliding table and a right Z-axle sliding table through a left Z-axle linear sliding block guide rail pair and a right Z-axle linear sliding block guide rail pair in a matched way and the left X-axle sliding table and the right X-axle sliding table are in transmission fit with the left Z-axle sliding table and the right Z-axle sliding table through a left Z-axle ball screw pair and a right Z-axle ball screw pair. The efficiency of the numerical control double-station mould engraving and milling machine is two times that of the conventional machine tool.

Owner:DOUBLE HEAD CNC

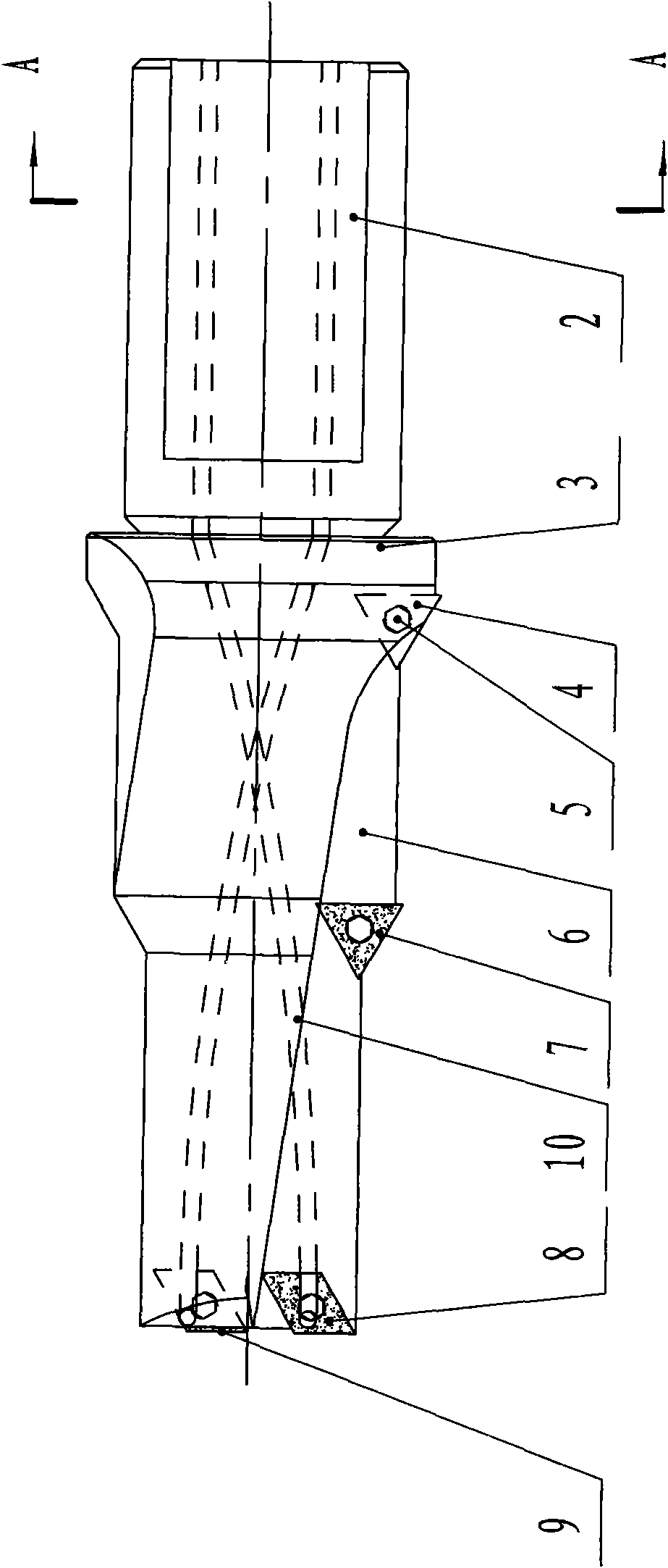

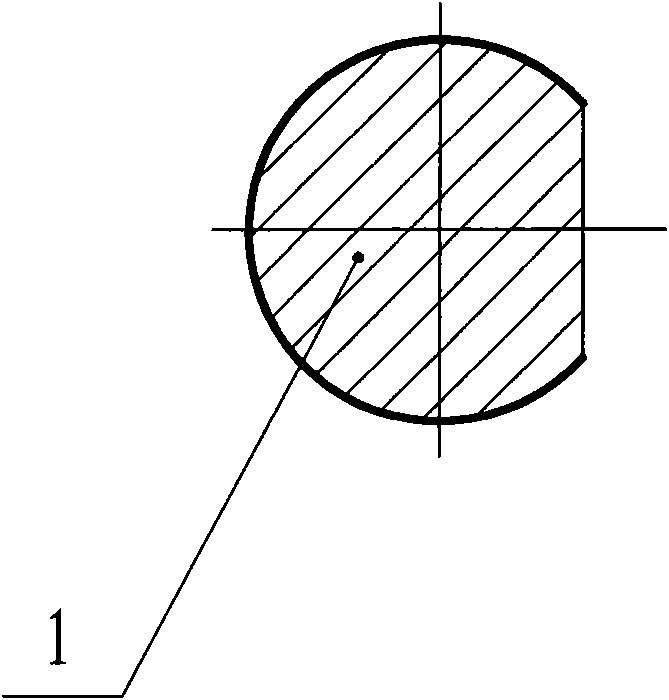

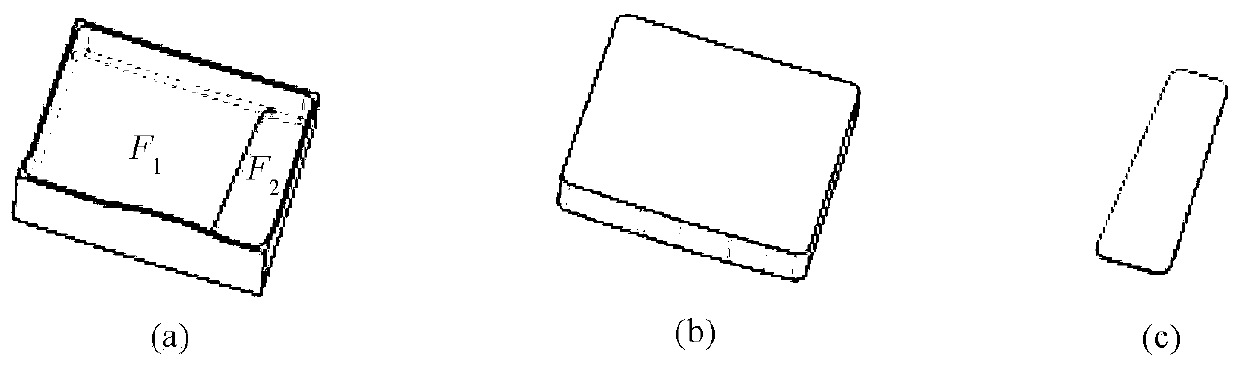

Inner-cooling indexable step drill and method for fabricating step hole

InactiveCN101524769ALow costImprove processing efficiencyTransportation and packagingTrepanning drillsEngineeringDrill bit

The invention provides an inner-cooling indexable step drill and a method for fabricating a step hole thereof. The inner-cooling indexable step drill comprises a fixed part and a drill bit body. The drill bit body is in columnar shape with steps. The outline of the axial section of the drill bit body is in step shape, and the outer diameter of one end of the drill bit body near the fixed part is larger than the outer diameter of the end far from the fixed part. The top of the drill bit body is respectively provided with an end inner knife block used for processing the central part of a hole and an end outer knife block used for processing the outer part of the hole. A step-shaped jut of the drill bit body is provided with an indexable blade. The surface of the drill bit body is provided with two spiral slots for containing drilling chips and cutting liquid. A material part of the drill bit body is provided with two spiral holes used for filling the cutting liquid with certain pressure. The invention also provides a method for fabricating the step-shaped hole by an indexable inner-cooling step drill. The invention is applied to fabricate the step-shaped hole and can fabricate the step hole by cutting feed at a time.

Owner:刘新平

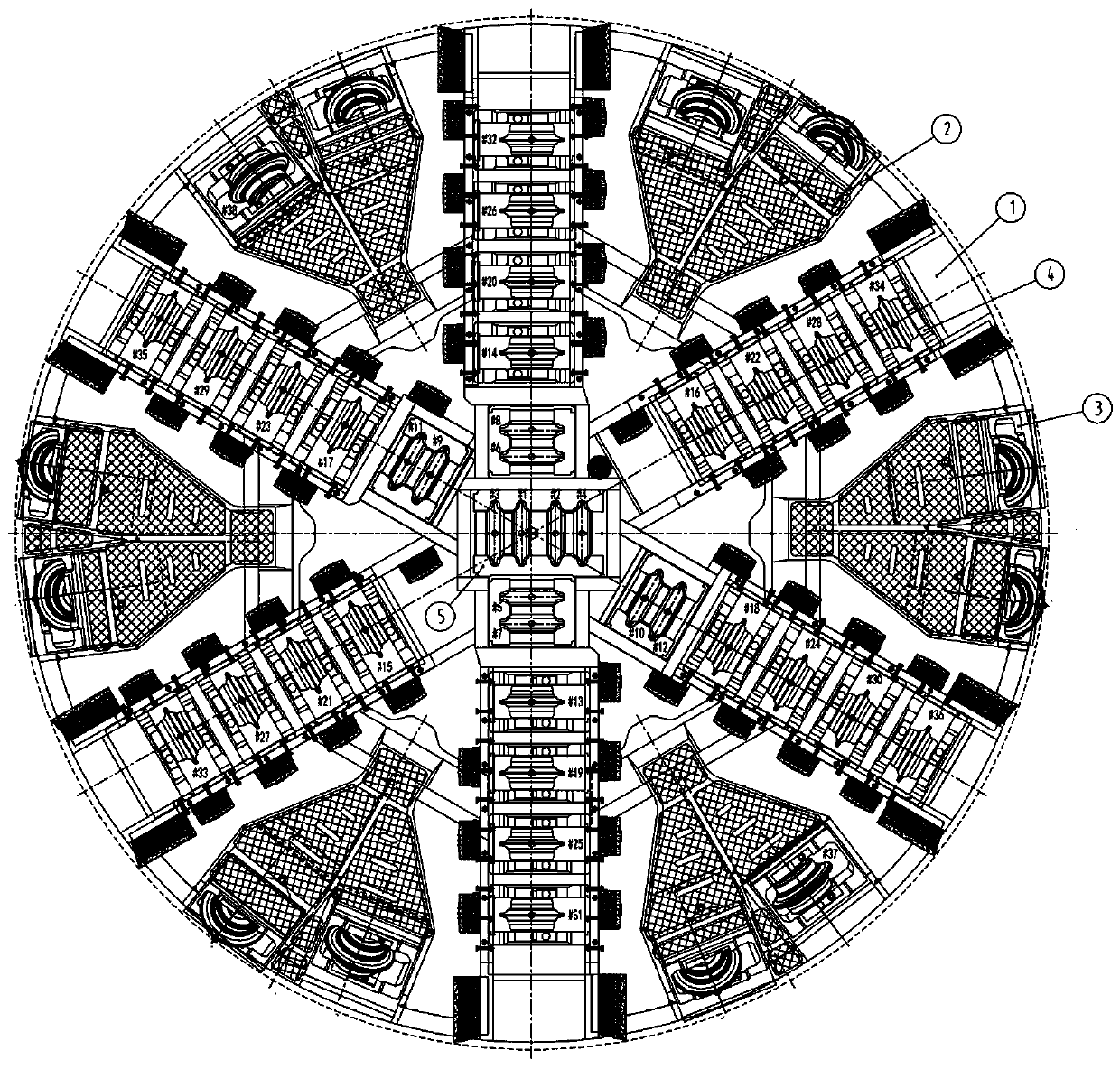

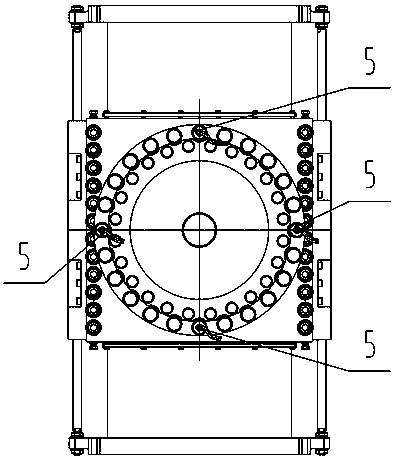

Microwave-assisted rock breaking TBM cutter head for hard rocks

PendingCN109763832AExpand coverageGood rock breaking effectDust removalFire preventionRock breakingDisc cutter

The invention discloses a microwave-assisted rock breaking TBM cutter head for hard rocks. The cutter head comprises a TBM cutter head body, wherein the TBM cutter head body mainly comprises a single-edge rock breaking hobbing cutter, a double-edge rock breaking hobbing cutter, a plurality of water injection dedusting openings and a plurality of microwave-assisted rock breaking emitters; the cutter head covers rock breaking paths in different tracks through the combination of the double-edge rock breaking hobbing cutter and the single-edge rock breaking hobbing cutter; a cutter head panel is provided with the water injection dedusting openings; the cutter head panel is provided with the microwave-assisted rock breaking emitters; each microwave-assisted rock breaking emitter comprises a microwave emitting disc, a wave guiding structure and a microwave emitting module. The cutter head has the advantages that a microwave emitting device is started in case of hard strata, rocks are rapidlyheated through microwave, mechanical properties of rocks, such as the point load strength, uniaxial compressive strength and tensile strength, are reduced, rock joint fissure assisted TBM hobbing cutter rock breaking is added, the penetration speed of disc cutters is improved, the rock breaking rate is improved, the thrust and torque of TBM equipment are reduced, abrasion of the hobbing cutters in hard rocks and cutter changing frequency are reduced, the construction period can be greatly reduced, and the construction investment can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

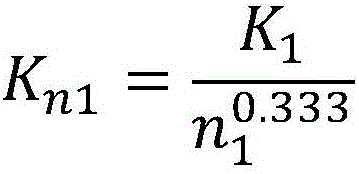

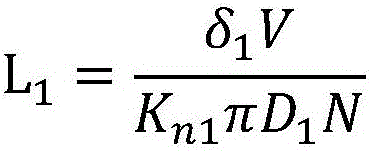

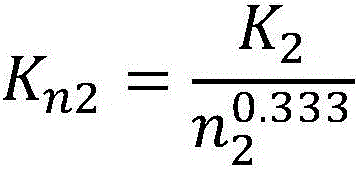

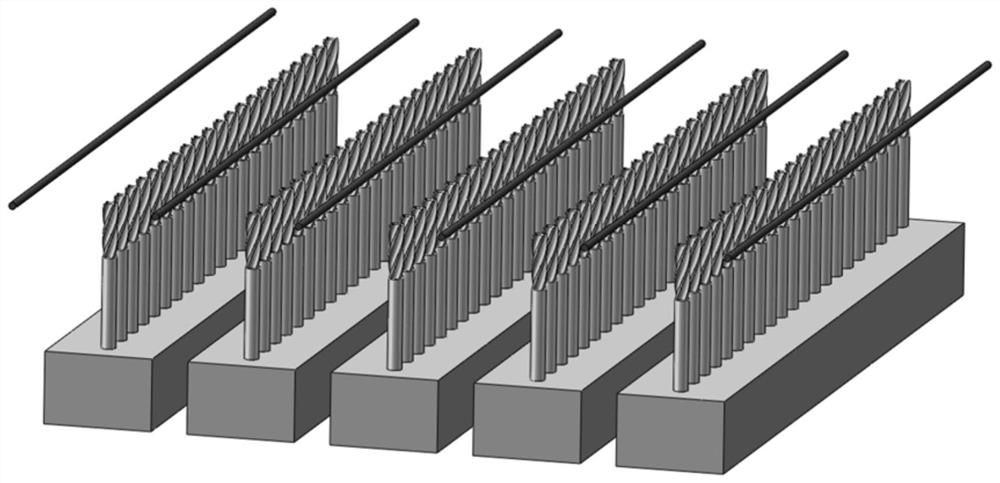

Deep cavity processing method based on titanium alloy monobloc forging component

InactiveCN105312835AReduce the number of tool changesImprove durabilityCooling methodsTitanium alloy

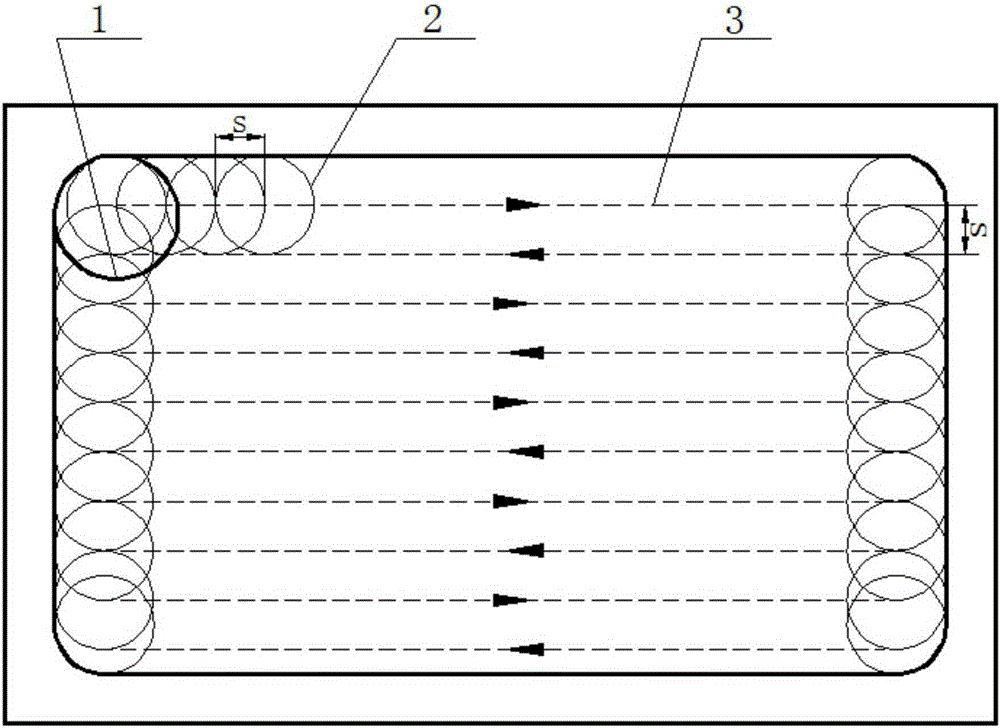

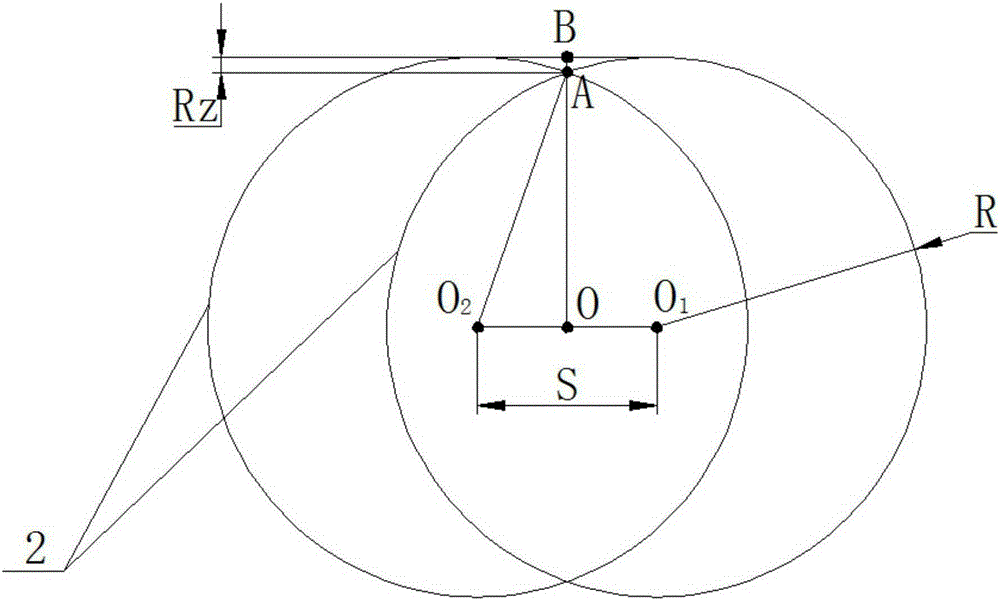

The invention discloses a deep cavity processing method based on a titanium alloy monobloc forging component. The deep cavity processing method comprises the following steps of: firstly performing hole drilling process by selecting an uncoated hard alloy drilling-and-cutting blade, wherein an internal cooling manner is adopted; performing inserting-and-drilling processing on a deep cavity by adopting a coated inserting-and-milling blade, wherein an S-shaped processing path is adopted, the row spacing S is 0.5 multiplied by the diameter of a blade, the cutting speed V is 30m / min, the radial knifing depth ae is 0.3 multiplied by the diameter of the blade, feed per tooth fZ is 0.08mm / z, and the blade is retracted in an arc manner; performing inserting-and-milling crude processing by adopting the same blade, wherein the S-shaped processing path is adopted, and the adopted row spacing S is 5mm; performing inserting-and-milling essence processing, wherein the S-shaped processing path is adopted, the adopted row spacing is shown as the description, the blade is retracted in the arc manner, and the internal cooling manner is adopted; performing milling-and-cutting processing on the bottom filleted corner of the deep cavity by adopting a round head milling blade; and finally polishing. Through the adoption of the deep cavity processing method disclosed by the invention, the number of the adopted blades during the deep cavity processing is small, the blade changing times and the corresponding assisting time are shortened, the durable degree of the blades is increased, and the processing precision of the deep cavity is guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

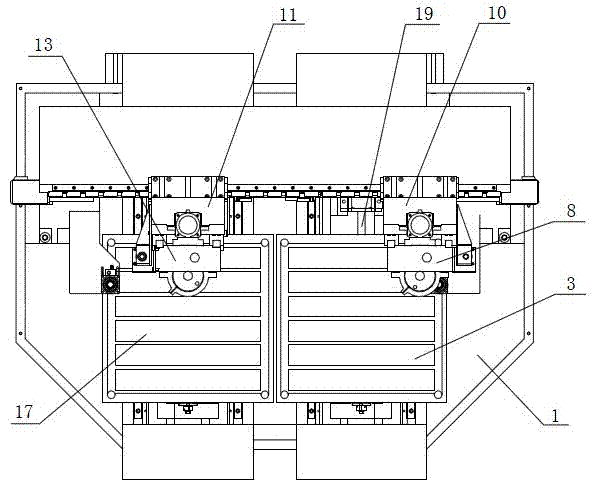

Computerized numerical controlled engraving and milling machine with symmetrical double station of shoe modules

InactiveCN101032765AIngenious structureSimple and fast operationMilling machinesLarge fixed membersNumerical controlEngraving

The symmetrical numerically controlled double site shoe mold carving and milling machine includes one machine pedestal, one right upright and one left upright with upper ends connected to the crossbeam, one right Z axis power mechanism and one left Z axis power mechanism slide fitting the crossbeam via the Z axis slide plate, one right X axis ball screw pair and one left X axis ball screw pair with opposite rotation direction for stroke control, one Z axis power head slide fitting the Z axis slide plate and transmission fitting to the Z axis ball screw pair, one Y axis bench slide fitting the machine pedestal and transmission fitting to the Y axis ball screw pair, and shoe mold fixture on the Y axis bench. The present invention has smart structure, simple operation and small size, and can machine one pair of shoe molds through once machining, resulting in doubled machining efficiency.

