Deep cavity processing method based on titanium alloy monobloc forging component

A technology of integral forging and machining method, applied in the deep cavity machining field, can solve the problem of not providing the parameters and methods of titanium alloy plunge milling machining, and achieve the effect of reducing the number of tool changes, ensuring machining accuracy and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

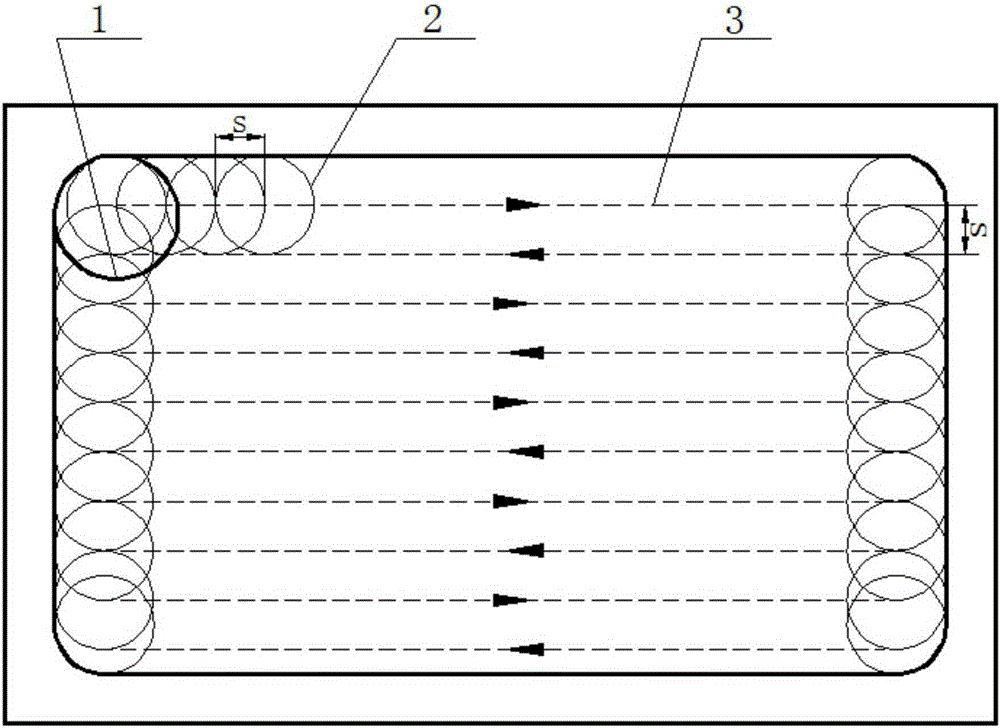

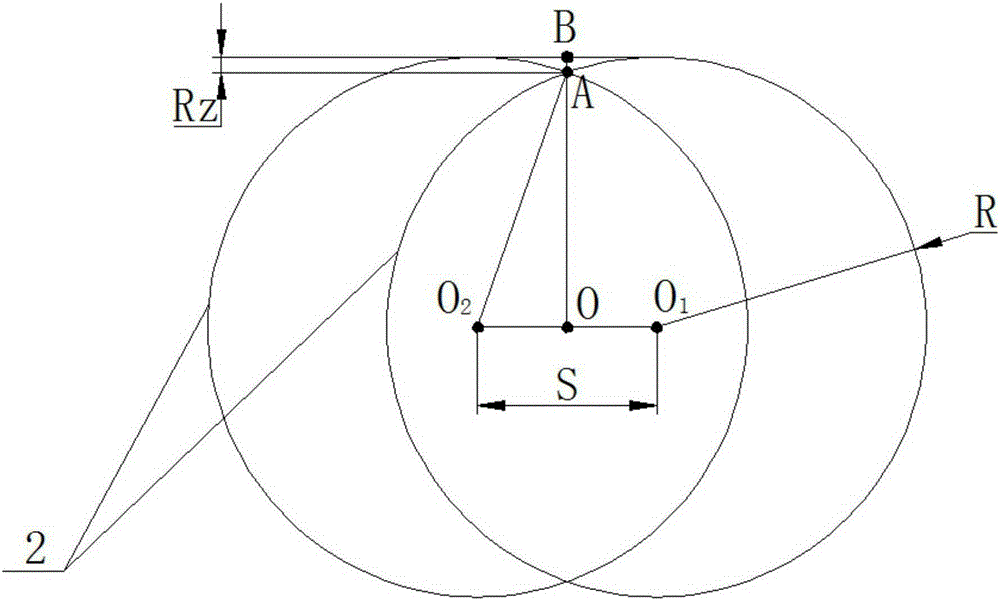

[0026] The patent of the present invention relates to the deep cavity processing of titanium alloy integral forging parts. Firstly, the processing of all the deep cavity processes is completed on a CNC milling machine or a machining center. In order to adapt to the characteristics of titanium alloy processing, that is, the tool wears quickly and consumes a lot, adopt Machined inserts and toolholders machine deep cavities.

[0027] See Figure 1 to Figure 4 , processing technology of the present invention comprises the steps:

[0028] Step 1: select the drilling tool of uncoated cemented carbide drilling insert and the corresponding cutter bar to form drilling 1 processing, the drilling tool diameter that the present invention adopts is 50mm, adopts internal cooling mode, as shown in the figure , into the upper surface of the titanium alloy integral forging, the processing parameters are as follows: cutting speed v = 50 ~ 60m / min, feed rate f z =0.08~0.1 mm / z. The depth of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com