Machining method for target material

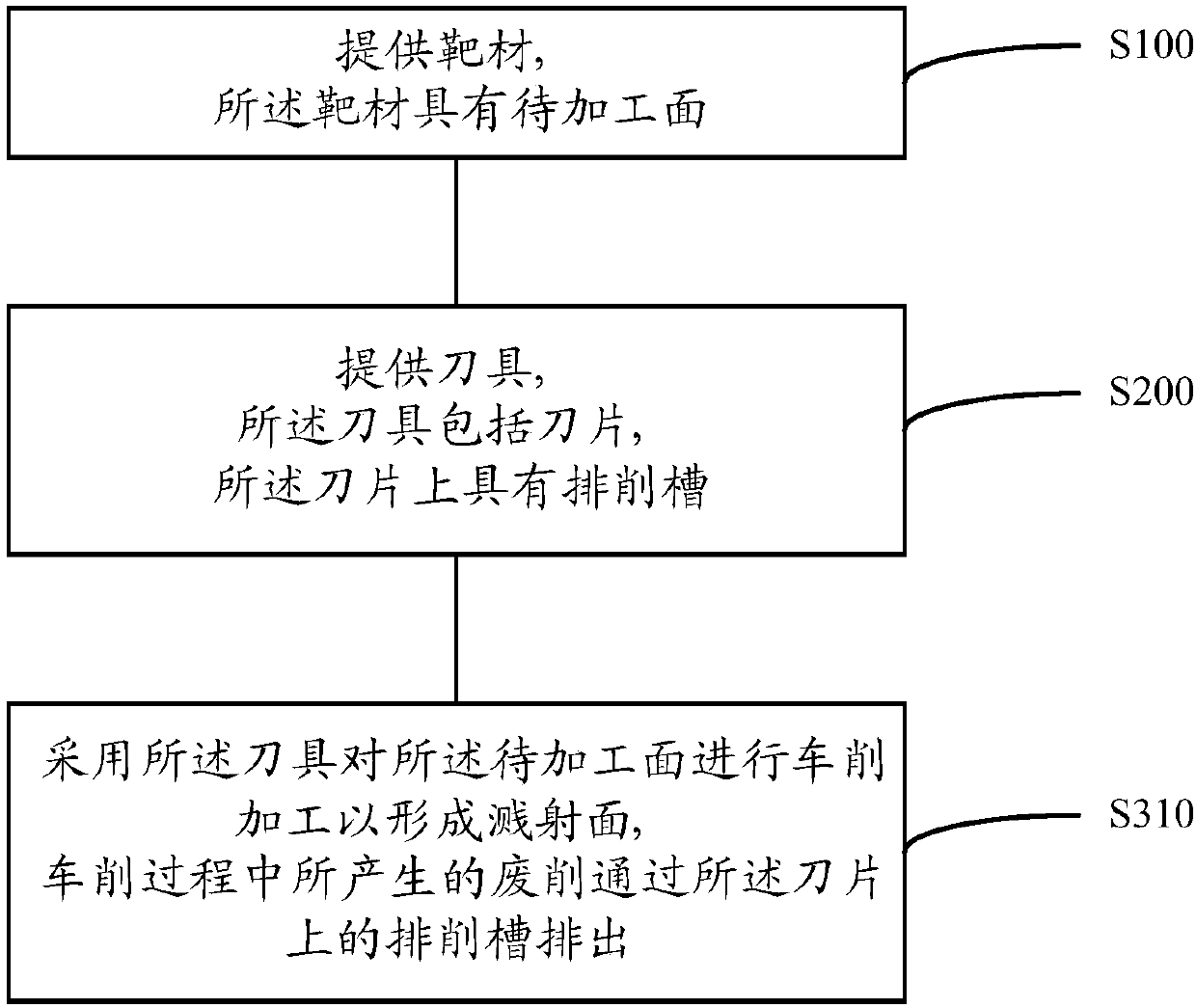

A processing method and target material technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of low processing efficiency, achieve the effects of improving processing efficiency, reducing the number of times of tool setting, and reducing the number of times of changing tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It can be seen from the background art that the target material processing method in the prior art has the problem of low processing efficiency. Now combined with the processing process of the target with V-shaped grooves on the sputtering surface in the prior art, the reasons for its low processing efficiency are analyzed:

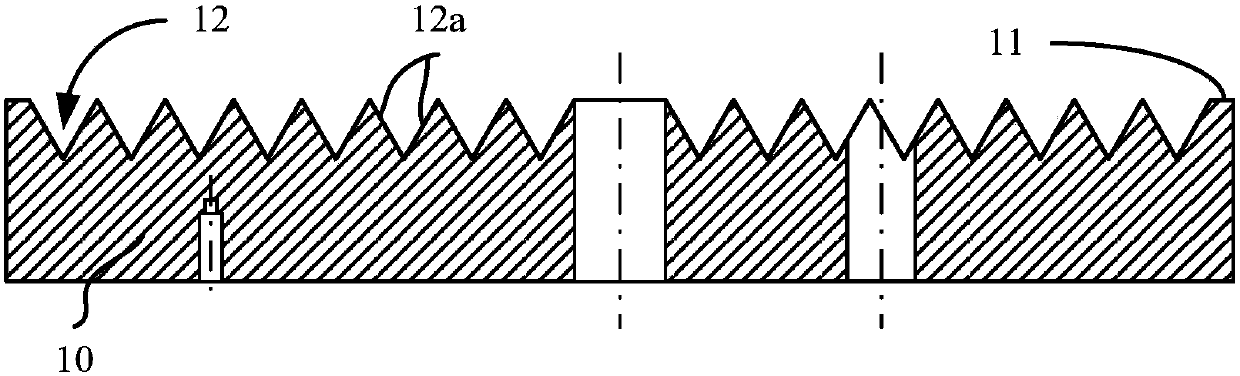

[0032] refer to figure 1 , showing a schematic cross-sectional structure of a sputtering surface with a V-groove target.

[0033] Such as figure 1 As shown, the target 10 has a sputtering surface 11, and a plurality of V-shaped grooves 12 are opened on the sputtering surface 11; the V-shaped grooves 12 have two side walls 12a oppositely arranged, and the two side walls 12a are connected at the bottom of the V-shaped grooves to form a "V" shape.

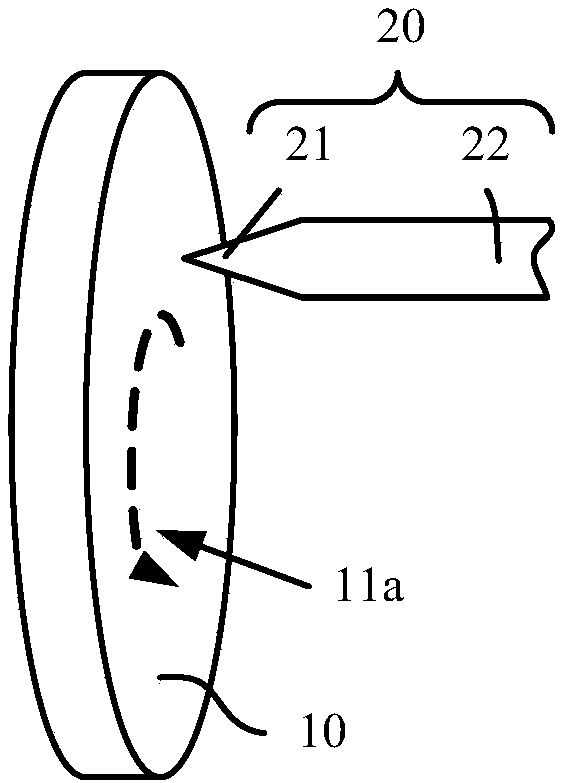

[0034] combined reference figure 2 ,show figure 1 Schematic diagram of the structure of the target processing method shown.

[0035] processing figure 1 For the target material shown, the V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com