Inner-cooling indexable step drill and method for fabricating step hole

A technology of stepped drilling and stepped hole, which is applied in the direction of manufacturing tools, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve the problems of poor cooling, poor lubrication effect and less cutting fluid, and save frequent tool changes. Time, cutting speed, and management reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings. The above and other objects, features and advantages of the present invention will be apparent to those skilled in the art from the detailed description of the present invention.

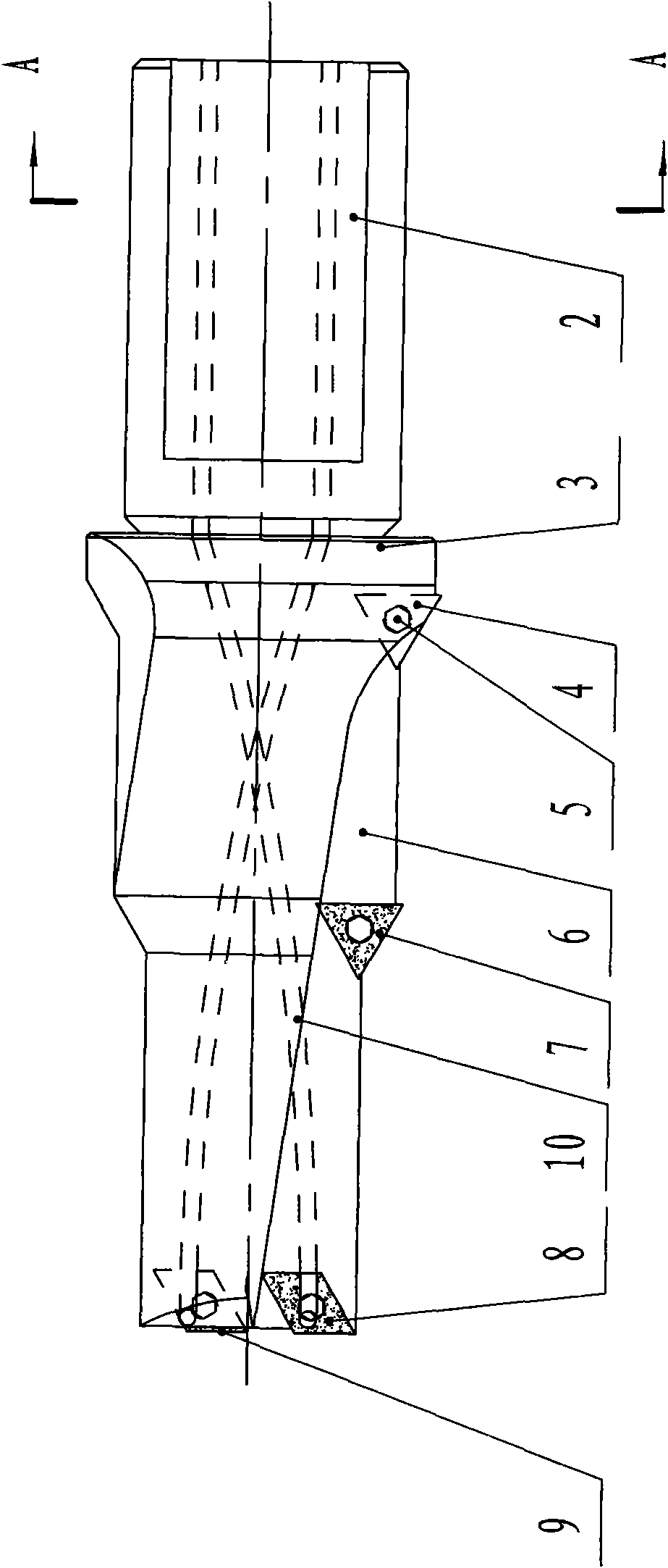

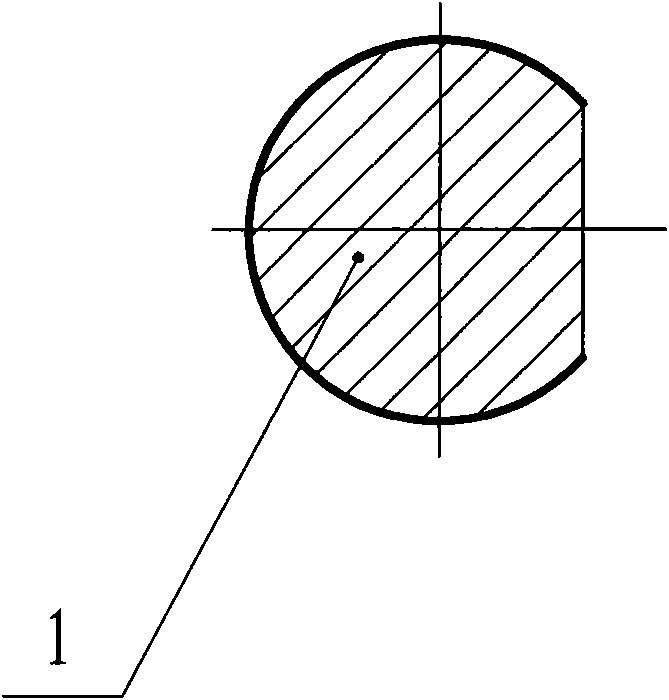

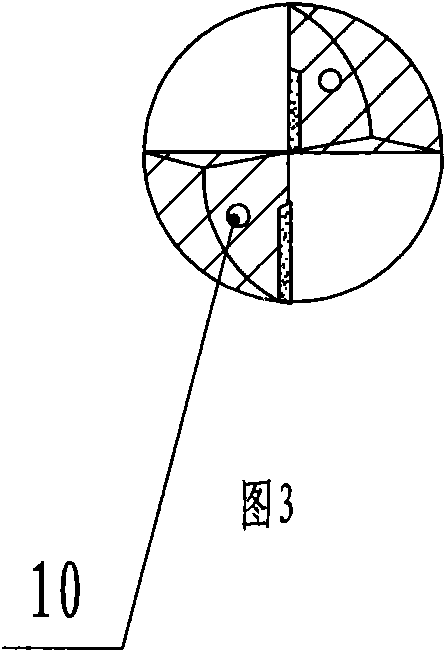

[0024] The internal cooling indexing stepped drill proposed by the present invention, its preferred embodiment structure is as follows figure 1 and image 3 As shown, it includes a fixing part and a drill body 1 . Such as figure 1 As shown, the drill body 1 is cylindrical with steps, the outer profile of the axial section of the drill body 1 is stepped, and the outer diameter of the end of the drill body near the fixed part is larger than the outer diameter of the end far away from the fixed part ; The top of the drill body 1 is respectively provided with an end face inner cutter block 9 for processing the central part of the hole and an end face outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com