Owner:郭云飞

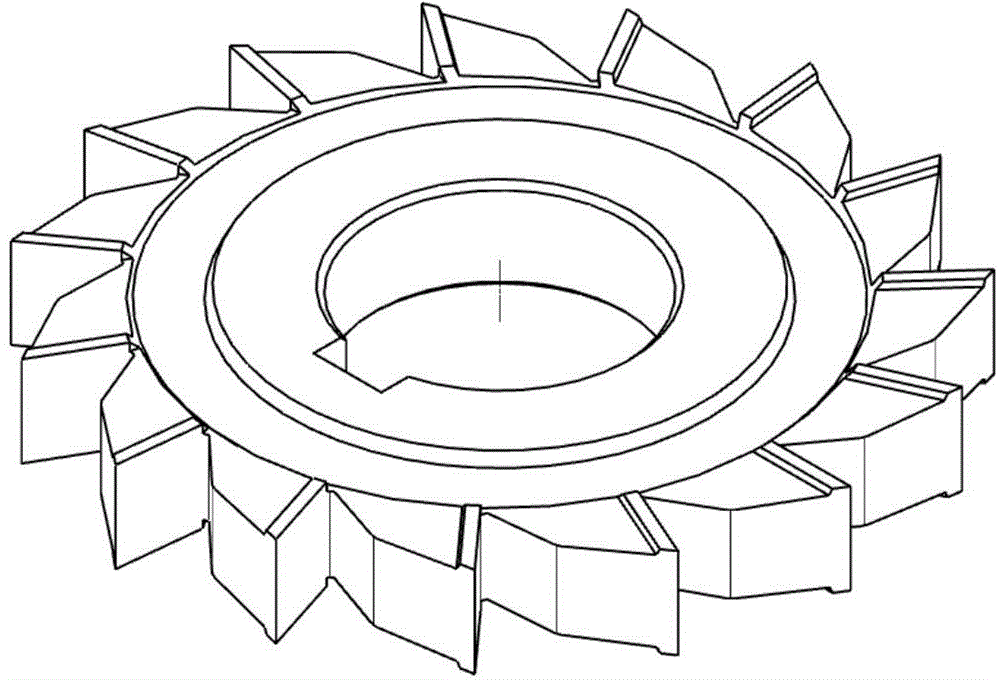

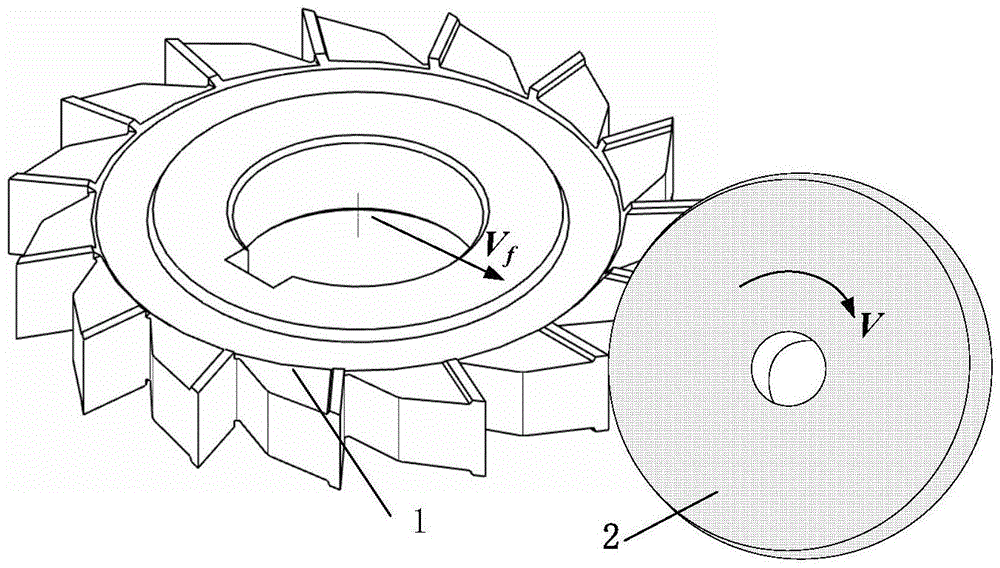

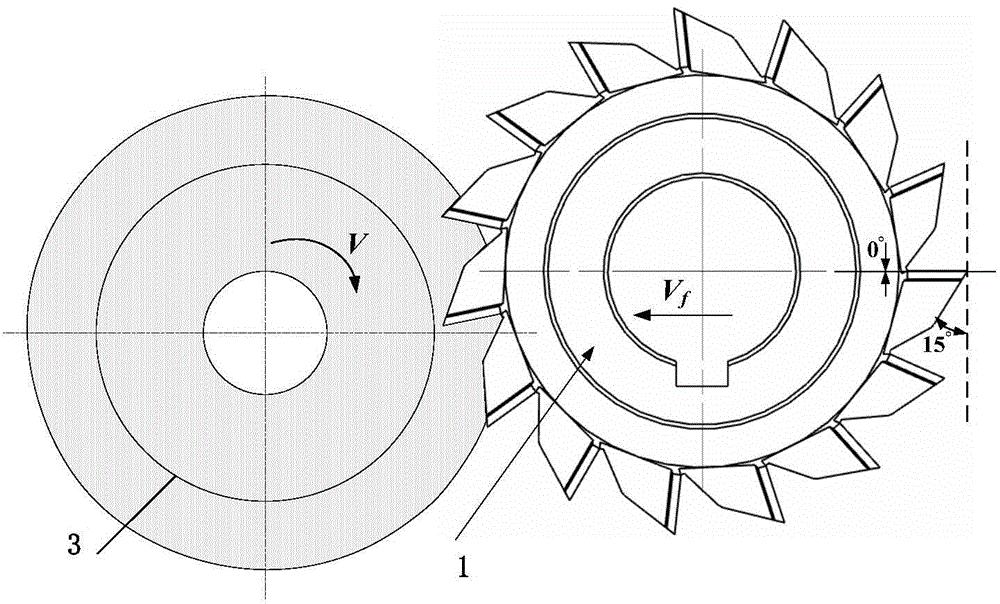

Integral full-ceramic super dense-tooth three-edge milling cutter and manufacturing method thereof

InactiveCN104889466AHigh hardnessImprove wear resistanceMilling cuttersMilling cutterTitanium carbonitride

The invention discloses an integral full-ceramic super dense-tooth three-edge milling cutter and a manufacturing method thereof. The integral full-ceramic super dense-tooth three-edge milling cutter comprises a three-edge milling cutter body; the three-edge milling cutter body is connected with a cutter handle through a keyway hole in the center of the three-edge milling cutter body, and comprises a main cutting edge and two side cutting edges; the front angle of the main cutting edge is (-10)-0 degree; the rear angle of the main cutting edge is 5-15 degrees; the rear angles of the two side cutting edges are 2-5 degrees respectively; the three-edge milling cutter body has 10-20 teeth, has a diameter of 50-200 mm, and is made of titanium carbonitride based metal ceramic. Through the adoption of the integral full-ceramic super dense-tooth three-edge milling cutter, high-speed and super high-speed machining can be realized, the material removing rate is improved, and the machining cost is reduced; when the total radial cutting depth remains unchanged, the radial cutting depth of a single cutting edge, the cutting force and the cutter abrasion can be reduced; the service life of the integral full-ceramic super dense-tooth three-edge milling cutter is effectively prolonged, the cutter replacement times are reduced, and the machining efficiency is improved. Compared with an indexable milling cutter, the integral full-ceramic super dense-tooth three-edge milling cutter has the advantages of being high in rigidity, positioning precision, and repeated sharpening property; moreover, the machining quality can be improved, and the machining cost is reduced.

Owner:SHANDONG UNIV

Manufacturing method for automobile transmission gear

The invention discloses a manufacturing method for an automobile transmission gear, and relates to the field of manufacturing of automobile parts. The method comprises the following steps: (1) blank forging, (2) spheroidizing annealing, (3) turning machining, (4) hobbing, (5) gear shaving, (6) carburization, (7) quenching and tempering and (8) grinding machining. According to the method, spheroidizing annealing treatment is adopted, so that the cutting performance of the gear is improved, a structure with spheroidized or granular carbide uniformly distributed on a ferrite substrate is obtained for preparation for subsequent heat treatment; a gas carburization method is adopted, and volatile kerosene is used as a carburizer, so that carburization effects are effectively improved, the thickness of a carburized layer is increased, the surface of the gear is hard and wear-proof, and high toughness of the core of the gear is maintained; quenching and tempering heat treatment is adopted after carburization, so that the carburization effects are further consolidated, and the mechanical performance of the gear is improved.

Owner:JIANGXI UNIV OF TECH

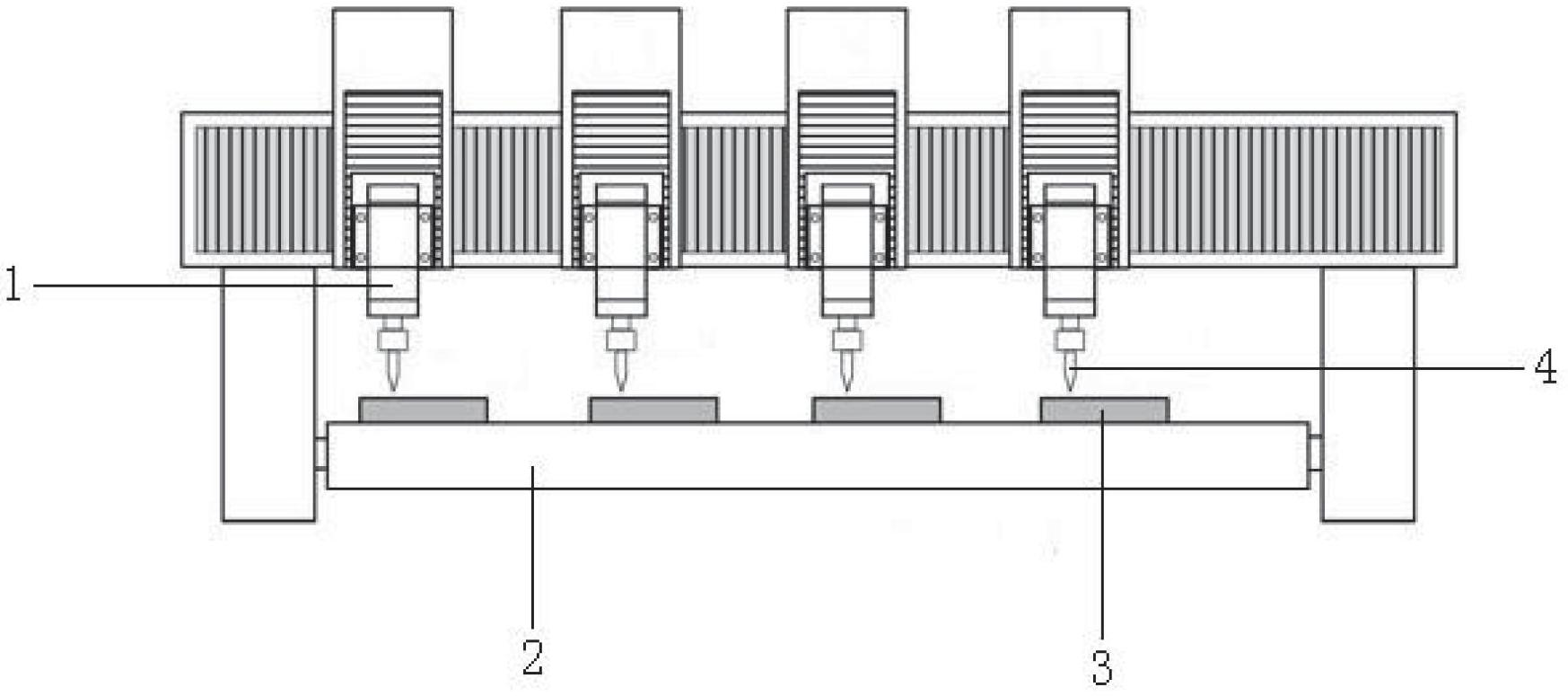

Numerical control machine with a plurality of main shafts

InactiveCN102689236AIncrease productionGuaranteed accuracyMetal working apparatusNumerical controlControl system

The invention discloses a numerical control machine with a plurality of main shafts. The numerical control machine with the main shafts comprises a working platform, a plurality of main shafts and a control system, wherein the main shafts are divided into n groups and distributed on a shaft rack; the n groups of main shafts are arranged at intervals and hang above the working platform along the Y-axis direction; a tool bit is arranged at the lower end of each main shaft; the control system sets the coordinate origin of the numerical control machine with the main shafts; each main shaft is provided with an independent driving circuit; each group of main shafts are arranged on a round disk rack; the round disk racks are provided with crossed holes aiming at the main shafts and embedded into the shaft rack; the shaft rack has two layers and is hollow; the control system drives edges of the main shafts to slide along the crossed holes by using a driver; and a stepped motor drives the main shafts. By the numerical control machine, a plurality of workpieces can be simultaneously machined, the yield is high, and the working efficiency is improved.

Owner:ZHANGZHOU TIANQU NUMERICAL CONTROL EQUIP CO LTD

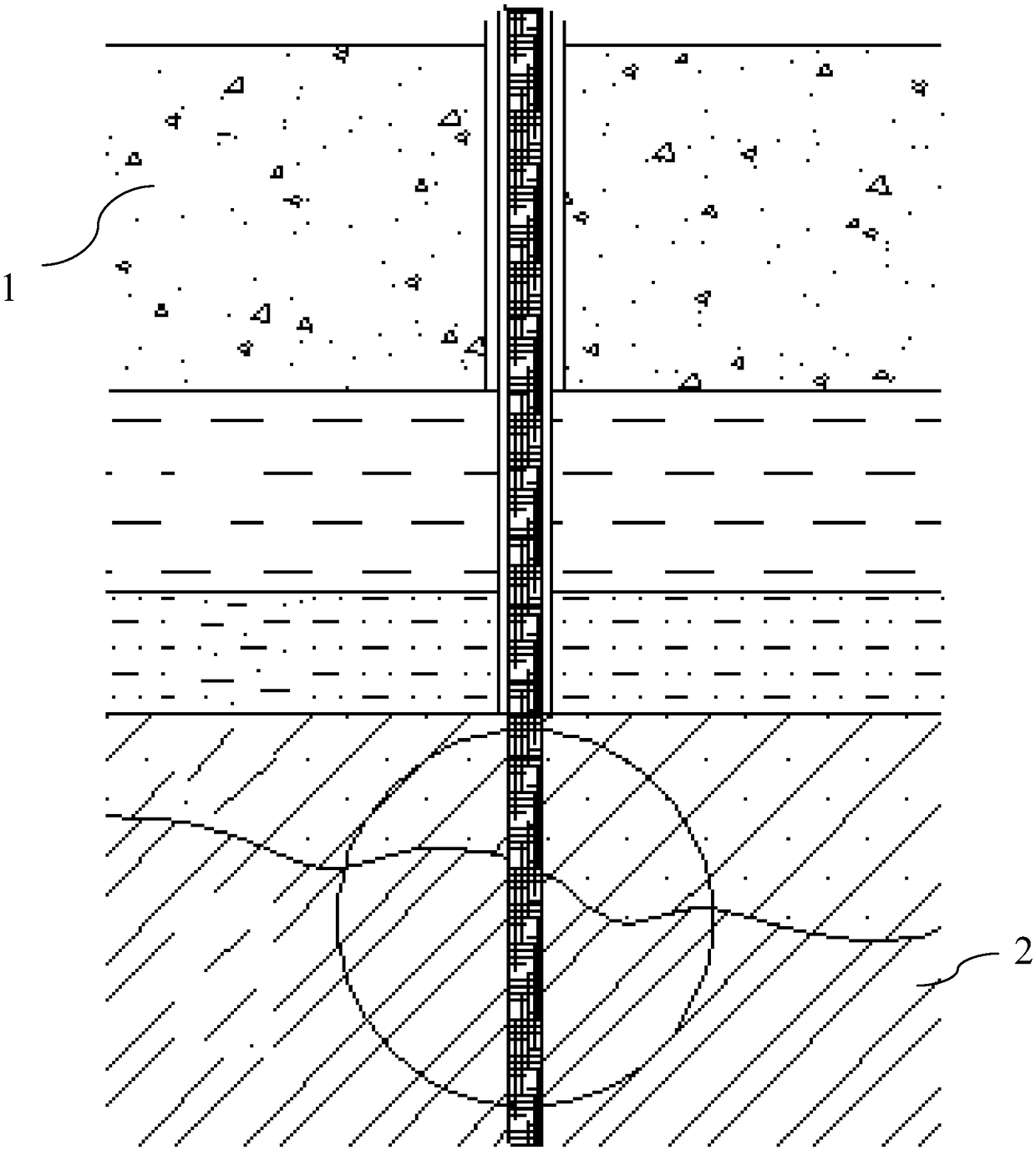

Construction method for pretreatment of bedrock and/or boulder stratum in shield tunnel

InactiveCN109026037AShield Tunneling Construction Goes SmoothlyImprove construction progressUnderground chambersTunnel liningSection planeBedrock

The invention provides a construction method for pretreatment of bedrock and / or boulder stratum in a shield tunnel, which comprises the following steps: 1) physical exploration of geological section within the range of a tunnel to be excavated is carried out; the geological section where bedrock and / or boulder exist in the strata to be excavated by a shield machine is identified as bad geologicalsection; 2) the location of a blasting hole within the range of the bad geological section is confirmed and the blasting hole is formed by drilling construction; 3) the blasting hole is loaded with adetonating charge to carry out blasting operations; 4) broken surrounding rock is reinforced by sublevel grouting in the bad geological section after blasting. The construction of the shield tunnel can be carried out smoothly, the construction progress can be speeded up and the frequency of tool-changing can be reduced.

