PLC (Programmable Logic Controller)-based automatic timing system and timing method thereof

A technology of automatic timing and position computer, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of waste of working hours, increase of weighing equipment and equipment maintenance costs, etc., to speed up production rhythm and save procurement and maintenance costs, and the effect of avoiding waste of man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

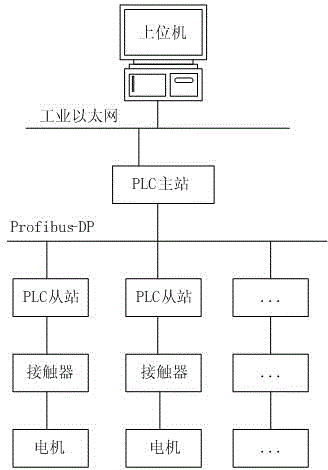

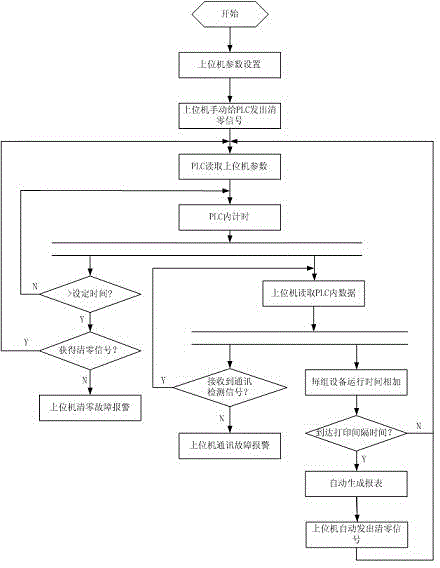

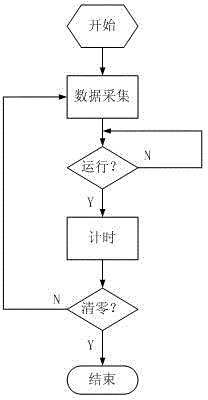

[0014] Such as figure 1 and figure 2 As shown, a PLC-based automatic working hour timing system includes motors installed on the wire drawing machine and the nail making machine, the drive control line of the motor is directly connected to the main contact of the AC contactor, and the AC contactor passes through Control the start and stop of the motor to realize the operation control of the wire drawing machine and the nail making machine; the auxiliary contact of the AC contactor is connected with the PLC slave station in the Siemens S7-400PLC through the control cable, and the PLC slave station is connected through the Profibus-DP The network communicates with the PLC master station, and the PLC master station communicates with the upper computer through the industrial Eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com