Numerical control machine with a plurality of main shafts

A CNC machine tool and multi-spindle technology, applied in the mechanical field, can solve problems such as low work efficiency, instability, waste of resources, etc., and achieve the effects of saving energy consumption, improving work efficiency, and reducing the number of tool changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

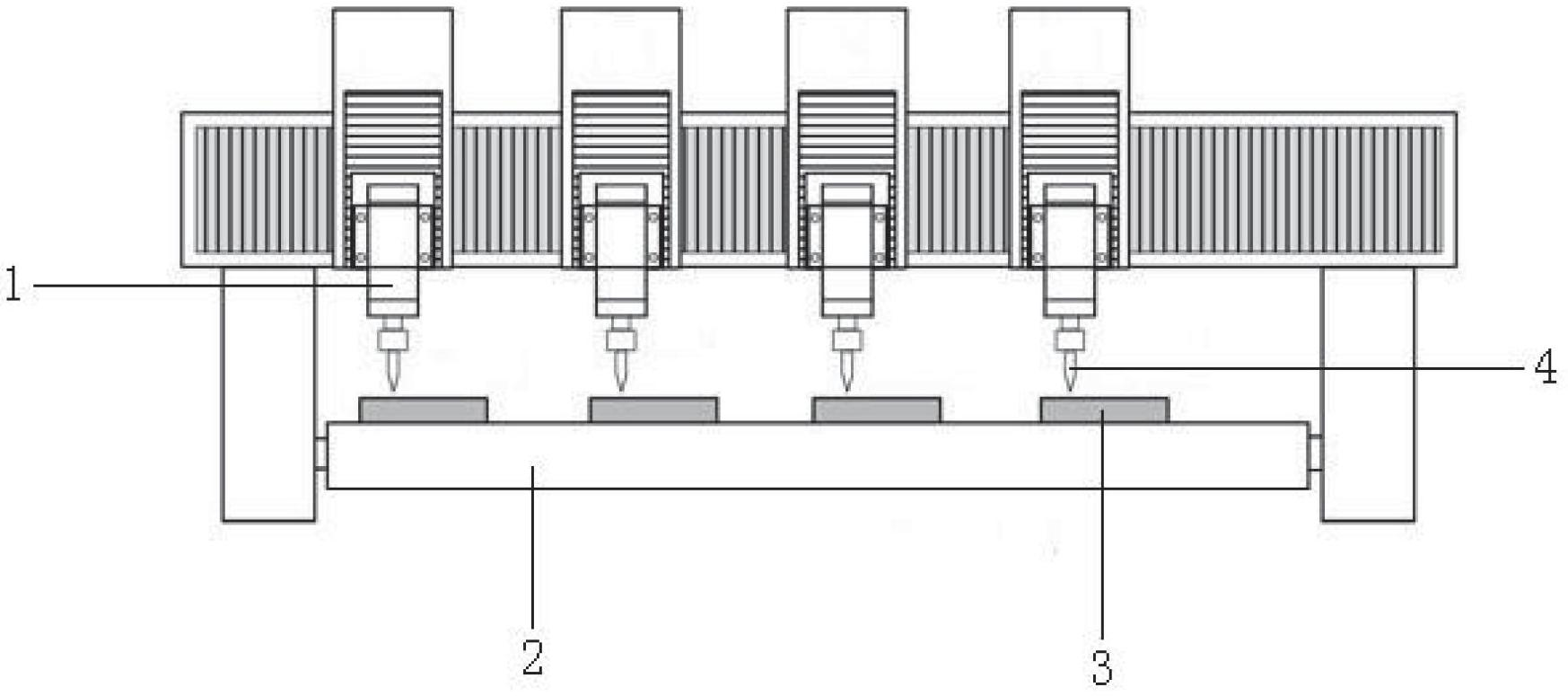

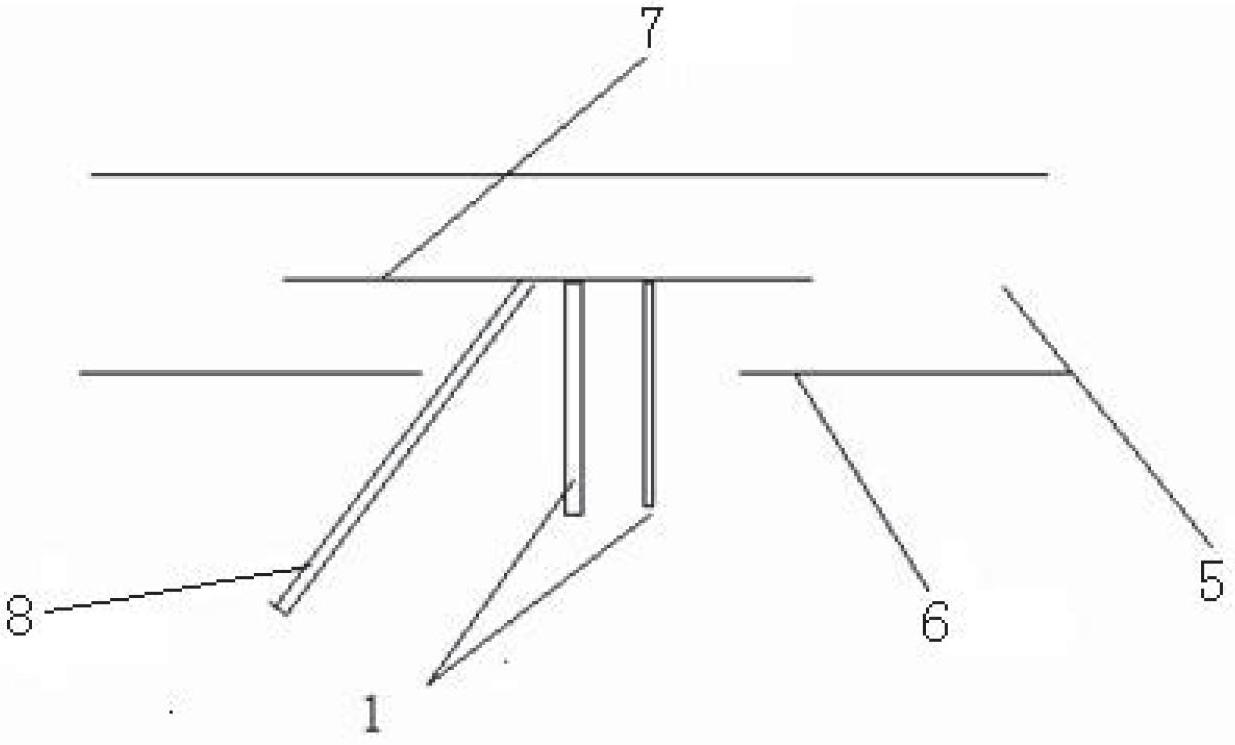

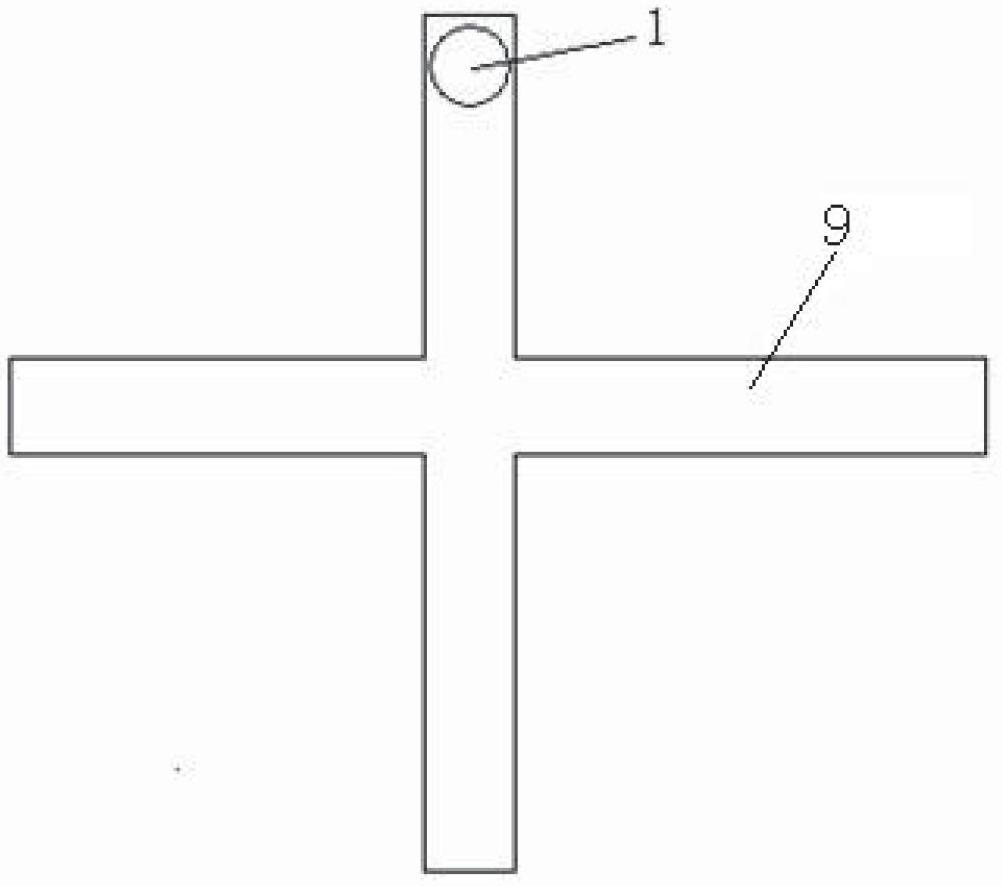

[0025] Such as figure 1 with figure 2 As shown, a multi-spindle CNC machine tool according to the present invention includes a work platform 2 on which a clamp for clamping a workpiece 3 is arranged to fix the workpiece 3 to be processed; a plurality of spindles 1, the Multiple spindles 1 are divided into n groups for setting, each group includes at least two spindles 1, each spindle 1 has independent three-dimensional degrees of freedom in X, Y, and Z directions, and the multiple spindles are distributed on a shaft frame 5 , each group of spindle 1 is set at intervals; you can set a number for each spindle 1, for example, the number is spindle A, spindle B, spindle C, and spindle D, etc. The purpose is to facilitate the setting of the program, and each spindle 1 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com