Owner:CHINA RAILWAY 12TH BUREAU GRP +2

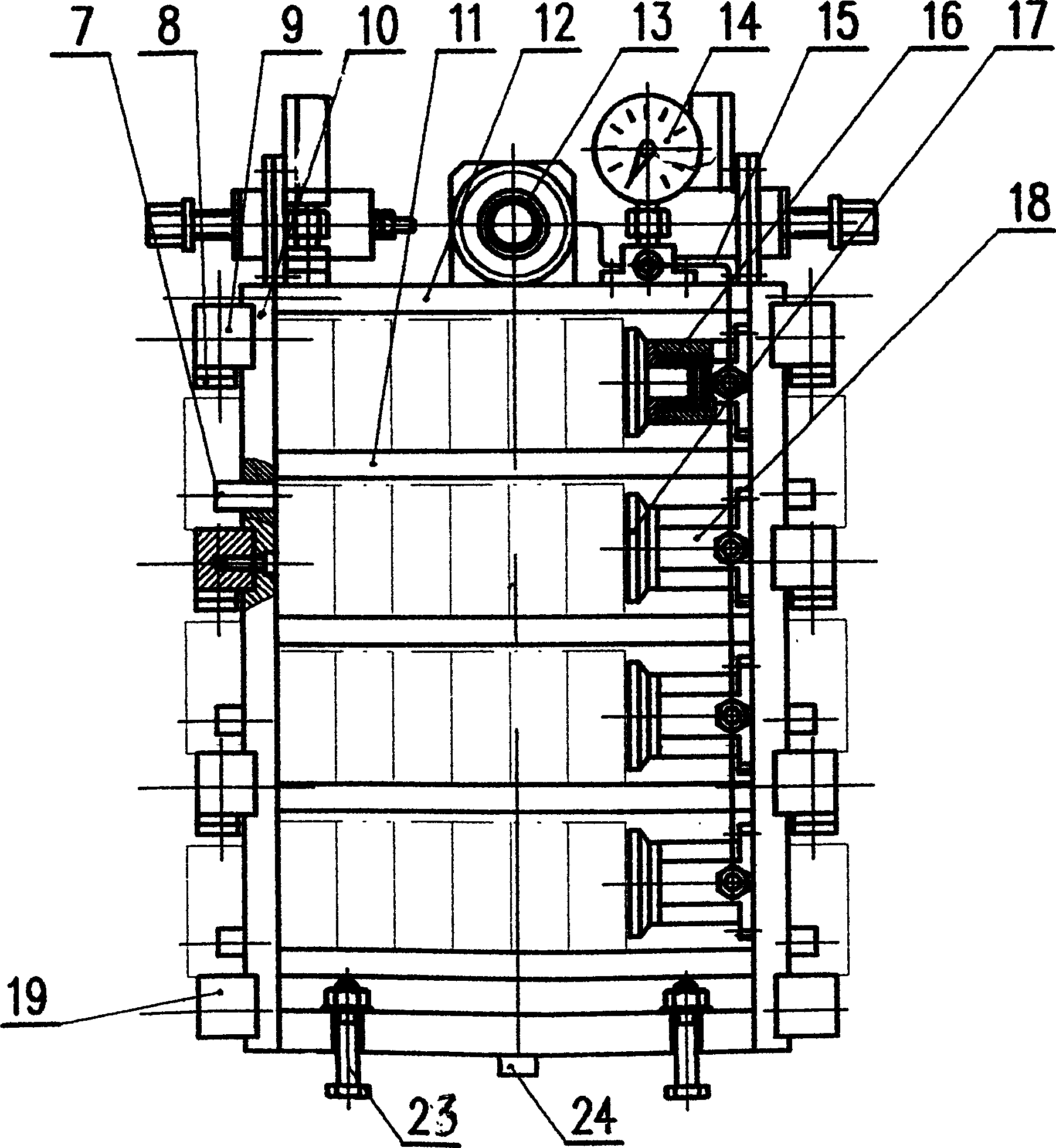

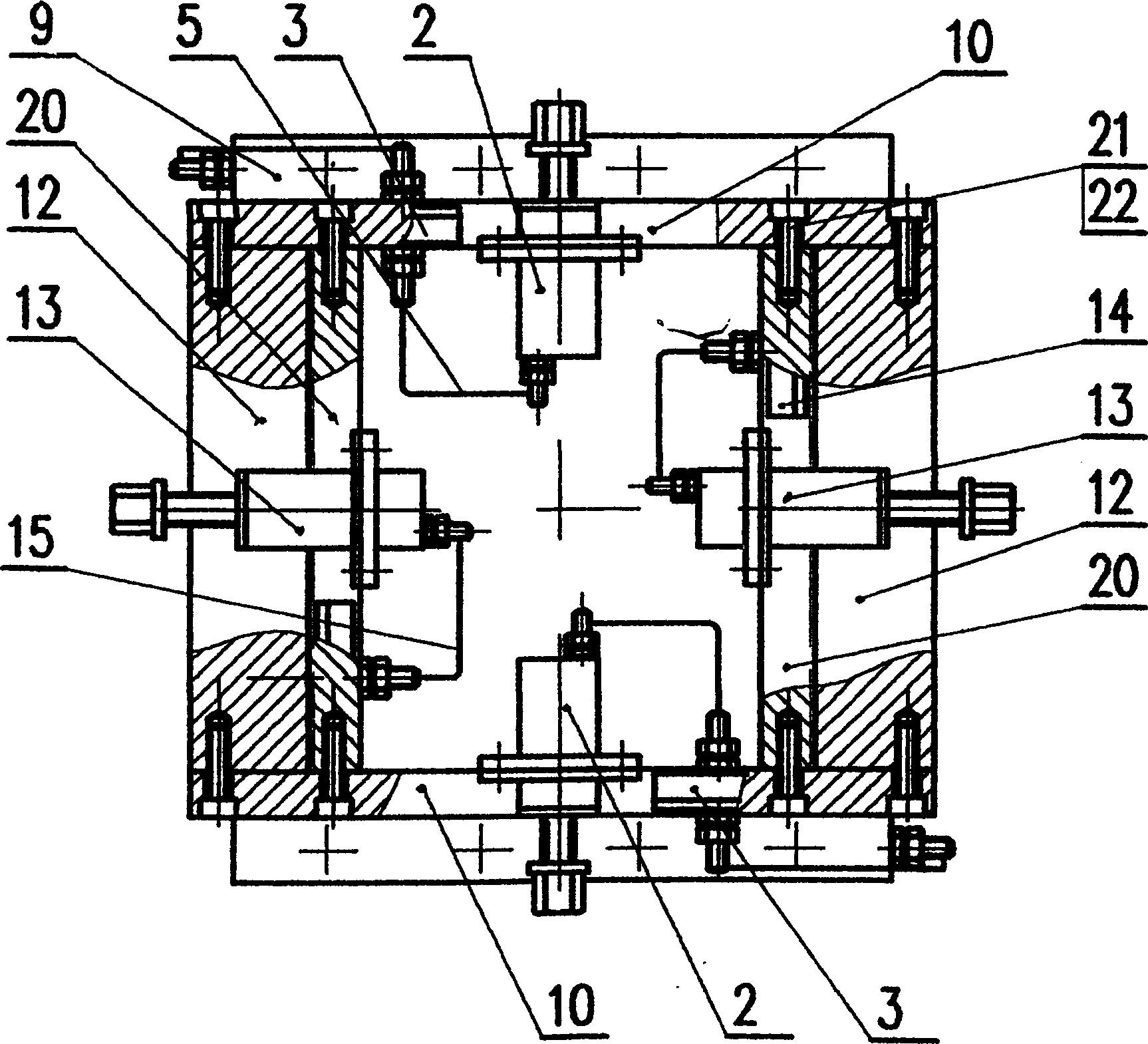

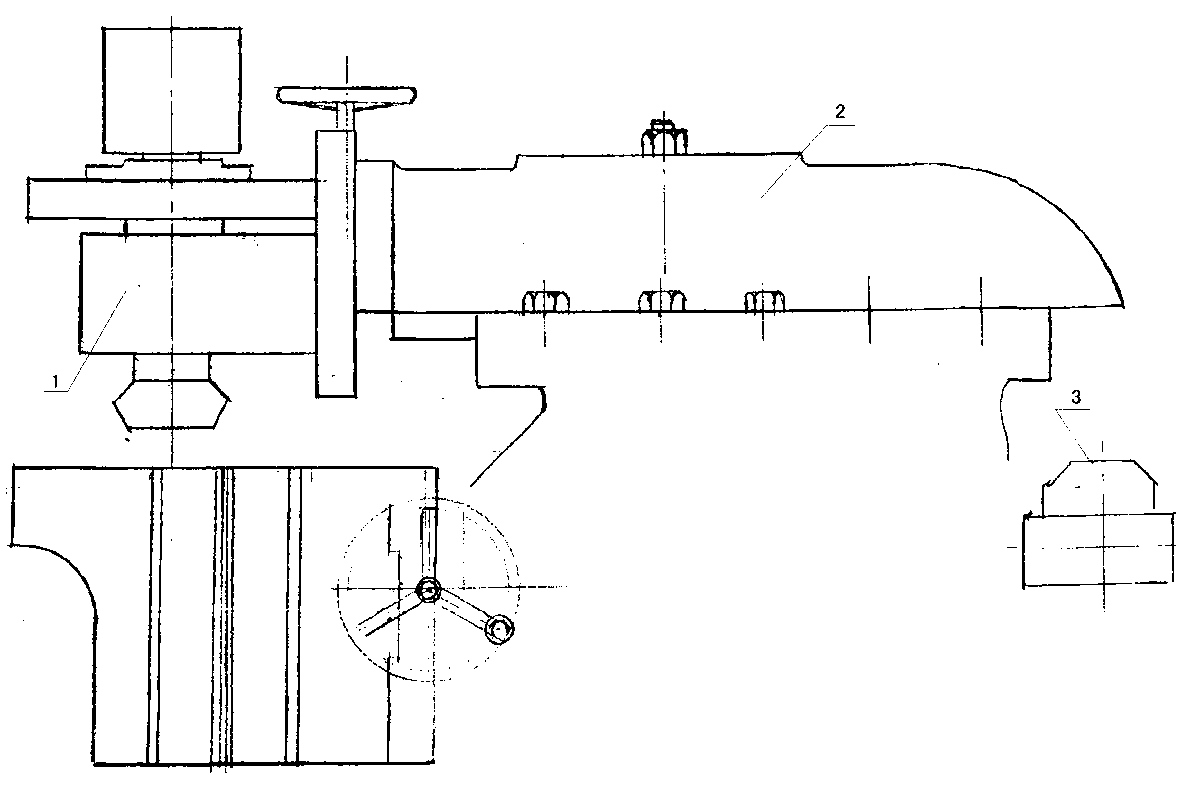

Processing method for hexahedral valve assembling block parts and clamp thereof

InactiveCN1593842AExpand clampingLarge processing areaPositioning apparatusMetal-working holdersEngineeringSwitching time

The invention relates to process for blocking accessory of cubic valves and the clump, which both belongs to the field of processing blocking accessory of cubic valves for hydraulic pressure controlling valve. The sets vertical quadrate clump box that has four faces on two revolving workbench of the chief horizontal processing table. Then set the six faces of the cubic valves to the four faces of the clump box. To finish the horizontal process and hole process of the six faces of the cubic valves through the revolving of quadrate clump box and the atomically tool switching of horizontal processing table. Processing, setting up and using of the invention are simple, so it needs only one step and lesser tool switching time to finish the horizontal process and hole process of the six faces of the cubic valves so that to product with high efficiency and high quality.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

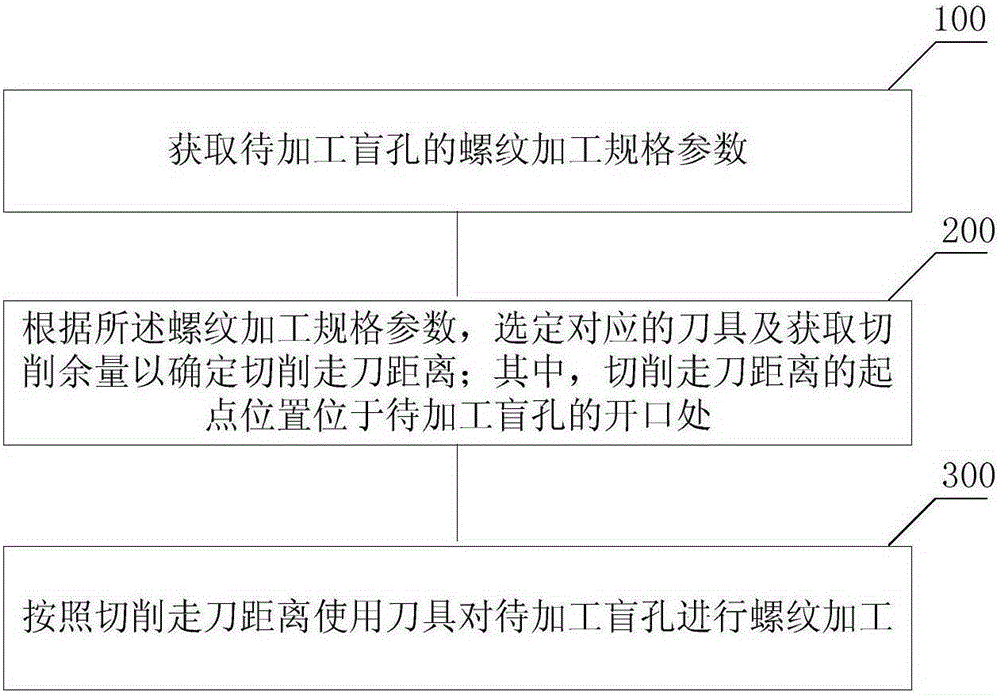

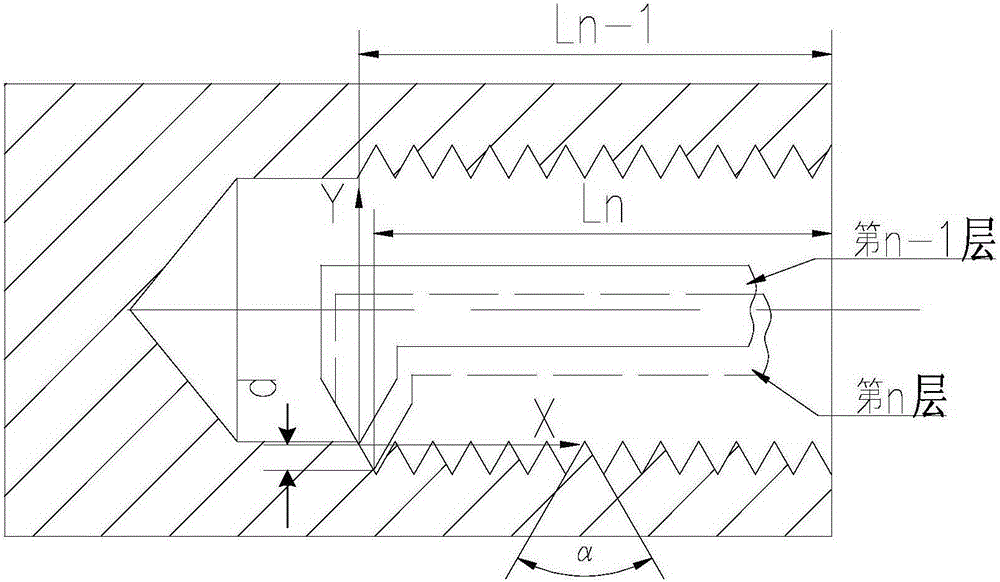

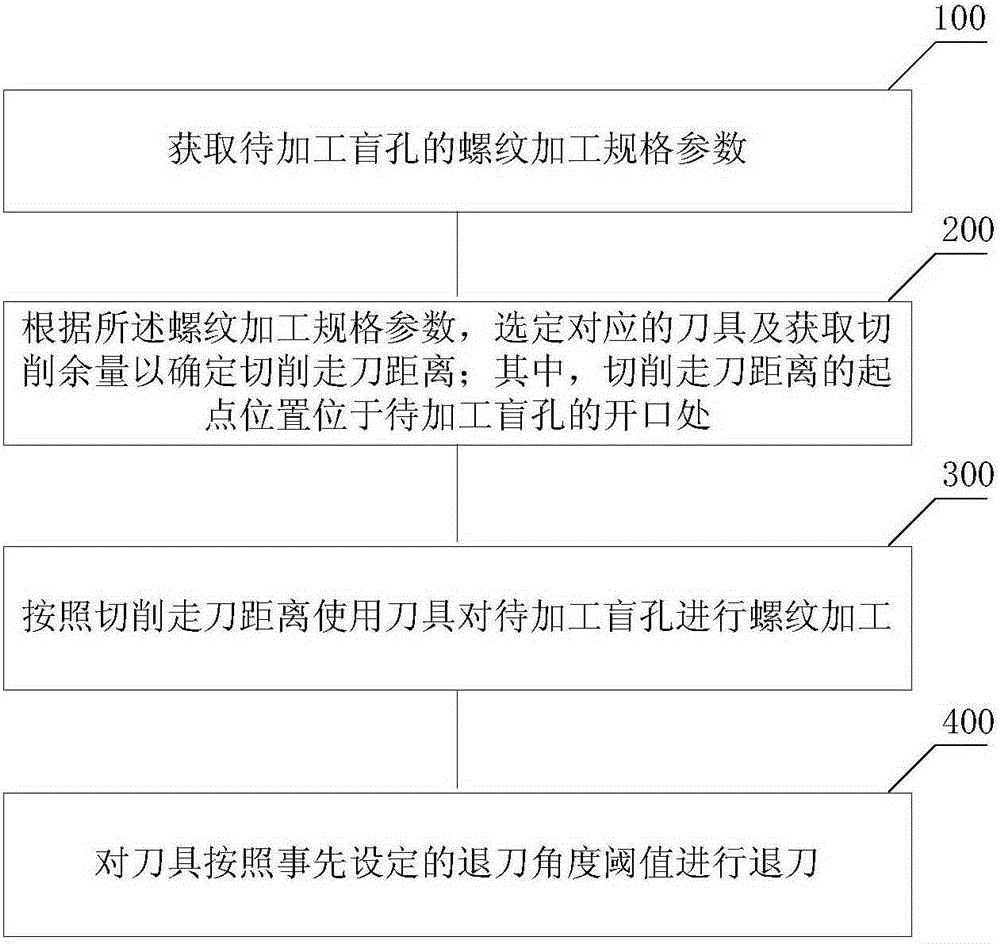

Method for machining internal thread of blind hole without tool withdrawal groove

The invention discloses a method for machining an internal thread of a blind hole without a tool withdrawal groove. The method comprises the steps that the machining specification parameter of the thread of the blind hole to be machined is obtained; a corresponding tool is selected and the cutting allowance is obtained according to the machining specification parameter of the thread so that the cutting feeding distance can be determined, and the initial position of the cutting feeding distance is located at an opening of the blind hole to be machined; and the thread is machined on the blind hole to be machined through the tool according to the cutting feeding distance. According to the method for machining the internal thread of the blind hole without the tool withdrawal groove, the thread machining precision is improved, and the quality of the thread is improved; the service life of the tool is prolonged, and the use cost of the tool is greatly reduced; machining efficiency is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

