Finish machining technology of stone plastic floor lock catch

A technology of stone-plastic flooring and processing technology, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as reduced tool life, low dimensional accuracy of locks, and shortened tool change cycle, so as to improve processing Surface quality, improvement of poor heat resistance, effect of reducing cutting heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

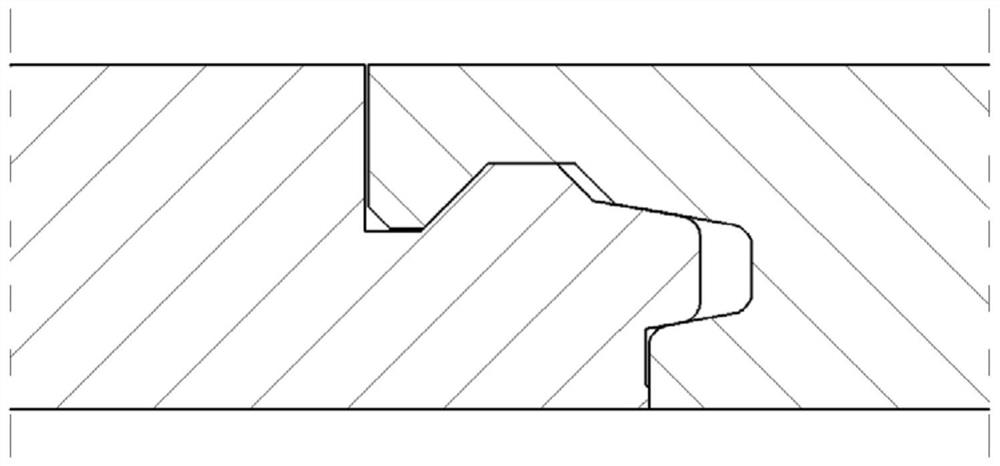

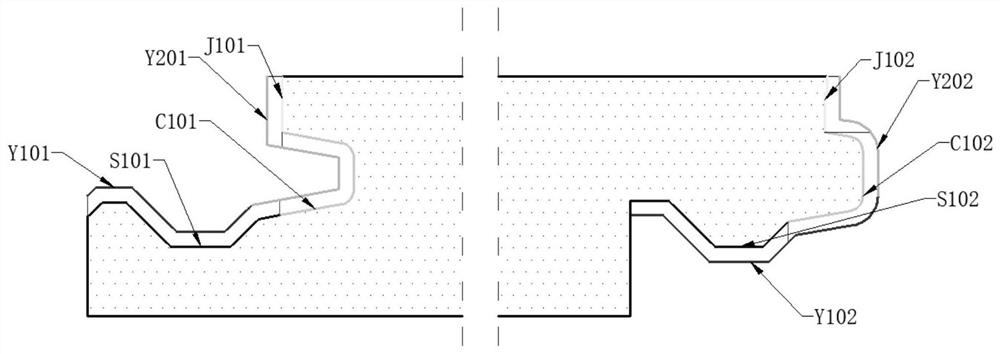

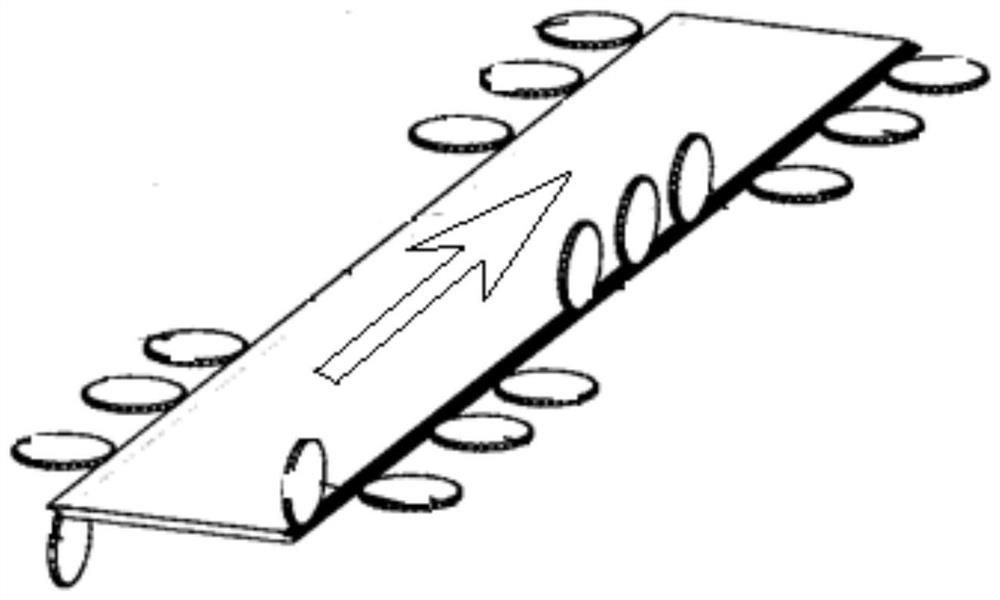

[0039] A processing technology of a stone-plastic floor lock, such as Figure 1-Figure 14 shown, it includes the following steps:

[0040] Step 1. Pre-cutting: Configure two milling cutters to complete the pre-cutting of the floor, remove the excess material outside the lock in two steps, and leave 0.5mm on the surface of finishing, forming, and finishing of the lock. margin;

[0041] Step 2. Finishing processing: configure two milling cutters for finishing, correct the offset of the floor during pre-cutting processing, and process the reference plane;

[0042]Step 3. Finishing of the lock: configure three milling cutters to perform lock milling on the concave groove of the lock to obtain the longitudinal tenon and tenon groove

[0043] Step 4. Forming processing: configure three milling cutters to perform rough machining on the tenon and tenon groove of the lock, and then perform fine processing to obtain the transverse tenon and tenon groove.

[0044] Among them, the mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com