Fixed planting plate soilless culture vegetable harvesting robot

A soilless cultivation and planting board technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low overall level, late start of research and application of soilless cultivation technology in greenhouses, etc., so as to improve harvesting efficiency and reduce The number of laborers and the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

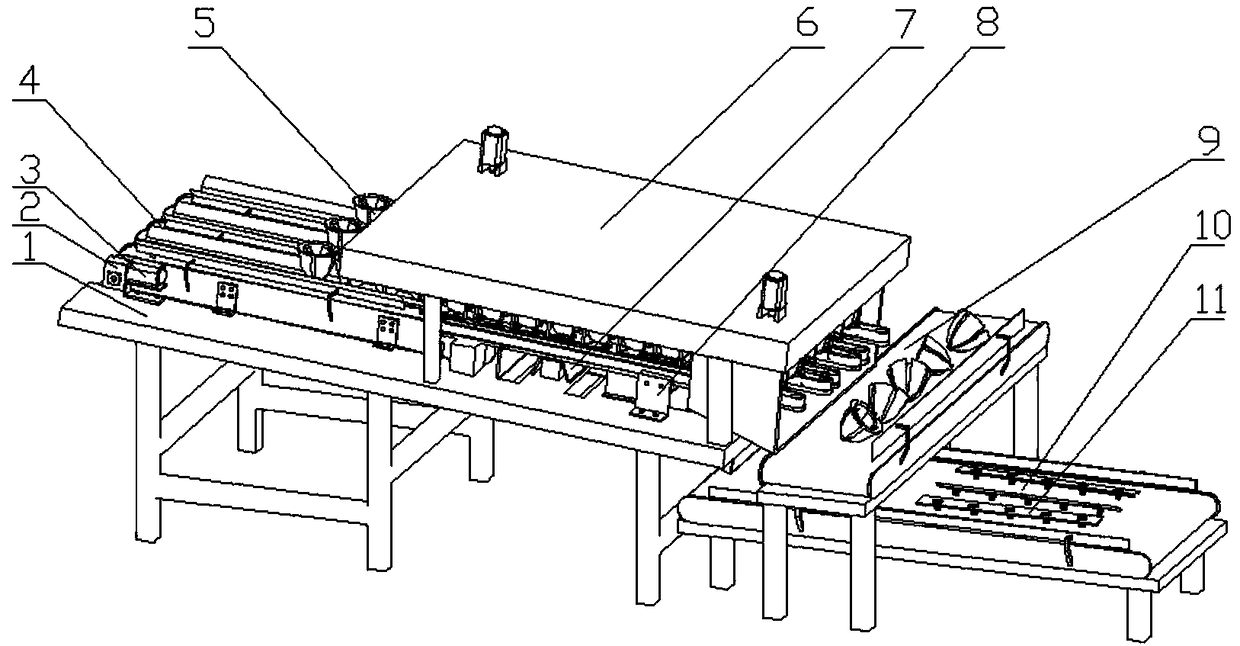

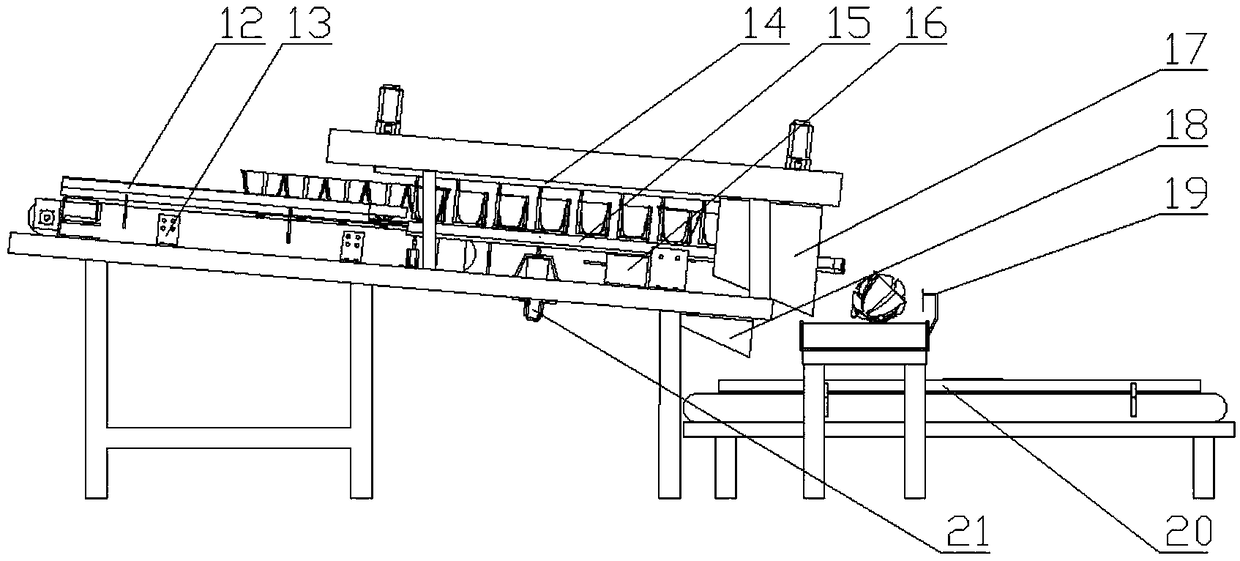

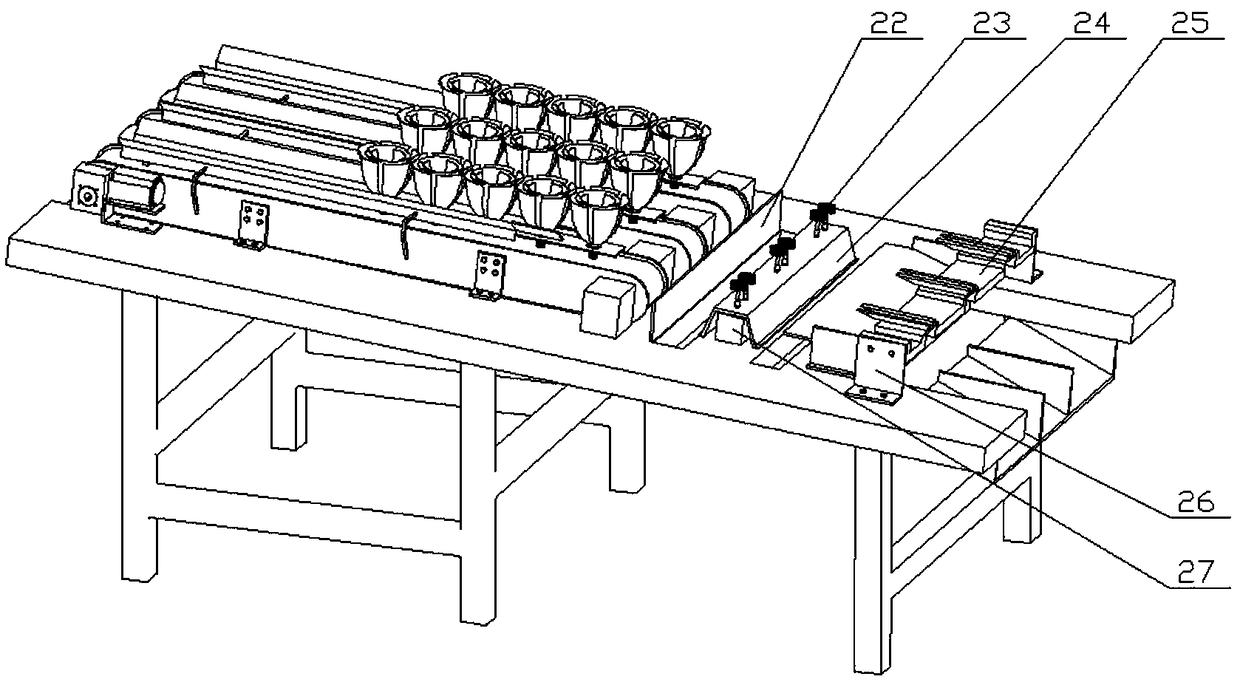

[0025] Such as figure 1 , figure 2 As shown, the patent of the present invention is a planting plate soilless cultivation vegetable harvesting robot, which is characterized in that: it includes a transport mechanism, a vegetable transfer mechanism, a vegetable root cutting mechanism and a cutting board separation and transportation mechanism; figure 1 As shown, the frame 1 and the conveyor belt I4 are the main bodies in the transport mechanism; the reducer 2 and the motor I3 are installed on the conveyor belt I4, and the conveyor belt I4 is fixed on the frame 1 through the L-shaped connecting plate I13, and the conveyor belt I blocks The side 12 is installed on both sides of the conveyor belt I4; it can prevent dumping during the conveying process; when the vegetable harvest starts, the strip-shaped planting plate 11 with vegetables 5 is placed on the conveyor belt I4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com