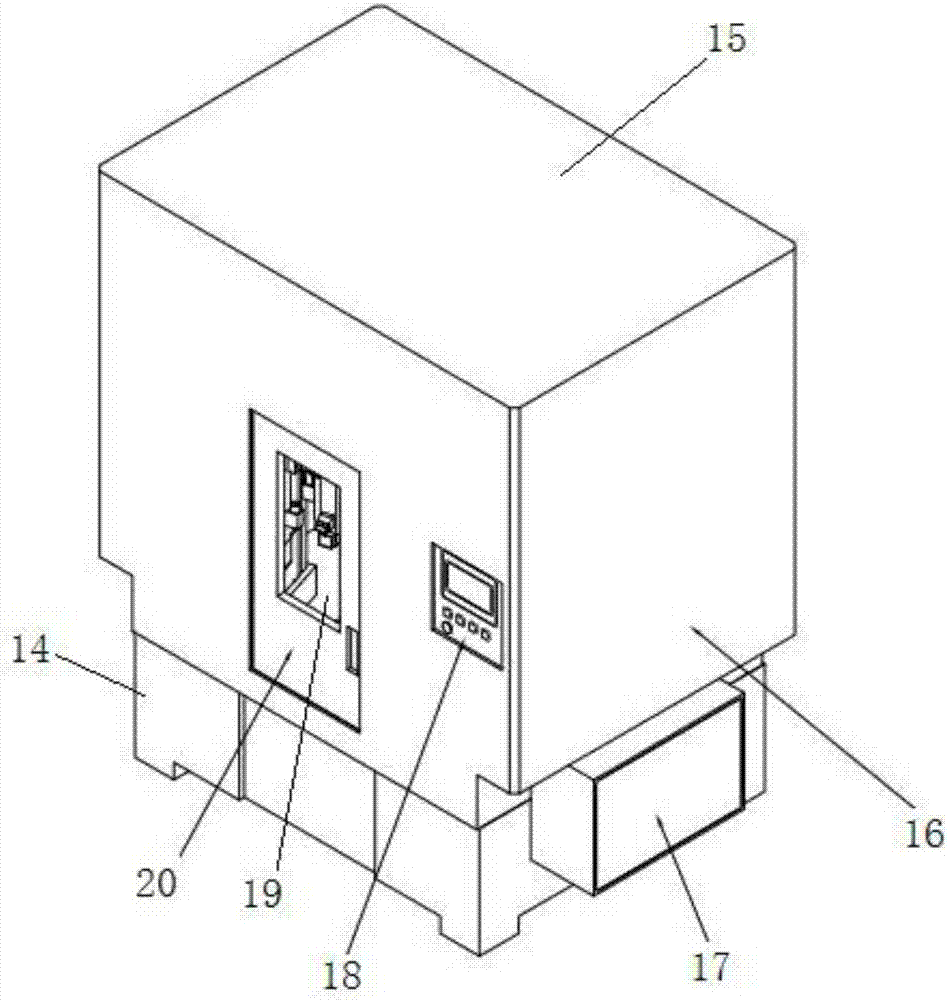

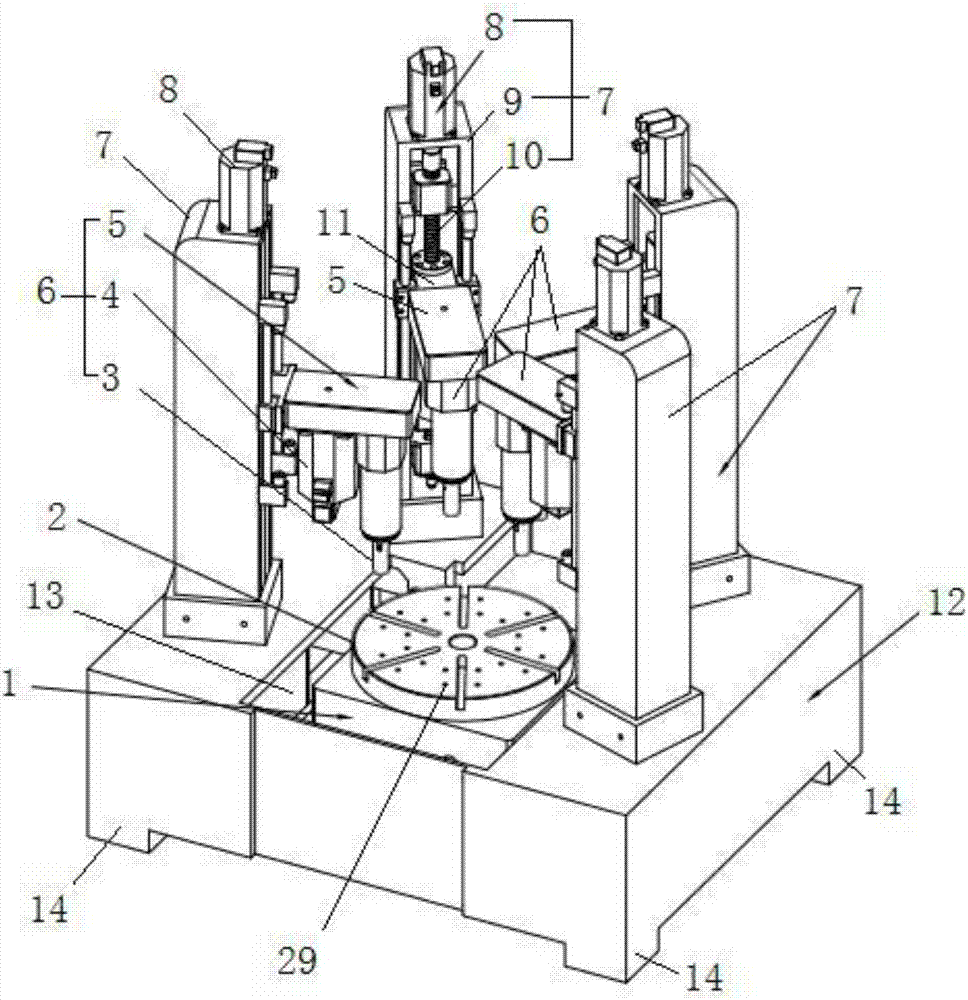

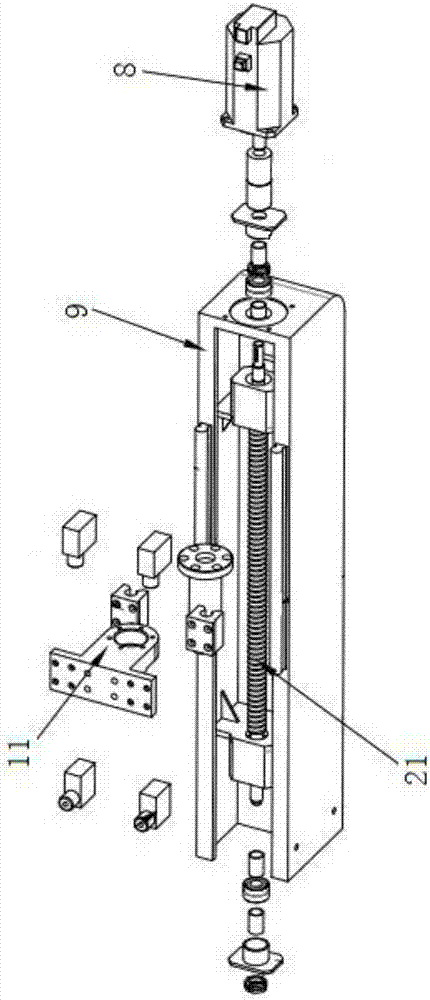

Five-station small drilling and tapping integrated machine

InactiveCN107052805ASmall processing flexibilitySmall footprintOther manufacturing equipments/toolsBall screwEngineering

The invention discloses a five-station small drilling and tapping integrated machine and belongs to the field of machining. The five-station small drilling and tapping integrated machine comprises a machine tool base. A rotary workbench and multiple longitudinal feeding mechanisms are arranged on the machine tool base. The rotary workbench comprises an index plate and a rotary transmission mechanism. The rotary transmission mechanism comprises a power main shaft and a workbench motor. Each longitudinal feeding mechanism comprise a lead screw seat fixedly arranged on the upper side of the machine tool base, a ball screw mechanism vertically arranged on the lead screw seat and a feeding motor for driving the ball screw mechanism. Nuts in the ball screw mechanisms drive corresponding power head assemblies. Each power head assembly comprises a working spindle for being connected with a drill bit or a screw tap and a spindle motor for driving the working spindle through a synchronous belt transmission device. The five-station small drilling and tapping integrated machine overcomes the defects that drilling and tapping integrated machines popular in the current market cannot conduct machining at the same time, the number of machined workpieces is small, the machining elasticity is low, the part replacement is complex, and the operation error is large.

Owner:HEFEI UNIV OF TECH

Normal-pressure tool changing cutter secondary beam with slag sliding function

The invention provides a normal-pressure tool changing cutter secondary beam with a slag sliding function, and aims to solve the problem that the flow rate of normal-pressure tool changing cutter slagfrom a front panel of a cutter to a soil warehouse is low. The secondary beam comprises the cutter, primary beams and secondary beam bodies, the primary beams and the secondary beam bodies are alternately arranged on the cutter, scrapers are arranged on the primary beams, the soil warehouse is connected with the rear of the cutter, normal-pressure changing tools are arranged on the primary beams,the secondary beam bodies comprises tool apron plates, slag sliding plates and slag retaining plates, the side walls of the slag sliding plates are vertically arranged in the middles of the slag retaining plates, the tool apron plates are arranged on two upper sides of the slag sliding plates, and cutting knives are arranged on the outer sides of the tool apron plates. The normal-pressure tool changing cutter secondary beam with the slag sliding function solves the problem that the flow rate of the slag from the front panel of the cutter to the soil warehouse of a shield tunneling machine islow, so that shield tunneling machine is provided with a normal-pressure tool changing cutter in order to adapt to high-water-pressure environments and improves tunneling efficiency when tool changingsafety is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Cermet cutter material, cutter and manufacture method

ActiveCN107587022AHigh hardnessStrong toughnessMilling cuttersTurning toolsHardnessOxidation resistant

A cermet cutter material comprises, by mass percentage, 70-90% of TiNC, 4-10% of Cr2C3, 1-2% of MoC2, 4-20% of Ni, and 0.4-1% of Y. A cermet cutter is made from the cermet cutter material. A manufacture method of the cermet cutter comprises: S1, preparing raw materials according to the formula of the cermet cutter material; S2, grinding the raw materials into powder, and drying the powder; S3, adding a forming agent to powder and performing granulation; S4, performing compression moulding to granules to obtain a cutter blank; S5, sintering the blank; and S6, performing coarse grinding, fine grinding and polishing to the sintered product to obtain the cermet cutter. The cutter made from the cermet cutter material is high in hardness, large in fracture toughness and flexure strength, and good in oxidation resistance and durability.

Owner:DONGGUAN HUAJING POWDER METALLURGY

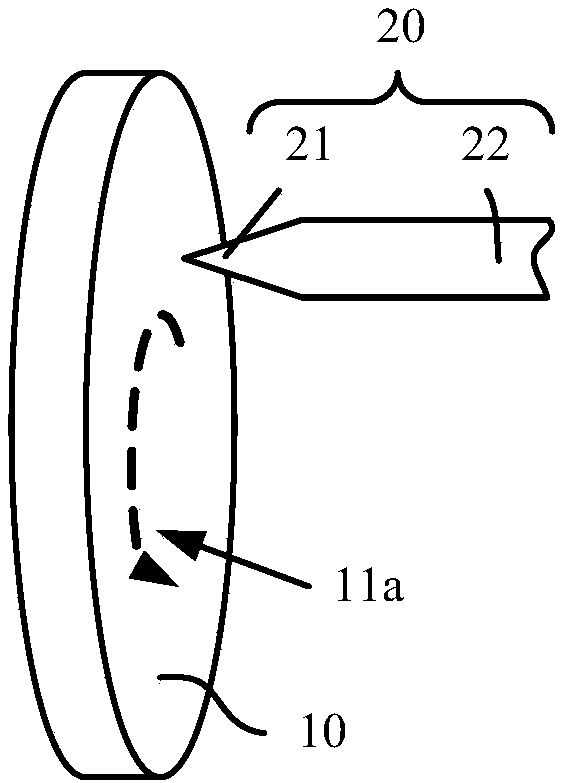

Machining method for target material

InactiveCN107790745AImprove cooling effectReduce the temperatureVacuum evaporation coatingSputtering coatingProcess efficiencyEngineering

The invention discloses a machining method for a target material. The machining method comprises the following steps: providing the target material, wherein the target material is provided with a surface to be machined; providing a tool, wherein the tool comprises a blade, and a chip discharge groove is formed in the blade; carrying out turning machining on the surface to be machined by adopting the tool to form a sputtering surface, wherein the waste chips generated in the turning process are discharged through the chip discharge groove in the blade. According to the technical scheme of the invention, in the turning process, the generated waste chips can be discharged through the chip discharge groove in the blade; and therefore, the heat generated in the turning process can be timely dissipated, improvement for the heat dissipation capacity of the adopted tool is improved, heat accumulation is reduced, lowering for the temperature of the tool in the turning process is improved, and reduction for the wear of the blade is improved, so that replacement times for the tool is reduced, and increasing for the machining efficiency is improved. In addition, in a machining process for thesputtering surface of the target material, tool setting times after tool replacement can also be reduced due to the reduction of the replacement times for the tool, so that increasing for process efficiency is also improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

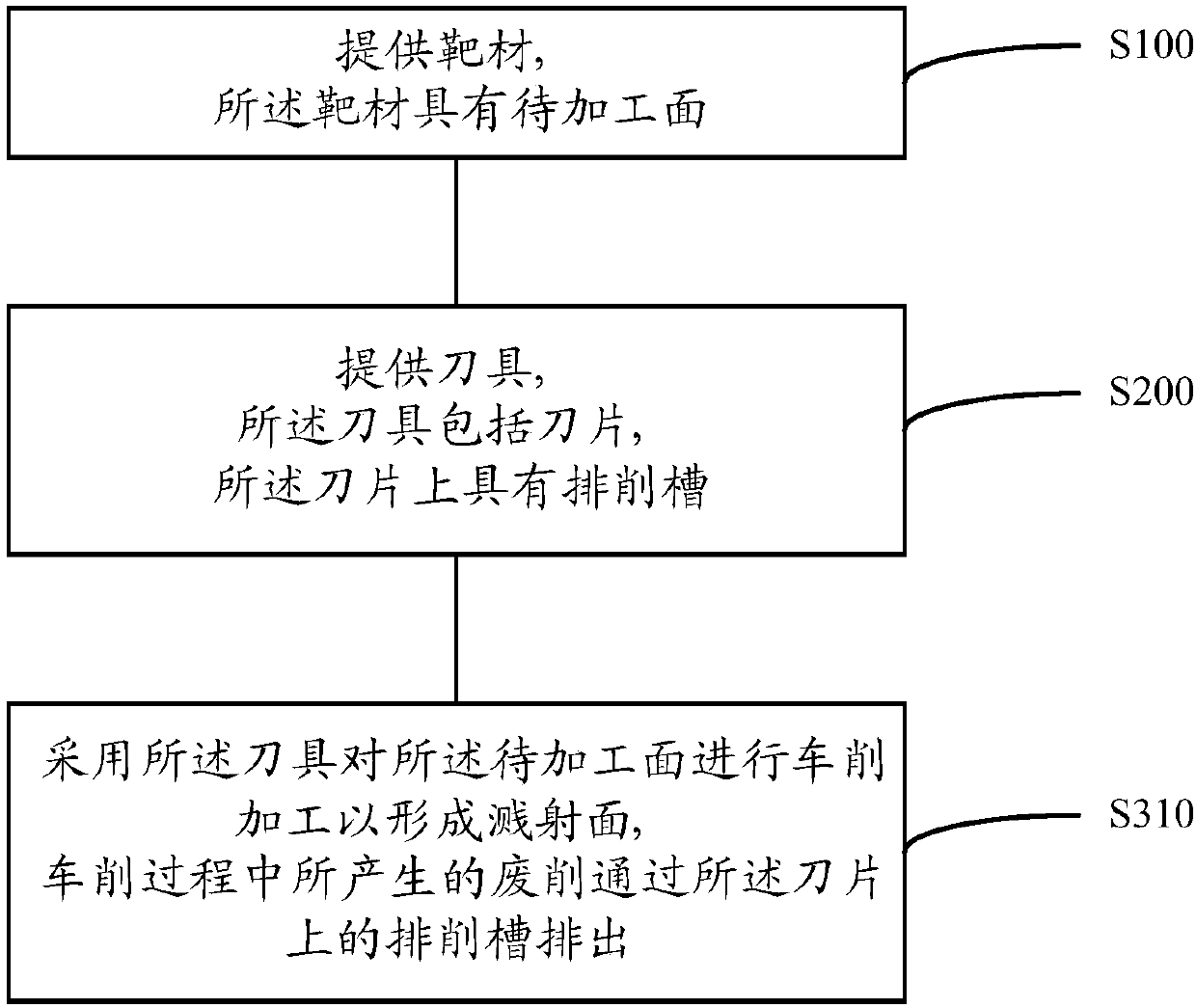

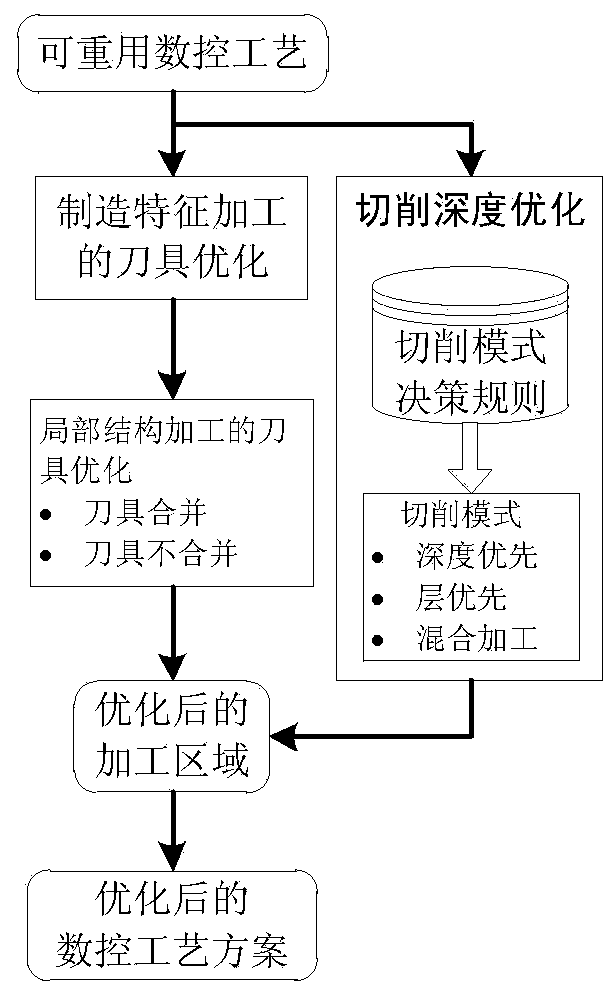

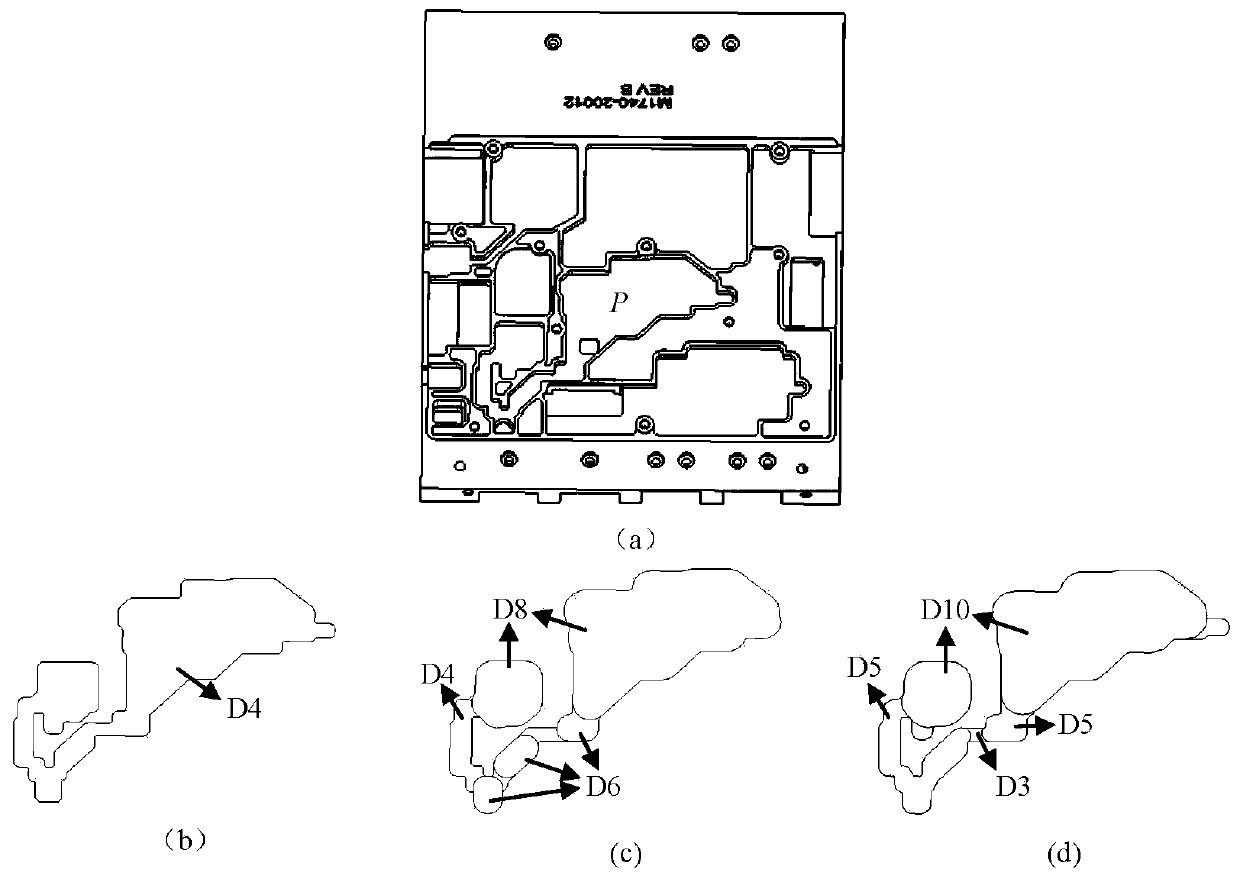

Complex part numerical control technology optimization and adjustment method facing technology reuse

ActiveCN109901514AReduce the number of tool changesShorten the length of the empty knifeProgramme controlComputer controlComputer scienceLocal structure

The invention discloses a complex part numerical control technology optimization and adjustment method facing technology reuse. The method is used to solve a technical problem that an existing numerical control technology optimization and adjusting method has low efficiency. In the technical scheme, optimization and adjustment are performed from aspects of cutter processing and a cutting depth. Onthe aspect of cutter processing, a processing cutter combination scheme of a complex characteristic is preferably selected, and partial structure processing cutters are merged and adjusted so as to reduce the number of cutter changing and shorten an empty cutter length. On the aspect of a cutting depth parameter, the cutting depth can be optimized through a reasonable cutting mode, and an optimized processing area can be obtained so as to fully use a cutter processing capability, finally acquire a high-efficient numerical control technology scheme and improve the processing efficiency of complex parts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

