Arrangement method of tools on composite cutterhead of shield tunneling machine

An arrangement method and technology of composite cutters, which are applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as engineering losses, and achieve the effect of reducing the number of cutter changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments.

[0025] A method for arranging cutters of a shield machine composite cutterhead according to the present invention, the composite cutterhead adopts a panel type cutterhead, and the cutter includes n i put disc hob and n j A cutter with a disc-shaped hob in the center of the cutter head, and a mixed configuration of cutters and disc-shaped hobs on the periphery;

[0026] the n i put disc hob and n j When the cutter is at the same excavation distance, it reaches the limit wear at the same time;

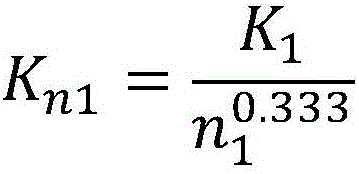

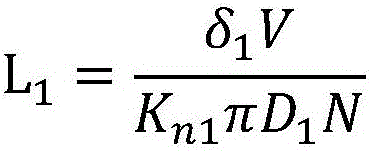

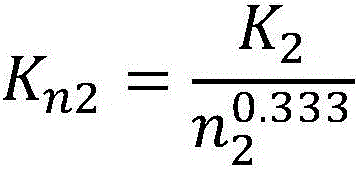

[0027] the n i Distribute the disc-shaped hobs on multiple excavation trajectories, and the number of disc-shaped hobs on the same excavation track is n 1 put, and n 1 >1, the wear coefficient K of each disc hob on the excavation track n1 for

[0028]

[0029] where K 1 is the wear coefficient of the disc hob;

[0030] Since the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com