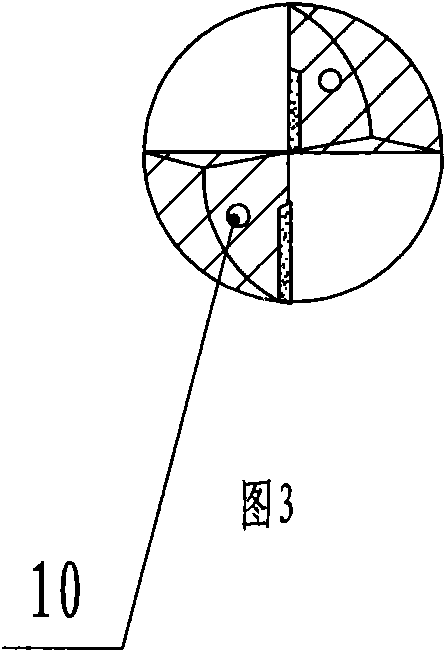

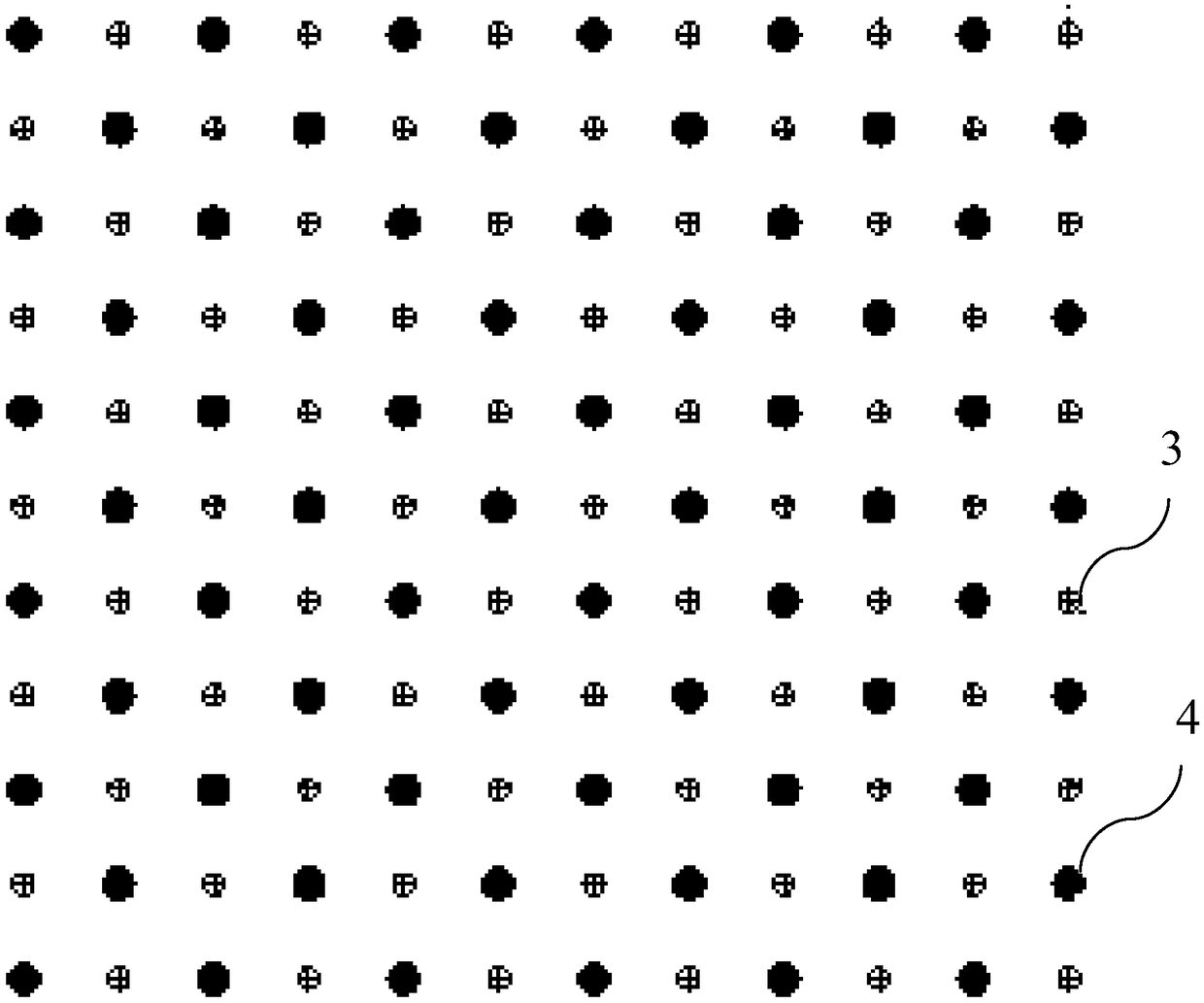

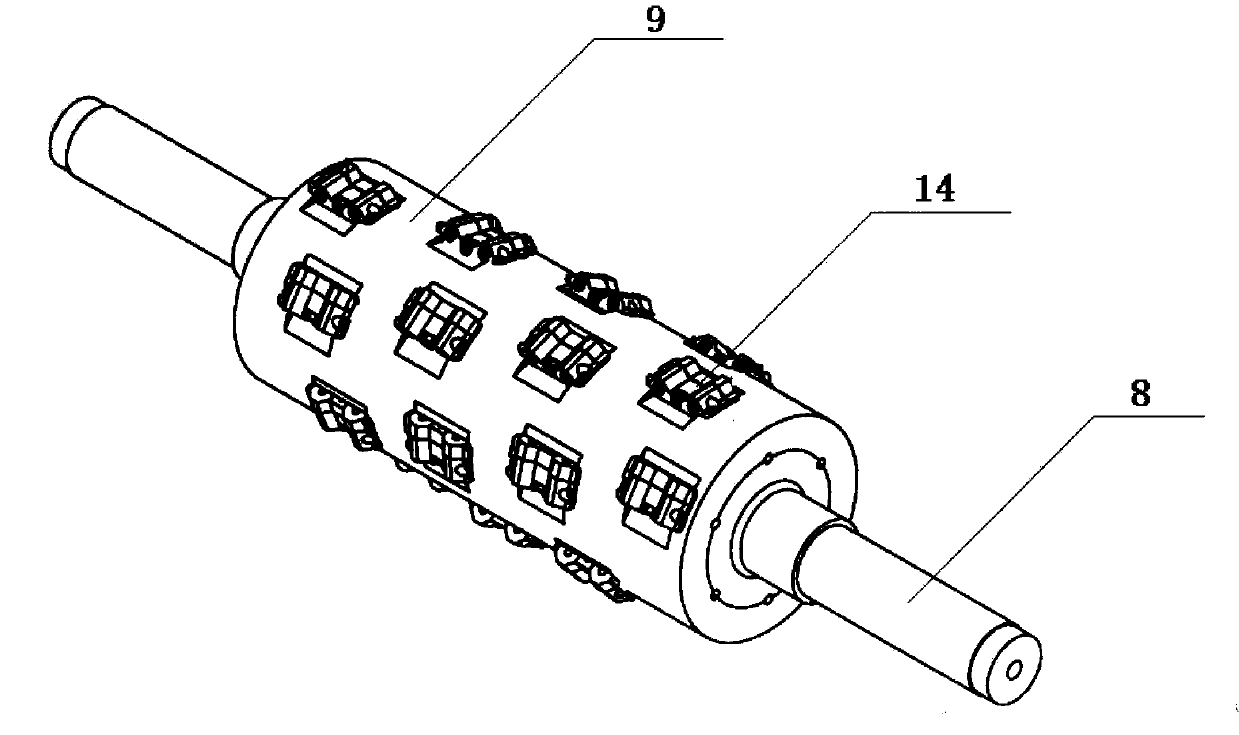

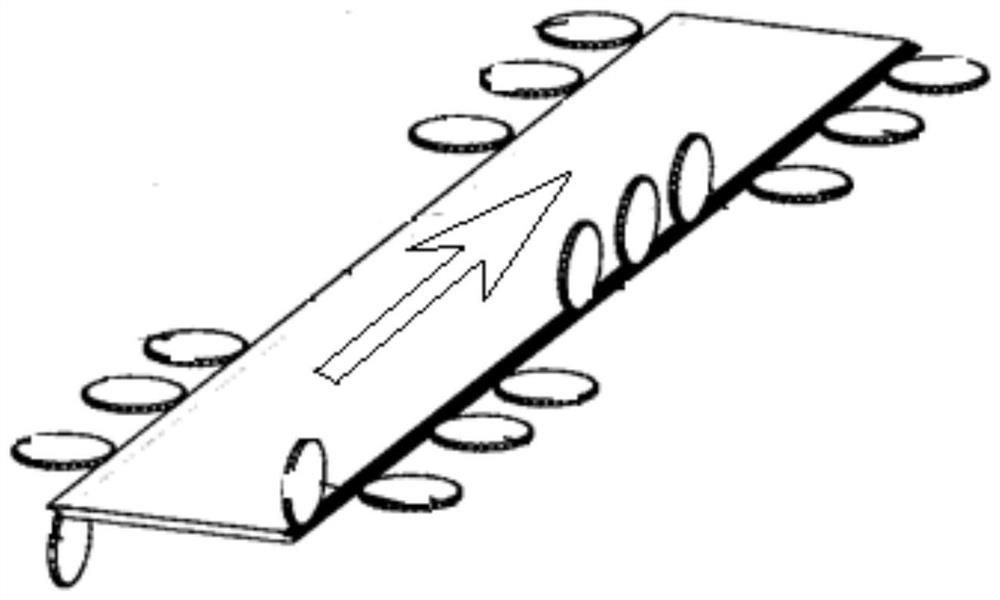

Shield machine cutter head with variable cutter spacing

ActiveCN110454181AEnsure rock breaking efficiencyEfficient excavationTunnelsRock breakingShield machine

The invention discloses a shield machine cutter head with variable cutter spacing, and solves the technical problem that the hob spacing on the existing shield machine cutter head is not variable. Theshield machine cutter head comprises a cutter main beam, wherein a hob assembly is arranged in the cutter main beam, and a compression bolt set for fixing the hob assembly is arranged on the cutter main beam at interval. The invention realizes the function of adjusting the cutter spacing of the hob correspondingly according to the construction geological change through changing the fixing mannerof the hob assembly, and achieves the efficient matching of the cutter spacing arrangement and the construction geology, and can ensure the rock-breaking efficiency of the hob in different geologies,reduces the construction difficulty, speeds up the construction progress, prolongs the cutter life, reduces the number of inspections and cutter change; meanwhile, the construction cost is reduced, the adaptability of the shield cutter is improved, and the long distance, efficient and reliable tunneling of the shield machine is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

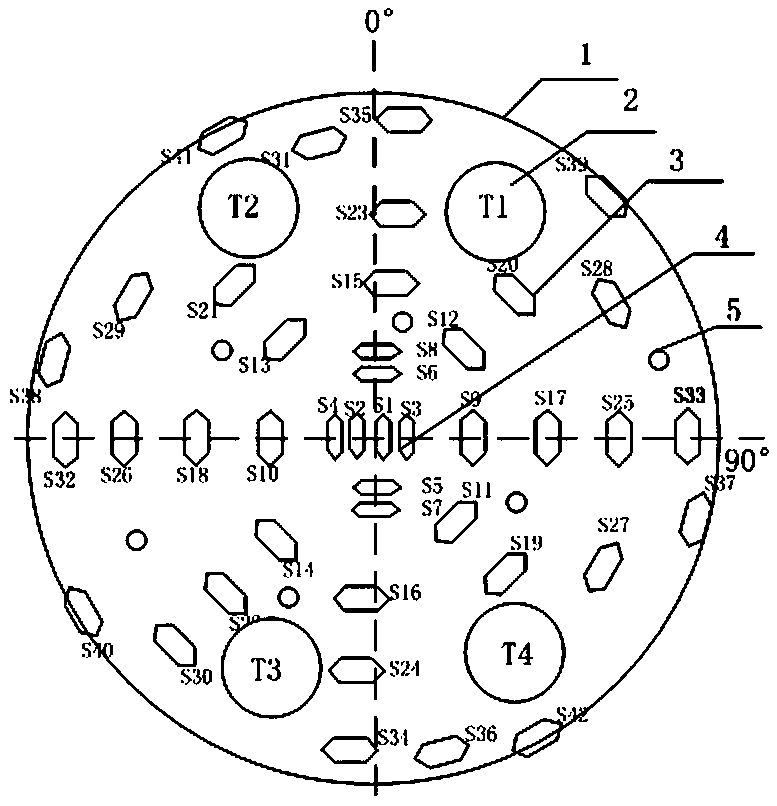

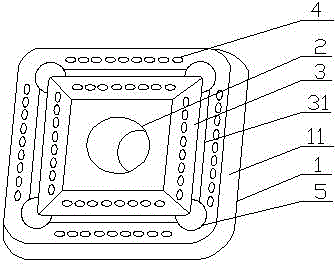

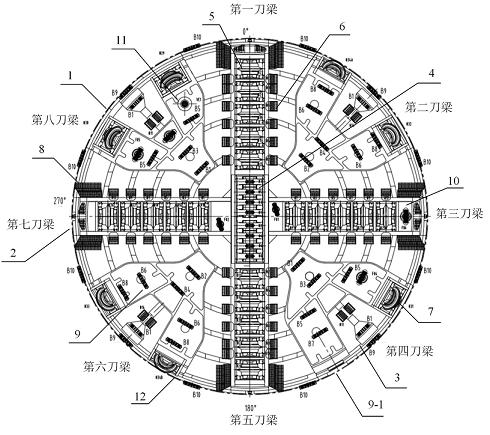

Arrangement method of tools on composite cutterhead of shield tunneling machine

The invention discloses an arrangement method of tools on a composite cutterhead of a shield tunneling machine. The composite cutterhead is a panel type cutterhead, and the arrangement method includes the arrangement method of cutters and hobs. The service lives of the cutters and the hobs are calculated equivalently through a formula, the mounting diameters of the cutters and the hobs are adjusted, and the service lives of the cutters and the service lives of the hobs are made to be the same by selecting different materials. The method for calculating the service lives of the tools of the cutterhead of the shield tunneling machine is designed, the abrasion degrees of the tools corresponding to the tunneling distances are calculated, and the tunneling distances of the tools within the service lives are further estimated; the service lives of the hobs and the service lives of the cutters are compared, and are made to be close by changing mounting diameters and increasing or decreasing the number of the cutters and the number of the hobs; and when the tools need to be replaced, the cutters and the hobs are replaced uniformly, the tool replacing frequency is reduced, safety and reliability are achieved, and the labor hour of the shield tunneling machine is guaranteed to a certain extent.

Owner:FUJIAN UNIV OF TECH

AlZrTiN composite multi-gradient multi-coating turning blade and preparation method thereof

ActiveCN104400024AReduce internal stressHigh bonding strengthLayered productsVacuum evaporation coatingWear resistantUltimate tensile strength

The invention discloses an AlZrTiN composite multi-gradient multi-coating turning blade and a preparation method thereof, and relates to the technical field of coating blades and preparation methods thereof. The turning blade comprises a blade basal body, wherein a Ti connecting layer, a TiN gradient transition layer, an AlZrTiN gradient transition layer, an AlZrTiN outer wear resistant layer and a TiN gradient transition outer lubricating layer are arranged on the surface of the blade basal body in sequence from inside to outside; the contents of Al, Zr and N elements in the AlZrTiN gradient transition layer are gradually increased from inside to outside; and the content of a Ti element in the TiN gradient transition outer lubricating layer is gradually increased from inside to outside. The preparation process comprises the following steps: firstly, the blade basal body is cleaned; and then, the blade basal body and a needed target are put in a vacuum chamber of a magnetron sputtering machine for coating. In the multi-coating turning blade, the bonding strength between coatings and the blade basal body and between the coatings is high, the internal stress of the coatings is low; and the turning blade has excellent wear resistance and comprehensive mechanical performance.

Owner:无锡锐志方达金属科技发展有限公司

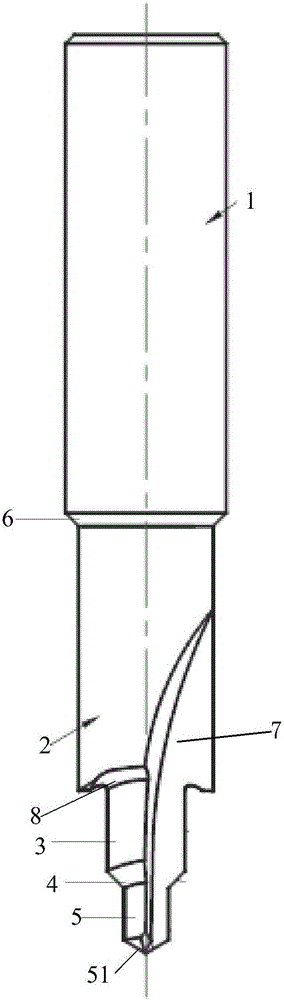

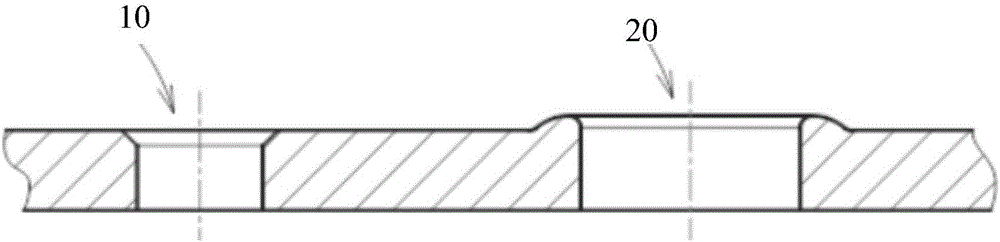

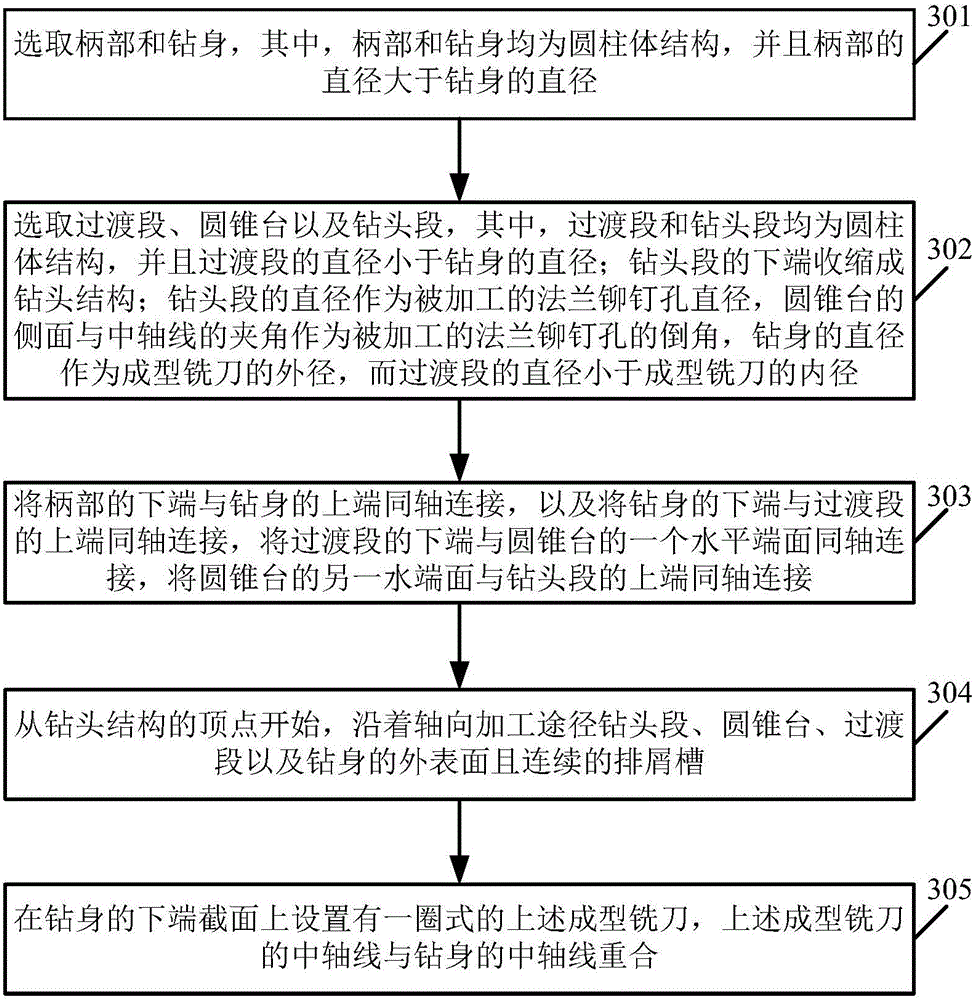

Combined drill molding milling cutter and manufacturing method thereof

InactiveCN105689766AEasy to processReduce the number of tool changesTransportation and packagingMilling cuttersMilling cutterCircular cone

The invention discloses a combined drill molding milling cutter and a manufacturing method thereof. The combined drill molding milling cutter comprises a handle part and a drill body which are both in a cylinder structure, wherein the diameter of the handle part is larger than the diameter of the drill body; the handle part, the drill body and a transition section in a cylinder structure are sequentially and coaxially connected; the diameter of the transition section is smaller than the diameter of the drill body; the transition section, a cone frustum and a drill bit section in a cylinder structure are sequentially and coaxially connected; the lower end of the drill bit section is contracted into a drill bit structure; the diameter of the drill bit section is taken as the diameter of a processed flange rivet hole; an included angle formed by the side of the cone frustum and a central axis is taken as a chamfer of the processed flange rivet hole; the diameter of the drill body serves as the outer diameter of the molding milling cutter; however, the diameter of the transition section is smaller than the inner diameter of the molding milling cutter; the drill bit section, the cone frustum, the transition section and a continuous chip groove in the surface of the drill body are arranged from the peak of the drill bit structure along the axial processing route; a coil type molding milling cutter is arranged on the section of the lower end of the drill body; and the central axis of the molding milling cutter and the central axis of the drill body are overlapped. The processing procedures for the flange rivet hole and a valve seat molding hole are simplified.

Owner:GUANGZHOU JUNJIE PRECISION TOOLS CO LTD

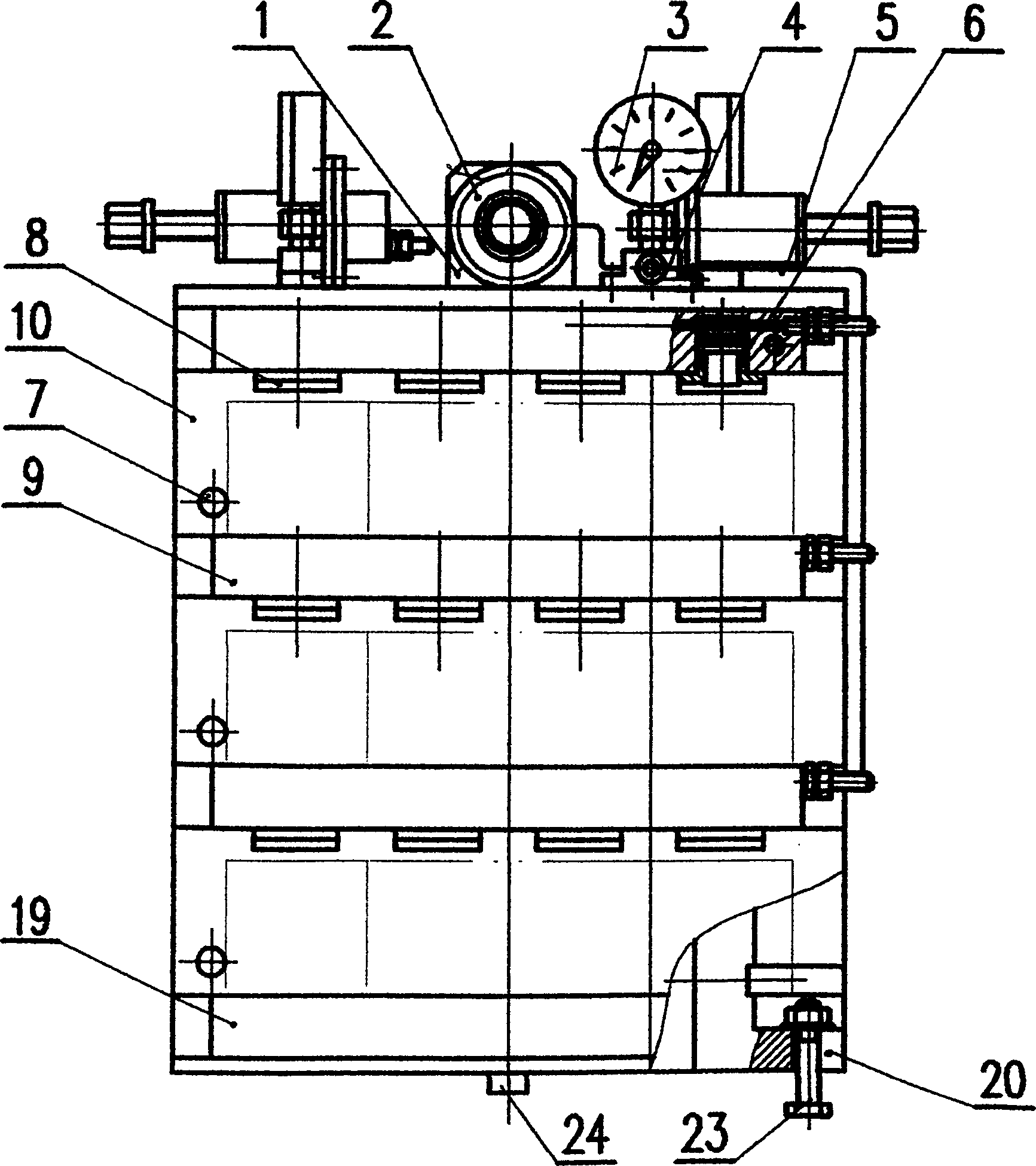

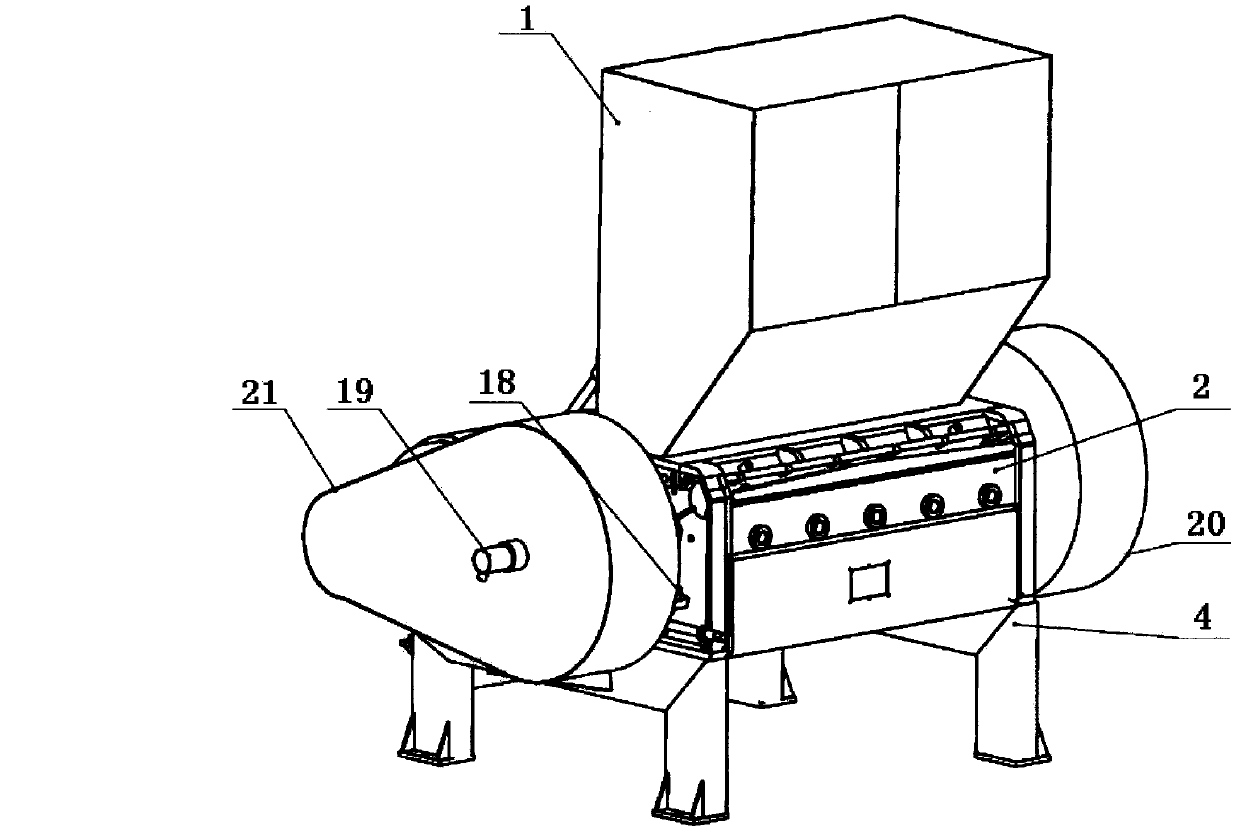

Steel wire separating machine

InactiveCN104174473ASimple structureReasonable structureGrain treatmentsElectric machineryEngineering

The invention relates to a steel wire separating machine which comprises a feeding hopper, a box body, a motor, a rack, a driving belt wheel, a belt, a driven belt wheel, a main shaft, a moving cutter roller, a stationary cutter, a screen bracket and a discharging bin. The box body is an irregular quadrilateral body which can be opened and closed vertically, the feeding hopper is communicated with the upper portion of the box body, the box body and the motor are both arranged on the rack, the driving belt wheel is arranged on the motor, the driven belt wheel is connected with the driving belt wheel through the belt, the driven belt wheel and the main shaft are connected in a key mode, the main shaft is arranged in the box body, the main shaft is sleeved with the moving cutter roller, the stationary cutter is arranged at a vertical port of the box body, the screen bracket is arranged on the lower portion of the box body, a screen is arranged on the screen bracket, and the discharging bin is connected with the screen bracket. The steel wire separating machine has the advantages of being simple and reasonable in structure, convenient to maintain, safe, reliable, and high in separating efficiency.

Owner:GUANGZHOU 3E MACHINERY

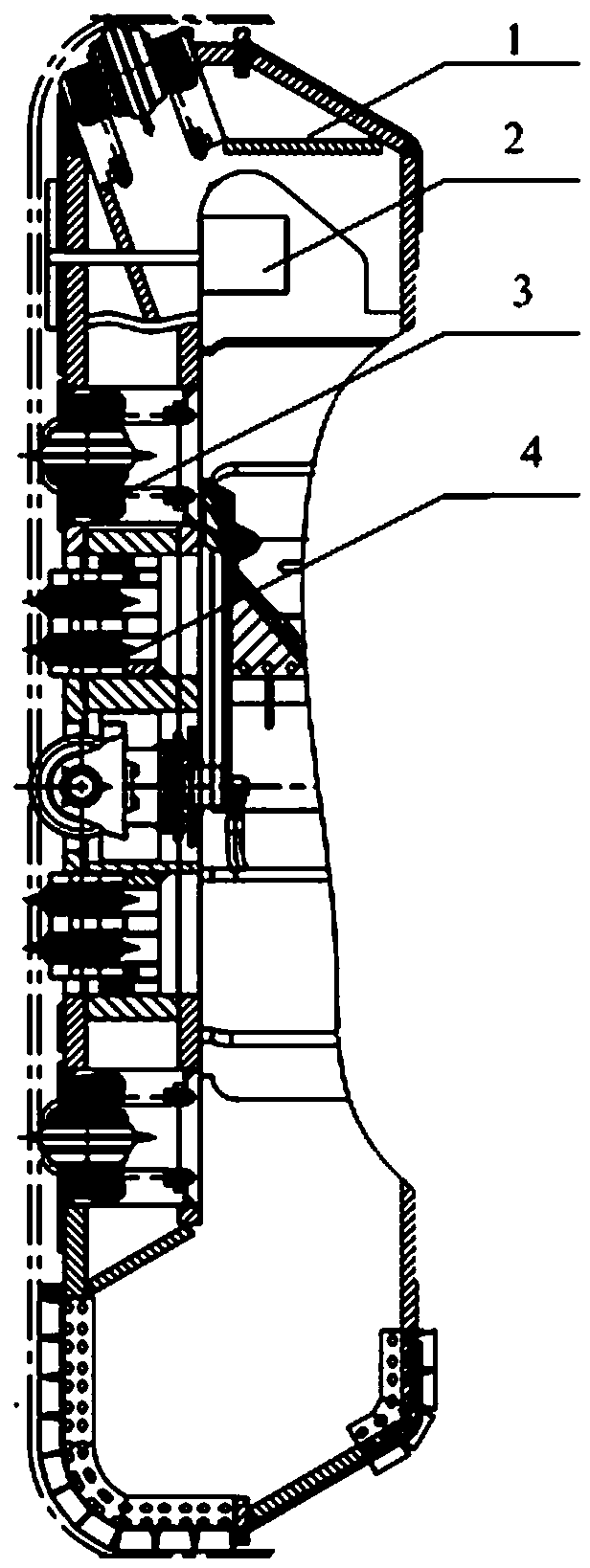

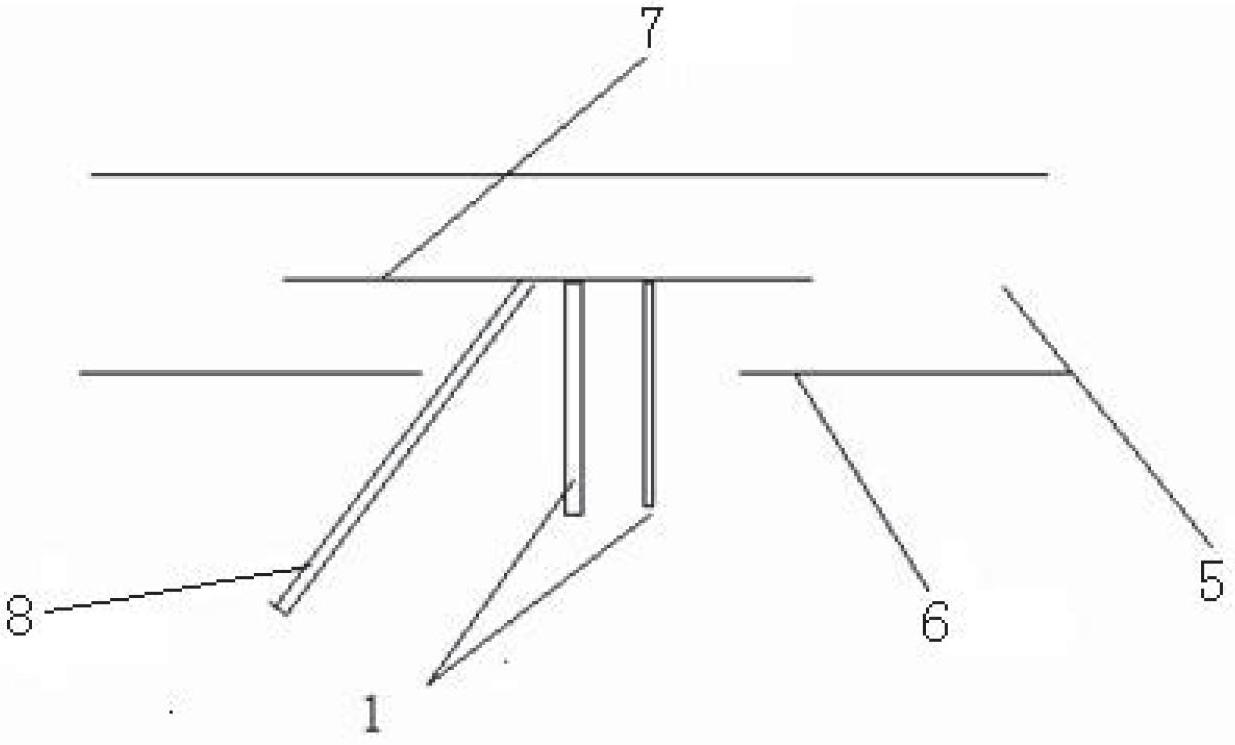

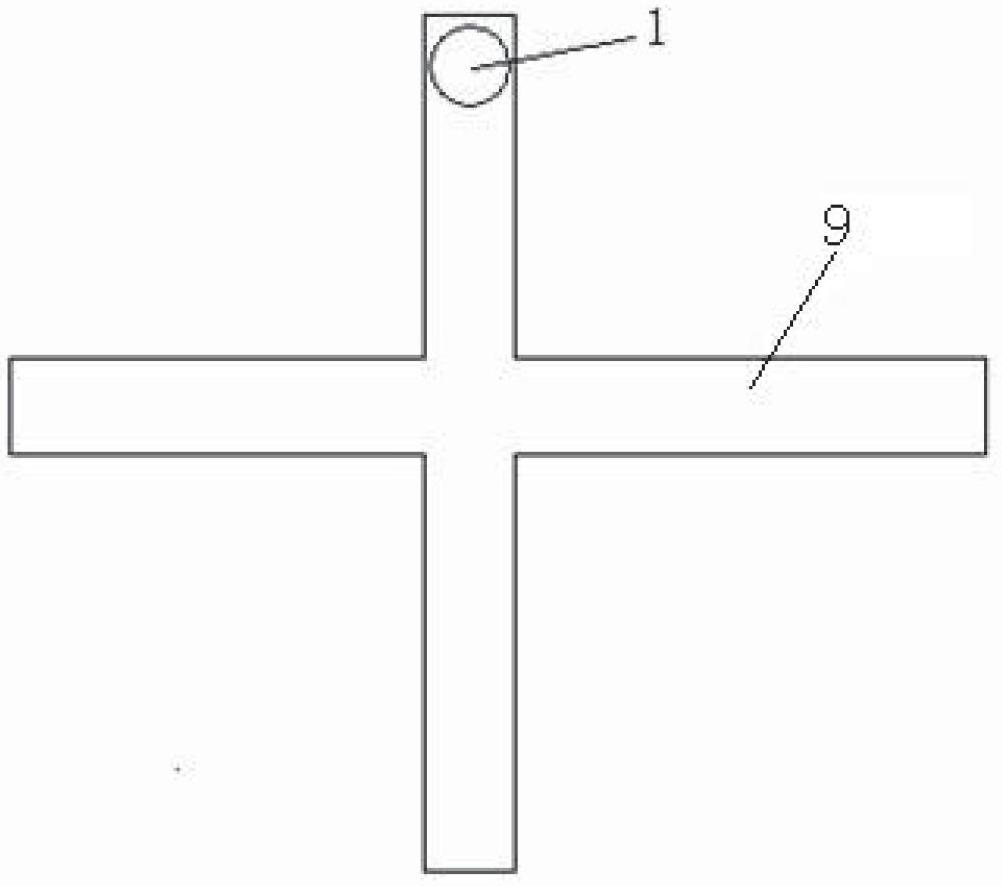

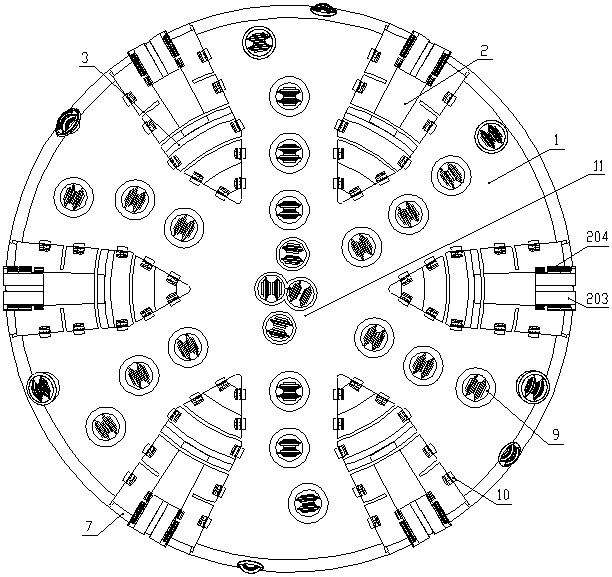

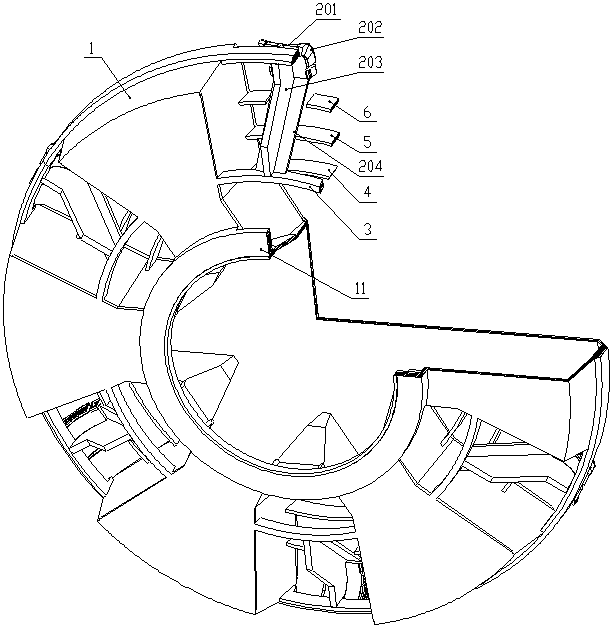

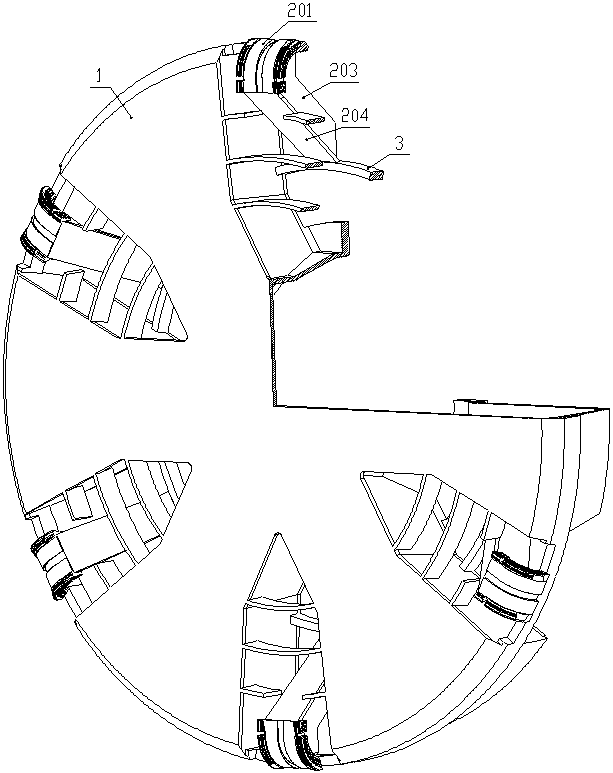

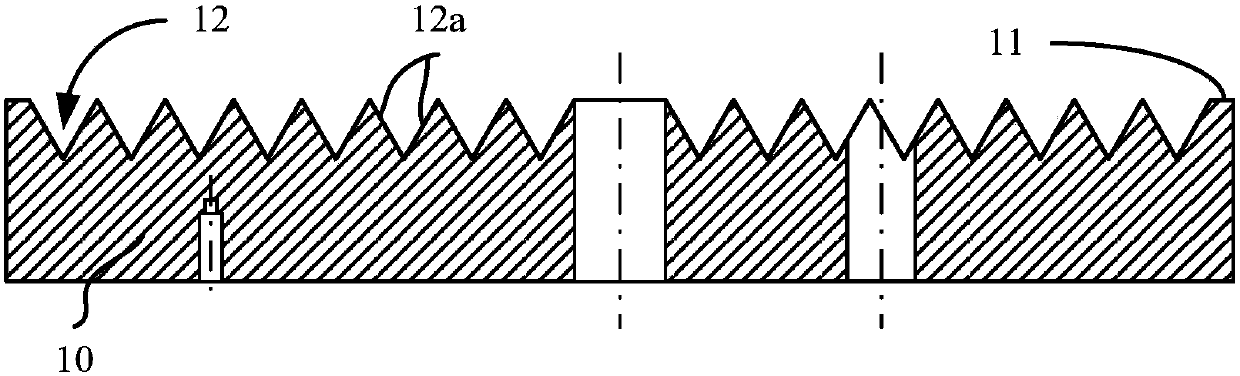

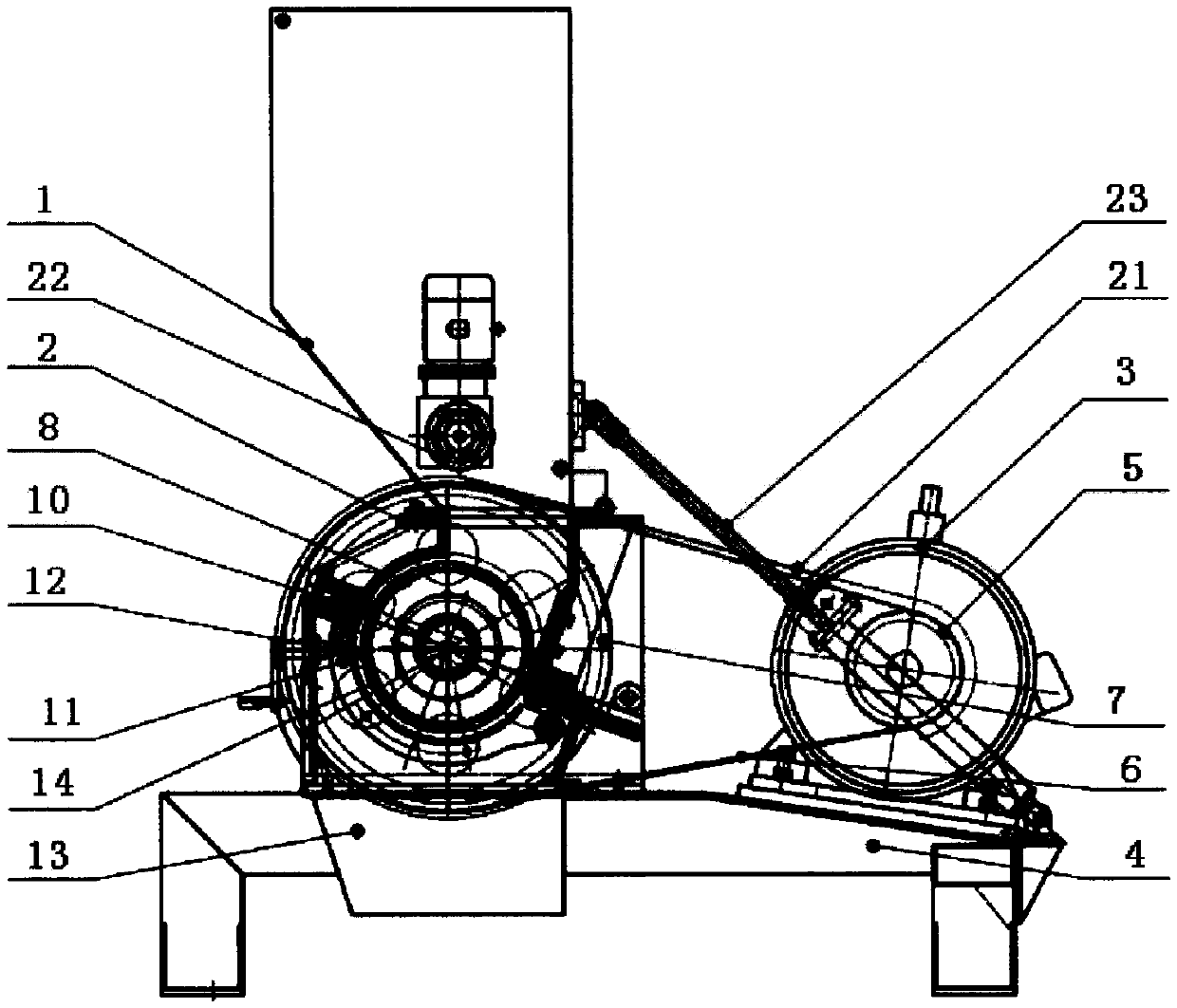

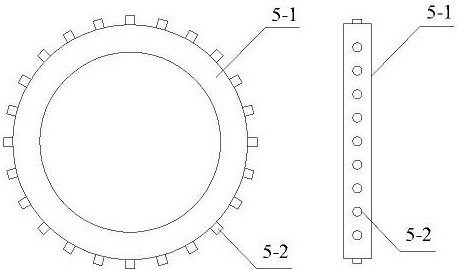

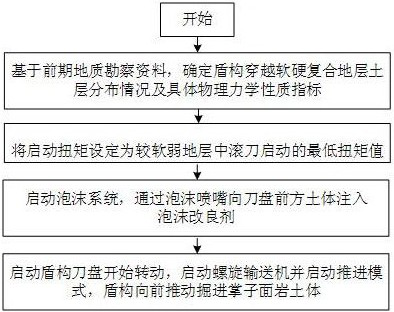

Shield cutter head suitable for soft and hard composite stratum and tunneling method

PendingCN112431601AEffective rotationGuaranteed stabilityTunnelsClassical mechanicsStructural engineering

The invention provides a shield cutter head suitable for a soft and hard composite stratum and a tunneling method. The cutter head comprises a shield cutter head body (1), a cross-shaped main cutter beam (2), an auxiliary cutter beam (3), a center serrated cutter (4), a front hob (5), a cutter (6), an edge hob (7), an edge scraper (8), a fixed serrated cutter (9), a foam nozzle (10), a wear detection cutter (11), a wear-resistant steel plate (12) and other components. The cross-shaped main cutter beam is composed of a first cutter beam, a third cutter beam, a fifth cutter beam and a seventh cutter beam, and the auxiliary cutter beam is composed of a second cutter beam, a fourth cutter beam, a sixth cutter beam and an eighth cutter beam. The method comprises the steps of determining the starting torque of the hobs, selecting and setting the starting torque of the hobs as the starting torque of the hobs of the soft soil stratum, starting a foam system to spray a foam modifier, and pushing a tunneling face rock-soil body forwards by a shield. The opening rate of the cutter head reaches 43%, the cutter head is particularly suitable for tunneling of a typical gravel-argillaceous siltstone composite stratum, and the risk of mud pasting of the cutter head is reduced.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP +1

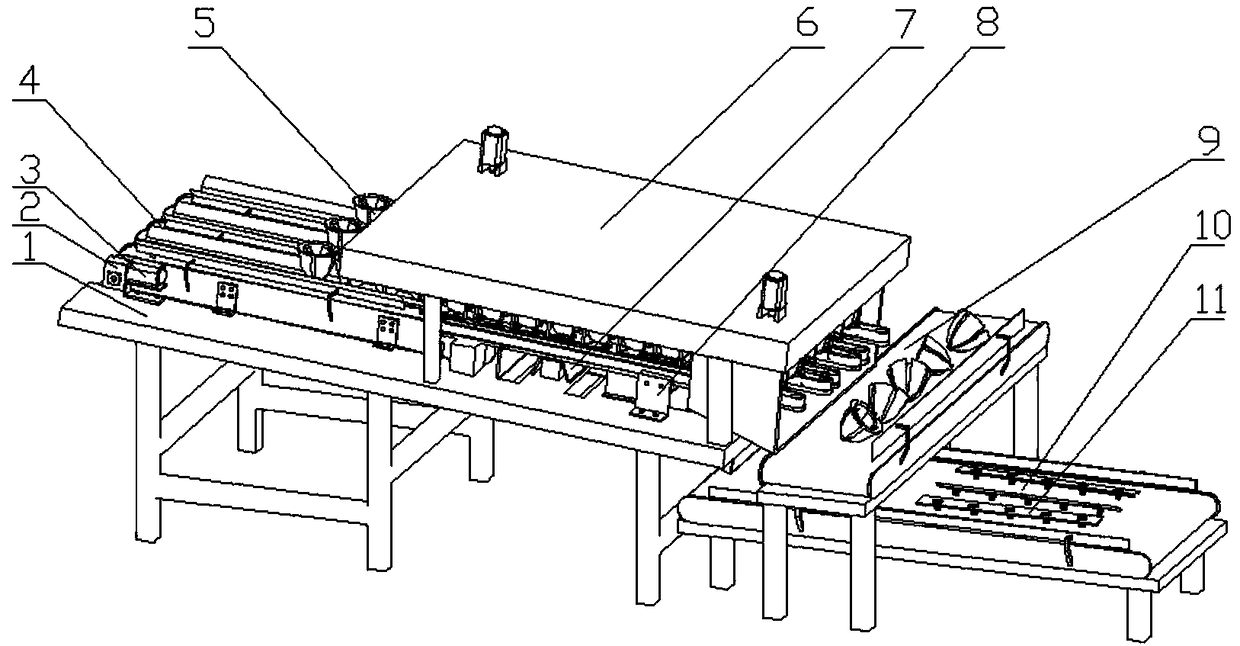

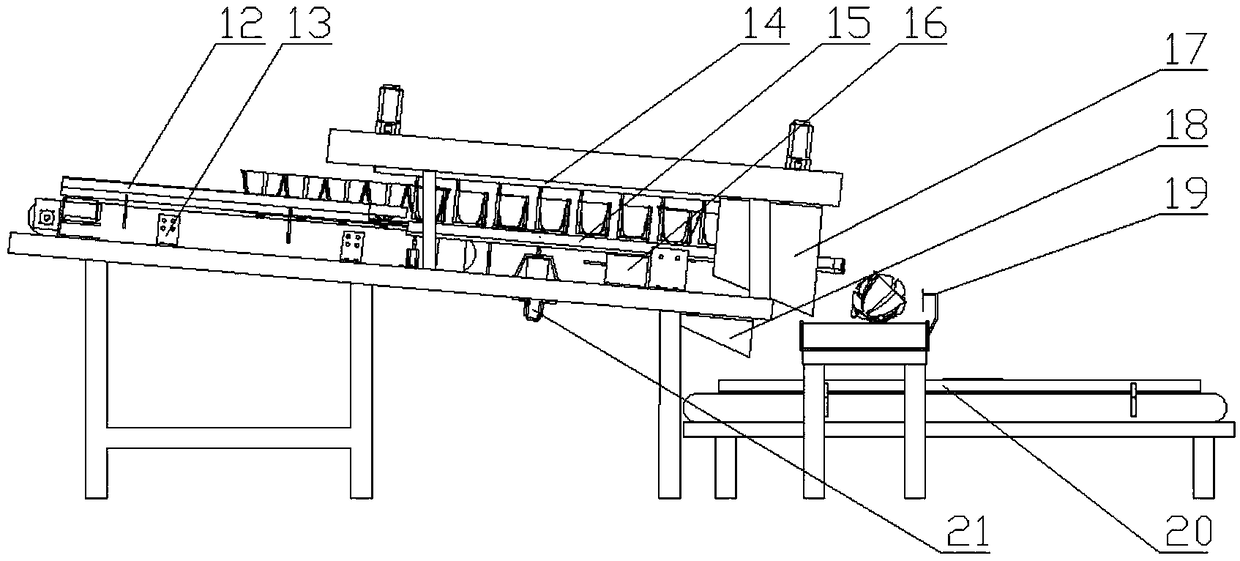

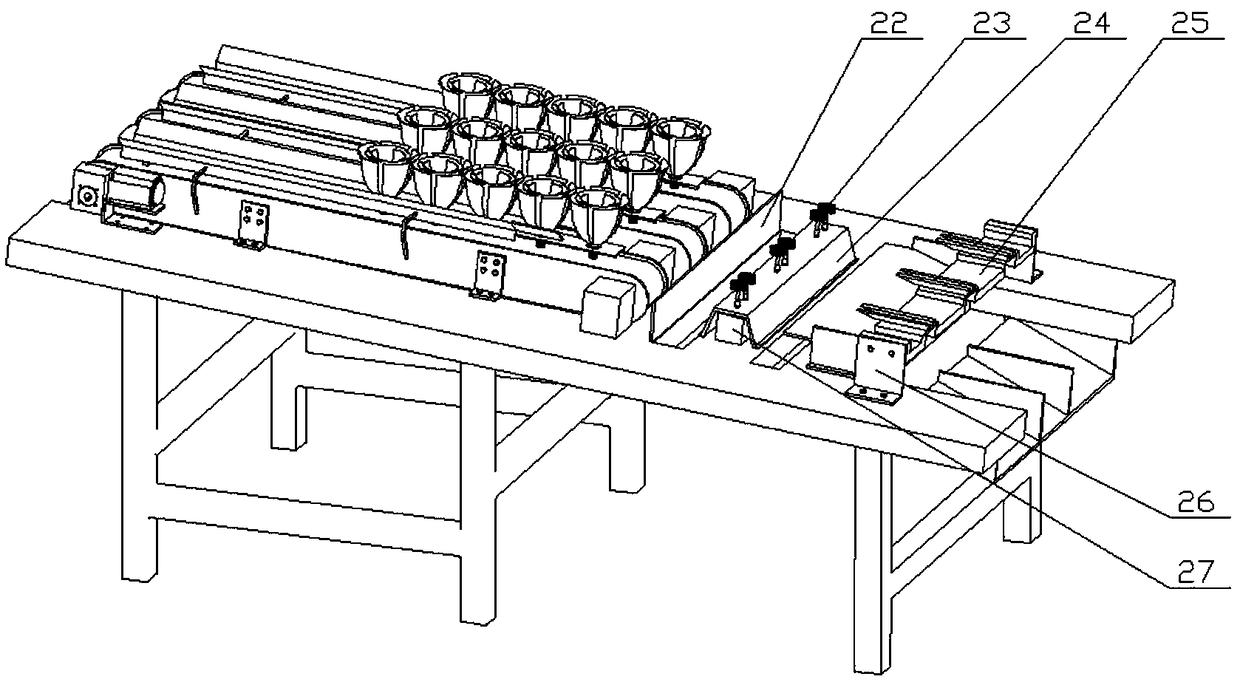

Fixed planting plate soilless culture vegetable harvesting robot

InactiveCN108834547AImprove harvesting efficiencyReduce in quantityHarvestersRoot systemTransfer mechanism

The invention discloses a fixed planting plate soilless culture vegetable harvesting robot and belongs to the field of automatic agricultural equipment. The fixed planting plate soilless culture vegetable harvesting robot comprises a conveying mechanism, a vegetable holding and transferring mechanism, a vegetable root cutting mechanism and a vegetable-plate separation and transportation mechanism,wherein stripy fixed planting plates with mature vegetables are placed on a conveyer belt and are conveyed to the vegetable holding and transferring mechanism through the conveyer belt; vegetables are tightly held by vegetable holding arms and are conveyed forwards at the same time; roots of the vegetables are kept at a suspended state; the root systems of the vegetables are cut off by rotating cutters; the vegetables are moved forwards continuously; the fixed planting plates are dissociated from vegetable main bodies through the vegetable-plate separation and transportation mechanism, are dropped onto a fixed planting plate transferring platform and further slide onto a conveyer belt II; the vegetables are dropped onto a conveyer belt III directly through a vegetable transferring platform. By adopting the robot, harvesting of soilless culture vegetables can be achieved, furthermore procedures that the harvested vegetables are sterilized and packaged, and the stripy fixed planting plates are cleaned, piled and the like can be carried out. The robot is high in harvested vegetable completeness, high in automation degree, low in working intensity of operators and stable and reliablein performance.

Owner:BEIJING UNIV OF TECH +1

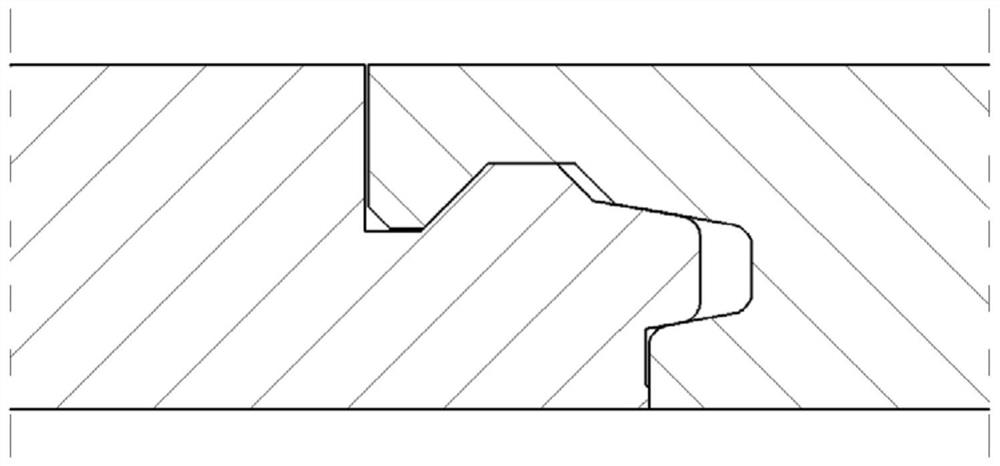

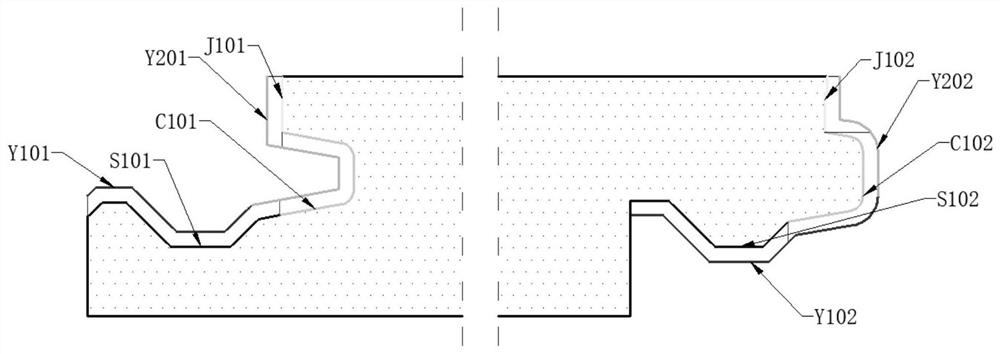

Finish machining technology of stone plastic floor lock catch

PendingCN111702231AImprove heat resistanceHigh precisionMilling equipment detailsMilling cutterStructural engineering

The invention relates to a finish machining technology of a stone plastic floor lock catch, and discloses a machining technology of the stone plastic floor lock catch. The technology comprises the steps that step 1, pre-cutting machining, specifically, two milling cutters are arranged to finish the pre-cutting machining on a floor, redundant materials on the outer side of the lock catch are cut off in two steps, and allowance of 0.5mm is reserved on the surface of finishing, forming and finish machining of the lock catch; step 2, finishing machining, specifically, two milling cutters are arranged for finishing, the deviation generated by the floor during the pre-cutting machining is corrected, and a reference surface is machined; step 3, fine machining of the lock catch, specifically, three milling cutters are arranged to mill the lock catch in a concave clamping groove of the lock catch so as to obtain a longitudinal tenon and a tenon groove; and step 4, forming, specifically, three milling cutters are arranged to perform rough machining on the tenon and the tenon groove of the lock catch, and then the fine machining is performed to obtain a transverse tenon and a tenon groove. The technology can effectively reduce cutter changing times and prolong the service life of the cutters, and has the advantages of improving the production efficiency, surface quality, dimensional accuracy and the like.

Owner:BOSHENG PREWI SHANGHAI TOOLS

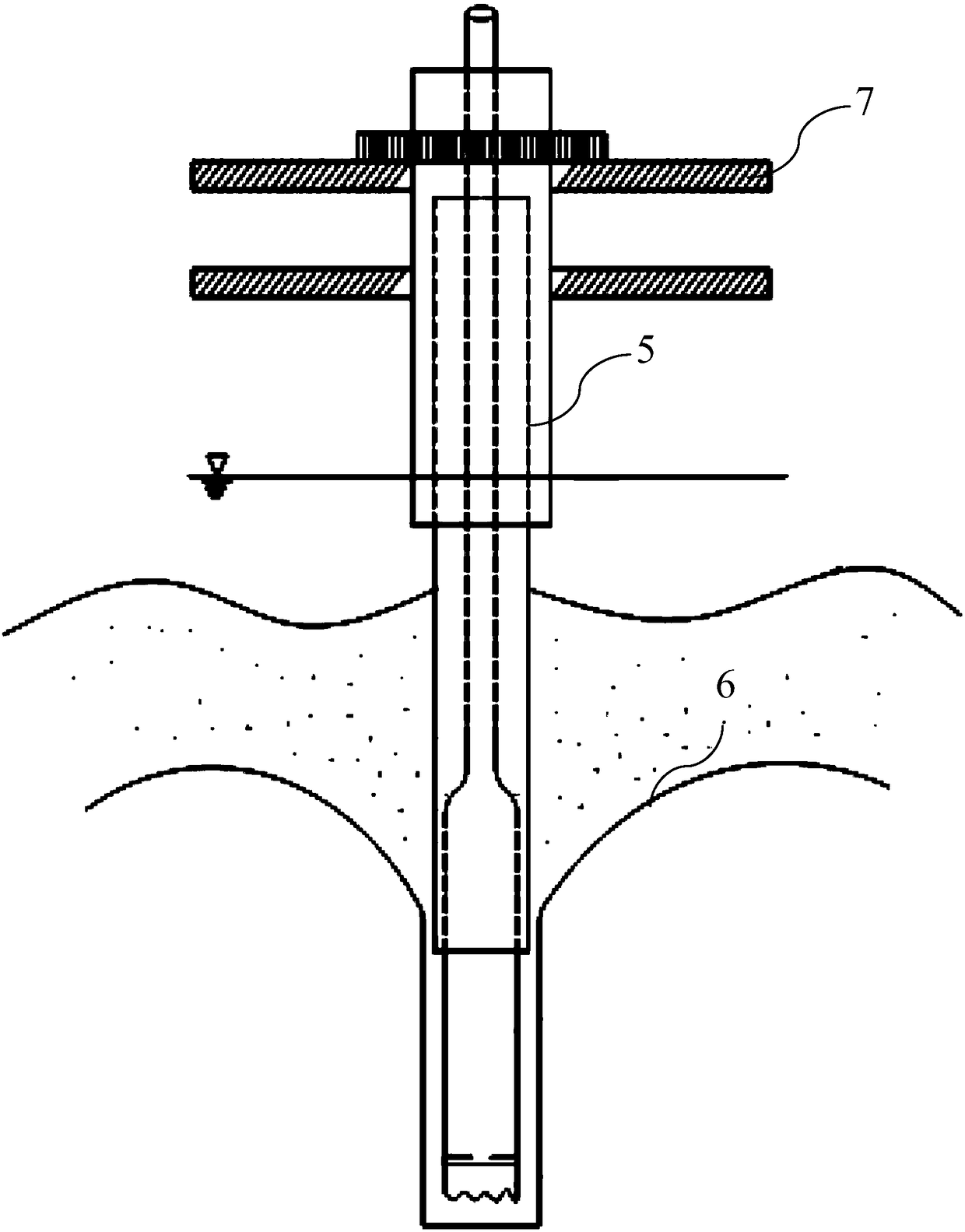

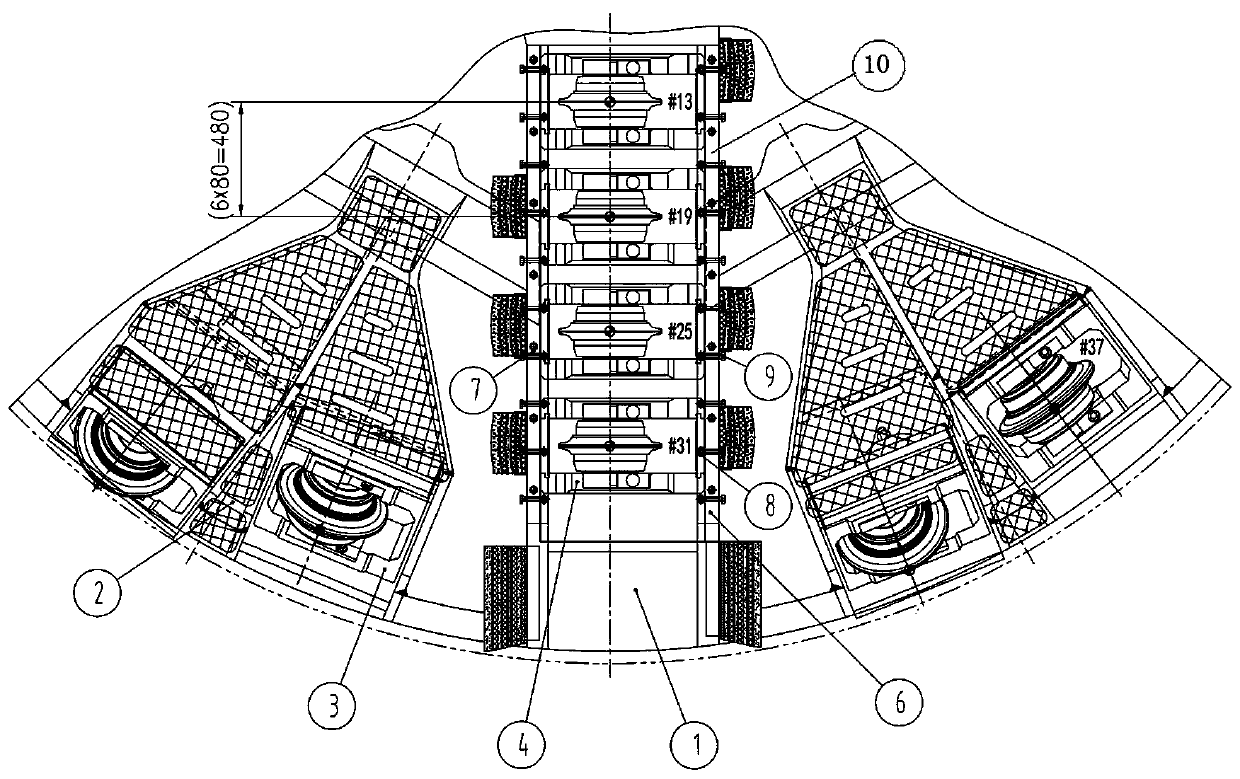

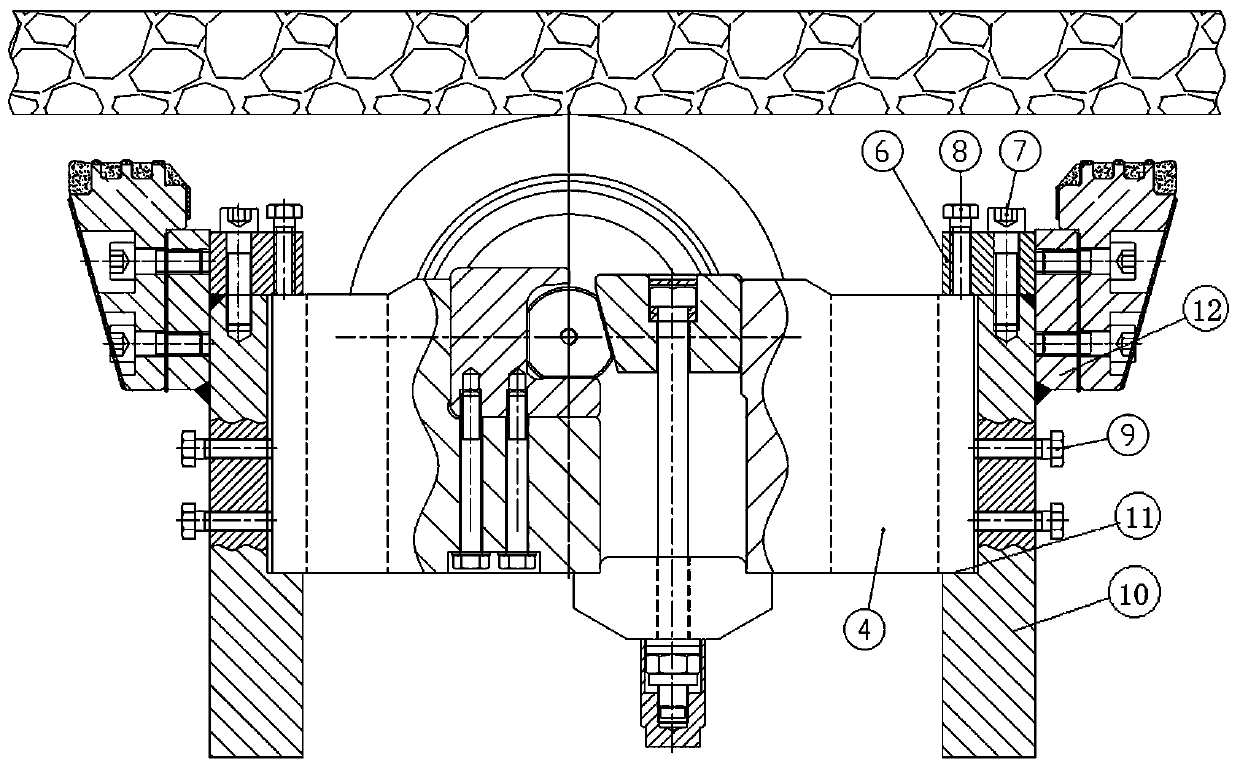

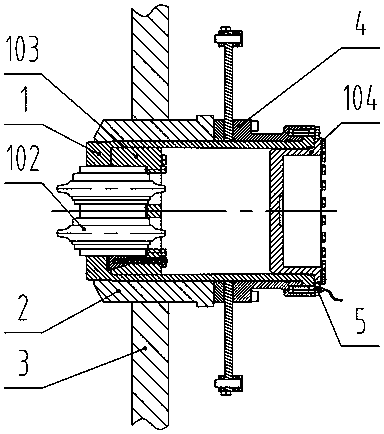

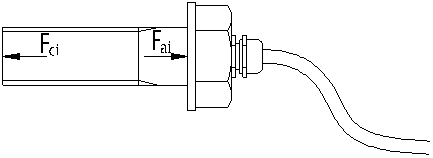

Real-time monitoring device and method for borne pressure of hobs of normal pressure hob-changing cutterhead

ActiveCN108286438AReduce consumptionImprove tunneling efficiencyApparatus for force/torque/work measurementTunnelsSignal conditioningEngineering

The invention provides a real-time monitoring device and method for the borne pressure of hobs of a normal pressure hob-changing cutterhead. According to the real-time monitoring device and method forthe borne pressure of the hobs of the normal pressure hob-changing cutterhead, geological information of the shield machine excavation face can be deduced according to the borne pressure, accordinglyshield machine tunneling parameters are adjusted; and in this way, on the one hand, overloading and severe vibration of the hobs are avoided, and the service life of the hobs is prolonged;, on the other hand, the shield tunneling efficiency is also improved, and the construction cost is reduced. The real-time monitoring device comprises a cylinder body. The cutterhead is arranged at the left endof the inner wall of the cylinder body and internally provided with the hobs; an end cover is arranged at the right end of the inner wall of the cylinder body; a welding seat and a normal pressure hob-changing device are sequentially arranged on the outer side of the cylinder body from left to right and detachedly and fixedly connected; and the normal pressure hob-changing device and a bottom flange of the cylinder are connected through bolts, the bolts are connected with a signal conditioning module through wires, the signal conditioning module is connected with a PLC, and the PLC is connected with a monitoring computer.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

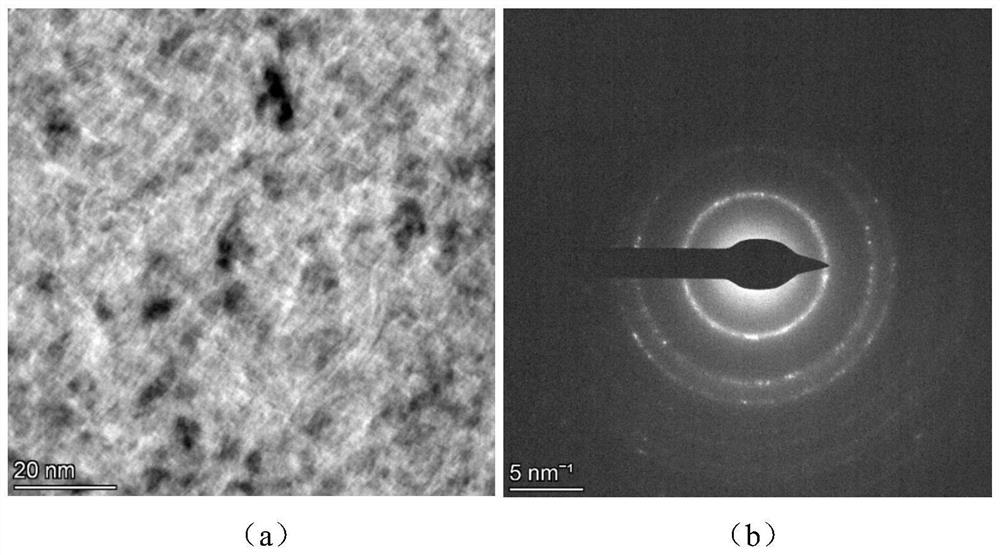

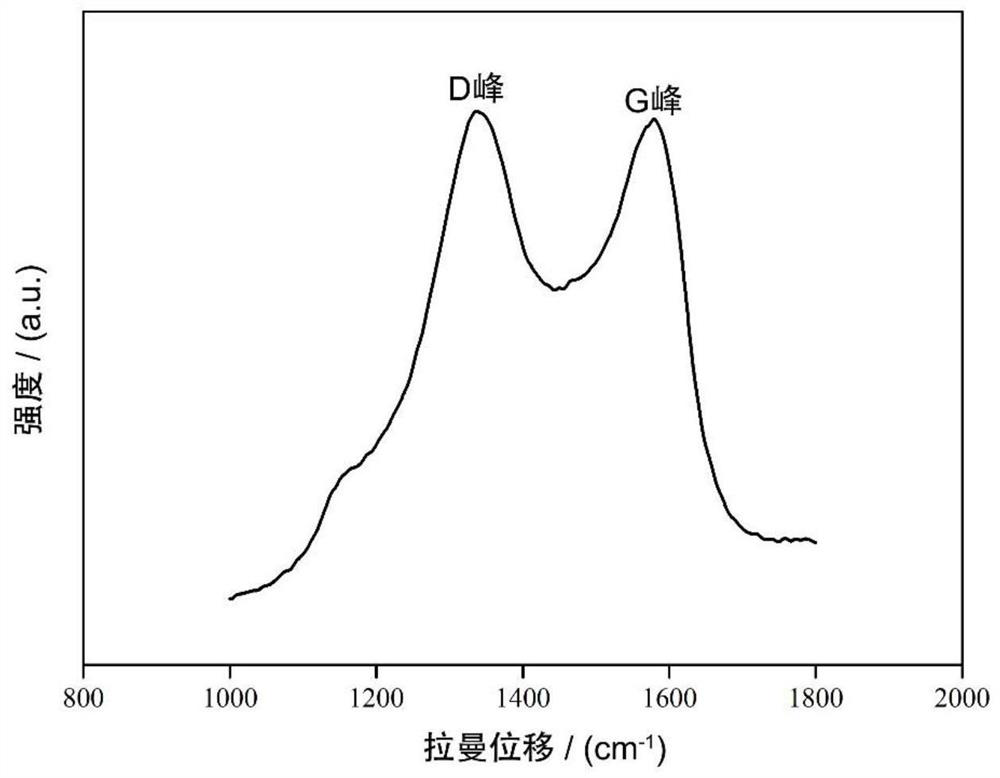

Batch preparation method of ultra-nano diamond coated cutting tool with high finish and complex shape

ActiveCN111647875AHigh surface finishReduce surface roughnessChemical vapor deposition coatingCemented carbideHigh surface

The invention discloses a batch preparation method of an ultra-nano diamond coated tool with high finish and a complex shape. An HFCVD process is used to deposit a layer of undoped or boron-doped ultra-nano diamond film on the surface of a pretreated complex-shaped cemented carbide tool. The pretreatment method is "surface roughening + surface cobalt removal + uniform crystal planting". The raw materials for the HFCVD process of the undoped ultra-nano diamond film are hydrogen and methane. The HFCVD process of the boron-doped ultra-nano diamond film uses a bubbling method. Hydrogen is used asa carrier to send a mixed liquid of trimethyl borate and acetone to the HFCVD reaction cavity, and the trimethyl borate and acetone are decomposed at high temperature to deposit a layer of boron-dopedultra-nano diamond film on the surface of a tool substrate. The batch preparation method can obtain the undoped or boron-doped ultra-nano diamond film coated tools with extremely high surface finish,extremely low surface roughness, and extremely small friction coefficient, can be applied to precision and ultra-precision cutting processing, and not only can improve the processing accuracy, but extend the service life of the tool.

Owner:SHANGHAI JIAO TONG UNIV

Milling machine

InactiveCN103008738AHigh working reliabilityReduce the number of tool changesMilling machinesPositioning apparatusMachineIndustrial engineering

The invention discloses a milling machine. The milling machine comprises a machine body, a workbench and a sliding rail, and is characterized by further comprising a milling head (1), a cutter (2), an automatic cutter feeding device (3) sliding transversely and a manual cutter feeding device sliding longitudinally. An adjusting technology of the milling machine can reduce the cutter changing times to the maximum extent and facilitates manual change of the cutter; and a machining center can automatically change the cutter, so that on the premise of meeting machining requirements, through reduction of the cutter changing times, the auxiliary time can be saved and the working reliability of the milling machine can be improved.

Owner:DALIAN HENRY CASTING

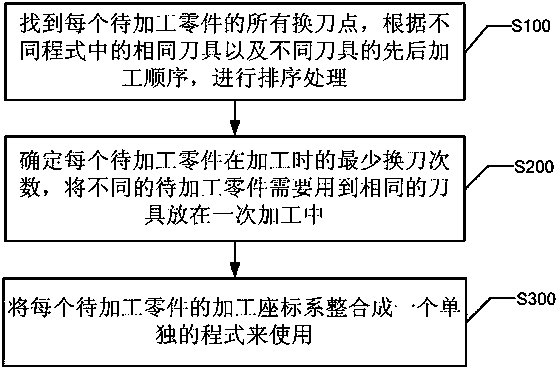

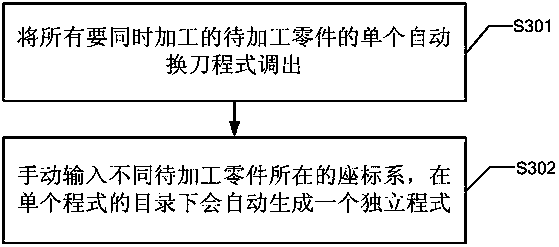

CNC batch processing program optimization method

ActiveCN108459561AExtend your lifeLower requirementProgramme controlComputer controlBatch processingSoftware engineering

The present invention discloses a CNC batch processing program optimization method. The method comprises the steps of: A, finding all the tool changing points of each part to be processed, and performing ordering processing according to the same tool in different programs and the processing sequence of different tools; B, determining the fewest number of times of tool changing when each part to beprocessed is processed, allowing the parts to be processed requiring using the same tools to be put in the same processing; and C, integrating processing coordinate systems of the parts to be processed into a single program for usage. The CNC batch processing program optimization method is simple to operate, the operation process does not need human intervention, machine operators can independently complete the optimization process. The method reduces the requirements for front-end programming personnel, can perform secondary optimization and then processing whatever an automatic tool changing machine or a manual tool changing machine, effectively reduce the number of times of tool changing, and improves the product efficiency and the tool life.

Owner:惠州市倍思特尔精密模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com